Professional Documents

Culture Documents

Automatic Transaxle Drive Axle: Section 3A

Uploaded by

Jarry PotterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Transaxle Drive Axle: Section 3A

Uploaded by

Jarry PotterCopyright:

Available Formats

SECTION 3A

AUTOMATIC TRANSAXLE DRIVE AXLE

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-1 Drive Axle Assembly . . . . . . . . . . . . . . . . . . . . . . . 3A-4

Fastener Tightening Specifications . . . . . . . . . . . 3A-1 Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-8

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-2 Outer Joint Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-8

Special Tools Table . . . . . . . . . . . . . . . . . . . . . . . . 3A-2 Inner Tripot Seal . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-9

Component Locator . . . . . . . . . . . . . . . . . . . . . . . . 3A-2 General Description and System

Front Drive Axles . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-13

Maintenance and Repair . . . . . . . . . . . . . . . . . . . . 3A-4 Front Drive Axle . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-13

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-4

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb-Ft Lb-In

Axle Shaft Caulking Nut Initial Torque 180 133 -

Axle Shaft Caulking Nut Final Torque 50+60_ 37+60_ -

Lower Ball Joint Nut and Bolt 60 44 -

Tie Rod Nut 60 44 -

Wheel Bolts 90 66 -

DAEWOO J-100 BL2 / BL3

3A -- 2 AUTOMATIC TRANSAXLE DRIVE AXLE

SPECIAL TOOLS

SPECIAL TOOLS TABLE

J-8059 KM-460-A

Snap Ring Pliers Axle Shaft Remover

A104A001 A106C032

KM-507-B J-35566

Ball Joint Separator Seal Clamp Pliers

A106C034 A104A008

COMPONENT LOCATOR

FRONT DRIVE AXLES

B104A003

DAEWOO J-100 BL2 / BL3

AUTOMATIC TRANSAXLE DRIVE AXLE 3A -- 3

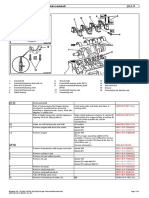

B104A008

1 Caulking Nut 8 Seal Retaining Clamp

2 C/V Joint 9 Drive Axle Inboard Seal

3 Snap Ring 10 Seal Retaining Clamp

4 Axle Shaft (right-hand shown, left-hand similar) 11 Tripot Joint Retaining Ring

5 Seal Retaining Clamp 12 Tripot Joint

6 Drive Axle Outboard Seal 13 Shaft Retaining Ring

7 Seal Retaining Clamp 14 Tripot Housing

DAEWOO J-100 BL2 / BL3

3A -- 4 AUTOMATIC TRANSAXLE DRIVE AXLE

MAINTENANCE AND

REPAIR

ON-VEHICLE SERVICE

DRIVE AXLE ASSEMBLY

Tools Required

KM-507-B Ball Joint Separator

KM-460-A Axle Shaft Remover

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheels. Refer to Section 2E, Tires and

Wheels.

3. Remove the engine under covers. Refer to Section

A104A045 9N, Frame and Underbody.

4. Remove the axle shaft caulking nut. Discard the nut.

5. Remove the lower ball joint nut and bolt.

B104A002

DAEWOO J-100 BL2 / BL3

AUTOMATIC TRANSAXLE DRIVE AXLE 3A -- 5

Notice: Use only the recommended tool for separating

the lower ball joint. Failure to use the recommended tool

may cause damage to the ball joint and the seal.

6. Separate the steering knuckle from the lower ball joint

using the ball joint separator KM-507-B.

B104A005

DAEWOO J-100 BL2 / BL3

3A -- 6 AUTOMATIC TRANSAXLE DRIVE AXLE

7. Remove the tie rod nut.

B104A007

Notice: Use only the recommended tool for separating

the tie rod from the knuckle/strut assembly. Failure to

use the recommended tool may cause damage to the

knuckle/strut assembly.

8. Separate the tie rod end using the ball joint separator

KM-507-B.

B104A006

9. Push the drive axle shaft from the wheel hub.

Important: Support the unfastened end of the drive

axle. Do not allow the drive axle to dangle freely from the

transaxle for any length of time after it has been re-

moved from the wheel hub.

