Professional Documents

Culture Documents

2010-2020 Nissan March Micra - LAN System

Uploaded by

Juan Antonio Ochoa Padron0 ratings0% found this document useful (0 votes)

44 views68 pagessistema redes

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsistema redes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views68 pages2010-2020 Nissan March Micra - LAN System

Uploaded by

Juan Antonio Ochoa Padronsistema redes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 68

ELECTRICAL & POWER CONTROL

scoron LAN

LAN SYSTEM

CONTENTS

CAN FUNDAMENTAL

PRECAUTION

PRECAUTIONS

Precautions for Trouble Diagnosis

Precautions for Harness Repair

SYSTEM DESCRIPTION ..

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEI

scription

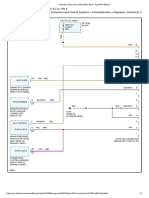

CAN COMMUNICATION SYSTEM : System Dia-

gram

CAN COMMUNICATION SYSTEM : CAN Com.

‘munication Control Circult

DIAG ON CAN

DIAG ON CAN : Description

DIAG ON CAN : System Diagram...

TROUBLE DIAGNOSIS

Condition of Error Detection

‘Symptom When Error Occurs in CAN Communi-

cation System .

CAN Diagnosis with CONSULT

Self-Diagnosis

CAN Diagnostic Support Monitor

How to Use CAN Communication Signal Chart ...

BASIC INSPECTION .

DIAGNOSIS AND REPAIR WORKFLOW

ys

‘Abbreviation List

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER"

Precautions for Trouble Diagnosis

Precautions for Harness Repair ..

SYSTEM DESCRIPTION ..

COMPONENT PARTS

Component Parts Location

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM :CAN Systom

Specification Chart

GAN COMMUNICATION SYSTEM : CAN Com.

munication Signal Chart

WIRING DIAGRAM ..

CAN SYSTEM ..

Wiring Diagram

BASIC INSPECTION .

DIAGNOSIS AND REPAIR WORKFLOW

Interview Sheet

DTC/CIRCUIT DIAGNOSIS

22

MALFUNCTION AREA CHART

Trouble Diagnosis Flow Chart Waintns

CAN Branch Line ..

HOW TO USE THIS MANUAL Short Circuit

HOW TO USE THIS SECTION MAIN LINE BETWEEN IPOI-E AND DLC

Caution

Revision: October 2016 LAN-1 2016 Micra

Diagnosis Procedure

ECM BRANCH LINE CIRCUIT

Diagnosis Procedure .....

ABS BRANCH LINE CIRCUIT

Diagnosis Procedure

IPDM-E BRANCH LINE CIRCUIT

Diagnosis Procedure

‘TCM BRANCH LINE CIRCUIT

Diagnosis Procedure

A-BAG BRANCH LINE CIRCUIT ..

Diagnosis Procedure ....

DLC BRANCH LINE CIRCUIT

Diagnosis Procedure

EPS BRANCH LINE CIRCUIT

Diagnosis Procedure

M&A BRANCH LINE CIRCUIT

Diagnosis Procedure

STRG BRANCH LINE CIRCUIT

Diagnosis Procedure .....

BCM BRANCH LINE CIRCUIT

Diagnosis Procedure

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure ....

CAN SYSTEM (TYPE 1)

DTC/CIRCUIT DIAGNOSIS

MAIN LINE BETWEEN IPDN-E AND DLC

cIRCUIT

Diagnosis Procedure

ECM BRANCH LINE CIRCUIT

Diagnosis Procedure

ABS BRANCH LINE CIRCUIT

Diagnosis Procedure

IPDM-E BRANCH LINE CIRCUIT

Diagnosis Procedure

A-BAG BRANCH LINE CIRCUIT ..

Diagnosis Procedure «

BE £2 88 RK

SS 88

88 68 GS RE

DLC BRANCH LINE CIRCUIT

Diagnosis Procedure

66 86

Revision: October 2016

LAN-2

EPS BRANCH LINE CIRCUIT

Diagnosis Procedure

M&A BRANCH LINE CIRCUIT ..

Diagnosis Procedure...

STRG BRANCH LINE CIRCUIT

Diagnosis Procedure .....

BCM BRANCH LINE CIRCUIT ..

Diagnosis Procedure

CAN COMMUNICATION CIRCUIT ..

Diagnosis Procedure...

CAN SYSTEM (TYPE 2)

DTC/CIRCUIT DIAGNOSIS

MAIN LINE BETWEEN IPDM-E AND DLC

CIRCUIT

Diagnos!

ECM BRANCH LINE CIRCUIT ..

Diagnosis Procedure

ABS BRANCH LINE CIRCUIT ..

Diagnosis Procedure

IPDM-E BRANCH LINE CIRCUIT

Diagnosis Procedure...

TCM BRANCH LINE CIRCUIT ..

Diagnosis Procedure

A-BAG BRANCH LINE CIRCUIT ..

Diagnosis Procedure

DLC BRANCH LINE CIRCUIT ..

Diagnosis Procedure

EPS BRANCH LINE CIRCUIT

Diagnosis Procedure .....

M&A BRANCH LINE CIRCUIT ..

Diagnosis Procedure

‘STRG BRANCH LINE CIRCUIT

Diagnosis Procedure

BCM BRANCH LINE CIRCUIT ..

Diagnosis Procedure

CAN COMMUNICATION CIRCUIT ..

Diagnosis Procedure...

a9 88

22 28 88 88

Bs

2016 Micra

PRECAUTIONS

< PRECAUTION >

PRECAUTION

PRECAUTIONS

Precautions for Trouble Diagnosis

CAUTION:

+ Never apply 7.0 V or more to the measurement terminal.

+ Use a tester with open terminal voltage of 7.0 V or less.

[CAN FUNDAMENTAL]

+ Turn the ignition switch OFF and disconnect the battery cable from the negative terminal when

checking the harness.

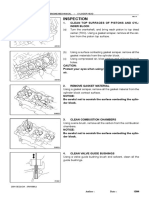

Precautions for Harness Repair

+ Solder the repaired area and wrap tape around the soldered area.

NOTE:

A tray of twisted lines must be within 110 mm (4.33 in),

+ Bypass connection is never allowed at the repaired area,

NOTE:

Bypass connection may cause CAN communication error. The

spliced wire becomes separated and the characteristics of twisted

line are lost.

+ Replace the applicable harness as an assembly if error is detected on the shield lines of CAN communica

tion line.

Revision: October 2016 LAN-3,

ne

/

/

(Ok: Soldered and taped

NG: Bypnss connection

SS 1

2016 Micra

SYSTEM

[CAN FUNDAMENTAL]

SYSTEM DESCRIPTION

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : System Description sooner

+ CAN communication is a multiplex communication system. This enables the system to transmit and receive

large quantities of data at high speed by connecting control units with two communication lines (CAN-H and

CAN-L).

+ Control units on the CAN network transmit signals using the CAN communication control circuit. They

receive only necessary signals from other control units to operate various functions,

+ CAN communication lines adopt twisted-pair line style (two lines twisted) for noise immunity.

CAN COMMUNICATION SYSTEM : System Diagram wowcennce mere

[contr un

Each control unit passes an electric current to the termination clroulls when transmitting CAN communication

‘signal. The termination circuits produce an electrical potential difference between CAN-H and CAN-L. CAN

tion system transmits and receives CAN communication signals by the potential difference.

