Professional Documents

Culture Documents

Research Paper

Uploaded by

elmonemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Research Paper

Uploaded by

elmonemCopyright:

Available Formats

Advances in Chemical Engineering and Science, 2011, 1, 191-197

doi:10.4236/aces.2011.14028 Published Online October 2011 (http://www.SciRP.org/journal/aces)

Copper and Cyanide Recovery in Cyanidation Effluents

José R. Parga1, Jesús L. Valenzuela2, Héctor Moreno3, Jaime E. Pérez1

1

Department of Metallurgy and Materials Science, Institute Technology of Saltillo, Saltillo, México

2

Departament of Chemistry and Metallurgy, University of Sonora, Hermosillo, México

3

Chemistry Department, Institute Technology of Laguna, Torreón, México

E-mail: jrparga@its.mx

Received August 26, 2011; revised September 13, 2011; accepted September 23, 2011

Abstract

Cyanidation is the main process for gold and silver recovery from its ores. In this study, a process is pro-

posed to recover copper and cyanide from barren solutions from the Merrill-Crowe cementation process with

zinc dust. This technology is based on inducing nucleated precipitation of copper and silver in a serpentine

reactor, using sodium sulfide as the precipitator, and sulfuric acid for pH control. Results show that pH value

has a significant effect on copper cyanide removal efficiency, and it was determined the optimal pH range to

be 2.5 - 3. At this pH value, the copper cyanide removal efficiency achieved was up to 97% and 99%, when

copper concentration in the influent was 636 and 900 ppm. respectively. In this process (sulphidiza-

tion-acidification-thickening-HCN recycling), the cyanide associated with copper cyanide complexes, is re-

leased as HCN gas under weakly acidic conditions, allowing it to be recycled back to the cyanidation process

as free cyanide. Cyanide recovery was 90%. Finally, this procedure was successfully run at Minera William

in México.

Keywords: Precipitation, Cyanide Removal, Copper Recovery, Cyanidation

1. Introduction Elsner’s Equation (1) shows that oxygen is critical for

the dissolution of gold. Stoichiometry of the process

Actually, the most common process for gold and silver shows that 4 moles of cyanide are needed for each mole

recovery from ores is cyanidation, due to the selectivity of oxygen present in solution. At room temperature and

of free cyanide for both metals, and the stability of the standard atmospheric pressure, approximately 8.2 mg of

cyanide complex ( Au (CN) 2 , k = 2 × 1038) [1]. Chemical oxygen are present in one liter of water. This corre-

recovery of gold from Merrill-Crowe process cyanide sponds to 0.27 × 10–3 mol/L. The corresponding sodium

solution, involves two different operations: 1) gold dis- cyanide concentration for a complete reaction (molecular

solution, where it is oxidized and dissolved to form Au (I) weight of NaCN = 49) should be equal to 4 × 0.27 × 10–3

ion and cyanide complex Au(CN) 2 , and 2) precipitation × 49 = 0.05 g/L or approximately 0.01%. This was con-

by reduction of metallic gold. In the cyanidation process, firmed in practice at room temperature by a very dilute

free cyanide ions in solution can only be provided at a solution of NaCN of 0.01% - 0.5% for ores, and 0.5% -

pH of 9.0. The pH of the pulp can be increased adding 5% for gold and silver concentrates [2]. Gold dissolution

alkalis (e.g. Ca(OH)2, NaOH, etc.), known as protective is an electrochemical reaction in which oxygen takes up

alkalis. It is accepted that gold dissolution in cyanide electrons at one section of the metallic surface [cathodic

solutions occurs as a sequence of two reactions, as zone], while the metal gives them up in another section

shown in Equations (1) and (2). These reactions apply to [anodic zone]. Details of this electrochemical reaction

silver as well. have received considerable attention and under certain

2Au 4NaCN O 2 2H 2 O 2Na Au CN 2 circumstances the reaction is limited by the coupled dif-

(1) fusion of CN– and O2 to the gold surface. Dissolution

2NaOH H 2 O 2 rate is normally mass-transport controlled in cyanide

solutions and the activation energy is 8 - 20 kJ/mol [3].

2Au 4NaCN H 2 O 2 2Na Au CN 2 2NaOH

The concentration of cyanide used to dissolve gold in

(2) ores is typically higher than the stoichiometric ratio, due

Copyright © 2011 SciRes. ACES

192 J. R. PARGA ET AL.

to the solubility of other minerals. Free cyanide produces 1.1. Copper Removal after the Merrill-Crowe

complexes with several metallic species, especially tran- Process

sition metals, which show a broad variation in both sta-

bility and solubility [4]: The presence of cyanide-soluble copper affects gold and

silver recovery from the cyanide solutions. In the

CN M CN y

2 xy

M y (3)

