Professional Documents

Culture Documents

EEX20402 Information Sources For Evaluating Circuit Breaker Installation

EEX20402 Information Sources For Evaluating Circuit Breaker Installation

Uploaded by

Honesto BautistaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EEX20402 Information Sources For Evaluating Circuit Breaker Installation

EEX20402 Information Sources For Evaluating Circuit Breaker Installation

Uploaded by

Honesto BautistaCopyright:

Available Formats

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

Information Sources for

Evaluating Circuit Breaker Installations

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramco’s

employees. Any material contained in this document which is not already

in the public domain may not be copied, reproduced, sold, given, or

disclosed to third parties, or otherwise used in whole, or in part, without

the written permission of the Vice President, Engineering Services, Saudi

Aramco.

Chapter : Electrical For additional information on this subject, contact

File Reference: EEX20402 W.A. Roussel on 874-1320

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

CONTENTS PAGES

TERMINOLOGY AND DATA ON CIRCUIT BREAKER NAMEPLATES ...........1

Continuous Current Rating.............................................................................1

Voltage Rating................................................................................................2

Maximum Design Voltage Rating.................................................................. 2

K Factor..........................................................................................................2

Basic Impulse Level (BIL) .............................................................................2

Short-Circuit Interrupting Rating ................................................................... 3

Maximum Symmetrical Interrupting Capability.............................................3

Maximum Asymmetrical Interrupting Capability (Momentary Rating).........4

Standard Operating Duty Rating .................................................................... 4

DOCUMENTATION THAT IS AVAILABLE FOR EVALUATION OF

CIRCUIT BREAKER INSTALLATIONS ................................................................5

SAES ..............................................................................................................6

SADP..............................................................................................................7

SAMSS...........................................................................................................8

Manufacturer’s Technical Manual................................................................10

TYPES OF DRAWINGS THAT ARE AVAILABLE FOR EVALUATION

OF CIRCUIT BREAKER INSTALLATIONS ........................................................14

One-Line Diagrams ......................................................................................14

Elementary Diagrams ...................................................................................17

Panel Diagrams.............................................................................................20

Interconnection Diagrams ............................................................................22

Construction Diagrams.................................................................................24

GLOSSARY ............................................................................................................26

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

TERMINOLOGY AND DATA ON CIRCUIT BREAKER NAMEPLATES

The terminology and data that are found on the nameplate of a circuit breaker define the

conditions that are recommended for the circuit breaker to properly operate. Such

terminology and data also indicate the limits of operation under which the circuit breaker can

safely operate. Operation of the circuit breaker in excess of the limits that are listed on the

circuit breaker’s nameplate can cause damage to occur to the circuit breaker. Dependent on

the amount by which the limits are exceeded, damage could also occur to the equipment that

the circuit breaker is designed to protect.

The following is a list of nameplate ratings that describe the capabilities of a circuit breaker:

• Continuous Current Rating

• Voltage Rating

• Maximum Design Voltage Rating

• K Factor

• Basic Impulse Level (BIL)

• Short Circuit Current Rating

• Standard Operating Duty Rating

Continuous Current Rating

The continuous current rating of a circuit breaker is the limit of current, expressed in rms

amperes, at the rated frequency that the circuit breaker is designed to continuously conduct

under normal operating conditions. An important point to understand is that this rating is a

continuous current value and not an instantaneous or short duration current value. The

continuous current rating of a circuit breaker can be exceeded under certain conditions of

operation for very short periods of time. If the continuous current that the circuit breaker is

carrying exceeds the continuous current rating of the breaker, the amount of heat that is

generated by the current flow will cause the breaker components to exceed their thermal

limits. Dependent on the amount by which the limits are exceeded and the duration of the

overcurrent condition, the parts that were used to construct the circuit breaker can overheat

and cause the integrity of the circuit breaker to degrade. This degradation can lead to circuit

breaker failure.

Saudi Aramco DeskTop Standards 1

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Voltage Rating

The voltage rating of a circuit breaker is the nominal voltage class or classes in which the

circuit breaker is rated. The voltage rating represents the rms voltage to which the operating

characteristics and the performance characteristics of the circuit breaker are referenced.

Maximum Design Voltage Rating

The maximum design voltage rating of a circuit breaker is the maximum voltage, expressed in

rms volts, at which the circuit breaker was designed to operate. The maximum design voltage

rating of a circuit breaker must be higher than the maximum anticipated operating voltage

under the worst case conditions of power line voltage regulation. Operation of a circuit

breaker at a voltage that is higher than the circuit breaker’s maximum design voltage rating

may cause the circuit breaker’s insulation to break down or degrade. Degraded insulation can

lead to overheating, shorts, or undesirable circulating currents that can cause the circuit

breaker to operate incorrectly or to completely fail.

