Professional Documents

Culture Documents

Safety Program Prosperidad

Safety Program Prosperidad

Uploaded by

GAhr Ceredon0 ratings0% found this document useful (0 votes)

17 views36 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views36 pagesSafety Program Prosperidad

Safety Program Prosperidad

Uploaded by

GAhr CeredonCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 36

L&L CONSTRUCTION

CONSTRUCTION SAFETY AND HEALTH

PROGRAM

NHA-PROSPERIDAD DREAM VILLAGE,

Purok 28, Poblacion, Prosperidad, Agusan del Sur

| DOLE-CARAGA |

Submitted to:

CHONA M. MANTILLA, CESO Ill

Regional Director

Department of Labor and Employment

Caraga Region

L & L CONSTRUCT ION

Li MAIN OFFICE: Tukuran BRANCH OFFICE: Zone-1, near IS. Kauswagan

CONSTRUCTION Zamboanga del Sur Cagayan de Oro city

= = Tel no. 880-2721

landiconst@ymail-com

August 4, 2017

CHONA M. MANTILLA, CESO Ili

Regional Director

Department of Labor and Employment

Caraga Regional Office

J, Rosales Ave., Butuan City

Dear Atty. Mantilla:

Greetings!

We are pleased to submit herewith our Construction Safety and Health Program for NHA-

PROSPERIDAD DREAM VILLAGE at Purok 28, Poblacion, Prosperidad, Agusan del Sur for your

approval. This is in compliance to DOLE Department Order No. 13, Guidelines Governing Occupational

Safety and Health in the Construction Industry and the Occupational Safety and Health Standards of

the Philippines.

We hope you would find the attachment in order.

STATEMENT OF COMMITMENT

WE the L&L CONSTRUCTION by accomplishing this Construction Safety and Health Program do hereby

commit and bind ourselves to comply with the requirements of the Department Order No. 13, series of

1998 — Guidelines Governing Occupational Safety and Health in the Construction Industry and the

applicable provisions of the Occupational Safety and Health Standards (OSHS).

We also acknowledge our obligation and responsibilities to provide throughout the course of the project

the appropriate Personal Protective Equipment (PPE) as added protection for our workers and employees.

We also hereby commit to implement the necessary job safety and health instructions and training to all

our workers for the entire duration of the project, as well as the safety of the general public.

L&L CONSTRUCTION

Represented by:

/6\VISAYA

d Area Manager

RHE

A

Department of labor and Employment APPLICATION FORM for APPROVAL OF

REGIONAL OFFICE NO. XIII-CAPAGA] eousTRUCTION SAFETY AND HEALTH PROGRAM

| OSH Personnel assigned to the project

— n = +, emt

Name of Appointed Safety Officer/s: Name of Appointed First-Aider/s:

DEBORAH E. BULAHAN

Date of his/her BOSH training: MAY 5-9, 2014 | Date of First Aid Training:

{Pis. attach photo copy of Certificate of Completion on the Validity of 1D:

Basic OSH Course for Construction Site Safety Officers issued

by DOLE-BWC accredited Safety Training Organizations or (Pis. attach photo copy of Certificate of First-Aid Training

recognized institutions) and Valid First Aider ID from PNRC

Other OH personnel (If more than 50 workers will be depl

Name

Date of BUSH Training

OH Nurse |

OH Physician |

—

Dentist |

(if Heavy Equipment will be used in the Project)

List of Heavy Equipment to be Used in the Project | Name of Heavy Equipment Operator/s (To attach photo

(Please attach additional sheet, if necessary) copy of skills certification from TESDA)

|

Profile of the person who prepared the CSH Program for the abovementioned Project:

Name and Signatui Educational Background:

BACHELOR OF SCIENCE IN CIVIL ENGINEERING

| Work Experience in OSH: |

Signaiure over printed name 7 YEARS |

Other Qualifications:

| HEREBY CERTIFY ON MY HONOR TO THE TRUTHFULLNESS OF THE AROVFMENTIONFD

INFORMATION. THE COMPANY HEREBY COMMIT TO STRICTLY IMPLEMENT THE ATTACHED

CONSTRUCTION SAFETY and HEALTH PROGRAM DESIGNED FOR THE ABOVEMENTIONED PROJECT.