‘Component Desorption

Main ine ‘CAN communication ine between spices

Branch tine CAN communication tine between splice and a contol unit

Splice ‘A point connecting a branch line with a main line

Termination circuit Refer to LAN-S, “CAN COMMUNICATION SYSTEM : CAN Communication Control Circuit’

Revision: October 2016 LAN-4 2016 Micra

SYSTEM

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

CAN COMMUNICATION SYSTEM : CAN Communication Control Circuit woos

‘enw comraer Mansonver iC se ie

Component Sysiom deseripion

CAN contoler Tr controls CAN communication signal transmission and reception, error detection, et

sransoeWver IC It converts digital signal nto CAN communication signal, and CAN communication signal into digital

signal

Noise fiter ILeliminates noise of CAN communication signal

Termination rout

(Resistance of approx. 120.0)

These are the only conol units wired with both ends of GAN communication system

DIAG ON CAN

DIAG ON CAN : Description seosnonceta279

“Diag on CAN’ is a diagnosis using CAN communication instead of previous DDL1 and DDL2 communication

lines, between control units and diagnosis unit,

1 produces potential dtference.

Revision: October 2016 LAN-5 2016 Micra

< SYSTEM DESCRIPTION >

SYSTEM

[CAN FUNDAMENTAL]

DIAG ON CAN : System Diagram

012 camuncation in (LINE)

Unt ith DDL commuyicatn ine (Re (or ost agnosis)

a bara ingconnacor

[jase

IrIsis-1S1210

+

{DOL esrmaneation ne (Pa)

CAN coneniten Ine (CANH.C8N

Dennen) [Dagon can) [Banana

ve mnoo2tanmraon iN ee

Tae Tas Doar

vou = Ws eee vite dagrove OAH and RL a te cnt)

oot? Wun Ws cdr voile agro. CAN nd CAN a sed cont)

can

ogoncan | SAN We ead errs dagee ard con

Revision: October 2016

LAN-6

2016 Micra

TROUBLE DIAGNOSIS

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Condition of Error Detection wovermneawere

DTC (e.g. U1000 and U1001) of CAN communication is indicated on SELF-DIAG RESULTS on CONSULT if a

CAN communication signal is not transmitted or received between units for 2 seconds or more.

CAN COMMUNICATION SYSTEM ERROR

+ CAN communication line open (CAN-H, CAN-L, or both)

+ CAN communication line short (ground, between CAN communication lines, other harnesses)

+ Error of CAN communication control circuit of the unit connected to CAN communication line

WHEN DTC OF CAN COMMUNICATION IS INDICATED EVEN THOUGH CAN COMMUNICATION

‘SYSTEM IS NORMAL

+ Removallinstallation of parts: Error may be detected when removing and installing CAN communication unit

and related parts while turning the ignition switch ON. (A DTC except for CAN communication may be

detected.)

+ Fuse blown out (removed): CAN communication of the unit may cease.

+ Voltage drop: Error may be detected if voltage drops due to discharged battery when turing the ignition

switch ON (Depending on the control unit which carries out CAN communication).

+ Error may be detected if the power supply circuit of the control unit, which carries out CAN communication,

malfunctions (Depending on the control unit which carries out CAN communication),

+ Error may be detected if reprogramming is not completed normally.

CAUTION:

CAN communication system Is normal if DTC of CAN communication Is indicated on SELF-DIAG

RESULTS of CONSULT under the above conditions. Erase the memory of the self-diagnosis of each

unit.

Symptom When Error Occurs in CAN Communication System nossa

In CAN communication system, multiple units mutually transmit and receive signals. Each unit cannot transmit

and receive signals if any error occurs on CAN communication line. Under this condition, multiple control units

related to the root cause malfunction or go into fail-safe mode.

ERROR EXAMPLE

NOTE:

+ Each vehicle differs in symptom of each unit under fail-safe mode and CAN communication tine wiring,

+ Refer to LAN-18, "Abbreviation List’ for the unit abbreviation.

Example: TCM branch line open circuit

EAN EA

cc] [cu] [ove] [ers] ona] [aes] [row] ove

Revision: October 2016 LAN-7 2016 Micra

TROUBLE DIAGNOSIS

< SYSTEM DESCRIPTION >

[CAN FUNDAMENTAL]

Unit name

‘Symptom

EPS control unit Normal operation.

Combination meter 1 Wang lamps at

‘ABS actuator and electric unit (contol unit) | Normal operation

Tom 'No impact on operation

POM ER Normal operation.

Example: Data link connector branch line open circuit

+ Shift postion indicator and OD OFF indicator turn OFF.

ECM BCM [o] eps| |MBa\

TOM iron

Unit name

‘Symptom

ecw

BcM

EPS eontral unt

Combination meter Normal operation

[ABS actuator ang electric unit (contral unit)

TOM

[POM EM

NOTE:

+ When data link connector branch line is open, transmission and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit,

+ The model (all units on CAN communication system are Diag on CAN) cannot perform CAN diagnosis with

‘CONSULT if the following error occurs. The error is judged by the symptom,

ror

Diference of symptom

Data Ink connestor branch ine open orcult Normal operation

‘Most ofthe units which are connected to the CAN communication

CAN-H, CAN-L hamess short-circuit

system enter fal-safe mode or are deactivate.

Revision: October 2016 LAN-8

2016 Micra

< SYSTEM DESCRIPTION >

TROUBLE DIAGNOSIS

[CAN FUNDAMENTAL]

Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open Circuit

4

EOM

Unitrame ‘Symptom

ECM Engine torque limiting is affected, and shit harshness increases.

+ Reverse warning chime does not sound,

Bem + The front wiper moves under continuous operation mode even though the front wip:

EPS control unit

Combination meter

‘ABS actuator and electric unit (control unit)

TOM

IPDM ER,

cer switch being in the intermittent position.

“The steering effort increases,

+ The shift postion indicator and OD OFF indicator tum OFF

+ The speedometer is inoperative,

+ The odartrip meter stops.

‘Normal operation

'No impact on operation

When the ignition switch is ON,

+ The headlamps (Lo) tum ON.

+The cooling fan continues to rotate,

Example: CAN-H, CAN-L Harness Short Circuit

AN

EOM

Revision: October 2016

LAN-9: 2016 Micra

TROUBLE DIAGNOSIS

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

Unt name ‘Symptom

Engine torque limiting is affected, and shit harehness increases,

Few + Engine speed drops,

+ Reverse waming chime does not sound.

+The front wiper moves under continuous operation made even though the front

wiper switch being inthe intermittent postion.

eM + The room lamp does not turn ON.

+ The engine dos not start (an error or malfunction occurs while turing the ign-

tion switen OFF)

+The steering lock does not release it an eror or malfunction occurs waile turning

the igntion switch OFF)

EPS control unit The steering effort increases.

+ The tachometer and the speedometer do not move

Combination meter + Warning lamps turn ON,

+ Incator lamps do not turn ON.

[ABS actuator and electric unit (Control unt) Normal operation.

Tom 'No impact on operation.

‘When the ignition switch is ON,

|POM ER, + The headlamps (Lo) turn ON,

+The cooling fan continues to rotate.

CAN Diagnosis with CONSULT wow eennevomcre

CAN diagnosis on CONSULT extracts the root cause by receiving the following information.

+ Response to the system call

+ Control unit diagnosis information

+ Self-diagnosis

+ CAN diagnostic support monitor

Self-Diagnosis wooamaoners

It communication signals cannot be transmitted or received among units communicating via CAN communica~

tion line, CAN communication-related DTC is displayed on the CONSULT “Self Diagnostic Result” screen.

NOTE:

The following table shows examples of CAN communication-related DTC. For other DTC, refer to the applica-

ble sections,

Salt diagnosis tom Sacontton| ~ostlncon

ore (CONSULT indication) DTC detection coat Inspection’Acti

‘When EOM isnot ransmiting or receiving CAN

ECM communication signal of OBD (emission-elat-

ed clagnosis) for 2 seconds or more.

