Professional Documents

Culture Documents

ME/ME-C Engines (Diesel and HFO) Guiding Overhaul Intervals and Expected Service Life

Uploaded by

Vlad PalomoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ME/ME-C Engines (Diesel and HFO) Guiding Overhaul Intervals and Expected Service Life

Uploaded by

Vlad PalomoCopyright:

Available Formats

ME/ME-C engines (diesel and HFO)

Guiding overhaul intervals and expected service life

Component Overhaul interval (hours) Expected service life (hours) Remarks

Cylinder liner Bore sizes Bore sizes Port inspection monthly.

Wear rate according to fuel type and

70-50 16,000 80-65 treatment, cylinder oil type/feed

70,000 rate and engine operation.

Piston rings Bore sizes 24,000 Bore sizes 24,000 Renew at each piston overhaul.

98-80 70- 16,000 98-80 70- 16,000 Wear rate according to fuel type and

50 12,000 50 12,000 treatment, cylinder oil type/feed

45-40 45-40 rate and engine operation.

Cermet-coated piston rings are to

be replaced according to the

prevailing Service Letter covering

cermet coating overhaul criteria

(new SL will be released in 2019).

Piston crown Bore sizes Bore sizes Pressure test at every 2nd piston

98-80 70- 24,000 98-90 80,000 overhaul and recondition/rechrome

50 16,000 80-65 60-50 70,000 as required (typically every 1-2

45-40 12,000 45-40 60,000 piston overhall). Piston crown can be

50,000 reconditioned by welding-up twice.

Stuffing box Bore sizes 24,000 Bore sizes Overhaul follows the overhaul of

98-80 70- 16,000 98-90 48,000 piston rings, but can be extended

50 12,000 80-65 45-40 32,000 based on observations.

45-40 Renew lamellas and sealing 24,000

Check gab of lamellas and ri ngs.

sealing rings.

Exhaust valve spindle Bore sizes Bore sizes 96,000 1)

Initial inspection

and bottom piece 98-60 95-60 64,000 Condition check of air spring

Initial inspections1) 6,000 & 12,000 50-35 according to the instruction manual.

Subsequent inspections2) 24,000 Inspection of seats. Maximum burn-

off rate of spindle disc underside to

Bore sizes be calculated for lifetime of spindle.

50-35 Time for subsequent inspection for

Initial inspections1) 4,000 & 8,000 overhaul and recondition to be

Subsequent inspections2) 16,000 planned. Minimum two valves to be

inspected.

2)

Subsequent inspections

Complete overhaul of exhaust

valve. To obtain the spindle

lifetime given, all spindle types can

be reconditioned by welding-up 3

times. For bottom piece seats: only

light grinding is usually required at

subsequent inspections.

You might also like

- Service Lifetime Expectations ME - Revjuly2008Document9 pagesService Lifetime Expectations ME - Revjuly2008Valeriy DomashenkoNo ratings yet

- RT-123 A1 Issue2 PDFDocument4 pagesRT-123 A1 Issue2 PDFMin MyatNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Overhaul Recommendadtion 28 - 32Document2 pagesOverhaul Recommendadtion 28 - 32Felipe RibasNo ratings yet

- Service Information M20Document72 pagesService Information M20Alexander100% (1)

- Guiding Overhaul Intervals: Service Letter SL09-509/SBJDocument7 pagesGuiding Overhaul Intervals: Service Letter SL09-509/SBJajeshkrishnanNo ratings yet

- Service Details Man BW PDFDocument7 pagesService Details Man BW PDFTapas ChaudhuriNo ratings yet

- SL2019 681 PDFDocument17 pagesSL2019 681 PDFRoman KulikovNo ratings yet

- MAK Main Generator 8M25 Service InformationDocument35 pagesMAK Main Generator 8M25 Service InformationСергий Цеценов100% (1)

- sl2023 744Document27 pagessl2023 744iodinecoil02No ratings yet

- RT-123 - A3 Appendix 3 (Issue 3) (Flex 82) Nov 2016Document7 pagesRT-123 - A3 Appendix 3 (Issue 3) (Flex 82) Nov 2016ajeshkrishnanNo ratings yet