K Factor

The K factor of a circuit breaker is the ratio of rated maximum voltage to the lower limit of

the range of operating voltage in which the required symmetrical and asymmetrical current

interrupting capabilities vary in inverse proportion to the operating voltage. The rated

maximum voltage divided by the K factor will yield the minimum operating voltage at which

the circuit breaker will interrupt its rated MVA. At voltages that are below the minimum

operating voltage, the circuit breaker is not designed to interrupt the rated MVA; the circuit

breaker will interrupt some value that is less than rated MVA. This fact is very significant in

the rating of power circuit breakers because a circuit breaker will interrupt a maximum of

only so many amperes regardless of voltage. At any voltage (kV) that is less than the

minimum operating voltage, the product of the maximum kilo-amperes (ka) interrupting

capability, the kV, and the square root of three is less than the MVA interrupting rating of the

circuit breaker.

Basic Impulse Level (BIL)

The basic impulse level (BIL) of a circuit breaker is the reference insulation level, expressed

as the impulse crest value of withstand voltage of a specified full impulse voltage wave, that

the circuit breaker must withstand without a flashover. The BIL is based on a test that uses a

wave that is intended to simulate a lightning stroke. The wave that is used for the test that is

performed on a circuit breaker is a 1.2 x 50 microsecond wave. The wave goes from zero to a

crest voltage in 1.2 microseconds, and the wave reaches a magnitude that is half of the value

of the crest voltage in 50 microseconds.

Saudi Aramco DeskTop Standards 2

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

The BIL describes the ability of a circuit breaker to withstand voltage surges that may occur

on the system that contains the circuit breaker. Voltage surges on the system can damage the

insulation on the conducting parts of the circuit breaker. If a circuit breaker is exposed to a

surge voltage that exceeds the BIL rating, circuit breaker insulation damage or failure can

occur. The design of the circuit breaker must account for the maximum amount of surge

voltage that the circuit breaker can be reasonably expected to withstand and must ensure that

insulation degradation does not occur at that maximum surge voltage.

Short-Circuit Interrupting Rating

The short-circuit interrupting rating of a circuit breaker can be expressed as two different

quantities: volt-amperes (VA) and amperes. The initial industry practice was to specify the

short-circuit rating in VA (kVA, MVA). The short-circuit interrupting rating of a circuit

breaker in VA is the product of the phase voltage of the circuit and the interrupting ability of

the breaker (in amperes) at stated intervals and a specific number of times. The current

(amperes) that is used is the rms value of current that exists during the first half-cycle of arc

between the contacts of the breaker on the opening stroke.

The present practice, and the practice that is specified in ANSI C37, is to designate the short-

circuit interrupting rating of a circuit breaker as a short-circuit current rating. The short-

circuit current rating of a circuit breaker is the maximum rms symmetrical current (ka) that the

circuit breaker can interrupt at the maximum rated voltage. All of the other required short-

circuit capabilities of a circuit breaker are related back to the short-circuit current rating. The

remainder of this section contains a brief discussion of the following circuit breaker

capabilities that are related to the short-circuit current rating:

• Maximum Symmetrical Interrupting Capability

• Maximum Asymmetrical Interrupting Capability (Momentary Rating)

Maximum Symmetrical Interrupting Capability

The maximum symmetrical interrupting capability of a circuit breaker is equal to K times the

rated short-circuit current. This value is the maximum symmetrical rms current that the

circuit breaker can interrupt. This value of current is also the three-second, short-time,

current-carrying capability of the circuit breaker. The circuit breaker can carry this amount of

current in the closed position for a period of three seconds to allow for relay operating times.

Saudi Aramco DeskTop Standards 3

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Maximum Asymmetrical Interrupting Capability (Momentary Rating)

The asymmetrical interrupting capability of a circuit breaker is the maximum rms

asymmetrical current that a circuit breaker can interrupt, including short circuit currents from

all sources and motors (induction and synchronous) and the dc component. This rating is

independent of the operating voltage for a given circuit breaker. The maximum rms

asymmetrical interrupting capability of a circuit breaker is equal to 1.6K times the rated short-

circuit current, and the maximum crest value is equal to 2.7K times the rated short-circuit

current.

Standard Operating Duty Rating

The standard operating duty rating or duty cycle of a circuit breaker is two unit operations

(close operation that is followed by an open operation, CO) with a 15 second interval between

operations. This duty cycle is represented as follows:

CO - 15 seconds - CO

The circuit breaker interrupting capabilities that were discussed in the previous sections are

based on this duty cycle.