1u1000 ‘CAN COMM CIRCUIT

When a control unit (except for ECM) is not

transmitting or receiving CAN communication Stat the inspection, Re

signal for 2 seconds or more. fer to the applicable sec-

tion of the incicated

\When ECM isnot transmiting or receiving CAN communi control unt

soot CAN COMM CIRCUIT cation signa other than OBD (emission~elated diagnosis)

for 2 seconds or mor.

‘When a contol units not transmiting or receiving CAN

Except

for ECM

roca SYSTEM COMM communication signal for 2 seconds or less.

When an eoris detected dung te intial gross for | Replace econo unt

Ur010 CONTROL UNIT(CAN) CAN controller of each control unit. indicating *U1010".

CAN Diagnostic Support Monitor wooamaemrs

MONITOR ITEM (CONSULT)

Revision: October 2016 LAN-10 2016 Micra

TROUBLE DIAGNOSIS

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

Example: CAN DIAG SUPPORT MNTR indication

Without PAST With PAST

ecu ENGINE

TONTORTENPRESENT-[—past—| | aoharon Tew (PASS

int x RANT DAG OK

“angi BAG Ox Woeresaes Tot

Fair Or NeTERMaA—Norcagranal

METERREA — lox Bose —ioK os

co cs ree" Roxas

iroveR—— ox aac Ter ogre

ey oe a ‘Oe on

ee oe (or

[rowem loc

Sian hat gaged

Without PAST

Tem PRESENT Description

(OK Normal at present

Initia agnosis

NG Gontrl unit error (Excopt for some contol units)

OK Normal at present

“Transmission diagnosis Unable to transmit signals for 2 seconds or mere

“ UNKWN .

Diagnosis not performed

(OK Nocmal at present

Control unt name Unable to receive signals for @ seconds or more.

(Reception diagnosis) _UNKWN Diagnesis nat performed

No control unit for receiving signals. (No applicable optional parts)

With PAST

Tier PRESENT |__PAST Description

(OK | Normal at present and in the past

ox ‘Normal at preset, but unable to transmit signals for 2 seconds or more

‘Tranemission diagnosis 1-39 | inthe past. (The number indicates the number of ignition switch cycles

from OFF to ON.)

UNKWN ° Unailo to transmit signals for 2 seconds or more at present,

(OK | Normal at present and in the past

oK ‘Normal at present, but unable to receive signals for 2 seconds or more

1-39 | inthe past. (The number indicates the number of ignition svtch cycles

Control unit name from OFF to ON)

(Reception diagnosis) | UxKWn o Unable to receive signals for 2 seconds or more at present,

Not diag: ~ | Diagnosis not pertormed

nosed No control unit for receiving signals, (No applicable optional paris)

MONITOR ITEM (ON-BOARD DIAGNOSIS)

NOTE:

For some models, CAN communication

|gnosis result is received from the vehicle monitor.

Revision: October 2016 LAN-11 2016 Micra

< SYSTEM DESCRIPTION >

Example: Venide Display

TROUBLE DIAGNOSIS

[CAN FUNDAMENTAL]

Resulting

tem aut ne Error counter Description

0K © Normal at present

CaN_comm Control unit eror

(iil atagnoss) Ne 150 | (Tho numborinceates how many times diagnosis has been

un)

OK © Normal at present

CAN.CIRC_1 Unable transmit for 2 seconds or more at present.

(Transmission diagnosis) UNKWN | 1-50 (The number indicates how many times diagnosis has been

run)

OK © Normal at present

Unable to transmit for 2 saoonds ot more at present.

(The number indicates how many times diagnosis has been

CAN.CIRC 2-9 run)

(Reception diagnosis ofeach uni -

nen dg UNKWN 1=50 _"Giagnosis not performed

No contol unit for receiving signals. (No applicable optional

pars)

How to Use CAN Communication Signal Chart wow concent

The CAN communication signal chart lists the signals needed for trouble diagnosis. It is useful for detecting

the root cause by finding a signal related to the symptom, and by checking transmission and reception unit.

Example: Tachometer does not move even though the engine rotates

Tr Tranamit_Ar Receive

Signa eametConnetng wnt

stao|

{IG eompressor feedback signal

‘AIG compressor request signal |

‘Accalerator pagal postion signal

Costing tan Pair operaion sara

Engine speed slgnat

uel eansurpion monitor sigaall

Matunetion indicator lamp signal

a} a4]a]4]] ecw

"NG wwiten sign

Ignition ewiteh signal

Sleepivake wp signal

Itingieates that an atror oceurs between ECM and MBA (Shaded ares)

ANH. CAML

Revision: October 2016

LAN-12 2016 Micra

DIAGNOSIS AND REPAIR WORKFLOW

[CAN FUNDAMENTAL]

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Trouble Diagnosis Flow Chart eowoneseaeers

DESCRIPTION

ecening venice

Interview wit customer * otarviow wit ustomes, (Sate when? In whieh eondion? Wet aymotoms? et.)

Ccneck voice condition | + Chack whether or not te reproducad arto,

VY

(creck CAN system ype | + Cheok CAN eystom type with CAN aytom type apeciention chat.

Intrsow sheet {Fil in ntriewed tems rom customer on the ntarvow shee.

+ Detect he root cause with CONSULT

Inepacton ey

‘Inspect he oot eause and repair or opin the epplieable pats

Interview with the customer is important to detect the root cause of CAN communication system errors and to

Understand vehicle condition and symptoms for proper trouble diagnosis.

DETAIL OF TROUBLE DIAGNOSIS FLOW CHART

1 .INTERVIEW WITH CUSTOMER

Points in interview

+ What: Parts name, system name

+ When: Date, Frequency

+ Where: Road condition, Place

+ In what condition: Driving condition/environment

+ Result: Symptom

Notes for checking error symotoms:

* Check normal units as well as error symptoms,

- Example: Circuit between ECM and the combination meter is judged normal if the customer indicates

‘tachometer functions normally.

Revision: October 2016 LAN-13 2016 Micra

DIAGNOSIS AND REPAIR WORKFLOW

+ When a CAN communication system error is present, multiple control units may malfunction or go into fail-

sate mode.

+ Indication of the combination meter is important to detect the root cause because it is the most obvious to

the customer, and it performs CAN communication with many units.

[CAN FUNDAMENTAL]

‘ven

‘Warning lamps turn ON

not move wie song,

>>GOTO2,

2..INSPECTION OF VEHICLE CONDITION

Check whether the symptom is reproduced or not.

NOTE:

Do not turn the ignition switch OFF or disconnect the 12V battery cable while reproducing the error. The error

may temporarily correct itself, making it difficult to determine the root cause.

>>GOTO3,

3.cHECK OF CAN SYSTEM TYPE (HOW TO USE CAN SYSTEM TYPE SPECIFICATION CHART)

Determine CAN system type based on vehicle equipment.

NOTE:

+ This chart is used if CONSULT does not automatically recognize CAN system type.

+ There are two styles for CAN system type specification charts. Depending on the number of available sys-

tem types, either style A or style 8 may be used.

+ CAN System Type Specification Chart (Style A)

NOTE:

Revision: October 2016 LAN-14 2016 Micra

DIAGNOSIS AND REPAIR WORKFLOW

[CAN FUNDAMENTAL]

CAN system type is easily checked with the vehicle equipment identification information shown in the chart.