Important: Place a drain pan below the transaxle to

catch the escaping fluid. Cap the transaxle drive open-

ing after the drive axle has been removed to keep the

fluid in and any contamination out.

10. Remove the drive axle from the transaxle using the

axle shaft remover KM-460-A.

A104A021

DAEWOO J-100 BL2 / BL3

AUTOMATIC TRANSAXLE DRIVE AXLE 3A -- 7

Installation Procedure

Notice: Do not damage the seals.

1. Clean the hub seal and the transaxle seal.

2. Install the drive axle into the transaxle.

3. Install the wheel hub onto the axle shaft.

A104A047

4. Mount the steering knuckle onto the lower ball joint.

B104A013

5. Install the tie rod into the knuckle/strut and install the

tie rod nut.

Tighten

Tighten the tie rod nut to 60 NSm (44 lb-ft).

B104A007

DAEWOO J-100 BL2 / BL3

3A -- 8 AUTOMATIC TRANSAXLE DRIVE AXLE

6. Install the lower ball joint bolt and nut.

Tighten

Tighten the lower ball joint bolt and nut to 60 NSm

(44 lb-ft).

B104A002

7. Loosely install a new axle shaft caulking nut. Always

use a new nut.

8. Install the engine under covers. Refer to Section 9N,

Frame and Underbody.

9. Install the wheels. Loosely install the bolts. Refer to

Section 2E, Tires and Wheels.

10. Lower the vehicle to the floor.

Tighten

Tighten the wheel bolts to 90 NSm (66 lb-ft).

A104A048

Tighten

Tighten the axle shaft caulking nut to 180 NSm

(133 lb-ft). Loosen the nut and re-tighten the nut to

50 NSm (37 lb-ft). Then tighten the nut further by

60 degrees.

11. Peen the caulking nut with a punch and a hammer

until the nut is locked into place on the axle shaft

hub.

12. Refill the transaxle fluid to the proper level. Refer to

Section 5A, 4T40E Automatic Transaxle.

A104A045

DAEWOO J-100 BL2 / BL3

AUTOMATIC TRANSAXLE DRIVE AXLE 3A -- 9

UNIT REPAIR

OUTER JOINT SEAL

Tools Required

J-8059 Snap Ring Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

’’Drive Axle Assembly’’ in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

A104A020

4. Degrease the joint.

5. Spread the snap ring using the snap ring pliers

J-8059 and remove the outer joint from the axle shaft.

Caution: Do not disassemble the outer joint assemĆ

bly. Parts are match fit and cannot be serviced sepaĆ

rately. Improper reassembly will adversely affect

both performance and safety.

6. Remove the seal from the joint assembly.

B104A009

Installation Procedure

Tools Required

J-35566 Seal Clamp Pliers

1. Install the seal onto the axle shaft.

2. Spread the snap ring using the snap ring pliers

J-8059 and install the outer joint onto the axle shaft.

3. Fill the joint seal with 175 to 195 g (6.2 to 6.9 ounces)

of the recommended grease. Repack the joint with

175 to 195 g (6.2 to 6.9 ounces) of the recommended

grease.

B104A009

DAEWOO J-100 BL2 / BL3

3A -- 10 AUTOMATIC TRANSAXLE DRIVE AXLE

4. Install a new large seal retaining clamp and a new

small seal retaining clamp.

A104A020

5. Crimp the new small seal retaining clamp and the

new large seal retaining clamp using the seal clamp

pliers J-35566.

6. Install the drive axle shaft to the vehicle. Refer to

‘‘Drive Axle Assembly’’ in this section.

A104A016

INNER TRIPOT SEAL

Tools Required

J-8059 Snap Ring Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

’’Drive Axle Assembly’’ in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

A104A022

DAEWOO J-100 BL2 / BL3

AUTOMATIC TRANSAXLE DRIVE AXLE 3A -- 11

4. Pry the tripot joint retaining ring from the tripot

housing.

B104A012

5. Remove the tripot housing from the seal.

A104A028

6. Degrease the tripot assembly.

7. Remove the shaft retaining ring using the snap ring

pliers J-8059.

A104A026

DAEWOO J-100 BL2 / BL3

3A -- 12 AUTOMATIC TRANSAXLE DRIVE AXLE

8. Remove the tripot and the tripot joint retaining ring

from the axle shaft.