Saudi Aramco DeskTop Standards 4

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

DOCUMENTATION THAT IS AVAILABLE FOR EVALUATION OF CIRCUIT

BREAKER INSTALLATIONS

The requirements that circuit breakers must meet as well as suggestions for the proper

operation of circuit breakers are found in the following documents:

• SAES

• SADP

• SAMSS

• Manufacturer’s Technical Manual

Saudi Aramco DeskTop Standards 5

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

SAES

An SAES is a Saudi Aramco Engineering Standard. In general, an SAES contains the

minimum mandatory requirements that govern a particular piece of equipment or a particular

type of installation. The SAES also refers to other codes and standards that apply to the

particular piece of equipment or type of installation. If a conflict should arise between an

SAES and another document that relates to the material that is in an SAES, the conflict must

be resolved by the Saudi Aramco Chief Engineer in Dhahran.

SAES-P-116 is the particular SAES that governs the evaluation and use of circuit breakers in

Saudi Aramco systems. SAES-P-116 lists some physical restrictions on the construction of

circuit breakers that are used in Saudi Aramco systems (e.g., oil circuit breakers are not

permitted in Saudi Aramco systems.) More importantly, SAES-P-116 indicates the reference

documents that are used as a guide during the performance of the testing that is required

before a circuit breaker can be used in Saudi Aramco systems and during the installation of

circuit breakers into Saudi Aramco systems. When a statement is made in an SAES that

indicates that a requirement of the SAES is found in another document, the applicable parts of

the referenced document, in essence, become part of the SAES.

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

SADP

An SADP is a Saudi Aramco Design Practice. The intent of the SADP is to provide

amplifying information on the technical requirements that are found in the SAES. The

information that is in the SADP is not mandatory; however, the SADP may contain some of

the mandatory requirements that are found in the SAES. Any mandatory SAES requirements

that are in an SADP are shown in upper case type.

Each SADP corresponds to a particular SAES. The SADP that applies to the evaluation and

use of circuit breakers in Saudi Aramco systems is SADP-P-116. The suffix P-116

corresponds to both the SAES and the SADP that apply to the evaluation and use of circuit

breakers. The SADP contains amplifying information about the following aspects of circuit

breaker evaluation and installation:

• Definitions.

• Published standards that govern the evaluation and installation of circuit

breakers.

• Examples of applications of circuit breakers in Saudi Aramco systems.

• Design conditions that will ensure the safe operation of circuit breakers

in Saudi Aramco systems.

• Derating of circuit breakers due to ambient conditions.

The use of the information in SADP-P-116 in conjunction with the requirements that are in

SAES-P-116 will aid in the proper testing and use of circuit breakers in Saudi Aramco

systems.

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

SAMSS

An SAMSS is a Saudi Aramco Materials System Specification. The function of the SAMSS

is similar to the function of the SAES in that the SAMSS provides minimum technical

requirements; however, the SAES provides the minimum technical requirements for an entire

system, while the SAMSS, in general, provides the minimum technical requirements for a

particular piece of equipment. Because a system is often made up of many individual pieces

of equipment, the possibility exists for an SAES to reference many SAMSS’s for pieces of

equipment that, when used in conjunction with each other, form a system.

The SAMSS’s that apply to the evaluation and installation of circuit breakers are:

• 16-SAMSS-501 Switchgear Assemblies Including Control

Switchboards.

• 16-SAMSS-502 Metal-Enclosed, Low-Voltage Switchgear

Assemblies.

• 16-SAMSS-503 Low-Voltage Motor Control Centers and Switchracks

(600 Volts and Below).

• 16-SAMSS-506 Medium-Voltage Motor Control Center.

16-SAMSS-501 defines the minimum technical requirements for switchgear assemblies that

include requirements for circuit breakers. The technical requirements are contained in

American National Standard Institute (ANSI) Specification C37.20-1974 and include the

additions and exceptions that are presented in 16-SAMSS-501.

16-SAMSS-502 defines the minimum mandatory requirements for the design, fabrication,

testing, and handling of metal-enclosed, low-voltage switchgear assemblies that include

requirements for circuit breakers. The technical requirements address construction

requirements, equipment ratings, protection and control devices, equipment accessories,

testing requirements (including the ANSI standards that govern the tests), and quality

assurance documentation requirements.

16-SAMSS-503 defines the minimum technical requirements for low-voltage motor control

centers that include circuit breakers as part of the assembly. The technical requirements

address the types of circuit breakers that are acceptable to use with different sizes of motor

control centers and the physical and electric characteristics of the circuit breakers that are

acceptable to use in motor control centers.

16-SAMSS-506 defines the minimum technical requirements for medium-voltage motor

control centers that include circuit breakers as part of the assembly. The technical

requirements address the types of circuit breakers that are acceptable to use with medium-

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

voltage motor control centers as well as the requirements that govern the physical placement

of the circuit breakers in relation to the low-voltage control devices that are required in

medium-voltage motor control centers.