\ontlo copped ae olow: Mago, AND, VOBBDE, CVT, VDC, an lige! Ka ye (

sytem yee)

ca system Speci

Setonina CaN opt

Boop ye

a

nae

“ition Koy oom x

2 [3

ion Chart

pe Wor te folowing specteston chart

Wage

20

OraSOE

os

aversion ype |

a

‘AN colon

‘Aiba agree

co

ineligsn ay oi

Stesng ang sansar

{5S cont unt

face ant (antl unt)

co

PoweR

%: Asscebie

x x{ x

VEHICLE EQUIPMENT IDENTIFICATION INFORMATION

Nove:

(Cheek GAN sytem tye trom the veniale shape ana enuiment

® ®

A

\

fir

Li f1y|\'

| (cea

ant

=

1. ¥OC OFF ein

win ve

+ CAN System Type Specification Chart (Style BY

NOTE:

LAN-15,

Revision: October 2016

> shows an example of CAN

Check the verile

supmon,

“The numer ndesse the

Eunice ype

in he avove sample

+ Checking VOC OFF ok

least ludze whshor or

rot VDC i ecipped

= checking he anton kn

loos fo ge hehe or

at clige’ Key sysiom

‘Sequppes

2016 Micra

DIAGNOSIS AND REPAIR WORKFLOW

[CAN FUNDAMENTAL]

‘CAN system type is easily checked with the vehicle equipment identification information shown in the chart.

Exar

Venlo Is equipped as flows:

Automate dvs poston.

‘CAN Systom Specitication Chart

Foterto he apoctcatn eo shown nto can,

7, 2D, HAZODE. CVT. ABS, Active AFS,Itligont Koy stom, Navigation syatom and

rows an example of CAN syst Wp)

chile equlpent

ppiabe vehicle equipment

Refer tone apectication cr.

| creck ne vehicle eaupment

peer bebebhbeecr

Tei Ty T

“iemanie eee pee we ee univer reas tbe CAN

type fa vile.

Intro above exami,

"Checking Xenon aut an banding lamp esd Yo

ge wnther or ot Acve APS 8 equsped

“Checking the lgniton kno lacs judge whether

‘rma tligent Key sytom i oquppes.

+ Checking dsley and muturetion aie ead to

ge whether ornot Navigation sytem

‘Checking seat momory sth aad to judge

‘abstr or not Auta drive posone a

>> GOTO 4,

4 CREATE INTERVIEW SHEET

Fill out the symptom described by the customer, vehicle condition, and CAN system type on the interview

sheet.

NOTE:

Revision: October 2016 LAN-16 2016 Micra

DIAGNOSIS AND REPAIR WORKFLOW

Interview Sheet (Example)

CAN Communication System Diagnosis Interview Sheet

Dato receives: [ 8, Fos 2008

Type: | BBAKGH vn no. [G1 208040

Modo: | BDRARGZG1EDA

Fret epee: | 79, s8n 2061 ] scan: [240

cangysem ype: [pet |

Headlamps sueny tun ON while dung the vehi

The ongne does ot rear atersopoing he vehce ana uring the orton

“The cooing fon conan clseg we turngthe igen sich ON.

Condon at nspacton

Ero Syrptom Cosa) Fast

“Tne ongine dows not tart

‘nie tare the iris sth ON,

"The peasanps (Lo) un ON. and ihe coating tan controsretsing.

The interior amp does ro tu ON

>>GOTOS.,

5..DETECT THE ROOT CAUSE

CAN diagnosis function of CONSULT detects a root cause.

>> GOTO6.

6..REPAIR OR REPLACE MALFUNCTIONING PART

Repair or replace malfunctioning parts identified by CAN diagnosis function of CONSULT.

Main line>> Refer to LAN-

30, "Main Line".

Branch line>> Refer to LAN-30, "Branch Line".

Short circuit>> Refer to LAN-30, "Short Circuit

Revision: October 2016

LAN-17

2016 Micra

[CAN FUNDAMENTAL]

HOW TO USE THIS SECTION

[CAN]

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

Caution soo commen acre

+ This section describes information peculiar to a vehicle and inspection procedures.

+ For trouble diagnosis procedure, refer to LAN-13, "Trouble Diagnosis Flow Chan.

Abbreviation List roma eset

Unit name abbreviations in CONSULT CAN diagnosis and in this section are as per the following list.

‘Abbreviation Unit name

BAG ‘Air bag diagnosis sensor unt

ABS [ABS actuator and electric unit (control unit)

ecu acm

pic Data lnk connector

ecu Ec

EPS EPS control unit

IPOME POM ER

Maa ‘Combination meter

STRG ‘Steering angie sensor

Tom Tem

Revision: October 2016 LAN-18 2016 Micra

PRECAUTIONS

< PRECAUTION > [CAN]

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" sooune

‘The Supplemental Restraint System such as “AIR BAG" and “SEAT BELT PRE-TENSIONER’, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

+ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

‘the event of a collision which would result in air bag inflation, it is recommended that all mainte-

nance and repair be performed by an authorized NISSAN/INFINITI dealer.

+ Improper repair, including incorrect removal and installation of the SRS, can lead to personal injury

caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module,

see the SR section.

+ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

+ When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

Ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

+ When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery or batteries, and wait at least three minutes before performing any service.

Precautions for Trouble Diagnosis neooonncas7e)

CAUTION:

+ Never apply 7.0 V or more to the measurement terminal.

+ Use a tester with open terminal voltage of 7.0 V or less.

+ Turn the ignition switch OFF and disconnect the battery cable from the negative terminal when

checking the harness.

Precautions for Harness Repair rood

+ Solder the repaired area and wrap tape around the soldered area.

NOTE:

A tray of twisted lines must be within 110 mm (4.33 in),

Revision: October 2016 LAN-19 2016 Micra

PRECAUTIONS

< PRECAUTION >

[CAN]

+ Bypass connection is never allowed at the repaired area.

NOTE:

Bypass connection may cause CAN communication error. The

spliced wire becomes separated and the characteristics of twisted

line are lost.

NG: Bypass connection

Se SSI

+ Replace the applicable harness as an assembly if error is detected on the shield lines of CAN communica-

tion line.

Revision: October 2016 LAN-20

2016 Micra

COMPONENT PARTS

< SYSTEM DESCRIPTION >

ICAN]

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts Location

1. Airbag diagnosis sensor unit 2. Combination meter 8. ABS actuator and electric unit (con-

trol unit)

4. EPS control unt, 5. IPOMER 6. Tom

7. ECM 8. BoM 8. Data ink connector

Steering angle sensor

Revision: October 2016

re

LAN-21 2016 Micra

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN System Specification Chart

Determine CAN system type from the following specification chart.

NOTE:

[CAN]

Refer to LAN-19, "Trouble Diagnosis Flow Chart” for how to use CAN system specification chart.

Body type

Axle

‘door Hatchback

‘WD

Engine

HATEDE

“Transmission

Brake control

voc

CAN system ype

ECM

[ABS actuator and electric unt (control unit)

‘CAN cornmunication unit

POM ER

Tom

‘Airbag diagnosis sensor unit

Data link connector

EPS contral unt

‘Combination meter

‘Steering angle sensor

CM

2 Applieable

CAN COMMUNICATION SYSTEM : CAN Communication Signal Chart

Refer to LAN-12, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

NOTE:

Refer to LAN-18, "Abbreviation List" for the abbreviations of the connecting units.

Signal name

ec

g

2

| IPome|

Tom

ABAG

EPS

MBA

T.Transmit_R: Receive

gs

5 | 8

‘AIC compressor request signal

‘Accelerator pedal position signal

‘ASCO status signal

Closed throttle position signal

Cooling fan speed request signal

Engine and A/T integrated control signal

Engine coolant temperature signal

Engine speed signal

Engine status signal

Fuel consumption monitor signal

Fuel filer cap warring display signal

Revision: October 2016

4444 a)a afaa aaa

LAN-22

zal4a

2016 Micra

< SYSTEM DESCRIPTION >

SYSTEM

ICAN]

Signal name

OM

ABs

Pome}

Tom

ADAG

EPS.