9. Remove the tripot joint seal from the axle shaft.

B104A011

Installation Procedure

Tools Required

J-35566 Seal Clamp Pliers

1. Install a new small seal retaining clamp onto the seal.

Do not crimp the seal retaining clamp.

2. Install the seal onto the axle shaft.

3. Install the tripot joint retaining ring and the tripot onto

the axle shaft.

B104A011

4. Install the shaft retaining ring onto the axle shaft us-

ing the snap ring pliers J-8059.

A104A026

DAEWOO J-100 BL2 / BL3

AUTOMATIC TRANSAXLE DRIVE AXLE 3A -- 13

5. Fill the tripot housing with 195 to 215 g (6.9 to 7.6

ounces) of the recommended grease. Repack the

tripot with 195 to 215 g (6.9 to 7.6 ounces) of the

recommended grease.

6. Install the tripot housing onto the tripot assembly.

A104A027

7. Install the tripot joint retaining ring into the tripot

housing.

B104A010

8. Install a new large seal retaining clamp. Crimp the

large seal retaining clamp using the seal clamp

pliers J-35566.

9. Crimp the new small seal retaining clamp using the

seal clamp pliers J-35566.

10. Install the drive axle shaft to the vehicle. Refer to

‘‘Drive Axle Assembly’’ in this section.

A104A035

DAEWOO J-100 BL2 / BL3

3A -- 14 AUTOMATIC TRANSAXLE DRIVE AXLE

GENERAL DESCRIPTION semblies. Each axle assembly consists of an inner and

an outer constant-velocity joint connected to an axle

AND SYSTEM OPERATION shaft. The inner joint is completely flexible and has the

ability to move in and out. The outer joint is also flexible,

but it cannot move in and out.

FRONT DRIVE AXLE

The drive axles use one type of outboard joint and one

General Description type of inboard joint. The inboard ends of both drive

Drive axles are flexible shaft assemblies that transmit axles incorporate a female spline that installs over a

rotational force from the transaxle to the front-wheel as- stub shaft protruding from the transaxle.

DAEWOO J-100 BL2 / BL3

You might also like

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- ATRA Seminar Book TableDocument22 pagesATRA Seminar Book TableossoskiNo ratings yet

- 2008 Ford Focus Wiring DiagramsDocument83 pages2008 Ford Focus Wiring Diagramsmike75% (4)

- SEM669C T2 Parts Manual (零部件图册国二) -V1-2014.3.31Document213 pagesSEM669C T2 Parts Manual (零部件图册国二) -V1-2014.3.31Sergio Muñoz67% (3)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- AXIS200 /: Operating Instructions Laser Wheel AlignerDocument52 pagesAXIS200 /: Operating Instructions Laser Wheel AlignerOk PalaceNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Rekluse Motor SportsDocument13 pagesRekluse Motor SportsJoshuaFulkersonNo ratings yet

- Power Tongs & Replacement Parts Index PageDocument57 pagesPower Tongs & Replacement Parts Index PagerezandriansyahNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual RAXDocument8 pages2003 Nissan Altima 2.5 Serivce Manual RAXAndy Dellinger100% (1)

- Audi r8 Transmission 0bzDocument129 pagesAudi r8 Transmission 0bzchoco84100% (3)

- SEBP4418-10-02 Excavadora 324D Serie CJX1-up, (Machine), DFP1-up, (Machine), KHX1-up (Engine) PDFDocument1,073 pagesSEBP4418-10-02 Excavadora 324D Serie CJX1-up, (Machine), DFP1-up, (Machine), KHX1-up (Engine) PDFOswaldo AndradeNo ratings yet

- Arctic Cat 2010 450 Service ManualDocument10 pagesArctic Cat 2010 450 Service Manualvictoria100% (50)

- Aisin Af406Document18 pagesAisin Af406emiliqn velikov100% (1)

- Meritor 120 125 SeriesSriveAxlesDocument15 pagesMeritor 120 125 SeriesSriveAxlesramsi17No ratings yet

- Ont & Rear AxleDocument22 pagesOnt & Rear Axleghar_dash100% (1)

- Toyota EtiosDocument4 pagesToyota EtiosRajanikantJadhav50% (2)