Merrill-Crowe process, the copper is precipitated along

Many common copper minerals are soluble in the di- with gold and silver, resulting in a higher consumption of

lute cyanide solution, typical of leach conditions found in zinc dust, fluxes in the smelting of the precipitate and

the gold cyanidation process. Minerals such as azurite shorter life for crucibles. For these reasons, copper must

and malaquite, are fast leached and soluble in dilute cya- be separated from the precious metals by digesting the

nide solutions. Enargite and chalcopyrite leach more silver/gold/zinc precipitated in sulfuric acid prior to

slowly but are sufficient soluble to cause excessive cya- smelting. This is a common practice in William Mining

nide loss and contamination of leach solutions with arse- Co., which produces a copper sulfate acidic solution that

nic [5]. For example, in the cyanidation of malachite and goes to the zinc and arsenopyrite froth flotation circuit or

azurite minerals, the copper carbonate component lea- to an iron cementation process before disposal. Cementa-

ches as follows: tion of copper using scrap iron is practiced when the

Malachite and Azurite (Leaching rate = Fast): quantity of copper makes recovery worthwhile. Also, to

increase the recovery of silver and gold, with less copper,

2CuCO3 8NaCN 2Na 2 Cu CN 3 2Na 2 CO3 CN 2 it is necessary to use conditions which result in the for-

(4) mation of Cu(CN)32 and Cu(CN)34 . High pH values

Then: and high free-cyanide concentrations stabilize copper in

solution resulting in lower levels of copper. Increment of

CN 2 2NaOH NaCNO NaCN H 2 O (5) copper in the barren solution poses serious metallurgical

problems in the cyanidation circuit and it is necessary to

Some others possible reactions are shown below: include a process to strip the copper, prior to the gold

Cuprite (Leaching rate = Fast): and silver leaching step. Failure to do so will result in

Cu 2 O 6NaCN H 2 O 2Na 2 Cu CN 3 2NaOH (6) lower dissolution of precious metals and production of

high-copper-silver/gold bullion.

Tenorite (Leaching rate = Fast): This research focuses on the removal of copper before

smelting the gold and silver precipitate and in prevention

2CuO 7NaCN H 2 O 2Na 2 Cu CN 3

(7) and/or minimization of the impact of copper in the barren

2NaOH NaCNO solution after the filter press in the Merrill-Crowe proc-

ess. Treatment of high-copper silver/gold leach solutions,

Chalcocite (Leaching rate = Fast): before or after precious metals recovery, is focused on

1 precipitation of copper as chalcocite (Cu2S) and cyanide

Cu 2S 7NaCN O 2 H 2 O 2Na 2 Cu CN 3 recovery.

2

2NaOH NaCNS

1.2. Cyanide and Copper Recovery Processes

(8)

Covellite (Leaching rate = Fast): There is a growing interest for the recovery of both cop-

1 per and cyanide from silver and gold barren solutions

2CuS 8NaCN O 2 H 2 O 2Na 2 Cu CN 3 due to high cyanide consumption costs. William Mining

2

Co. is also interested in reducing costs in this way. The

2NaOH 2NaCNS cost of recovering and recycling cyanide from the barren

(9) leach solution will be lower than the cost of purchasing

The cyanidation of Cu (II) minerals with the conse- new cyanide. It has been almost a century since the

quent formation of cynogen, (CN)2 results in the loss of Mills-Crowe process for cyanide regeneration was de-

cyanide in the proportion of 0.5 mol of cyanide per mole veloped by the Mining Company Beneficiadora de

of Cu (II) leached, i.e., 0.39 kg NaCN/kg Cu (II). Cupric Pachuca in México (England Patent No. 241669, 3.9.24)

cyanogen complexes are first formed and then they are [7] and until today no significant changes to the process

broken down to the cuprous form liberating cyanogen, have been made. The simplest process for cyanide recy-

which in turn reacts with alkali to form cyanide and cy- cling involves acidifying the barren clarified solution

anate [6]. (pH between 2 and 5). During acidification, free cyanide

Copyright © 2011 SciRes. ACES

J. R. PARGA ET AL. 193

and relatively weakly complexed cyanide (Ag, Cu, Zn, If cyanide ions are present in the barren solution after

Fe) are converted into HCN gas, which is then volatil- precipitation from the Merrill Crowe process as free cya-

ized by passing a stream of air bubbles through the solu- nide (pKa = 9.4), it is possible to convert 99% of the

tion. The air/HCN gas stream is scrubbed in a caustic cyanide into HCN gas by lowering the pH value of the

solution in a second tower reactor to convert the HCN solution to about 6:

back into free cyanide ions for recycling [8]. In this

CN H HCN g (14)

process copper and silver are not recovered for resale.

This has prompted interest to also recover copper by se- On the other hand, if cyanide ions are present as me-

lective metal sulphide precipitation. The copper sulphide tal-cyanide complexes, pH must be lowered to more aci-

precipitate is then recovered by conventional clarifica- dic values to break down the complex and produce HCN

tion and filtration to produce a filter cake (45% to 60% gas. As an example, the weak zinc-cyanide complex (log

Cu) which can be shipped to a copper smelter. B4 = 17.4) breaks down completely at a pH close to 5,

Among the chemical precipitation methods, precipita- producing zinc sulfate as an aqueous soluble species,

tion of metal hydroxides is the most conventional, but it plus HCN gas:

suffers from shortcoming, such as high solubilities for

Zn CN 4 2H 2SO 4 ZnSO 4 s 4HCN g SO 24 (15)

