Professional Documents

Culture Documents

Nitoproof 230 UAE

Nitoproof 230 UAE

Uploaded by

MDhana SekarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitoproof 230 UAE

Nitoproof 230 UAE

Uploaded by

MDhana SekarCopyright:

Available Formats

Fosroc Nitoproof 230 constructive solutions

Rubberised high build elastomeric membrane

Uses Properties

Nitoproof 230 is an elastomeric high build, cold applied, Drying time : 6 hours @ 35ºC

rubberised bitumen. Suitable for use as a waterproofing Solid Contents : 55 - 60%

membrane on all wet area floors, walls and roofs where Overcoating time : 12 hours minimum @ 35ºC

concrete substrate cracking may occur. Also suitable for Chemical resistance : Resistant to water, aqueous

protecting concrete foundations, tie beams and substruc- salt solutions, common

tures from vapour / chloride / sulphate contaminated soil in detergent solution, mild

areas above the watertable. Nitoproof 230 will bridge minor mineral acid and alkali

live cracks. It is also designed to provide a continuous barrier solutions. Not resistant to

to the passage of water and water vapour and can be used organic solvents.

to produce vapour barriers. Reaction to fire

(ASTM E84) : Class A

Advantages Flame Spread Index (FSI)

and Smoke Development

Single component

Index (SDI)

Water based - non toxic

Note: Drying & Overcoating times will be extended under

Damp tolerant & applicable on green concrete

conditions of low temperature and high humidity.

Elastomeric

Non flammable Instructions for use

Resists attack by chloride and sulphate ions

Surface Preparation

Asbestos free

All surfaces must be clean and dry and free from dirt, dust,

Suitable for horizontal and vertical application

oil and grease. All loosely adhering particles such as rust,

Suitable to use as curing compound scale, cement laitance etc should be removed. All organic

growth should be removed using a fungicidal wash, followed

Standards compliance by thorough washing with clean water.

Nitoproof 230 complies with concrete curing requirements

Application

of ASTM C309-93 when applied at a rate of 0.87m2/litre.

Nitoproof 230 should be applied by brush or squeegee to

Nitoproof 230 complies with ASTM E84 for Flame Spread prepared surfaces. Stir well before use, replace lid when not

Index(FSI) and Smoke Development Index(SDI) : Class A. in use. Soak up any spillage with sand or sawdust and wash

down surface immediately.

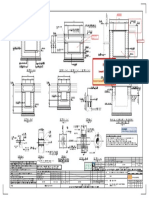

Description

Damp proof membrane and vertical vapour barrier

Nitoproof 230 is a high build rubber reinforced bitumen

emulsion. The emulsion is dark brown in colour and dries to Apply Nitoproof 230 at the rate of 0.87m2 per litre per coat to

form a black, flexible coating. Nitoproof 230 is formulated for give a dry film thickness of 0.75 mm. Two coats should be

use in Middle East conditions. applied, allowing the first coat to dry completely before

applying the second. The second coat should be applied at

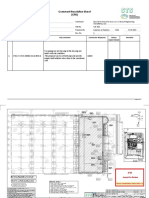

Specification right angles to the first. All applications should be continued

up verticals to the existing damp proof course. Ensure the

Elastomeric rubberised bitumen emulsion waterproofer. membrane is not punctured or damaged during subsequent

Concrete surfaces shall be waterproofed with Nitoproof 230, operations. Where the surface is to receive a render or

an elastomeric high build rubberised bitumen emulsion. Two plaster finish, a keyed surface should be formed by gritting

coats shall be applied each at a rate of 0.87m2 per litre the second coat of Nitoproof 230 with clean, dry sand. Allow

providing a total dry film thickness of 1.5 mm. The two coats a minimum of 48 hours drying period before plastering,

shall be applied at right angles to each other. rendering, laying floor screed and backfilling.

Nitoproof 230

Nitoproof 230 complies with ASTM E84 for Flame Spread

Index(FSI) and Smoke Development Index(SDI) : Class A.

Fosroc Nitoproof 230

Repairs Precautions

Damaged areas of Nitoproof 230 can be readily overcoated Fire

to restore the continuity of the membrane.

Nitoproof 230 is non-flammable.

Cleaning

Fosroc Solvent 102 is flammable. Ensure adequate ventila-

Nitoproof 230 can be removed with clean water, however tion. Do not use near a naked flame and do not smoke

once the Nitoproof 230 has dried, it can only be removed during use.

with Fosroc Solvent 102.

Flash points

Fosroc Solvent 102 : 33ºC

Limitations

Application should not commence if the temperature is below Additional Information

6ºC or above 45ºC.

Fosroc manufactures a wide range of complementary

products which include :

Technical support

waterproofing membranes & waterstops

Fosroc offers a comprehensive technical support service to

specifiers, end users and contractors. It is also able to offer joint sealants & filler boards

on-site technical assistance, an AutoCAD facility and dedi-

cementitious & epoxy grouts

cated specification assistance in locations all over the world.

specialised flooring materials

Estimating

Fosroc additionally offers a comprehensive package of

Supply

products specifically designed for the repair and refurbish-

Nitoproof 230 : 20 & 200 litre drums

ment of damaged concrete. Fosroc’s ‘Systematic Approach’

Coverage to concrete repair features the following :

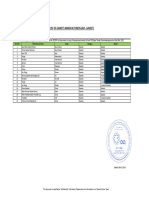

Nitoproof 230 : 0.87m2/litre/coat (to comply

hand-placed repair mortars

with ASTM C309)

spray grade repair mortars

Storage

fluid micro-concretes

Nitoproof 230 will have a minimum shelf life of 12 months if

chemically resistant epoxy mortars

stored in normal warehouse conditions between 15 and

40°C. Protect from temperatures below 10°C. anti-carbonation/anti-chloride protective coatings

chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of

Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to obtain the latest version.