Maa,

sTRG.

acm

Maifunctioning indicator lamp signal

‘il pressure warning lamp signal

‘ABS operation signal

‘ABS warning lamp signal

Brake waming lamp signal

Vehicle speed signal (ABS)

Front wiper stop postion signal

High beam status signal

Ignition switch ON signal

Low beam status signal

Push - button ignition switch status signal

Rear window defogger control signal

‘Sleep-reacy signal

‘Starter control relay signal

‘0D OFF indicator signal

‘Shit postion signal

EPS operation signal

EPS warming lamp signal

‘Overdrive contol switch signal

‘Seat belt buckle awitch signal (iver side)

aaa

2

>

4p 2/2

Vehicle speed signal (Meter)

Wake up signal

‘Steering angle sensor signal

aalaaa

AIGON signal”

Blower fan ON signal

Buzzer output signal

Door switch signal

Engine start operation indicator lamp signal

Front fog light request signal

pala >

Front wiper request signal

High beam request signal

Low beam request signal

Poston light request signal

‘Shit P warning lamp signal

‘Sloop wake up signal

‘Stop amp switch signal

“Turn indicator signal

4444.44 4a)aalaa a a)> a 2)a

STwth manual air condtioning

Revision: October 2016

LAN-23

2016 Micra

CAN SYSTEM

< WIRING DIAGRAM >

WIRING DIAGRAM

CAN SYSTEM

Wiring Diagram

Devon

regener

fox}

gens

&

CAN SYSTEM

Revision: October 2016 LAN-24

[CAN]

2016 Micra

CAN SYSTEM

ICAN]

< WIRING DIAGRAM >

HWS a o

awe 1 ee

2H on eed

eumuiews SB “oN etn

0) a w FeNwa 7 z

i} 4 cs HD 3 .

urn mists | om fon muse cuewues | 28H, fon monuar|

M8 | wioieo ves | wo

Suna

909 UE]

“NETRA [HO REINS]

anaoy “IRN wosNas evr [195 1900005]

TOHLNO AH WDE |awER o2=4N09) SISONDW1d Sa uly [aweN omewse9| “TRIN TOUINDD 543 [auEN OeUHED|

saa | “en iwa09) ean] oN mp Zan] en eeu29)

HWS a oy Hawa 5 5 = 5 x

ava 1 € Wo a z = 7 3

aunve uit on eae fouen mis | emi Fon eave owen ark on won|

fesse | helo wis | wis

F|

sine [a5 Euan 999 1029] nm [eo peU29)

TALIA NOUMNEWOS [aUEN 80ND WOSNES STBNY BNTHTaLS | auEN OD=NIC {WOISSNNOD ST w1va [oun 2204009)

an] eh ZH0UN09) Sin] ow o98H09 ent] “en et0u009)

SHOLOANNOD WALSAS NVO

2016 Micra

LAN-25,

Revision: October 2016

[CAN]

raw 7 Trane 7 a = 7 z

TWO a 8 WO a rn = a °

cumyieuds OM on une | urn mutis | 2 | oy essen cuen bs | 2, [ow wena

Sn [5 wRHNNED|

1)09 sow? (hogy stun sinaoH Sina

eee NGUABIYISIC USMod |SvEN oneLNC9|

wos [owen s6ue9| ANSON UB NOS a1 SHUN

813) oN o08WE9 ENTE 3

CAN SYSTEM

cuenmis | att, [ow omnes

< WIRING DIAGRAM >

= +

- J - +4

= i comms fr

= “ Seto, ON

= i

= i ae pa mH Sanwa [era mo

—te SR-BELEENNOS INF IS SEH 3am [ay mer

cosas (SR ou ma sar| “eeu a aS

2016 Micra

LAN-26

Revision: October 2016

CAN SYSTEM

ICAN]

< WIRING DIAGRAM >

TO) a)

awa 2 |

awsmovers | SBM, [on mass]

2aRO

vz

Fi

Tavis [aS a] = z @

Emon 70H Koo = ow uaa [9 woe]

NO}SS NSH) ND [owen sae09| weupaes | iM Ton eae Fam O1 au [owen a 20.19

ia] ensaee09| Ne eis [enema 2013] “en meu]

: ro ci 7

= ae a9 4

‘um mot BHR “on mona wen oan on one

NMOS |itly oN MUWE wes | ial fon munuen

= 7

7 Fi

= i Bi: ova [905 HHH

= ¢

068 UN

= a aura | 0 awe] AowuNo? Nn oR owen 20.9

ei @ESWOLDRTINOD ANOT [AUN I8H09| Reso va Sav

owen Ss a

Ww

e913] “eNsAPaWN09|

36] oN opUID

2016 Micra

LAN-27

Revision: October 2016

CAN SYSTEM

< WIRING DIAGRAM > [CAN]

: ;

effi 38) e|4

Revision: October 2016 LAN-28 2016 Micra

DIAGNOSIS AND REPAIR WORKFLOW

ICAN]

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Interview Sheet econ atores

CAN Communication System Diagnosis Interview Sheet

Date received:

Type: VIN No.

Model:

First registration: Mileage:

CAN system type:

‘Symptom (Results from interview with customer)

Condition at inspection

Error symptom : Present / Past

Revision: October 2016 LAN-29

2016 Micra

AN

MALFUNCTION AREA CHART

[CAN]

DTC/CIRCUIT DIAGNOSIS

MALFUNCTION AREA CHART

Main Line ova aon

alfunetion area

Raterenoe

Main tne between IPDM E/R and data Ink connector

TANS, "Diagnosis Procedure”

Branch Line

Malfonetion area

EGM branch ine circuit

ABS actuator and electric unit (control unt) branch line circuit

IPDM EIR branch ine circuit

"TEM branch line circuit

‘Airbag diagnosis sensor unit ine creult

Data lnk connector branch line deult

EPS control unit branch line circuit

‘Combination meter branch line cicult

‘Steering angle sensor branch line circuit

BOM branch ine circuit

Short Circuit

TANS?, "Diagnosis Procedure”

LANS9, "Diagnosis Procedure"

LANA, "Diggnosis Procedure”

alfonetion area

Reterenoe

‘CAN communication circuit

Revision: October 2016

LAN-30

2016 Micra

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

< DTC/CIRCUIT DIAGNOSIS >

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis Procedure

1 «CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and hamess side).

= Hamess connector £105

- _ Hamess connector M177

Is the inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

7. Disconnect the following harness connectors.

- IPDMER

= Hamess connectors E105 and M77

2. Check the continuity between the IPDM E/R harness connector and the harness connector.

TPDM EIR hamess connector Famess connector

—_BRM ER emesscomedor__|___Famessconmett entity

Connector No Terminal No Connector No. Terminal No.

2 0 Existed

E10 E105

# & Existed

1g ihe inspection result normal?

YES >>GOTO3.

NO >> Repair the main line between the IPDM E/R and the hares connector E105.

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

heck the continuity between the harness connector and the data link connector.

arness comector Data nk connector

Continuity

Connector No Terminal No, Connector No Terminal No

0 @ Bisted

wz wa

at 4 Existed

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the IPDM E/R and the data link connector.

NO >> Repair the main line between the hamess connector M77 and the data link connector.

Revision: October 2016

LAN-31

2016 Micra

ECM BRANCH LINE CIRCUIT

[CAN]

ECM BRANCH LINE CIRCUIT

Diagnosis Procedure wowcennce mere

1 .cHeck ConNECTOR

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ECM for damage, bend and loose connection (unit side and

connector side),

Isthe inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ECM.

2, Check the resistance between the ECM hamess connector terminals.

EGM hamess connector

Resistance (0)

Connector No. “Terminal No.

E18 84 3 ‘Approx. 108 — 182

ue wi fication?

YES >>GOTO3,

NO >> Repair the ECM branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ECM. Refer to EO-155, "Diagnosis Procedure™.

Is the inspection result normal?

YES (Present error}>>Replace the ECM. Refer to EC-468, "Removal and Installation’.