- 4B3.3 Bolt TorquesDocument57 pages4B3.3 Bolt TorquesPanagiotis PanagosNo ratings yet

- Overdrive WikiDocument5 pagesOverdrive WikiMunim AbdulNo ratings yet

- Sec5 PDFDocument21 pagesSec5 PDFJim LassNo ratings yet

- BOBCAT 2200 UTILITY VEHICLE Service Repair Manual SN A59Z11001 & ABOVE (2200 DIESEL) PDFDocument86 pagesBOBCAT 2200 UTILITY VEHICLE Service Repair Manual SN A59Z11001 & ABOVE (2200 DIESEL) PDFfhsjekkdmme0% (1)

- AR0500B5521DDocument3 pagesAR0500B5521DLUKAS100% (1)

- Engine Brake Flap MB 542.9Document2 pagesEngine Brake Flap MB 542.9GeorgeNo ratings yet

- Smart Fortwo CatalogueDocument112 pagesSmart Fortwo CatalogueRadu_ISNo ratings yet

- Manual Transaxle Drive Axle: Section 3BDocument17 pagesManual Transaxle Drive Axle: Section 3BJarry PotterNo ratings yet

- Manual Transaxle Drive Axle: Section: 3BDocument13 pagesManual Transaxle Drive Axle: Section: 3BananNo ratings yet

- Manual de Transmisión de Daewoo NubiraDocument90 pagesManual de Transmisión de Daewoo NubiraFelipe ChimborazoNo ratings yet

- Section 2C: General SpecificationsDocument36 pagesSection 2C: General SpecificationsJarry PotterNo ratings yet

- Identification: Drive Axle Noise DiagnosisDocument48 pagesIdentification: Drive Axle Noise DiagnosisRoberto Ortega MicalizziNo ratings yet

- Section 4A - Powerhead: Special ToolsDocument26 pagesSection 4A - Powerhead: Special ToolsRandall PettersonNo ratings yet

- Power Steering Gear: Section 6CDocument36 pagesPower Steering Gear: Section 6CJarry PotterNo ratings yet

- Sostituzione Cuscinetto - Paraolio - Anteriore PDFDocument19 pagesSostituzione Cuscinetto - Paraolio - Anteriore PDFdario024No ratings yet

- ATV Section 6Document32 pagesATV Section 6Kevin HarrisNo ratings yet

- Front & Rear AxleDocument26 pagesFront & Rear AxleSteve BelangerNo ratings yet

- R&I Rear Axle ShaftDocument4 pagesR&I Rear Axle ShaftEmanuel Theodor RaduNo ratings yet

- Royal Flushometer: Parts ListDocument3 pagesRoyal Flushometer: Parts ListDanny AlejandroNo ratings yet

- Front Axle: SectionDocument24 pagesFront Axle: SectiontsudsingNo ratings yet

- 2005 RG Diesel SMDocument333 pages2005 RG Diesel SMMFNo ratings yet

- Axle Shafts RearDocument19 pagesAxle Shafts RearCarlos VelázquezNo ratings yet

- Sostituzione Cuscinetto - ParaolioDocument8 pagesSostituzione Cuscinetto - Paraoliodario024No ratings yet

- Bumpers and Fascias: Section 9ODocument14 pagesBumpers and Fascias: Section 9OJarry PotterNo ratings yet

- 4runner Tylna Oś I Most PDFDocument36 pages4runner Tylna Oś I Most PDFAbc AbcNo ratings yet

- Clutch: Section 5CDocument24 pagesClutch: Section 5CJarry PotterNo ratings yet

- Remove Install Engine Brake Cylinder For Engine Brake FlapDocument2 pagesRemove Install Engine Brake Cylinder For Engine Brake FlapAhmad EdyNo ratings yet

- Sterndrive Unit: Gear Housings Mr/Alpha One/Alpha One SsDocument56 pagesSterndrive Unit: Gear Housings Mr/Alpha One/Alpha One SsdarrylloachNo ratings yet

- Read and Understand All Instructions and Warnings Prior To Installation of System and Operation of Vehicle. Safety Warning Product Safety WarningDocument10 pagesRead and Understand All Instructions and Warnings Prior To Installation of System and Operation of Vehicle. Safety Warning Product Safety WarningRASNo ratings yet