Saudi Aramco DeskTop Standards 9

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Manufacturer’s Technical Manual

The manufacturer’s technical manual (MTM) is a document that is prepared by the

manufacturer of a circuit breaker. The MTM is intended to provide its reader with the

information that the reader will need to know from the receipt of the circuit breaker from the

manufacturer to the maintenance of the circuit breaker after it has been placed in operation.

In general, all MTM’s contain the same information; however, the depth of the discussion of

certain topics can vary from manufacturer to manufacturer. Usually, the MTM will discuss,

to some degree, the following topics:

• Instructions on how to receive, unpack, and handle the circuit breaker

after delivery from the manufacturer.

• A description of the components that are used to construct the circuit

breaker.

• A list of tests that are to be performed after receipt of a circuit breaker.

• Instructions on how to install the circuit breaker.

• A description of the initial adjustments that need to be made to the

circuit breaker.

• A description of the operating adjustments that need to be made to the

circuit breaker.

• An explanation of how the circuit breaker suppresses an arc (i.e., how

the circuit breaker works.)

• A description of typical circuit breaker performance.

• An identification of the operating mechanism of the circuit breaker and

instructions for the installation, adjustment, operation, and maintenance

of the operating mechanism.

• A description of the maintenance of the circuit breaker.

• A description of inspection procedures that are to be performed during

the routine maintenance of the circuit breaker.

The MTM provides instructions that pertain to the delivery of a circuit breaker from the

manufacturer. The MTM will detail how to remove the packaging material from the circuit

breaker, and it will explain how to move the circuit breaker without causing damage.

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

The operation of a circuit breaker requires many components of the circuit breaker to work in

concert. The MTM will point out the components that make up the circuit breaker. Diagrams

are provided in the MTM that indicate where the individual components are located in the

circuit breaker.

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Many times, a circuit breaker must be stored for an extended period of time before the circuit

breaker is installed. Tests should be performed on the circuit breaker before the circuit

breaker is put into storage. The tests will establish “as delivered” qualities for the circuit

breaker. The tests should be performed again just prior to the installation of the circuit

breaker, and a comparison should be made to the results of the “as delivered” tests to

determine whether the circuit breaker was damaged during storage. The MTM will specify

the tests that are to be performed on the circuit breaker as well as the procedures that should

be followed to perform the tests.

To ensure that the circuit breaker will properly and safely operate, the circuit breaker must be

correctly installed. The MTM will provide step-by-step instructions on how to install the

circuit breaker. Strict adherence to the instructions that are provided by the manufacturer will

ensure that the circuit breaker installation performs its intended function in a manner that will

not be a safety hazard.

During fabrication, the manufacturer of a circuit breaker may install pieces into the spaces of

the circuit breaker to ensure that internal components of the circuit breaker will not be

damaged during transit. The initial adjustments to a circuit breaker include removal of these

protective devices as well as other adjustments that will ensure proper initial operation of the

circuit breaker. The MTM will detail the adjustments that need to be performed.

In general, once the initial adjustments have been made to the circuit breaker, the circuit

breaker should be manually cycled through its open-close operation. The circuit breaker

should then be left in the closed position so that operating adjustments can be made. The

operating adjustments are similar in nature to the initial adjustments except that the initial

adjustments are made with the circuit breaker in the open position and the operating

adjustments are made with the circuit breaker in the closed position. Again, the MTM will

detail the adjustments that need to be performed.

The installation of a circuit breaker provides protection for some piece of electrical

equipment. The switching mechanism that the circuit breaker uses to break a circuit will

cause an arc to be formed across the contacts of the circuit breaker as the contacts open. The

method that is used to suppress the arc varies for different types (e.g., air, oil) of circuit

breakers. The means by which various types of circuit breakers suppress an arc were

discussed in Module EEX 204.01; however, the MTM also should discuss how the circuit

breaker suppresses an arc.

Saudi Aramco DeskTop Standards 12

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

As part of the design process of a Saudi Aramco electrical system, the operational

characteristics of a circuit breaker under normal operating conditions may need to be known.

The MTM should list the operational characteristics of the circuit breaker under normal

operational conditions. The operational characteristics include the minimum amount of fault

current that will actuate the operation of the circuit breaker and the number of cycles that will

be required for the circuit breaker’s contact to open and extinguish an arc.

To properly operate, a circuit breaker must have a mechanism that will open the circuit

breaker’s contacts. The MTM should identify the type of mechanism that the circuit breaker

employs to open the circuit breaker’s contacts (e.g., a solenoid or a pneumatic mechanism).