YES (Past error}>>Error was detected in the ECM branch line,

NO” >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-32 2016 Micra

ABS BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN]

ABS BRANCH LINE CIRCUIT

Diagnosis Procedure seooesa%5

1 .cHEck CONNECTOR

1. Tum the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

it re 2

YES >>GOTO2,

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of ABS actuator and electric unit (control unit).

2. Check the resistance between the ABS actuator and electric unit (control unit) harness connector termi-

nals.

"ABS actuator and electric unit (control unit) hamess connector

Resistance (2)

Connector No. Terminal No.

ES4 28 4 ‘Approx. 54 — 68

the measurement value within the specification?

YES >>GOTO3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to

Is the inspection result normal?

‘YES (Present error)>>Replace the ABS actuator and electric unit (control unit). Refer to BRC-143, "Removal

and Installation”.

YES (Past error)>>Error was detected in the ABS actuator and electric unit (control unit) branoh line,

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-33, 2016 Micra

IPDM-E BRANCH LINE CIRCUIT

[CAN]

IPDM-E BRANCH LINE CIRCUIT

Diagnosis Procedure wowsennce mere

1 .cHeck ConNECTOR

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

8. Check the terminals and connectors of the IPDM E/R for damage, bend and loose connection (unit side

and connector side).

Isthe inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of IPDM E/R.

2, Check the resistance between the IPDM E/R hamess connector terminals,

TPOM EMR harness connector

Resistance (0)

Connector No. “Terminal No.

E10 2 1 Approx. 54-66

ue wi fication?

YES >>GOTO3,

NO >> Repair the IPDM E/R branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the IPDM EUR. Refer to POS-27.. "Diagnosis Procedure”.

Is the inspection result normal?

YES (Present error}>>Replace the IPDM E/R. Refer to PCS-28, "Removal and Installation’.

YES (Past error}>>Error was detected in the IPOM E/R branch line.

NO” >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-34 2016 Micra

TCM BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN]

TCM BRANCH LINE CIRCUIT

Diagnosis Procedure seooemaeiac

1 .cHEck CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the following terminals and connectors for damage, bend and loose connection (unit side and con-

nector side).

- Tom

- Harness connector F46

= Harness connector E6

Is the inspection result normal?

YES >>GOT02.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of TCM.

2. Check the resistance between the TCM hamess connector terminals.

"TEM hamess connector

‘Connector No. Terminal No.

Fi 6 23 Approx. 5466

ith 2

Resistance (2)

YES >>GOTO3.

NO >> Repair the TOM branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the TCM. Refer to TM-248, "Diagnosis Procedure”

1s the inspection result normal?

YES (Present error)>>Replace the TCM. Refer to TM-276, "Removal and installation’.

YES (Past error)>>Error was detected in the TCM branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-35, 2016 Micra

A-BAG BRANCH LINE CIRCUIT

[CAN]

A-BAG BRANCH LINE CIRCUIT

Diagnosis Procedure wowsennce mere

WARNING:

+ Before servicing, turn ignition switch OFF, disconnect battery negative terminal, and wait 3 minutes

‘or more. (To discharge backup capacitor.)

+ Never use unspecified tester or other measuring device.

1 .cHECK CONNECTOR

1. Turn the ignition switch OFF.

2, Disconnect the battery cable from the negative terminal.

3, Check the terminals and connectors of the air bag diagnosis sensor unit for damage, bend and loose con-

nection (unit side and connector side).

Is the inspection result normal?

YES >>GOTO2

NO >> Replace the main harness.

2..CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Check the air bag diagnosis sensor unit. Refer to SAC-35, "Work Flow’.

Is the inspection result normal?

YES >> Replace the main harness.

NO >> Replace parts whose air bag system has a maffunction.

Revision: October 2016 LAN-36 2016 Micra

DLC BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN]

DLC BRANCH LINE CIRCUIT

Diagnosis Procedure seooess\ac

1.cHeck connector

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the data link connector for damage, bend and loose connection

(connector side and hamess side),

inspection r 2

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

Check the resistance between the data link connector terminals.

Data ink connector

—____ Keer Resistance (0)

‘Connector No, Terminal No,

Me 6 14 Approx. 54 ~ 68

is the measurement value within the specification?

YES (Present error)>>Check CAN system type decision again.

‘YES (Past error)>>Error was detected in the data link connector branch line circuit,

NO >> Repair the data link connector branch line.

Revision: October 2016 LAN-37 2016 Micra

EPS BRANCH LINE CIRCUIT

[CAN]

EPS BRANCH LINE CIRCUIT

Diagnosis Procedure wowcenonce mene

1 .cHeck ConNECTOR

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

8. Check the terminals and connectors of the EPS control unit for damage, bend and loose connection (unit

side and connector side).

mt mal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of EPS control unit.

2, Check the resistance between the EPS control unit hamess connector terminals,

EPS contol unit harness connector

Resistance (0)

Connector No. “Terminal No.

Mar 2 1 Approx. 54— 66

ue wi fication?

YES >>GOTO3,

NO >> Repair the EPS control unit branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the EPS control unit. Refer to STO-21, “Diagnosis Proce=

ure".

i mal?

YES (Present ertor)>>Replace the EPS control unit, Refer to STC-39, "Removal and Installation’,

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-38 2016 Micra

M&A BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN]

M&A BRANCH LINE CIRCUIT

Diagnosis Procedure seooess'ace

1.cHeck connector

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the combination meter for damage, bend and loose connection

(unit side and connector side),

inspection r rmal?

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connactor of combination meter.

2. Check the resistance between the combination meter harness connector terminals,

‘Combination meter hamess connector

Resistance (0)

Connector No. Terminal No.

M34 8 10 ‘Approx. 54 ~ 66

thi 2

YES >>GOTO3.

NO >> Repair the combination meter branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the combination meter. Refer to MUWI-40, "COMBINATION

Is the inspection r mal?

YES (Present error)>>Replace the combination meter. Refer to MWI-S3, "Removal and Installation’,

YES (Past error)>>Error was detected in the combination meter branch line.

NO >> Repair the power supply and the ground circuit,

Revision: October 2016 LAN-39 2016 Micra

STRG BRANCH LINE CIRCUIT

[CAN]

STRG BRANCH LINE CIRCUIT

Diagnosis Procedure wowcennce mente

1 .cHeck ConNECTOR

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

8. Check the terminals and connectors of the steering angle sensor for damage, bend and loose connection

(unit side and connector side).

rt mal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2, Check the resistance between the steering angle sensor harness connector terminals.

‘Sisering angle sensor hamess connector

Resistance (0)

Connector No. “Terminal No.

Mis 5 2 Approx. 54— 66

ue wi fication?

YES >>GOTO3.

NO >> Repair the steering angle sensor branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BHO-45, "Wiring Dia:

gram".

i mal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-146, "Removal and Installation’,

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-40 2016 Micra

BCM BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN]

BCM BRANCH LINE CIRCUIT

Diagnosis Procedure seooess'ace

1.cHeck connector

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the BCM for damage, bend and loose connection (unit side and

connector side).

inspection r 2

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of BCM.

2. Check the resistance between the BCM hamess connector terminals.

‘BOM hamess connector

Connector No. “Terminal No. Resistance (0)

Mes 39 40 ‘Approx. 108 — 182

ith 2

YES >>GOTO3.

NO >> Repair the BCM branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

‘Check the power supply and the ground circuit of the BOM. Refer to BOS-48, "Diagnosis Procedure™.

Is the inspection result normal?

YES (Present error)>>Replace the BCM. Refer to "Removal and Installation’.

YES (Past error)>>Error was detected in the BCM branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-41 2016 Micra

CAN COMMUNICATION CIRCUIT

[CAN]

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure wowsennce menos

1 .conNECTOR INSPECTION

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

3. Disconnect all the unit connectors on CAN communication system.

4, Check terminals and connectors for damage, bend and loose connection.

