Professional Documents

Culture Documents

220902flyer DyeMaster EN V2 9 A3

220902flyer DyeMaster EN V2 9 A3

Uploaded by

JimenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

220902flyer DyeMaster EN V2 9 A3

220902flyer DyeMaster EN V2 9 A3

Uploaded by

JimenaCopyright:

Available Formats

Benninger DyeMaster Facts

Water Supply System (WSS)

Soft water cold (in)

Cooling water

Drain water hot

Process Waste

water water

hot hot

Waste water cold (out) Cooling water warm

FACTS

• No dyestuff dust contamination outside of dyestuff

kitchen

• Centralized chemicals store in protected

environment

• IBC or original chemical suppliers container can be

used and therefore no manual manipulation and

dangerous handling in workshop

• “Just in Time” supply, not waiting time at machine

and therefore high reproducibility on dyeing process The Water Supply System WWS provides the

• Human error elimination dyehouse permanently with hot water at constant

• Permanent hot water availability – shorter heating temperature and pressure. Incorporated heat recovery

up time cools down the process water by counterflow principle

• No preheating tank at Jet dyeing machine required and heats up cold fresh water to 50 °C with a pay

(less cost, less space) back of less than 1 year. Furthermore discharging

• High degree of heat recovery and 40% saving of water is cooled down to fullfill local discharge

heating energy (steam) regulations and/or the requirement of the biological

• No hot discharge to effluent treatment plant effluent treatment plants.

• HOST System manages complete dyehouse

equipment including the sub systems.

DyeMaster

Central dyehouse supply systems

20% less processing time on dyeing machines

No waiting time for the machine

Higher reproducibility

Pay back less than 1 year

Headquarter

Swiss Engineering and Technology

Benninger AG Benninger Reiden Benninger Zittau Benninger IndiaPrivate Ltd.

Küsters Textile GmbH

9240 Uzwil, Schweiz 6260 Reiden, Schweiz 02763 Zittau, Deutschland Mumbai 400 014, Indien

T +41 71 955 85 85 T +41 62 745 16 00 T +49 3583 83 0 T +91 22 2417 5361

info @benningergroup.com info@lab-pro.ch kuesters@benningergroup.com benindia@benningergroup.com

www.benningergroup.com

Issue V2.9 / May 2020

Benninger DyeMaster Datasheet Benninger DyeMaster Design

Chemical Dispensing (CDS) Chemical Dispensing System (CDS)

Dyestuff Dissolving & Dosing (DDS) 2- 15 machines

Powder Dissolving, Storing and Dosing (PDSD) up to 24 chemicals

2 min

Water Supply System (WSS)

Air

Applications • Liquid chemical dispensing for dyeing machines and stenter frames H2O

• Dyestuff dissolving

• Soda & Soda dissolving , storage and distribution

• Waste water heat recovery systems

Chemical preconditions 0.7-1.5 g/cm3 / 0 -12000 mPas Dyestuff Dissolving and Dosing (DDS)

MOM AISI 316 L (Liquor contact parts)

PVC or EPDM hose pipe Mixing on 4 2- 10 machines

H2O

Controllers Sedo Treepoint, Setex levels circulation

H2O

Host systems Sedomaster/ Sedo Treepoint, Orgatex /Setex

250 l/ 50 kg dyestuff E

10 – 20 min

Powder Dissolving (PDSD)

2 min

E

E

E

Mixing circulation

Hopper

E

Salt E

H2O

-1

00

Solution

0k

g

E

Powder weighing and dissolving 2 min

tank with precision scale Soda (identical to salt)

You might also like

- Water Treatment PlantsDocument40 pagesWater Treatment PlantsMAZIGHINo ratings yet

- Crude Oil Treatment ProcessDocument73 pagesCrude Oil Treatment ProcessFidal SibiaNo ratings yet

- Heat and ThermodynamicDocument220 pagesHeat and ThermodynamicBo ZhaoNo ratings yet

- Multi Organics-MEEP-180118-31.12.2018 PDFDocument28 pagesMulti Organics-MEEP-180118-31.12.2018 PDFArjun KrishnakumarNo ratings yet

- Techno Commercial Proposal For 50KLD STP For Bhakti EnterprisesDocument21 pagesTechno Commercial Proposal For 50KLD STP For Bhakti Enterprisesamol100% (1)