- Mission 85 DTH Hammer: Operation and Maintenance GuidelinesDocument8 pagesMission 85 DTH Hammer: Operation and Maintenance GuidelinesVEERAMANINo ratings yet

- GUIDING OVERHAUL INTERVALS sl2017-643 PDFDocument13 pagesGUIDING OVERHAUL INTERVALS sl2017-643 PDFKyriakos LamprinakisNo ratings yet

- SL2017-643SRJ-Guiding Overhaul Intervals 2017Document13 pagesSL2017-643SRJ-Guiding Overhaul Intervals 2017pavlo_790317697No ratings yet

- MAN Service Letter 2017 Overhaul Hours PDFDocument13 pagesMAN Service Letter 2017 Overhaul Hours PDFFernando César CarboneNo ratings yet

- sl2017 643 PDFDocument13 pagessl2017 643 PDFbeu catalinNo ratings yet

- sl2017 643 PDFDocument13 pagessl2017 643 PDFRishav RajNo ratings yet

- SL2017-650 - Guiding Overhaul IntervalsDocument14 pagesSL2017-650 - Guiding Overhaul IntervalsajeshkrishnanNo ratings yet

- Service Letter SL2019-689/KAMO: Extended Guiding Overhaul IntervalsDocument2 pagesService Letter SL2019-689/KAMO: Extended Guiding Overhaul IntervalscocoisolisgmailcomNo ratings yet

- Reguler Inspection & MaintenanceDocument3 pagesReguler Inspection & MaintenanceMuhammad FaizNo ratings yet

- Intervalos de Mantenimiento KBB ST7Document2 pagesIntervalos de Mantenimiento KBB ST7Tibor KomaromyNo ratings yet

- SXP-D Maintenance ScheduleDocument2 pagesSXP-D Maintenance ScheduleGerardo Sanchez LopezNo ratings yet

- Law InternationalDocument7 pagesLaw InternationalnebaNo ratings yet

- Pipeline Pump TestingDocument4 pagesPipeline Pump TestingzhangjieNo ratings yet

- Oil Piping Flushing: G Nuovo PignoneDocument14 pagesOil Piping Flushing: G Nuovo Pignonecvg ertdNo ratings yet

- SB 063 Issue 2 - 4000 Series - Preventive Maintenance ScheduleDocument3 pagesSB 063 Issue 2 - 4000 Series - Preventive Maintenance Scheduleaung minhtetNo ratings yet

- Man B&W Serv LTR Sl09-509-Sb-jDocument7 pagesMan B&W Serv LTR Sl09-509-Sb-jafsal999No ratings yet

- Drrdock Repair Jobs (Excluding DD Routines) No 2Document12 pagesDrrdock Repair Jobs (Excluding DD Routines) No 2Amit Raj AnandNo ratings yet

- Guide For Scavenge InspectionDocument36 pagesGuide For Scavenge InspectionNeelakantan SankaranarayananNo ratings yet

- RT-123 - A3 - Issue4 - Inspection and OverDocument7 pagesRT-123 - A3 - Issue4 - Inspection and OverGeorgios MariolisNo ratings yet

- Kinematic ViscosityDocument4 pagesKinematic ViscosityRashaad CoxNo ratings yet

- B70 Rock Breaker Care Operation Manual For TH86Document21 pagesB70 Rock Breaker Care Operation Manual For TH86Latifa EngineeringNo ratings yet

- WinGD Guide Condition Piston Running Components 2018Document36 pagesWinGD Guide Condition Piston Running Components 2018pavlo_790317697No ratings yet

- Automotive Vehicles - Valves and Valve Accessories For Pneumatic Tyres - Specification (Document20 pagesAutomotive Vehicles - Valves and Valve Accessories For Pneumatic Tyres - Specification (deepak.mbrubbersNo ratings yet

- 3B Series Excavators: Lube and MaintenanceDocument63 pages3B Series Excavators: Lube and MaintenancesuriantoNo ratings yet

- CJ Generalrequirementsfor Vibratorsformassconcreting, ImmersiontypeDocument5 pagesCJ Generalrequirementsfor Vibratorsformassconcreting, ImmersiontypeRahul ChaudharyNo ratings yet

- Third Review Team22Document20 pagesThird Review Team22jagdish castroNo ratings yet