- Narrow Aisle Flexi 15N-1000Document79 pagesNarrow Aisle Flexi 15N-1000ihianbissellNo ratings yet

- Ear Axle 35Document108 pagesEar Axle 35donnieee77No ratings yet

- AR05.00-B-5541B.fm Dismount and Mount The Rocker Arm Mechanism 04.08.97Document3 pagesAR05.00-B-5541B.fm Dismount and Mount The Rocker Arm Mechanism 04.08.97LUKASNo ratings yet

- Fa PDFDocument29 pagesFa PDFblumngNo ratings yet

- Remove - Install CrankshaftDocument4 pagesRemove - Install Crankshaftptsi rekrutNo ratings yet

- 25 Propeller ShaftDocument11 pages25 Propeller ShaftEdinaldo GuimaraesNo ratings yet

- Front Drive Shaft: Section 4ADocument13 pagesFront Drive Shaft: Section 4ARaidul WafiNo ratings yet

- Suspension, Assembly Overview: Electronic Parts Catalog "ETKA"Document11 pagesSuspension, Assembly Overview: Electronic Parts Catalog "ETKA"pabloNo ratings yet

- SM 23Document17 pagesSM 23carlos contreras moyaNo ratings yet

- Camshaft Gear - Remove and Install Removal ProcedureDocument3 pagesCamshaft Gear - Remove and Install Removal ProcedureCristian LuqueNo ratings yet

- 211 642 Engine MountDocument2 pages211 642 Engine MountgzgwzdxggyNo ratings yet

- J3 Axis R-2000iCDocument14 pagesJ3 Axis R-2000iCCesar PuenteNo ratings yet

- RAXDocument12 pagesRAXRafaelCazalesFuentesNo ratings yet

- Engine Mechanical: IVG30EDocument54 pagesEngine Mechanical: IVG30EWSMengine WSMengineNo ratings yet

- Sterndrive Unit: Section 3A - Drive Shaft HousingDocument50 pagesSterndrive Unit: Section 3A - Drive Shaft HousingАлександр ГершукNo ratings yet

- Set Basic Position of CamshaftsDocument2 pagesSet Basic Position of CamshaftsAntonio OgNo ratings yet

- Rear Axle ShaftDocument8 pagesRear Axle ShaftSalud y Cuidado AutomotrizNo ratings yet

- Accessory DriveDocument14 pagesAccessory DriveLarry GalloNo ratings yet

- Specifications: 2008 Ford Ranger 2008 Ford RangerDocument15 pagesSpecifications: 2008 Ford Ranger 2008 Ford RangerwawanNo ratings yet

- BMW C650 GT Belt and Roller Service (v2)Document15 pagesBMW C650 GT Belt and Roller Service (v2)Jorge ArijaNo ratings yet

- Alpha Stern Drive: Installation and AdjustmentsDocument14 pagesAlpha Stern Drive: Installation and AdjustmentsiwessberNo ratings yet

- Rear AxleDocument108 pagesRear AxleSlobodanNo ratings yet

- Drive ShaftDocument9 pagesDrive ShaftSteven AmadorNo ratings yet

- Front Disc Brakes: Section 4DDocument11 pagesFront Disc Brakes: Section 4DJarry PotterNo ratings yet

- Bumpers and Fascias: Section 9ODocument14 pagesBumpers and Fascias: Section 9OJarry PotterNo ratings yet

- Seats: Section 9HDocument17 pagesSeats: Section 9HJarry PotterNo ratings yet

- Glass and Mirrors: Section 9LDocument18 pagesGlass and Mirrors: Section 9LJarry PotterNo ratings yet

- Interior Trim: Section 9GDocument25 pagesInterior Trim: Section 9GJarry PotterNo ratings yet

- Remote Keyless Entry and Perimeter/Ultrasonic Anti-Theft SystemDocument27 pagesRemote Keyless Entry and Perimeter/Ultrasonic Anti-Theft SystemJarry PotterNo ratings yet

- Audio Systems: Section 9FDocument15 pagesAudio Systems: Section 9FJarry PotterNo ratings yet

- Waterleaks: Section 9IDocument6 pagesWaterleaks: Section 9IJarry PotterNo ratings yet

- Lighting Systems: Section 9BDocument51 pagesLighting Systems: Section 9BJarry PotterNo ratings yet