2

some metals. Sulphide precipitation of metals is a viable

alternative process for copper recovery from the barren

The copper cyanide complex does not break down

cyanide solutions because of the possible high degree of

completely, even in strong acid solution, unless there is

metal removal over a broad pH range. However; hydro-

an oxidant present in the solution. In the absence of an

gen sulfide is odorous and highly toxic. It tends to accu-

oxidant, the copper tricyanide (which is the most stable

mulate in poorly ventilated spaces because it is heavier

copper complex under normal cyanidation conditions:

than air. Exposure to low level concentrations of this gas

log B3 = 28) decomposes to form a CuCN precipitate,

can result in eye irritation, sore throat and cough, short-

plus HCN gas (Equation (16)), at pH values lower than 3.

ness of breath, and fluid in the lungs [9]. Sulphide pre-

Hence, 33% of potentially recoverable cyanide is lost to

cipitation of metals has several advantages over hydrox-

the precipitate:

ide precipitation, such as low solubility, high stability of

Cu CN 3 2H CuCN s 2HCN g

2

metal sulphides, fast reaction rates, better settling prop- (16)

erties and potential for re-use of sulphide precipitates by

smelting. The thermodynamic equilibrium involved in Barren solution in the William Mining Co. process

metal sulphide precipitation has been proposed as [10]: also contains ferrocyanide and cuprous cyanide that, a

pH = 4, produces double metal cyanide precipitates such

HS H

as Cu2Fe(CN)6 and Cu4Fe(CN)6:

HS H , K p1

H 2S Kp1

, pK1 6.99

H 2S 4Cu CN 3 Fe CN 6 12H Cu 4 Fe CN 6 s

2 4

(10)

12HCN g

S2 H

HS 2

S H , K p2

Kp2

, pK 2 17.4 (17)

HS

From the stoichiometry, it can be seen that the ferro-

(11) cyanide molecule releases the third molecule of CN from

the copper tricyanide complex. Therefore, the presence

M 2 S2 MS s (12) of ferrocyanide results in increased recovery of cyanide

from the copper-cyanide species.

M 2 HS MS s H (13) When thiocyanate is present, as it is often the case

These equations show that concentration of sulphur when leaching sulphide-bearing ores, insoluble CuSCN

species is a strong function of pH. The pK2 value is cur- may also be responsible for copper precipitation and

rently the most reliable value. HCN gas formation in acid conditions, the following

The use of sulphide precipitation process for copper reaction show this behavior:

Cu CN 3 SCN 3H CuSCN s 3HCN g (18)

2

and cyanide recovering after cyanidation has a key ad-

vantage, the ability to operate in the barren solution to

first recover copper/silver and after that establish acidic Addition of sulphide ions (Na2S) to the acidified cya-

conditions in the solution. This results in rapid release of nide solution results in the precipitation of cuprous sul-

free cyanide (HCNgas) that is easily recoverable by vola- phide (chalcocite), which is favored because of its ex-

tilization at lowered pH value. tremely low solubility (Ksp = 2.3 × 10–48) [11]. The fol-

Copyright © 2011 SciRes. ACES

194 J. R. PARGA ET AL.

lowing reaction takes place: round-bottomed reaction vessel with ports for an over-

head stirred, a gas sparger and a pH electrode. The pH

2Cu CN 3 2H 2SO 4 H 2S g Cu 2S s 6HCN g

2

meter is VWR 8005 Scientific and stirring motor with a

glass impeller driven BDC 1850 CAFRAMO and cone

2SO 24

size settler (1000 ml). The barren solutions used had

(19) copper, silver, zinc and iron ions of varying concentra-

Stoichiometric rate of sulfide is approximately 0.25 tion. The pH of the barren was adjusted to the required

grams S2– per gram of copper, 0.44 grams NaHS per level with sulfuric acid and then a mixture of Na2S/water

gram of copper or 0.61 grams Na2S per gram of copper. was added. All experimental samples of the liquor and

However, the actual sulfide dosage required for near- solid were taken at known times, solutions and solids

complete copper precipitation is normally in excess of from the process were separated by filtration through

200% due to additional ions in the barren solution. In cellulose filter paper. The sludge from the precipitation

precipitating copper, sulfide addition also results in the was dried either in an oven or under vacuum at room

near-complete precipitation of silver, as shown in the temperature. Analysis of copper, silver, zinc, iron, and

following reaction: arsenic were performed by digestion of the precipitate

and subsequent ICP/Atomic Emission Spectrometry de-

2Ag CN 2 H 2S g Ag 2S s 4HCN g

(20)

termination and free cyanide content was determined

Based upon reactions 15 - 20, acid conditions may directly via titration, whereas the total cyanide was

cause the dissociation of the complexes, due to the for- measured by means of titration after distillation. At the

mation of some copper precipitate and subsequent libera- end of the experiment, HCN volatilization reached effi-

tion of HCN by volatilization, considering these reac- ciencies above 97% and the capture of cyanide gas by

tions, up to 99% of copper could be recovered and HCN NaOH (1 M) solution was almost 95%.

gas could be stripped from the barren solutions and ad-

sorbed in an alkali solution of NaOH. The simplified 3. Results and Discussion

chemistry of the process is presented in the following

reaction: The experimental results of the copper, silver, zinc and

iron precipitation as well as CN removal (%) at different

HCN g NaOH NaCN H 2 O (21) pH values are presented in Table 1.