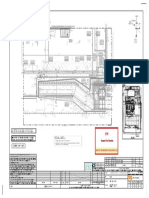

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc Co. LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

UAE/0187/21/K

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- OQ AVL-ValvesDocument3 pagesOQ AVL-ValvesMDhana SekarNo ratings yet

- OQ Approved Vendor List (Pipes)Document1 pageOQ Approved Vendor List (Pipes)MDhana SekarNo ratings yet

- S781-CV-DWG-00006-03-213036-A - OQ Comments - 19.03.2023Document1 pageS781-CV-DWG-00006-03-213036-A - OQ Comments - 19.03.2023MDhana SekarNo ratings yet

- OQ Approved Vendor List (Gasket)Document1 pageOQ Approved Vendor List (Gasket)MDhana SekarNo ratings yet

- S781-CV-DWG-00006-06-213036-A - OQ Comments - 19.03.2023Document1 pageS781-CV-DWG-00006-06-213036-A - OQ Comments - 19.03.2023MDhana SekarNo ratings yet

- A927 031 81 41 16355 - 0 - RenditionFileDocument2 pagesA927 031 81 41 16355 - 0 - RenditionFileMDhana SekarNo ratings yet

- OQ AVL FastenersDocument1 pageOQ AVL FastenersMDhana SekarNo ratings yet

- Comment Resolution Sheet (CRS) : SN. Reference OQ Comment Contractor Response Status Open/Closed RemarksDocument3 pagesComment Resolution Sheet (CRS) : SN. Reference OQ Comment Contractor Response Status Open/Closed RemarksMDhana SekarNo ratings yet

- S781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023Document2 pagesS781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023MDhana SekarNo ratings yet

- S781-CV-DWG-00006-04-213036-A - OQ Comments - 19.03.2023Document1 pageS781-CV-DWG-00006-04-213036-A - OQ Comments - 19.03.2023MDhana SekarNo ratings yet

- S781 CV DWG 00004 04 213036 B CorrectionDocument2 pagesS781 CV DWG 00004 04 213036 B CorrectionMDhana SekarNo ratings yet

- Drawing Limit: North 58.1139734° 90°Document1 pageDrawing Limit: North 58.1139734° 90°MDhana SekarNo ratings yet

- Comment Resolution Sheet (CRS) : As ListedDocument2 pagesComment Resolution Sheet (CRS) : As ListedMDhana SekarNo ratings yet

- S781 CV DWG 00004 01 213036 B CorrectionDocument1 pageS781 CV DWG 00004 01 213036 B CorrectionMDhana SekarNo ratings yet

- S781-CV-DWG-00006-05-213036-A - OQ Comments - 19.03.2023Document1 pageS781-CV-DWG-00006-05-213036-A - OQ Comments - 19.03.2023MDhana SekarNo ratings yet

- Comment Resolution Sheet (CRS) : SN. Reference OQ Comment Contractor Response Status Open/Closed RemarksDocument2 pagesComment Resolution Sheet (CRS) : SN. Reference OQ Comment Contractor Response Status Open/Closed RemarksMDhana SekarNo ratings yet

- S781 CV DWG 00001 04 213036 BDocument1 pageS781 CV DWG 00001 04 213036 BMDhana SekarNo ratings yet

- O - (TOC) - SOP - 011 - R0 - SOP For External Painting and CoatingDocument10 pagesO - (TOC) - SOP - 011 - R0 - SOP For External Painting and CoatingMDhana SekarNo ratings yet

- Nitoproof 231Document6 pagesNitoproof 231MDhana SekarNo ratings yet

- North 58.1139734° 90°: For Continuation Refer Drawing No. S000-CV-DWG-01658-00-TCMT (3911-AQ-DA-AE812 - 095-001)Document1 pageNorth 58.1139734° 90°: For Continuation Refer Drawing No. S000-CV-DWG-01658-00-TCMT (3911-AQ-DA-AE812 - 095-001)MDhana SekarNo ratings yet

- O - (TOC) - SOP - 019 - R0 - SOP For Steel Structure Fabrication and ErectionDocument8 pagesO - (TOC) - SOP - 019 - R0 - SOP For Steel Structure Fabrication and ErectionMDhana SekarNo ratings yet

- 44AC9100-000-D.02-0015-A4 SITE FABRICATED ITEMS Rev 0Document3 pages44AC9100-000-D.02-0015-A4 SITE FABRICATED ITEMS Rev 0MDhana SekarNo ratings yet

- Indirect Manpower Deployment ScheduleDocument1 pageIndirect Manpower Deployment ScheduleMDhana SekarNo ratings yet

- Equipment Deployment ScheduleDocument2 pagesEquipment Deployment ScheduleMDhana SekarNo ratings yet

- O - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlDocument8 pagesO - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlMDhana SekarNo ratings yet

- Direct Manpower Deployment ScheduleDocument2 pagesDirect Manpower Deployment ScheduleMDhana SekarNo ratings yet

- Manpower HistogramDocument1 pageManpower HistogramMDhana SekarNo ratings yet

- O - (TOC) - SOP - 017 - R0 - SOP For For Static Equipment InstallationDocument8 pagesO - (TOC) - SOP - 017 - R0 - SOP For For Static Equipment InstallationMDhana SekarNo ratings yet

- 6-44-0005 Rev 7Document446 pages6-44-0005 Rev 7MDhana SekarNo ratings yet

- A927-520-81-41-04704 - Area 4 - Rev 3Document1 pageA927-520-81-41-04704 - Area 4 - Rev 3MDhana SekarNo ratings yet