- XCMG Company Profile - Factory Trip - 30.05.2023Document68 pagesXCMG Company Profile - Factory Trip - 30.05.2023abangNo ratings yet

- WTP Brochure 020817Document12 pagesWTP Brochure 020817Ravindra VemuriNo ratings yet

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Document24 pagesSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- Midrex Process Water DegasserDocument2 pagesMidrex Process Water DegasserMorteza RafieiNo ratings yet

- Golf Course Irrigation: Environmental Design and Management PracticesFrom EverandGolf Course Irrigation: Environmental Design and Management PracticesNo ratings yet

- Presentation - MBBR-Fair Electronics (Samsung) by ShakibDocument32 pagesPresentation - MBBR-Fair Electronics (Samsung) by Shakibshakib nazmus0% (1)

- Water Reduction and Reuse in The Petroleum IndustryNovemberDocument57 pagesWater Reduction and Reuse in The Petroleum IndustryNovemberwaheed2286No ratings yet

- Water Treatment Plant Filtration Plant in RWSS of GWSSB PDFDocument21 pagesWater Treatment Plant Filtration Plant in RWSS of GWSSB PDFDiya VaghelaNo ratings yet

- Thermax WWS BrochureDocument6 pagesThermax WWS BrochureAquasoul CoNo ratings yet

- Flyer Dyemaster en v2.9Document4 pagesFlyer Dyemaster en v2.9Hossein IzadanNo ratings yet

- CD Wet: Water Enhancement TechnologyDocument4 pagesCD Wet: Water Enhancement TechnologyNikhilNo ratings yet

- Company Profile Indo Prawita Sekawan 2015Document11 pagesCompany Profile Indo Prawita Sekawan 2015AndriZiNo ratings yet

- World Water Works: Resource DafDocument6 pagesWorld Water Works: Resource DafWilmer Martelo SarabiaNo ratings yet

- Production Chemistry in Flow AssuranceDocument63 pagesProduction Chemistry in Flow AssuranceSyafiqah Rosmarina AhmadNo ratings yet

- Protech BroucherDocument7 pagesProtech BroucherFaheem MalikNo ratings yet

- Water Solutions For Downstream Oil & GasDocument8 pagesWater Solutions For Downstream Oil & Gastkortiz24No ratings yet

- Pulsar System - Biodiesel Plants - CT SystemsDocument12 pagesPulsar System - Biodiesel Plants - CT SystemsSagar DhuriNo ratings yet

- 9 Soybean Processing Sustainability - by Mr. D.V. ChameDocument18 pages9 Soybean Processing Sustainability - by Mr. D.V. ChameshyamalNo ratings yet

- Industrial Membrane TechnologyDocument8 pagesIndustrial Membrane TechnologyNikhilNo ratings yet

- 270 CRP Basic Info EN 140312Document2 pages270 CRP Basic Info EN 140312Usman KhanNo ratings yet

- Comparison of Common H2S Removal Technologies For Biogas and Landfill GasDocument1 pageComparison of Common H2S Removal Technologies For Biogas and Landfill GasJess GohNo ratings yet

- Efficient Water Utilisation in Textile Wet Processing PDFDocument4 pagesEfficient Water Utilisation in Textile Wet Processing PDFPaul MocanuNo ratings yet

- MVR MSFDocument2 pagesMVR MSFBaba DookNo ratings yet

- DS21Document3 pagesDS21vsdfsd258No ratings yet

- Welcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyDocument17 pagesWelcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyrpshvjuNo ratings yet

- IVBR Hospitality Sector BrochureDocument8 pagesIVBR Hospitality Sector Brochuresagar kulkarniNo ratings yet

- Kandhari Beverages Pvt. LTD.: (Coca Cola)Document27 pagesKandhari Beverages Pvt. LTD.: (Coca Cola)Veeraprasad CGNo ratings yet

- Biodiesel Plants - CT SystemsDocument12 pagesBiodiesel Plants - CT SystemsSagar DhuriNo ratings yet

- MR Jayaraman Rajavel, Thermax PDFDocument21 pagesMR Jayaraman Rajavel, Thermax PDFselva pNo ratings yet

- Saudi Aramco Project Development: Wastewater Treatment Facilities Jeddah Refinery and Marine AreaDocument34 pagesSaudi Aramco Project Development: Wastewater Treatment Facilities Jeddah Refinery and Marine AreaSrewaBenshebilNo ratings yet