Results show that pH has a significant effect on copper

The precipitate is a sellable copper product on its own, cyanide removal efficiency, and it was determined the

or can be blended with the arsenopirite flotation concen- optimal pH range to be 2.5 - 3. With these pH values,

trate from the flotation sulphide plant. when influent copper concentration was 636 ppm, copper

cyanide removal efficiency was 99%. Some black pre-

2. Materials and Methods cipitates were observed in the solution of experiments 2

to 6; which suggested the presence of copper, silver, ar-

Experiments were carried out on barren cyanide solution senic, zinc and iron as sulphides. The presence of these

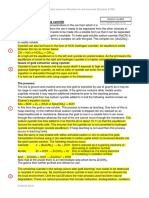

after the filter press on the Merrill Crowe process. The sulphides was confirmed in Figure 1. The measured

pregnant solution came from the cyanidation leach plant sample, which was collected from experiments of pH 2,

(500 ton/day), where the ores, from the Minera William 3 and 4 (see Table 2), gives rise to peaks corresponding

mines, are a mixture of oxides and sulfides, with the to covellite, esfalerite and pyrite. The size, EDAX and

copper ranging from 0.04% to 0.25% as the norm an morphology of the solids are also shown in Figure 1 by

average sample contains: 1.7 g/ton Au, 100 g/ton Ag, SEM micrograph and EDAX analysis. The solids in the

0.6% Pb, 0.61% Zn, 0.12% Cu, 2.3 % Fe and 2% of As. precipitate are spherical and approximately 100 nm in

A wet screen analysis of the plant sample indicated that diameter.

the granulometry was 80%—74 m. The leaching practice The SEM micrograph confirms the excellent crystal-

in the plant was: leach pulps containing 40% solids over linity of synthetic covellite (CuS) formed during the sul-

a period of 72 hours leaching at Ph = 11.0, O2 = 5 ppm phide precipitation process. The EDAX chemical analy-

and 2 kg/ton NaCN; leached residue: 0.20 g/ton Au and sis pattern of the precipitate at different pH values is

0.18 g/ton Ag. Then, copper precipitation and cyanide shown in Table 2.

regeneration experiments were performed to determine Results of Table 2, indicate that pH = 2 to 3 is the best

the effect of different process conditions on the solids of condition for the sulphide precipitation of copper, be-

copper/silver sulphide produced by sulphide precipitation. cause the high recoveries > 99% of Cu and excellent

Precipitation experiments were carried out in a 1 liter quality.

Copyright © 2011 SciRes. ACES

J. R. PARGA ET AL. 195

Table 1. Results of copper, silver, zinc and iron sulphide precipitates and CN removal at different pH values.

Ag Zn Cu Fe Na2S (grs) pH CN Removal (%)

Feed Barren Solution(ppm) 0.1 184 636 4 0 10.95

Solution 1 (ppm) 0 73 389 2 1.0 6 68

Precipitate 1 (%) 124 17.60 44.90 1.2 - -

Solution 2 (ppm) 0 93 420 2 0.5 6.0 63

Precipitate 2 (%) 121 21.40 40.70 1.0 - -

Solution 3 (ppm) 0 22 31 2 1.0 5.5 75

Precipitate 3 (%) 114 11.90 51.70 1.0 - -

Solution 4 (ppm) 0 8 0 0 1.0 5.0 80

Precipitate 4 (%) 119 13.4 51.27 1.0 - -

Solution 5 (ppm) 0 32 0 0 1.0 4.5 95

Precipitate 5 (%) 138 9.92 56.34 0.9 - -

Solution 6 (ppm) 0 54 0 0 1..0 4 96

Precipitate 6 (%) 118 1.49 62.68 1.1 - -

Solution 7 (ppm) 0 40 0 0 1.0 3.0 99

Precipitate 7 (%) 129 9.53 62.24 1.1 - -

Solution 8 (ppm) 0 134 0 0 1.0 2.5 99

Precipitate 8 (%) 106 11.24 60.5 0.9 - -

Table 2. EDAX analysis of solids precipitates at different pH values.

pH = 2 pH = 3 pH = 4

Element

Weight% Atomic% Weight% Atomic% Weight% Atomic%

OK 7.69 20.37 9.64 24.35 7.73 20.03

Na K 2.51 4.52

SK 27.85 36.80 29.02 36.57 26.44 34.18

Ca K 0.60 0.61 0.45 0.46

Fe K 2.06 1.56 1.96 1.42 1.90 1.41

Cu K 43.46 28.98 41.19 26.19 39.94 26.06

Zn K 18.94 12.28 17.58 10.87 21.04 13.34

Totals 100.00 100.00 100.00

Figure 1. SEM micrograph (×5000) and Chemical analysis of the powder as determined by EDAX, shows the presence of

copper, sulphur, zinc and iron in a sulphide particle.