In a manner that is similar to the instructions that are provided for the circuit breaker, the

MTM should provide instructions that pertain to the installation, adjustment, operation, and

maintenance of the operating mechanism of the circuit breaker.

To maintain a circuit breaker in its optimum operating condition after initial installation, a

maintenance schedule should be identified and employed. The MTM should identify a

schedule for the replacement of the circuit breaker’s parts. The MTM should also identify

other forms of maintenance that should be performed on the circuit breaker (e.g., cleaning and

the application of lubrication to the movable parts). The MTM should also identify various

inspections and adjustments that should be performed.

Saudi Aramco DeskTop Standards 13

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

TYPES OF DRAWINGS THAT ARE AVAILABLE FOR EVALUATION OF CIRCUIT

BREAKER INSTALLATIONS

In most cases, pieces of electrical apparatus operate in conjunction with a circuit breaker. To

permit evaluation of a circuit breaker installation as a whole, the physical characteristics of

the circuit breaker as well as the pieces of electrical apparatus must be considered. The

following types of diagrams are available to use to evaluate circuit breaker installations:

• One-Line Diagrams

• Elementary Diagrams

• Panel Diagrams

• Interconnection Diagrams

• Construction Diagrams

One-Line Diagrams

A one-line diagram is a simple, graphic representation of an electrical system or device. The

individual parts of the electrical system or device are represented by symbols. Because

confusion could arise if different symbols were used to represent the same individual parts,

standardized symbols were developed by ANSI and IEEE. These standardized symbols are

used to represent pieces of electrical equipment in one-line diagrams. Figure 1 contains

examples of standard symbols.

At times, a symbol may be further defined by a number. The number will usually appear

inside the symbol that it describes. The numbers refer to ANSI/IEEE standard device

numbers. For example, 87 is the standard device number for a differential protective relay.

One-line diagrams can be drawn with varying degrees of accuracy. The amount of accuracy

that is put into the one-line diagram will depend on the use or application of the one-line

diagram. For example, a one-line diagram that is used for a future electric load study would

not need to list the types and locations of the electric system’s protective relays and circuit

breakers. A one-line diagram that is prepared to study the stability of an electric system

would need to show the protective relays and circuit breakers in their positions in the electric

system. Such a one-line diagram may also need to provide some of the electric ratings of the

protective relays and circuit breakers.

Saudi Aramco DeskTop Standards 14

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Examples of One-Line Diagram Symbols

Figure 1

Saudi Aramco DeskTop Standards 15

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

In general, rules do not exist that dictate the amount of detail that must appear in a one-line

diagram; however, good engineering practice would indicate that as much detail as possible

should be provided. The person who draws the one-line diagram must know the purpose of

the one-line diagram and then provide sufficient information for the drawing to accomplish

that purpose. While not required, additional information may provide a future reader with

details that, otherwise, may require more research.

Figure 2 (an excerpt from SAES-P-114) is an example of a one-line diagram. A generator bus

is on the left side of the diagram and a high voltage (HV) bus is on the right side of the

diagram. Figure 2 is a graphic representation of the two buses, the transformer that is

between the two buses, and the protective equipment for the transformer.

Example of a One-Line Diagram

Figure 2

Saudi Aramco DeskTop Standards 16

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

The generator bus is represented by the vertical line that is labeled “GENERATOR BUS.”

The high voltage bus is represented by a vertical line that is labeled “HV BUS.” The power

circuit breakers that protect the transformer windings are represented by the squares. The

windings of the power transformer are represented by the connected half-circles that are

drawn so that the bottom of one half-circle is connected to the top of the next half-circle. The

triangle and the “Y” at the top of the transformer windings indicate how the transformer’s

windings are connected. The triangle indicates that the transformer’s windings on that side of

the transformer are connected in a delta configuration. The “Y” indicates that the

transformer’s windings on that side of the transformer are connected in a wye configuration.

The symbol that looks like a transformer winding with a line drawn through is a

representation of a current transformer. The current transformers are the devices that provide

the signal for the relays to operate. The relays are represented by the circles with an

alphanumeric inside of the circle. The alphanumeric characters represent a particular type of

relay. The types of relays that these symbols represent are listed on the drawing from which

Figure 2 was excerpted.

As was stated earlier, a one-line diagram allows for the graphic representation of an electrical

system or device. The electrical system that is represented in Figure 2 is the electrical

connection between a generating station and a high-voltage transmission line. The electrical

connection is made by using a power transformer that is delta-connected on the generator side

and wye-connected on the load or HV bus side. The transformer is protected on both sides by

circuit breakers, and the circuit breakers are actuated by relays. The relays, which are

identified by number, are actuated by current transformers that are located on both sides of the

power transformer. The one-line diagram merely shows the physical connections between the

components that make up an electrical system; it does not indicate the direction of current

flow or the amount of current flow.