- Disaster Management Unit For Drinking Water: TreatmentDocument2 pagesDisaster Management Unit For Drinking Water: Treatmentmaksudur4No ratings yet

- Desmet Ballestra - Waste Water Steam GenerationDocument2 pagesDesmet Ballestra - Waste Water Steam Generationhamid vahedil larijaniNo ratings yet

- Designing Domestic Hot Water Recirculation Systems - Part 1 - MMMDocument1 pageDesigning Domestic Hot Water Recirculation Systems - Part 1 - MMMXixxixaNo ratings yet

- Decanter Centrifuge - WikipediaDocument7 pagesDecanter Centrifuge - WikipediaYounas SardarNo ratings yet

- Caustic Recovery in Textile IndustryDocument6 pagesCaustic Recovery in Textile Industrytextilerd9939100% (1)

- Low Temperature Distillation (Ltdis) : Make The Right Choice..Document4 pagesLow Temperature Distillation (Ltdis) : Make The Right Choice..LexNo ratings yet

- C18-Andrew LiewDocument24 pagesC18-Andrew LiewCheong Wen YuanNo ratings yet

- CLBGEN14004 - CB-8489 - Boiler Feed Cond Recovery Brochure - November2015 PDFDocument12 pagesCLBGEN14004 - CB-8489 - Boiler Feed Cond Recovery Brochure - November2015 PDFjose arangoitiaNo ratings yet

- EDL Sulzer DeOiling en DruckDocument2 pagesEDL Sulzer DeOiling en DruckOsamah AdelNo ratings yet

- New Updated Profile Bimal WaterDocument25 pagesNew Updated Profile Bimal WaterJaved HasanNo ratings yet

- DOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsDocument2 pagesDOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsMauricio Fernandez GuevaraNo ratings yet

- Se-dcf-En-05 11 Crossflow Filter PrayefsDocument4 pagesSe-dcf-En-05 11 Crossflow Filter Prayefslimim56582No ratings yet

- Leading Beverage Producer Selects Zeeweed 500D MBR For Wastewater TreatmentDocument1 pageLeading Beverage Producer Selects Zeeweed 500D MBR For Wastewater TreatmentAbinash PatroNo ratings yet

- Water SoftenersDocument3 pagesWater SoftenersyashjbtechNo ratings yet

- DewatsDocument36 pagesDewatsCHAMPAK_8No ratings yet

- 01 - Watertreatment BasicsDocument37 pages01 - Watertreatment BasicsAbdul ManafNo ratings yet

- Brochure - Producedwater - Sorbwater - FOR WEBDocument12 pagesBrochure - Producedwater - Sorbwater - FOR WEBjuan vazquezNo ratings yet

- AA Series RO SystemsDocument2 pagesAA Series RO SystemsFranco LimaNo ratings yet

- Modular Pure Water SolutionsDocument4 pagesModular Pure Water SolutionsPetrica DascaluNo ratings yet

- ORIONDocument4 pagesORIONAlon CarlosNo ratings yet

- Mechanically Cleaned Filters Shown at Pollutec: Biogas Dehumidification System Aims To Protect From CorrosionDocument1 pageMechanically Cleaned Filters Shown at Pollutec: Biogas Dehumidification System Aims To Protect From CorrosionPhạm Thế VinhNo ratings yet

- Products - Aswathi Industries Limited PDFDocument2 pagesProducts - Aswathi Industries Limited PDFAswathi IndustriesNo ratings yet

- Short Path Film Evaporation Distillation SpduDocument25 pagesShort Path Film Evaporation Distillation SpduisepcontrolNo ratings yet

- BRK Electronic Descaling SystemDocument5 pagesBRK Electronic Descaling SystemSuresh DNo ratings yet

- Fluent Comprehensive BrochureDocument6 pagesFluent Comprehensive Brochurepallavan.kNo ratings yet

- Discrete Wavelet Transformations: An Elementary Approach with ApplicationsFrom EverandDiscrete Wavelet Transformations: An Elementary Approach with ApplicationsNo ratings yet

- Q700 / Q500 Accessories Indirect Horn OptionsDocument3 pagesQ700 / Q500 Accessories Indirect Horn OptionsLinh LeeNo ratings yet

- A New & Improved Charge Controller Based On The 555 ChipDocument11 pagesA New & Improved Charge Controller Based On The 555 Chipvikas_mahadik2363No ratings yet