3.1. Industrial Application A feed pump located in the precipitation area.

A line carrying barren solution at a rate of 10 li-

Based on the experimental evidence, obtained with the ters/second, with 1500 ppm of cyanide, 600 to 900

sulphide precipitation study for copper and cyanide ppm of copper complexes and 0.1 ppm of silver and

removal from the barren solution after the Merrill- at a pH of 11. At this flow rate precipitation of cal-

Crowe process, this process was installed on a mine cium sulphate (scale) would not occur.

site at full scale. A Serpentine. Barren solution is currently feed

A simplified process flow diagram, which uses so- along with Na2S solution and sulphuric acid, to a 4

dium sulphide to precipitate copper/silver, and to con- inch plastic pipe section in the shape of a SER-

vert cyanide to HCN gas, under acid conditions (pH 2 PENTINE, (with inside tripack rings mixers as tur-

to 3) is shown in Figure 2. bulence promoters).

The system consists of: Three enclosed vacuum vessels of various sizes/

Copyright © 2011 SciRes. ACES

196 J. R. PARGA ET AL.

Figure 2. A schematic diagram, showing the SERPENTINE process for Cu, Ag precipitation and cyanide recovering.

shapes meant to be sulfide precipitate collectors. Minera William in México, the National Council of Sci-

Formulation of poly-electrolyte conditioners that ence and Technology (CONACYT) and to the Dirección

effectively flocculate the fine metal sulfide particles General de Educación Superior Tecnológica (DGEST)

has eliminated the difficulty in separating the pre- from México.

cipitate from the discharge and has resulted in

sludges that are easily dewatered. 6. References

A HCN gas collection system, located over all ves-

sels with a gas adsorption tower, with sodium hy- [1] F. Habashi, “One Hundred Years of Cyanidation Histori-

droxide as the absorbant. cal Note,” CIM Bulletin, Vol. 80, No. 905, 1987, pp. 108-

114.

A pump in the treated barren solution line to feed

the filter press. [2] J. R. Parga, J. L. Valenzuela and F. Cepeda, “Pressure

Cyanide Leaching for Precious Metals Recovery,” Jour-

In five continuous working days the treated solution

nal of Metals, Vol. 59, No. 10, 2007, pp. 43-47.

exited the circuit at a pH value of 4, carrying about 0 to doi:10.1007/s11837-007-0130-4

10 ppm of copper and 200 ppm cyanide and was

[3] F. Habashi, “Kinetics and Mechanism of Gold and Silver

pumped to two neutralizing (pH 7) tanks. Dissolution in Cyanide Solution,” Bulletin No. 59, Bure-

au of Mines and Geology, State of Montana, 1967.

4. Conclusions [4] J. R. Parga, H. M. Casillas, V. Vazquez and J. L. Valen-

zuela, “Cyanide Detoxification of Mining Wastewaters

The SERPENTINE system is a viable technology for the with TiO2 Nanoparticles and Its Recovery by Electroco-

recovery of copper, silver and subsequent recovery of agulation,” Chemical Engineering and Technology, Vol.

HCN gas by scrubbing in NaOH. 32, No. 12, 2009, pp. 1901-1908.

Advantages of the SERPENTIN include: an odor free doi:10.1002/ceat.200900177

hermetic process and compact treatment facility, high [5] D. M. Muir, “A Review of the Selective Leaching of

precipitation rate of copper and silver (99%) and rela- Gold from Oxidised Copper-Gold Ores with Ammonia-

cyanide and New Insights for Plant Control and Opera-

tively low operation cost, and also the precipitate is a

tion,” Minerals Engineering, Vol. 24, No. 6, 2011, pp.

sellable copper/silver product. However; the main ad- 576-582. doi:10.1016/j.mineng.2010.08.022

vantages of using the SERPENTIN system are: low en-

[6] C. A. Fleming, “Cyanide Recovery,” Developments in

ergy consumption, production of high grade copper sul- Mineral Processing, Vol. 15, 2005, pp. 703-727.

phide precipitate in the range of 40% to 55% of Cu with doi:10.1016/S0167-4528(05)15029-7

130 gr/ton Ag, and recoveries of cyanide of 90%. [7] C. W. Lawr, “Cyanide Regeneration as Practiced by Com-

pañia Beneficiadora de Pachuca,” Mexico Technical Pub-

5. Acknowledgements lication AIME, Vol. 6, No. 208, 1929, pp. 1-37.

[8] J. R. Parga and D. L. Cocke, “Enhance Cyanide Recovery

The authors acknowledge the support of this project to by Using Air-Sparged Hydrocyclone,” Chemical Engi-

Copyright © 2011 SciRes. ACES

J. R. PARGA ET AL. 197

neering and Technology, Vol. 26, No. 4, 2003, pp. 503- Hydrometallurgy, Vol. 104, No. 2, 2010, pp. 222-234.

507. doi:10.1002/ceat.200390075 doi:10.1016/j.hydromet.2010.06.010

[9] Z. M. Shareefdeen, W. Ahmed and A. Aidan, “Kinetics [11] M. Adams, R. Lawrence and M. Bratty, “Biogenic Sul-

and Modeling of H2S Removal in a Novel Biofilter,” Ad- phide for Cyanide Recycle and Copper Recovery in

vances in Chemical Engineering and Science, Vol. 1, No. Gold-Copper Ore Processing,” Minerals Engineering,

2, 2011, pp. 72-76. doi:10.4236/aces.2011.12012 Vol. 21, No. 6, 2008, pp. 509-517.