Elementary Diagrams

An elementary diagram is a diagram that allows its reader to see the electrical connections and

functions of a specific circuit arrangement. Elementary diagrams and schematic diagrams

provide the same type of information, and the names are interchangeably used. Like the one-

line diagram, the elementary diagram also uses graphic symbols to designate specific parts of

the circuit arrangement. The symbols that are used in elementary diagrams are similar to the

symbols that are used in the preparation of one-line diagrams.

Saudi Aramco DeskTop Standards 17

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

While the elementary diagram allows its reader to trace the connections and functions of a

specific circuit arrangement, it does not provide any information about the physical size,

shape, or location of the individual components that make up the circuit arrangement. The

information that is found on an elementary diagram tends to pertain to the positions of relay

contacts, the types of relays, the types of circuit breakers, and indicating lights that are used in

a circuit arrangement.

Figure 3 is an example of an elementary diagram. The elementary diagram that is depicted in

Figure 3 is a graphic representation of a directional switch that controls a motor. The top

portion of Figure 3 shows the power circuit of the motor, and the bottom portion of Figure 3

shows the control circuit of the motor.

The power portion of Figure 3 indicates that the motor supply lines (i.e., L1, L2, and L3) are

connected to two switches. One of the switches, the F switch, will run the motor in a forward

direction, and the other switch, the R switch, will run the motor in a reverse direction. Two of

the supply lines, L1 and L2, contain overload (OL) relays that are connected upstream of the

motor. The supply lines are connected to leads that connect to the motor’s windings (i.e., T1,

T2, and T3). The flow of current through the two switches indicates how the motor’s

direction can be reversed.

The bottom portion of the circuit indicates how the control circuit can control the direction of

the motor. When the forward switch is pressed, current will flow from L1, through the stop

switch, the reverse switch, the forward switch, the forward contactor (F), and the overload

contact to L3. This current flow causes the forward contactor to energize, which closes the

four “F” contacts. The three “F” contacts that are in the power circuit energize the motor in

the forward direction. The “F” contact that is in the control circuit provides a means to keep

the forward contactor energized after the forward switch is released. If the stop switch, the

reverse switch, or the overload contact opens while the motor is running in the forward

direction, the “F” contacts will open and the motor will stop. The reverse switch functions in

the same manner as the forward switch. The only difference is that the reverse switch causes

the reverse (R) contacts to operate.

Saudi Aramco DeskTop Standards 18

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Example of an Elementary Diagram

Figure 3

Saudi Aramco DeskTop Standards 19

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Panel Diagrams

A panel diagram for a circuit breaker installation is a diagram that shows the location and

termination of each wire that is connected to a circuit breaker. The panel diagram is limited to

those connections that are inside the panel that contains the circuit breaker. Because of this

limitation in scope, the panel diagram is sometimes referred to as an internal wiring diagram.

The panel diagram should include the connections that are made to the circuit breaker, the

relays that are associated with the operation of the circuit breaker, and all terminal blocks that

may be required for the proper operation of the circuit breaker. As was the case for an

elementary diagram, many of the standard symbols that are used in the preparation of one-line

diagrams are used in the preparation of panel diagrams.

During the preparation of a panel diagram, an attempt should be made to draw the devices on

the diagram in the same relative positions as they appear inside of the panel. For example, if

the panel contains a relay that is above a terminal block that is above another relay, then the

panel diagram should be drawn so that a relay appears over a terminal block that appears over

another relay. This method of orientation helps to alleviate confusion when the drawing is

used in the field. The labels that are used to identify devices in a panel drawing should also

be the same as the labels that appear on the devices in the field.

The wires that are used to make connections between the devices should be drawn so that a

label appears on each termination of the wire; each label should describe where the other end

of the wire is terminated. Figure 4 describes these concepts in pictorial form.

In Figure 4, an 8-pin relay is labeled “A”; a 16-terminal block is labeled “TB1”; and a circuit

breaker is labeled “CB-1”. The label “CT-1” that appears next to the wires that are connected

to TB1-13 and TB1-15 refers to a current transformer that is located outside of the panel.

Relay pins A1, A8, A7, A6, A2, and A3 are connected to terminal block terminals TB1-8,

TB1-16, TB1-1, TB1-9, TB1-13, and TB1-15, respectively. The CB-1A and CB-1B terminals

that are on CB-1 refer to the solenoid that actuates the operation of the circuit breaker. The

diagram indicates that the wires that run from the CB-1A and CB-1B terminals of the circuit

breaker are connected to relay pins A4 and A5, respectively. An examination of the diagram

from the circuit breaker to the relay indicates that the wires are connected as indicated by the

labels.