- FD Fan MotorDocument4 pagesFD Fan Motorkarim karimNo ratings yet

- 2gnt 420a OverhaulDocument62 pages2gnt 420a OverhaulElsa Elizabeta Dekovic100% (1)

- Ade MillsDocument47 pagesAde Millsanon_787758227100% (1)

- RTX Piston Running GuideDocument32 pagesRTX Piston Running GuideDaniel TsvetilovNo ratings yet

- Technical System Pumps Specifications of Equipment For Each WWTPDocument13 pagesTechnical System Pumps Specifications of Equipment For Each WWTPBimal DeyNo ratings yet

- Registro Italiano Navale Rules For Classification of Ship, January 2016Document6 pagesRegistro Italiano Navale Rules For Classification of Ship, January 2016David MestanzaNo ratings yet

- Deutz 912 Construction Engine Spec SheetDocument6 pagesDeutz 912 Construction Engine Spec SheetAbdelrahmanNo ratings yet

- Kohler K295-1 Service DataDocument4 pagesKohler K295-1 Service Datanative112472No ratings yet

- Quoting and Proposals: Carrier Compressor Inspection OfferDocument12 pagesQuoting and Proposals: Carrier Compressor Inspection OfferIwan HusaeniNo ratings yet

- Santa Fe 3.5 2010 2012 Jan 2014Document1 pageSanta Fe 3.5 2010 2012 Jan 2014Mohammed AldaffaieNo ratings yet

- Pa-18 Pa-18a Inspection Reportv1999Document4 pagesPa-18 Pa-18a Inspection Reportv1999Jessey StonerNo ratings yet

- PM 4000 SeriesDocument3 pagesPM 4000 SeriesmohamedNo ratings yet

- The Influence of Port Fuel Injection On Combustion StabilityDocument11 pagesThe Influence of Port Fuel Injection On Combustion Stabilitystefan.vince536No ratings yet

- SBMX 75 BMX 200 400 - 600: Stainless Steel P.D. MetersDocument6 pagesSBMX 75 BMX 200 400 - 600: Stainless Steel P.D. MetersCao Văn PhongNo ratings yet

- Main Data, Operating Data & General DesignDocument2 pagesMain Data, Operating Data & General DesignAwliya TaqwaNo ratings yet

- Inspection Interval For Engine AuxiliariesDocument3 pagesInspection Interval For Engine Auxiliariesadeel ghouseNo ratings yet

- WinGD Guide For Judging Condition of Relevant Piston Running Components V4 June 2020 PDFDocument36 pagesWinGD Guide For Judging Condition of Relevant Piston Running Components V4 June 2020 PDFStancu PetricăNo ratings yet

- WWE Filter Press OperationDocument20 pagesWWE Filter Press OperationMf LuiNo ratings yet

- Perkins-A4 318Document29 pagesPerkins-A4 318Mahdi JafaryNo ratings yet

- .E.mfix - , R - SuffixDocument2 pages.E.mfix - , R - Suffixoscar bastidasNo ratings yet

- Basketball TournamentDocument10 pagesBasketball TournamentVlad PalomoNo ratings yet

- Working ClothesDocument2 pagesWorking ClothesVlad PalomoNo ratings yet

- Officer MatrixDocument1 pageOfficer MatrixVlad PalomoNo ratings yet

- CREW 025 - Safety Security Tour FamiliarizationDocument7 pagesCREW 025 - Safety Security Tour FamiliarizationVlad PalomoNo ratings yet

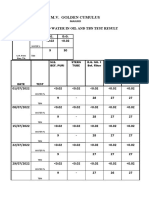

- 20 Water & TBN Lub Oil Onboard Test Report July 2022Document2 pages20 Water & TBN Lub Oil Onboard Test Report July 2022Vlad PalomoNo ratings yet

- Chapter 4-Electronic Fuel Injection (EFI)Document35 pagesChapter 4-Electronic Fuel Injection (EFI)Wybar MujahidNo ratings yet

- Canter 3c13 L enDocument2 pagesCanter 3c13 L enDavid RJ BrownNo ratings yet

- 95 - Kithil 2001. Small Shelters and Safety From LightningDocument5 pages95 - Kithil 2001. Small Shelters and Safety From LightningJorge A. C.No ratings yet