[10] A. E. Lewis, “Review of Metal Sulphide Precipitation,” doi:10.1016/j.mineng.2008.02.001

Copyright © 2011 SciRes. ACES

You might also like

- Treatment of A Copper-Rich Gold Ore by C PDFDocument11 pagesTreatment of A Copper-Rich Gold Ore by C PDFGeorgi SavovNo ratings yet

- Metallurgy of GoldDocument7 pagesMetallurgy of Goldvenkat_786100% (1)

- Polymetalic FlotationDocument7 pagesPolymetalic FlotationOSCAR FUENTES FLORESNo ratings yet

- Alkaline Sulfide Gold Leaching KineticsDocument9 pagesAlkaline Sulfide Gold Leaching KineticsJoseFidel MatosNo ratings yet

- Chapter 6 General Principles and Processes of Isolation of ElementsDocument11 pagesChapter 6 General Principles and Processes of Isolation of ElementsNAVEEN BUNKARNo ratings yet

- Chapter 6Document9 pagesChapter 6Christeena HenryNo ratings yet

- Application of The SART Process To Heap Leaching of Gold Copper Ores at Maricunga Chile by Kevan J. R. Ford, Chris A. FlemingDocument20 pagesApplication of The SART Process To Heap Leaching of Gold Copper Ores at Maricunga Chile by Kevan J. R. Ford, Chris A. FlemingFerudun AkyolNo ratings yet

- Mercury Control in The Cyanidation of Gold OresDocument14 pagesMercury Control in The Cyanidation of Gold OresarodriguezhNo ratings yet

- Chapter 31 Zinc Cementation 2016 Gold Ore ProcessingDocument8 pagesChapter 31 Zinc Cementation 2016 Gold Ore ProcessingMarioHReyesNo ratings yet

- General Principles and Process of Isolation of ElementDocument3 pagesGeneral Principles and Process of Isolation of ElementAjay WaliaNo ratings yet

- Minerals Engineering: E.A. Oraby, J.J. EksteenDocument8 pagesMinerals Engineering: E.A. Oraby, J.J. EksteenfabianraNo ratings yet

- Removal of Heavy Metals and Cyanide From Gold Mine WastewaterDocument24 pagesRemoval of Heavy Metals and Cyanide From Gold Mine WastewaterHans FandiñoNo ratings yet

- Extractive Separation of Copper and NickDocument5 pagesExtractive Separation of Copper and NickDavid GarciaNo ratings yet

- Stability ConstantDocument9 pagesStability ConstantYasirNo ratings yet

- General Principles and Processes of Isolation Elements: Chapter - 6Document28 pagesGeneral Principles and Processes of Isolation Elements: Chapter - 6Mukul MathurNo ratings yet

- Handout - Gold OreDocument30 pagesHandout - Gold OreHikmal NasutionNo ratings yet

- 12 Finland 181 190 PDFDocument10 pages12 Finland 181 190 PDFuliNo ratings yet

- General PrincipalDocument6 pagesGeneral PrincipalthinkiitNo ratings yet

- General Principles and Process of Isolation of Elements-Anil-hssliveDocument7 pagesGeneral Principles and Process of Isolation of Elements-Anil-hssliveRanit MukherjeeNo ratings yet

- Leaching Kinetics of Low-Grade Copper Ore Containing Calcium-Magnesium Carbonate in Ammonia-Ammonium Sulfate Solution With PersulfateDocument9 pagesLeaching Kinetics of Low-Grade Copper Ore Containing Calcium-Magnesium Carbonate in Ammonia-Ammonium Sulfate Solution With PersulfateSeba DonosoNo ratings yet

- ActiveCarbon ArticleDocument12 pagesActiveCarbon ArticleCristian Cruz SilvaNo ratings yet

- Copper Leaching Behavior From Waste Printed Circuit Board in Ammoniacal Alkaline SolutionDocument5 pagesCopper Leaching Behavior From Waste Printed Circuit Board in Ammoniacal Alkaline SolutionJhon Barzola PalominoNo ratings yet

- Cyanidation of GoldDocument11 pagesCyanidation of GoldBea Christine LedesmaNo ratings yet

- General PrinciplesDocument19 pagesGeneral PrinciplesGovardhan AshokanNo ratings yet

- G7Document21 pagesG7Maame Ama FrempongNo ratings yet

- Electrodialytic Remediation of Copper Mine Ta - 2005 - Journal of Hazardous MateDocument5 pagesElectrodialytic Remediation of Copper Mine Ta - 2005 - Journal of Hazardous MateEnzo GonzalezNo ratings yet

- BKLT 1206-1Document6 pagesBKLT 1206-1Vijay KumarNo ratings yet

- Minerals: Predicting Cyanide Consumption in Gold Leaching: A Kinetic and Thermodynamic Modeling ApproachDocument13 pagesMinerals: Predicting Cyanide Consumption in Gold Leaching: A Kinetic and Thermodynamic Modeling ApproachMollin SiwellaNo ratings yet