Although Figure 4 shows a relatively simple example, it does emphasize the need to properly

label a panel diagram. The connections that are shown in the diagram are easy to follow;

however, in the field, the connections are not as easy to trace. Because panel diagrams are

mainly used as troubleshooting documents, correct panel diagram labels are very important.

Saudi Aramco DeskTop Standards 20

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Example of a Panel Diagram

Figure 4

Saudi Aramco DeskTop Standards 21

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Interconnection Diagrams

Interconnection diagrams show the complete connections between pieces of equipment,

equipment assemblies, and the associated pieces of apparatus that are required to operate the

equipment. The scope of the diagram is limited to the connections between electrical panels

and omits the electrical connections that are made inside each panel. Because of this

limitation in scope, interconnection diagrams are sometimes referred to as external wiring

diagrams.

An interconnection diagram should use the same labeling scheme as the other types of

diagrams with which the interconnection diagram is associated. For example, a terminal

block that is labeled TB1 in a panel diagram should be labeled TB1 in an interconnection

diagram. To provide further clarification, the individual terminals of each terminal block

should be provided with designations. Figure 5 is an example of an interconnection diagram

that could apply to the panel diagram that was presented in Figure 4.

Figure 5 contains the electrical components of the panel diagram that was depicted in Figure

4. The circuit breaker panel that was depicted in Figure 4 is labeled as CB-1 panel. From the

CB-1 panel, the connections that are made to the current transformer (CT-1) are drawn.

Because they do not run out of the panel, all of the other connections that were drawn on the

terminal block in Figure 4 are left off of the interconnection diagram in Figure 5.

The electrical system that is described by Figure 5 also has two other circuit breakers that are

used to provide protection for the system. The panels for these two circuit breakers are

labeled as CB-2 panel and CB-3 panel. According to the diagram, these two circuit breakers

have connections to current transformers. The circuit breakers also have connections to an

emergency power supply to ensure the proper operation of the circuit breakers. The

interconnection diagram gives only enough information to indicate that the connections to the

current transformers and the emergency power supply are made. If more specific information

that pertains to how the connections are made is required, then the panel diagrams that pertain

to the CB-2 panel and CB-3 panel must be examined.

Saudi Aramco DeskTop Standards 22

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Example of an Interconnection Diagram

Figure 5

Saudi Aramco DeskTop Standards 23

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Construction Diagrams

A construction diagram is a diagram that describes the physical configuration of a circuit

breaker installation. The construction diagram will provide very little, if any, information

about the electrical ratings of the components that are required to construct the circuit breaker

installation. The construction diagram will provide information that describes the installation

of the circuit breaker panel and will give dimensional information for the panel. The scope of

the dimensional information should describe the dimensions between the components that are

inside the circuit breaker panel as well as the dimensions between the panel and other

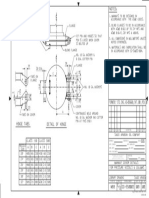

structures in the vicinity (e.g., the ground and other panels). Figure 6 is a construction

diagram that describes the physical configuration of the panel that was depicted in Figure 4.

Figure 6 shows the components that are inside of the panel box as they were described in

Figure 4. From Figure 6, the distance from the top of the relay to the top of the panel and the

distance from the top of the circuit breaker to the top of the panel is 20.32 cm (8 in). The

relay is a device that is 5.08 cm (2 in) in length on all sides. There are 10.16 cm (4 in)

between the relay and the terminal block. The terminal block measures 30.48 cm (12 in) by

3.81 cm (1.5 in), and it is located 15.24 cm (6 in) to the right of the left side of the panel box.

The circuit breaker measures 20.32 cm (8 in) by 45.72 cm (18 in), and it is located 30.48 cm

(12 in) to the right of the relay. The front opening of the panel box measures 91.44 cm (36 in)

by 60.96 cm (24 in), and the bottom of the panel box should be 121.92 (48 cm) above ground

level.

A review of Figure 6 indicates that some of the electrical features of the devices that are in the

panel box are identified on the construction diagram; however, the reason for their inclusion

in the diagram is to provide the reader with a reference of orientation when looking into the

panel box. The pin numbers that are on the relay and the line and load (A, B, and C; and L1,

L2, and L3, respectively) labels are provided to give a frame of reference as the reader relates

the information that is on the drawing to what is present in the panel box.

Saudi Aramco DeskTop Standards 24

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

Example of a Construction Diagram

Figure 6

Saudi Aramco DeskTop Standards 25

Engineering Encyclopedia Electrical

Information Sources for Evaluating Circuit Breaker Installations

GLOSSARY

basic impulse The reference insulation level, expressed as the impulse crest

value of

level (BIL) withstand voltage of a specified full impulse voltage wave, that an

electrical device must withstand without the occurrence of a

flashover.

continuous The limit of rms amperes that a circuit breaker is designed to

carry under

current rating normal operating conditions.

fault A partial or total local failure in the insulation or continuity of a

conductor. In general, a short circuit occurs at a fault.