Isthe inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector terminals.

Data nk connector

Continuity

Connector No. "Terminal No.

Ma 6 4 Not existed

Is the inspection result normal

YES >>GOTO3.

NO >> Check the hamess and repair or replace (if shield line or fuse block (J/B) is short) the root cause.

3.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector and the ground,

Data ink connector

Continuity

Connector No. Terminal No,

Ground

6 Not existed

ma

4 Nat existed

isthe ini in result normal?

YES >>GOTO4.

NO 5>Check the hamess and repair or replace (if shield line or fuse block (J/B) is short) the root cause.

4.cHECK ECM AND 8CM TERMINATION CIRCUIT

1. Remove the ECM and the BCM.

2. Check the resistance between the ECM ter

als.

ow

“Terminal No.

aa 3 ‘Approx. 108 — 132

3. Check the resistance between the BCM terminals.

Resistance (2)

BoM

Resistance (1

“Terminal No. o

39 40 Approx. 108 182

isthe measurement value within the specification?

YES >>GOTOS.

NO >> Replace the ECM and/or the BCM.

5.cHECK SYMPTOM

Connect all the connectors. Check if the symptoms described in the “Symptom (Results from interview with

customer)” are reproduced.

Revision: October 2016 LAN-42 2016 Micra

CAN COMMUNICATION CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > ICAN]

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again, Follow the trouble diagnosis procedure when past error is

detected.

6.cHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and BCM have a termination circuit. Check other units first

4, Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)" are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected,

AN

Revision: October 2016 LAN-43, 2016 Micra

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

[CAN SYSTEM (TYPE 1)]

DTC/CIRCUIT DIAGNOSIS

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis Procedure ovat

1 .cHECK CONNECTOR

1. Turn the ignition switch OFF.

2, Disconnect the battery cable from the negative terminal.

3, Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side),

~ Harness connector £105

= Harness connector M77

Is the inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector.

2..CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the following hamess connectors.

- IPOMEIR

+ Harness connectors £105 and M77

2. Check the continuity between the IPDM E/R hamess connector and the harness connector.

TPOM EIR hamess connector Hames connector

Continuity

Connector No. “Terminal No. Connector No "Terminal No.

72 20 Enxisted

E10 E105

1 at Enistod

Is the inspection result normal?

YES >>GOTO3.

NO >> Repair the main line between the IPDM E/R and the harness connector E105.

3.cHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Check the continuity between the harness connector and the data link connector.

Harness connector Data ink connector Comin

Connector No. “Terminal No. ‘Connector No. “Terminal No. inuiy

80 6 Existed

Marr —— me

a 4 Existed

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the IPDM E/R and the data link connector.

NO >> Repair the main line between the harness connector M77 and the data link connector.

Revision: October 2016 LAN-44 2016 Micra

ECM BRANCH LINE CIRCUIT

[CAN SYSTEM (TYPE 1)]

ECM BRANCH LINE CIRCUIT

Diagnosis Procedure wove

1.cHeck connector

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the ECM for damage, bend and loose connection (unit side and

connector side).

inspection r 2

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of ECM.

2. Check the resistance between the ECM hamess connector terminals.

ECM hamess connector

Resistance (0)

Connector No. Terminal No.

E18 a 8 ‘Approx. 108 — 132

thi 2

YES >>GOTO3.

NO >> Repair the ECM branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the EOM. Refer to EO-155, "Diagnosis Procedure”.

1s the inspection result normal?

YES (Present error)>>Replace the ECM. Refer to EC-468, "Removal and Installation’.

YES (Past error)>>Error was detected in the ECM branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-45, 2016 Micra

ABS BRANCH LINE CIRCUIT

[CAN SYSTEM (TYPE 1)]

ABS BRANCH LINE CIRCUIT

Diagnosis Procedure wroocrmenams

1 .cHeck ConNECTOR

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

3, Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

Isthe inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of ABS actuator and electric unit (control unit)

2, Check the resistance between the ABS actuator and electric unit (control unit) hamess connector termi-

nals.

"ABS aciualor and elecivc unit (control uni) harness connector

Connector No. ‘Terminal No.

E34 6 4 Approx. 54~ 66

Is the measurement value within the specification?

YES >>GOTO3.

NO 53> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to

BRC-69, "Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the ABS actuator and electric unit (control unit). Refer to BRC-143, "Removal

and Installation":

YES (Past error)>>Error was detected in the ABS actuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit.

Resistance (0)

Revision: October 2016 LAN-46 2016 Micra

IPDM-E BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

IPDM-E BRANCH LINE CIRCUIT

Diagnosis Procedure seooen as

1 .cHEck CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the IPDM E/R for damage, bend and loose connection (unit side

and connector side).

inspection r 2

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of IPDM EIR.

2. Check the resistance between the IPDM E/R hamess connector terminals.

TPDM E/R hamess connector

Resistance (0)

Connector No. Terminal No.

E10 72 1 ‘Approx. 54— 68

thi 2

YES >>GOTO3.

NO >> Repair the IPDM E/R branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the IPDM E/R. Refer to POS-27, "Diagnosis Prosadure™

Is the inspection result normal?

YES (Present error)>>Replace the IPDM E/A. Refer to PCS-28, "Removal and In

YES (Past error)>>Error was detected in the IPDM_E/R branch line,

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-47 2016 Micra

A-BAG BRANCH LINE CIRCUIT

[CAN SYSTEM (TYPE 1)]

A-BAG BRANCH LINE CIRCUIT

Diagnosis Procedure wroocercaams

WARNING:

+ Before servicing, turn ignition switch OFF, disconnect battery negative terminal, and wait 3 minutes

‘or more. (To discharge backup capacitor.)

+ Never use unspecified tester or other measuring device.

1 .cHECK CONNECTOR

1. Turn the ignition switch OFF.

2, Disconnect the battery cable from the negative terminal.

3, Check the terminals and connectors of the air bag diagnosis sensor unit for damage, bend and loose con-

nection (unit side and connector side).

Is the inspection result normal?

YES >>GOTO2

NO >> Replace the main harness.

2..CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Check the air bag diagnosis sensor unit. Refer to SAC-35, "Work Flow’.

Is the inspection result normal?

YES >> Replace the main harness.

NO >> Replace parts whose air bag system has a maffunction.

Revision: October 2016 LAN-48 2016 Micra

DLC BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

DLC BRANCH LINE CIRCUIT

Diagnosis Procedure seooes a

1.cHeck connector

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the data link connector for damage, bend and loose connection

(connector side and hamess side),

inspection r 2

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

Check the resistance between the data link connector terminals.

Data ink connector

—____ Keer Resistance (0)

‘Connector No, Terminal No,

Me 6 14 Approx. 54 ~ 68

is the measurement value within the specification?

YES (Present error)>>Check CAN system type decision again.

‘YES (Past error)>>Error was detected in the data link connector branch line circuit,

NO >> Repair the data link connector branch line.

Revision: October 2016 LAN-49 2016 Micra

EPS BRANCH LINE CIRCUIT

[CAN SYSTEM (TYPE 1)]

EPS BRANCH LINE CIRCUIT

Diagnosis Procedure wroocercn ams

1 .cHeck ConNECTOR

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

8. Check the terminals and connectors of the EPS control unit for damage, bend and loose connection (unit

side and connector side).

mt mal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of EPS control unit.

2, Check the resistance between the EPS control unit hamess connector terminals,

EPS contol unit harness connector

Resistance (0)

Connector No. “Terminal No.

Mar 2 1 Approx. 54— 66

ue wi fication?

YES >>GOTO3,

NO >> Repair the EPS control unit branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the EPS control unit. Refer to STO-21, “Diagnosis Proce=

ure".

i mal?