- Effect of Silver, Nickel and Copper Cyanides On Gold AdsorptionDocument12 pagesEffect of Silver, Nickel and Copper Cyanides On Gold AdsorptionEduardo CandelaNo ratings yet

- 13.ekstraksi Emas 8-9 Januari 2020Document9 pages13.ekstraksi Emas 8-9 Januari 2020SandhiNo ratings yet

- 55b84355471c1 PDFDocument7 pages55b84355471c1 PDFjuan9gonzalez_9No ratings yet

- General Principles ProcessesDocument19 pagesGeneral Principles ProcessesAnand MurugananthamNo ratings yet

- Cbse Test Paper-01 CLASS - XII CHEMISTRY (General Principles and Processes of Isolation of Elements) (Answers)Document2 pagesCbse Test Paper-01 CLASS - XII CHEMISTRY (General Principles and Processes of Isolation of Elements) (Answers)Shreyash KolekarNo ratings yet

- Minerals Engineering 137 (2019) 232-240Document9 pagesMinerals Engineering 137 (2019) 232-240Tatica Vargas BNo ratings yet

- Extraction MetallurgyDocument123 pagesExtraction MetallurgyRoberto NoriegaNo ratings yet

- General Principle of Isolation Neet MCQDocument10 pagesGeneral Principle of Isolation Neet MCQmanan10jas1529No ratings yet

- Class 12 Chemistry Isolation of ElementsDocument12 pagesClass 12 Chemistry Isolation of ElementsTabithaDsouzaNo ratings yet

- DPP 02 Chemical Bonding JH Sir-4165Document28 pagesDPP 02 Chemical Bonding JH Sir-4165Prabhakar BandaruNo ratings yet

- Extraction Metallurgy C B Perry 123sDocument123 pagesExtraction Metallurgy C B Perry 123smtanaydinNo ratings yet

- Chile Conference - Thesis - Lapshin - 25 05 EngDocument13 pagesChile Conference - Thesis - Lapshin - 25 05 EngНикита КравченкоNo ratings yet

- Issues of Gold Extraction Using CyanideDocument2 pagesIssues of Gold Extraction Using Cyanideabdoamer.2553No ratings yet

- Heavier Elements (Metallurgy)Document34 pagesHeavier Elements (Metallurgy)Natish JaglanNo ratings yet

- Leaching ProcessesDocument65 pagesLeaching ProcessesSegundo Colorado VillarNo ratings yet

- Issues of Gold Extraction Using CyanideDocument2 pagesIssues of Gold Extraction Using CyanideTingwe PoulNo ratings yet

- Recovery of Gold and Silver and Removal of Copper, Zinc and Lead Ions in Pregnant and Barren Cyanide SolutionsDocument14 pagesRecovery of Gold and Silver and Removal of Copper, Zinc and Lead Ions in Pregnant and Barren Cyanide SolutionsArief RHNo ratings yet

- Cbse Test Paper-04 CLASS - XII CHEMISTRY (General Principles and Processes of Isolation of Elements) (Answers)Document2 pagesCbse Test Paper-04 CLASS - XII CHEMISTRY (General Principles and Processes of Isolation of Elements) (Answers)Shreyash KolekarNo ratings yet

- The Mechanism of Gold Cyanide of Elution From Activated CarbonDocument2 pagesThe Mechanism of Gold Cyanide of Elution From Activated CarbonwandadwilestariNo ratings yet

- The Mechanism of Gold Cyanide of Elution From Activated CarbonDocument10 pagesThe Mechanism of Gold Cyanide of Elution From Activated CarbonDiegoNo ratings yet

- Tratamiento de Un Cobre - Mena de Oro Rica Por Amoníaco Asistió A Lixiviación de CianuroDocument10 pagesTratamiento de Un Cobre - Mena de Oro Rica Por Amoníaco Asistió A Lixiviación de CianuroMetalurgista SosNo ratings yet

- General Principles and Processes of Isolation of Elements: (I) Concentration of The Ore: Removal of UnwantedDocument17 pagesGeneral Principles and Processes of Isolation of Elements: (I) Concentration of The Ore: Removal of UnwantedPriyankaNo ratings yet

- Characterization of Refractory Behaviour of Complex Gold/silver Ore by Diagnostic LeachingDocument7 pagesCharacterization of Refractory Behaviour of Complex Gold/silver Ore by Diagnostic Leachingdavid mNo ratings yet

- 14 - Panayotova Panayotov - Vtori DokladDocument9 pages14 - Panayotova Panayotov - Vtori DokladGeorgi SavovNo ratings yet

- CH 6Document11 pagesCH 6Tr Mazhar PunjabiNo ratings yet

- Leaching Laterite PDFDocument5 pagesLeaching Laterite PDFMuhammadKhabirNo ratings yet

- Introduction To Hydrometallurgy - UI - Lecture NotesDocument20 pagesIntroduction To Hydrometallurgy - UI - Lecture NotesOkky Intan50% (2)

- Extraction Metallurgy: Part 2: Case StudiesDocument132 pagesExtraction Metallurgy: Part 2: Case Studiesalborz99No ratings yet