- Transmisión ZF 2060 - EspecificacionesDocument4 pagesTransmisión ZF 2060 - EspecificacionesJorge Arrieta TorresNo ratings yet

- Introduction To Hybrid Drive TrainsDocument16 pagesIntroduction To Hybrid Drive TrainsAkhilesh RavichandranNo ratings yet

- Influence of The Camber Trailing Edge Win 2022 International Journal of NavaDocument12 pagesInfluence of The Camber Trailing Edge Win 2022 International Journal of NavaNguyen Phuc LinhNo ratings yet

- Vent Screen HalliburtonDocument2 pagesVent Screen HalliburtonAlejandro ChavarriaNo ratings yet

- CONTENTS Hyundai Excavator - R35Z 7 - Operation 246pagesDocument19 pagesCONTENTS Hyundai Excavator - R35Z 7 - Operation 246pagesKen LeeNo ratings yet

- The Three Mile Island Disaster: By:-Jash (J058) Priyam (J059) Rishit (J063)Document12 pagesThe Three Mile Island Disaster: By:-Jash (J058) Priyam (J059) Rishit (J063)wander boyNo ratings yet

- Propex Compact 1600 Instructions 2Document4 pagesPropex Compact 1600 Instructions 2Paul ChurchNo ratings yet

- MCC - Remaining Works To CompleteDocument1 pageMCC - Remaining Works To CompleteRhannie GarciaNo ratings yet

- Dah HCM78X9-435-460WDocument2 pagesDah HCM78X9-435-460WMarcio AbreuNo ratings yet

- Thesis For Solar Air Heater PDFDocument6 pagesThesis For Solar Air Heater PDFtarajensenfargo100% (1)

- Manual de Instalacao LG Cassete ATW24GPLP0Document33 pagesManual de Instalacao LG Cassete ATW24GPLP0Luciano CarvalhoNo ratings yet

- PC VRF Systems 2Document50 pagesPC VRF Systems 2pallavNo ratings yet

- Shop Lighting: Led LampsDocument1 pageShop Lighting: Led LampsGabriel Paolo CañeteNo ratings yet

- 4-1 & 4-2 Outlines - DIGITALDocument3 pages4-1 & 4-2 Outlines - DIGITALVictor GuaramatoNo ratings yet

- Engineering Mechanics - Ce198-1/A06: QuestionsDocument37 pagesEngineering Mechanics - Ce198-1/A06: QuestionsLisa Valois PedrigalNo ratings yet

- Voyager 1996-1999 Manual-Ignition-SystemDocument70 pagesVoyager 1996-1999 Manual-Ignition-SystemАндрей ФроловNo ratings yet

- Iom Yutaki s80 enDocument39 pagesIom Yutaki s80 enAnton DlabacNo ratings yet

- 12TH Physcics Chapter 4 ThermodynamicsDocument123 pages12TH Physcics Chapter 4 ThermodynamicsAbdurahman Pathan100% (1)

- Direction: MULTIPLE CHOICE: Write Using Big Letter of The Correct Answer Beside Each NumberDocument3 pagesDirection: MULTIPLE CHOICE: Write Using Big Letter of The Correct Answer Beside Each NumberRosita CayananNo ratings yet

- Welding Procedure Specification: JOINTS (QW-402)Document3 pagesWelding Procedure Specification: JOINTS (QW-402)Nitin KurupNo ratings yet

- Chapter No.2 Ac CircuitsDocument7 pagesChapter No.2 Ac CircuitsPavankumar GosaviNo ratings yet

- Courses MSC in Climate Change and Development MSCCD 2015 (2071)Document13 pagesCourses MSC in Climate Change and Development MSCCD 2015 (2071)Pujan Amit GurungNo ratings yet

- C Certificate of Non-AvailmentDocument1 pageC Certificate of Non-AvailmentRon Cedric GarciaNo ratings yet

- Flame StabilityDocument11 pagesFlame StabilityMir Reza Negahban100% (1)

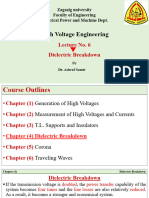

- Lecture 6Document30 pagesLecture 6Ahmed FarahatNo ratings yet

- Optimization-Based Energy Management For Multi-EneDocument211 pagesOptimization-Based Energy Management For Multi-EneOGOLA DANIEL BNo ratings yet