YES (Present ertor)>>Replace the EPS control unit, Refer to STC-39, "Removal and Installation’,

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-50 2016 Micra

M&A BRANCH LINE CIRCUIT

[CAN SYSTEM (TYPE 1)]

M&A BRANCH LINE CIRCUIT

Diagnosis Procedure woven

1.cHeck connector

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the combination meter for damage, bend and loose connection

(unit side and connector side),

inspection r rmal?

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connactor of combination meter.

2. Check the resistance between the combination meter harness connector terminals,

‘Combination meter hamess connector

Resistance (0)

Connector No. Terminal No.

M34 8 10 ‘Approx. 54 ~ 66

thi 2

YES >>GOTO3.

NO >> Repair the combination meter branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the combination meter. Refer to MUWI-40, "COMBINATION

Is the inspection r mal?

YES (Present error)>>Replace the combination meter. Refer to MWI-S3, "Removal and Installation’,

YES (Past error)>>Error was detected in the combination meter branch line.

NO >> Repair the power supply and the ground circuit,

Revision: October 2016 LAN-51 2016 Micra

STRG BRANCH LINE CIRCUIT

[CAN SYSTEM (TYPE 1)]

STRG BRANCH LINE CIRCUIT

Diagnosis Procedure wowcenonce sete

1 .cHeck ConNECTOR

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

8. Check the terminals and connectors of the steering angle sensor for damage, bend and loose connection

(unit side and connector side).

rt mal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2, Check the resistance between the steering angle sensor harness connector terminals.

‘Sisering angle sensor hamess connector

Resistance (0)

Connector No. “Terminal No.

Mis 5 2 Approx. 54— 66

ue wi fication?

YES >>GOTO3.

NO >> Repair the steering angle sensor branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BHO-45, "Wiring Dia:

gram".

i mal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-146, "Removal and Installation’,

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-52 2016 Micra

BCM BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

BCM BRANCH LINE CIRCUIT

Diagnosis Procedure seooes a3

1.cHeck connector

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the BCM for damage, bend and loose connection (unit side and

connector side).

inspection r 2

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of BCM.

2. Check the resistance between the BCM hamess connector terminals.

‘BOM hamess connector

Connector No. “Terminal No. Resistance (0)

Mes 39 40 ‘Approx. 108 — 182

ith 2

YES >>GOTO3.

NO >> Repair the BCM branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

‘Check the power supply and the ground circuit of the BOM. Refer to BOS-48, "Diagnosis Procedure™.

Is the inspection result normal?

YES (Present error)>>Replace the BCM. Refer to "Removal and Installation’.

YES (Past error)>>Error was detected in the BCM branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-53 2016 Micra

CAN COMMUNICATION CIRCUIT

[CAN SYSTEM (TYPE 1)]

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure wrowcermcnamst

1 .conNECTOR INSPECTION

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

3. Disconnect all the unit connectors on CAN communication system.

4, Check terminals and connectors for damage, bend and loose connection.

Isthe inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector terminals.

Data nk connector

Continuity

Connector No. "Terminal No.

Ma 6 4 Not existed

Is the inspection result normal

YES >>GOTO3.

NO >> Check the hamess and repair or replace (if shield line or fuse block (J/B) is short) the root cause.

3.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector and the ground,

Data ink connector

Continuity

Connector No. Terminal No,

Ground

6 Not existed

ma

4 Nat existed

isthe ini in result normal?

YES >>GOTO4.

NO 5>Check the hamess and repair or replace (if shield line or fuse block (J/B) is short) the root cause.

4.cHECK ECM AND 8CM TERMINATION CIRCUIT

1. Remove the ECM and the BCM.

2. Check the resistance between the ECM ter

als.

ow

“Terminal No.

aa 3 ‘Approx. 108 — 132

3. Check the resistance between the BCM terminals.

Resistance (2)

BoM

Resistance (1

“Terminal No. o

39 40 Approx. 108 182

isthe measurement value within the specification?

YES >>GOTOS.

NO >> Replace the ECM and/or the BCM.

5.cHECK SYMPTOM

Connect all the connectors. Check if the symptoms described in the “Symptom (Results from interview with

customer)” are reproduced.

Revision: October 2016 LAN-54 2016 Micra

CAN COMMUNICATION CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again, Follow the trouble diagnosis procedure when past error is

detected.

6.cHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and BCM have a termination circuit. Check other units first

4, Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)" are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected,

AN

Revision: October 2016 LAN-55, 2016 Micra

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

[CAN SYSTEM (TYPE 2)]

DTC/CIRCUIT DIAGNOSIS

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis Procedure ovata

1 .cHECK CONNECTOR

1. Turn the ignition switch OFF.

2, Disconnect the battery cable from the negative terminal.

3, Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side),

~ Harness connector £105

= Harness connector M77

Is the inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector.

2..CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the following hamess connectors.

- IPOMEIR

+ Harness connectors £105 and M77

2. Check the continuity between the IPDM E/R hamess connector and the harness connector.

TPOM EIR hamess connector Hames connector

Continuity

Connector No. “Terminal No. Connector No "Terminal No.

72 20 Enxisted

E10 E105

1 at Enistod

Is the inspection result normal?

YES >>GOTO3.

NO >> Repair the main line between the IPDM E/R and the harness connector E105.

3.cHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Check the continuity between the harness connector and the data link connector.

Harness connector Data ink connector Comin

Connector No. “Terminal No. ‘Connector No. “Terminal No. inuiy

80 6 Existed

Marr —— me

a 4 Existed

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the IPDM E/R and the data link connector.

NO >> Repair the main line between the harness connector M77 and the data link connector.

Revision: October 2016 LAN-56 2016 Micra

ECM BRANCH LINE CIRCUIT

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

ECM BRANCH LINE CIRCUIT

Diagnosis Procedure seooem a

1.cHeck connector

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal

3. Check the terminals and connectors of the ECM for damage, bend and loose connection (unit side and

connector side).

inspection r 2

YES >>GOTO2

NO >> Repair the terminal and connector,

2.CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of ECM.

2. Check the resistance between the ECM hamess connector terminals.

ECM hamess connector

Resistance (0)

Connector No. Terminal No.

E18 a 8 ‘Approx. 108 — 132

thi 2

YES >>GOTO3.

NO >> Repair the ECM branch line.

3.cHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the EOM. Refer to EO-155, "Diagnosis Procedure”.

1s the inspection result normal?

YES (Present error)>>Replace the ECM. Refer to EC-468, "Removal and Installation’.

YES (Past error)>>Error was detected in the ECM branch line.

NO >> Repair the power supply and the ground circuit.

Revision: October 2016 LAN-57 2016 Micra

ABS BRANCH LINE CIRCUIT

[CAN SYSTEM (TYPE 2)]

ABS BRANCH LINE CIRCUIT

Diagnosis Procedure wroainrce amet

1 .cHeck ConNECTOR

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

3, Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

Isthe inspection result normal?

YES >>GOTO2.

NO >> Repair the terminal and connector,

2..CHECK HARNESS FOR OPEN CIRCUIT

7. Disconnect the connector of ABS actuator and electric unit (control unit)

2, Check the resistance between the ABS actuator and electric unit (control unit) hamess connector termi-

nals.

"ABS aciualor and elecivc unit (control uni) harness connector

Connector No. ‘Terminal No.

E34 6 4 Approx. 54~ 66

Is the measurement value within the specification?

YES >>GOTO3.

NO 53> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to

BRC-69, "Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the ABS actuator and electric unit (control unit). Refer to BRC-143, "Removal

and Installation":

YES (Past error)>>Error was detected in the ABS actuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit.

Resistance (0)

Revision: October 2016 LAN-58 2016 Micra

IPDM-E BRANCH LINE CIRCUIT