- Treatment of Pyritic Matrix Gold SilverDocument6 pagesTreatment of Pyritic Matrix Gold SilverMarcelino Vargas QueaNo ratings yet

- Jeffrey 2001Document8 pagesJeffrey 2001david mNo ratings yet

- A Comparative Study of Gold Refractoriness by The Application of QEMSCAN and Diagnostic Leach ProcessDocument12 pagesA Comparative Study of Gold Refractoriness by The Application of QEMSCAN and Diagnostic Leach ProcessLuis CañariNo ratings yet

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesFrom EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesRating: 5 out of 5 stars5/5 (1)

- 1051 Water Applied AdditivesDocument7 pages1051 Water Applied AdditiveselmonemNo ratings yet

- Research Paper1Document8 pagesResearch Paper1elmonemNo ratings yet

- Acsomega 8b00413Document14 pagesAcsomega 8b00413elmonemNo ratings yet

- Zhejiang University: Seeking Truth, Pursuing InnovationDocument18 pagesZhejiang University: Seeking Truth, Pursuing InnovationelmonemNo ratings yet

- Introduction To Mineral Processing 2010Document24 pagesIntroduction To Mineral Processing 2010elmonemNo ratings yet

- ml18 Chapter-31 UsaDocument11 pagesml18 Chapter-31 UsaelmonemNo ratings yet

- Acacia ReactorDocument11 pagesAcacia ReactorelmonemNo ratings yet

- 1057 FinalDocument10 pages1057 FinalelmonemNo ratings yet

- 9701 w16 QP 53Document12 pages9701 w16 QP 53Ahmed AttaNo ratings yet

- The Future of FansDocument88 pagesThe Future of Fansdman200No ratings yet

- 2 Heat of PrecipitationDocument9 pages2 Heat of PrecipitationPew LingNo ratings yet

- Chem - Rev-WS-01Document4 pagesChem - Rev-WS-01DhivegaNo ratings yet

- EAS Corporate PresentationDocument14 pagesEAS Corporate PresentationMukhlis OemarNo ratings yet

- Chem Review CH 8, 9, 10, 11Document2 pagesChem Review CH 8, 9, 10, 11eherrerahghsNo ratings yet

- 31 E23 D 01Document5 pages31 E23 D 01Alou JacintoNo ratings yet

- M - ENG - DIS v1.1Document96 pagesM - ENG - DIS v1.1Ahmed Emad Ahmed100% (1)

- GOC AllenDocument27 pagesGOC AllenAshish RanjanNo ratings yet

- Illustrated Silver Gold Plated KitchedwareDocument140 pagesIllustrated Silver Gold Plated Kitchedwaredoggydog100% (1)

- 2007 Effect of Alloying Elements and Tarnishing EffectsDocument15 pages2007 Effect of Alloying Elements and Tarnishing EffectsmarcosNo ratings yet

- Chemical EquationsDocument10 pagesChemical Equationsme-elormNo ratings yet

- Sample PaperDocument13 pagesSample PaperDeAdKiLler 075No ratings yet

- Analyse Organic and Inorganic Unknowns WORDDocument5 pagesAnalyse Organic and Inorganic Unknowns WORDcydney mackenzieNo ratings yet

- Class 8 THDocument9 pagesClass 8 THSuman SainiNo ratings yet

- 0620 w16 QP 21Document20 pages0620 w16 QP 21Jia RuNo ratings yet

- CookBook 10Document42 pagesCookBook 10Le HuyNo ratings yet

- MCQ Questions For Class 10 Science Chemical Reactions and Equations With AnswersDocument12 pagesMCQ Questions For Class 10 Science Chemical Reactions and Equations With AnswersNadim BashirNo ratings yet

- Mettler Toledo Electrodes2007Document100 pagesMettler Toledo Electrodes2007Ninit MiyuNo ratings yet

- Dictionary of American History 3rd Vol 03 PDFDocument583 pagesDictionary of American History 3rd Vol 03 PDFa100% (1)

- Millar 2017Document54 pagesMillar 2017Krishna DangiNo ratings yet

- Binary Ionic Naming and FormulasDocument4 pagesBinary Ionic Naming and FormulasRania AbdellatifNo ratings yet

- Counterfeit Studios and Their Coins HandDocument88 pagesCounterfeit Studios and Their Coins HandSteven FernandezNo ratings yet

- Professional Jewelry MakingDocument29 pagesProfessional Jewelry MakingChristian Stämpfli52% (23)

- The Chemistry of PhotographyDocument416 pagesThe Chemistry of PhotographyBoris Yershov100% (5)

- Brosur - Vacuum DistillationDocument12 pagesBrosur - Vacuum DistillationAde SatriaNo ratings yet

- Electroplating and ElectrorefiningDocument694 pagesElectroplating and ElectrorefiningAFLAC ............100% (1)

- Age Work Mixture Digit Motion ProblemsDocument23 pagesAge Work Mixture Digit Motion ProblemsEunice GonzalesNo ratings yet

- Balancing Word Equations PracticeDocument3 pagesBalancing Word Equations PracticemmNo ratings yet

- CH 3 Chemical Reaction WorksheetDocument19 pagesCH 3 Chemical Reaction WorksheetStephanus AbednegoNo ratings yet