- Cruise Control System: Section 9UDocument19 pagesCruise Control System: Section 9UJarry PotterNo ratings yet

- Squeaks and Rattles: Section 9KDocument3 pagesSqueaks and Rattles: Section 9KJarry PotterNo ratings yet

- Body Front End: Section 9RDocument14 pagesBody Front End: Section 9RJarry PotterNo ratings yet

- Doors: Section 9PDocument31 pagesDoors: Section 9PJarry PotterNo ratings yet

- Windnoise: Section 9JDocument2 pagesWindnoise: Section 9JJarry PotterNo ratings yet

- Body Wiring System: Section 9ADocument11 pagesBody Wiring System: Section 9AJarry PotterNo ratings yet

- MTCO 1324 Owners ManualDocument24 pagesMTCO 1324 Owners ManualJarry PotterNo ratings yet

- J 8bDocument82 pagesJ 8bJarry PotterNo ratings yet

- Section 8 - Body & AccessoriesDocument1,394 pagesSection 8 - Body & AccessoriesMTK2016No ratings yet

- Corvette - America's Star-Spangled Sports Car by Karl Ludvigsen - Table of ContentsDocument4 pagesCorvette - America's Star-Spangled Sports Car by Karl Ludvigsen - Table of ContentsBentley PublishersNo ratings yet

- Volkswagen PDFDocument11 pagesVolkswagen PDFPrasadNo ratings yet

- Ford Sierra 0903-WD Wire DiagramDocument47 pagesFord Sierra 0903-WD Wire Diagramhalo35100% (1)

- PLH - Pneumatic Long Hole: A Personalized ServiceDocument2 pagesPLH - Pneumatic Long Hole: A Personalized ServiceIng del PeleNo ratings yet

- Lamborghini AventadorSVJRoadster AC37EZ 19.05.17Document16 pagesLamborghini AventadorSVJRoadster AC37EZ 19.05.17Lucian NicolaeNo ratings yet

- Automotive Customers One PagerDocument2 pagesAutomotive Customers One PagerAdam SmithNo ratings yet

- Shutdown SIS: Backhoe Loader 420D Backhoe Loader FDP 420D Backhoe Loader FDP18400-UP (MACHINE) POWERED BY 3054C EngineDocument3 pagesShutdown SIS: Backhoe Loader 420D Backhoe Loader FDP 420D Backhoe Loader FDP18400-UP (MACHINE) POWERED BY 3054C Enginearmando vara chavezNo ratings yet

- 22r Diagrama ElectricoDocument14 pages22r Diagrama Electricostuardo CcjNo ratings yet

- Groups 060 - 069 Throttle Valve ControlDocument3 pagesGroups 060 - 069 Throttle Valve ControlZatovonirina RazafindrainibeNo ratings yet

- 2011-09-16 Amarok Aufbaurichtlinien enDocument80 pages2011-09-16 Amarok Aufbaurichtlinien enJosé Julio Pantac LiNo ratings yet

- 68 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page68 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- JLR 24 02 21 - 1E - DISCOVERY L462 MY2017 - Fuse and Relay Locations (1a)Document3 pagesJLR 24 02 21 - 1E - DISCOVERY L462 MY2017 - Fuse and Relay Locations (1a)DanieleNo ratings yet

- MINI Cooper Countryman AutomaticDocument2 pagesMINI Cooper Countryman AutomaticSolo MinisNo ratings yet

- Ford Territory BrochureDocument5 pagesFord Territory Brochuremysterybox PhNo ratings yet

- RX 50 SpecDocument1 pageRX 50 SpecFelipe HernándezNo ratings yet

- XYG MouldingDocument71 pagesXYG MouldingJack ZengNo ratings yet

- Delo Bumper-to-Bumper Protection For Waste Truck Service: Engine CrankcaseDocument1 pageDelo Bumper-to-Bumper Protection For Waste Truck Service: Engine CrankcaseflyinzeskyNo ratings yet

- Astra ADTd25-6x6-ING PDFDocument6 pagesAstra ADTd25-6x6-ING PDFwalasmaya1No ratings yet

- Accessory Installation InstructionsDocument10 pagesAccessory Installation InstructionsMohd Saifol IshakNo ratings yet