K factor The ratio of rated maximum voltage of a circuit breaker to the

lower limit of the range of operating voltage in which the

required symmetrical and asymmetrical current interrupting

capabilities vary in inverse proportion to the operating voltage.

maximum design The maximum rms voltage at which a circuit breaker was

designed to

voltage rating operate.

pole The portion of a device that is exclusively associated with one

electrically separated conducting path of the main circuit of the

device.

root mean square A commonly used term that is calculated by taking the square

root of the

(rms) average of the squared value of a periodic function over one

period of the function. RMS values commonly describe values

of current and voltage in a power system.

short circuit The maximum rms symmetrical current that a circuit breaker can

interrupt at

current its maximum rated voltage.

rating

voltage rating The nominal voltage class or classes in which a circuit breaker is

rated.

Saudi Aramco DeskTop Standards 26

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- General: AP-A203169A Technical Specification Rev.00Document4 pagesGeneral: AP-A203169A Technical Specification Rev.00Honesto BautistaNo ratings yet

- SAPSA140Document1 pageSAPSA140Honesto BautistaNo ratings yet

- EEX30108 Cpmpleting and Turning Over WorkDocument55 pagesEEX30108 Cpmpleting and Turning Over WorkHonesto BautistaNo ratings yet

- SAPSA102Document2 pagesSAPSA102Honesto BautistaNo ratings yet

- 95000201Document1 page95000201Honesto BautistaNo ratings yet

- Company OIL Saudi Arabian: Water Outlet See Detail-BDocument1 pageCompany OIL Saudi Arabian: Water Outlet See Detail-BHonesto BautistaNo ratings yet

- SAPSA131Document1 pageSAPSA131Honesto BautistaNo ratings yet

- Notes: C: CLASS 150 A B C A B C CLASS 300Document1 pageNotes: C: CLASS 150 A B C A B C CLASS 300Honesto BautistaNo ratings yet

- SAPSA101Document1 pageSAPSA101Honesto BautistaNo ratings yet

- Notes:: DB-950076 001 00 S M88Document1 pageNotes:: DB-950076 001 00 S M88Honesto BautistaNo ratings yet

- EEX10403 Selecting SwitchgearDocument52 pagesEEX10403 Selecting SwitchgearHonesto BautistaNo ratings yet

- Cole-Parmer Technical LibraryDocument3 pagesCole-Parmer Technical LibraryHonesto BautistaNo ratings yet

- EEX30106 Commissioning UPSDocument50 pagesEEX30106 Commissioning UPSHonesto BautistaNo ratings yet

- EEX10401 Industrial Facility SubstationDocument64 pagesEEX10401 Industrial Facility SubstationHonesto Bautista100% (1)

- EEX30201 Electrical System CommissioningDocument24 pagesEEX30201 Electrical System CommissioningHonesto BautistaNo ratings yet

- AESB005Document10 pagesAESB005Honesto BautistaNo ratings yet

- Best Practice: Spread Footings DesignDocument44 pagesBest Practice: Spread Footings DesignHonesto BautistaNo ratings yet

- EEX10406 Substation Control PowerDocument30 pagesEEX10406 Substation Control PowerHonesto BautistaNo ratings yet

- Engineering Calculation Report GuidelinesDocument2 pagesEngineering Calculation Report GuidelinesHonesto BautistaNo ratings yet

- Print Article - Equivalent LengthsDocument2 pagesPrint Article - Equivalent LengthsHonesto BautistaNo ratings yet

- How To Read A Pump CurveDocument3 pagesHow To Read A Pump CurveHonesto BautistaNo ratings yet

- Pump Manual 2100 Specifying and Purchasing ProcedureDocument7 pagesPump Manual 2100 Specifying and Purchasing ProcedureHonesto BautistaNo ratings yet

- Appendix H. Factory Test Procedure: H1.0 Scope and PurposeDocument14 pagesAppendix H. Factory Test Procedure: H1.0 Scope and PurposeHonesto BautistaNo ratings yet

- 700 Miscellaneous Pumps: Pumps Manual (Chevron USA, Denver)Document18 pages700 Miscellaneous Pumps: Pumps Manual (Chevron USA, Denver)Honesto BautistaNo ratings yet

- PMP 900Document6 pagesPMP 900Honesto BautistaNo ratings yet

- 1100 Startup and Troubleshooting: Chevron Corporation 1100-1 January 1991Document30 pages1100 Startup and Troubleshooting: Chevron Corporation 1100-1 January 1991Honesto BautistaNo ratings yet