- Land Rover Defender Sales Brochure PDFDocument2 pagesLand Rover Defender Sales Brochure PDFJan Svein HammerNo ratings yet

- Spare Parts List: Chain Saws 135 Mark IIDocument26 pagesSpare Parts List: Chain Saws 135 Mark IIopreacornel2002yahoo.comNo ratings yet

- Air Comm Corporation: 1575 W. 124 Ave, Suite 210 Westminster, Co. 80234 PHONE: 303-440-4075 FAX: 303-440-6355Document58 pagesAir Comm Corporation: 1575 W. 124 Ave, Suite 210 Westminster, Co. 80234 PHONE: 303-440-4075 FAX: 303-440-6355Angel Reyes100% (2)

- JTHB Shop Manual Sen06343-00Document112 pagesJTHB Shop Manual Sen06343-00Ser EscamNo ratings yet

- SB-914-039 - Extension of Time Between Overhauls (TBO) For ROTAX Engine Type 914 (Series)Document6 pagesSB-914-039 - Extension of Time Between Overhauls (TBO) For ROTAX Engine Type 914 (Series)Dennis HNo ratings yet

- Maneklal and Sons (Exports) : H S A W N M MDocument3 pagesManeklal and Sons (Exports) : H S A W N M MhattaliNo ratings yet

- PC228 - Engine - SAA6D107E 1G W S N 26500006 UPDocument89 pagesPC228 - Engine - SAA6D107E 1G W S N 26500006 UPThiago Fredy100% (1)

- HM300-2 Shop ManualDocument1,330 pagesHM300-2 Shop ManualPeetNo ratings yet

- Marketing Mix TATA NanoDocument7 pagesMarketing Mix TATA NanoSalonee ShuklaNo ratings yet

- Table Of: 4x4 CatalogueDocument180 pagesTable Of: 4x4 CatalogueTan JaiNo ratings yet

- Process Performance MetricsDocument4 pagesProcess Performance MetricsJoseph Roland Hernandez100% (1)

- CEF-T-2021-AFIF Cut-Off 4 List of Projects FINAL 0Document2 pagesCEF-T-2021-AFIF Cut-Off 4 List of Projects FINAL 0Massimiliano ZocchiNo ratings yet

- 卧式离心泵说明书英文(大连双龙)Document16 pages卧式离心泵说明书英文(大连双龙)kamal arabNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerRamon MontesNo ratings yet

- THP SL eDocument2 pagesTHP SL eRyan LeeNo ratings yet

- Yzf-R25a R25 Abs Rear WheelDocument2 pagesYzf-R25a R25 Abs Rear Wheelnico sugiarto putraNo ratings yet

- TD1469-01 Service Manual TT-Axle 60-0xDocument72 pagesTD1469-01 Service Manual TT-Axle 60-0xabdelhadi houssinNo ratings yet

- Pennzoil Platinum High Mileage SAE 5W-20 Full Synthetic Motor OilDocument2 pagesPennzoil Platinum High Mileage SAE 5W-20 Full Synthetic Motor OilСергій БоженкоNo ratings yet

- Id616265 Rev02Document2 pagesId616265 Rev02Prakash Surgond (KFIL)No ratings yet

- Condor Body Installation ManualDocument154 pagesCondor Body Installation ManualProfessional TrustNo ratings yet

- Clarck Tmx12 25 (Lot No - 9597)Document212 pagesClarck Tmx12 25 (Lot No - 9597)paulo_gallina_2No ratings yet

- Gear Condition Monitoring Technics: December 2017Document26 pagesGear Condition Monitoring Technics: December 2017Ashwin MahoneyNo ratings yet

- 1540 - Kat - EM - en - LoRes Elektromotoren PDFDocument134 pages1540 - Kat - EM - en - LoRes Elektromotoren PDFSavin CristiNo ratings yet

- IoT Applications in TransportationDocument10 pagesIoT Applications in Transportation有川静寂No ratings yet

- Park/Neutral Position Switch Assy (Atm) : ReplacementDocument3 pagesPark/Neutral Position Switch Assy (Atm) : ReplacementluisNo ratings yet

- 6068HF158Document2 pages6068HF158Nabil Ibrahim100% (1)

- PD300-01 SpecSheetDocument4 pagesPD300-01 SpecSheetJeremy DruffelNo ratings yet