Submitted By: ‘

\

A

Signature Quer Printed Name _MA- ZENFTH\L. PAMA

t

\

Position, _PKOPRITUK/MANAGER \

Date: SEPTEMBER 14, 2017 ~~

Meavinest Fara: CSHP-DO 13-98

Revised Torn. CSHP-OG 15-30

Date of Revision: June1, 2014 Page 3 of 3

COMPANY PROFILE

Name of Establishment: Land L_ CONSTRUCTION

Address: Near LS, Kauswagan, Cagayan de Oro City

~ Telephone / Fax Number: 088) 880-2721

Proprietress / Manager: = MA. ZENITH L. PAMA

_ Number of Years in Business: 20 years

Nature of Business: CONSTRUCTION

Number of Employees: 20

2 regular (1) Female (1) Male

18 Contractual

i a) Male; 11

b} Female: |

~Name and Address of Labor Union: None

BIR Registration Number: 135-989-934

Technical Information:

a.} Machinery : (1) Single Bagger ¢ ~oncrete Mixer, (1 Tile Cutter, (1) Electric Bar Culter,

(1) Electric Grinder. (1) Welding Machine. (1) Concrete Vibrator. (1) Plate Compactor,

a (1) Air Compressor, (1) Water Pump (1) Cutting Ouffit, (1) Rooter, (1) Pipe Jointing Machine

b.) Materials Handling Equipment : (1) Forward Dump Truck,

| hereby certify that the above information is true and correct.

Approved By:

l. COMPANY POLICY

Providing safe working conditions and maintaining continuity of employment is of critical concern for

— the management of L and L Construction. Thus it's imporlang that adequate policies and procedures be

developed and adhered to in order to'ensure safe, efficient operating conditions for the employees of Land L

Construction. Safety rules shall be strictly observed ai alll times. Although these rules are fo be considered very

important, it is Impossible to publish a rule that covers every circumstance. If a rule that might cover a specific

__ hazardous condition has been omitted, that shall not be an excuse for disregard of common sense in the safe

performance of the work. The possession of consumption of alcohol, drugs or any other controlled substance is

agains! company policy and violators are subject to suction (this will be elaborately discussed below). Each

_temployee is urged to cooperate fully with the company policy. Abuse or disregard of this policy is a violation

and will be treated accordingly. L and L Construction Is focused on aiming for zero accidents.

i. PROJECT DESCRIPTION

Pavey Yee erreeee

a. Name of Project: Ref. No. 2016 - 014 NHA- Properidad Dream Village

Housing Project located at Purok 18 Poblacion,

= Prosperidad, Agusan Del Sur

b. Location of Project : Pyrok 18 Poblacion, Prosperidad, Agusan Del Sur

c. Project Classification : Building

d. Project Owner : NHA - National Housing Authority

e. Name of Contractor : Land L Construction

f. Estimated Start: ape pe

g. Project.Duration:: 120 Calendar Days

Q. Estimated no. of Workers : 20 workers including staff, skilled and unskilled

- h. Contract Amount: - P10,855,610.64

he Ht ESTIMATED SAFETY BUDGET PER EMPLOYEE

It is a major concem for L and | Construction fo allot a budget for the implementation of the

_ safety and health of the employees in the company, while it is under contract with this project. The

company have estimated that 3 percent of the contract amount be used for the employees safety and

health.

IV. SAFETY ANND HEALTH COMMITTEE

SAFETY ANND FEA Eee

= Safety and accident prevention is believed to be everyone's responsibility in our company. Each

employee is expected to follow all company rules and to pérform their work in safe manner. The project

Vv.

SITE SAFETY AND PERSONNEL

As required by Department Order No. 13s. 1998 of the DOLE/WC our company

—appointed a Safety Officer which have undergone the required 40 hrs. training on “Consiruction Safety and

Healih Course foe Site Safety Officer” see attached certification.

A First Alder was also appointed based on the workers as per D.O 13, duly certified by the Philippine

—National Red Cross, See attached Certification.

1, PROJECT MANAGER

Has overall responsibility for the company's safely and health program and regularly reaffirms

support for loss control activities.

Insures that all employees are informed of top management commitment io safety and the

abidance of the department of labor.

Establish company safety rules and programs, and provides supervision with the backing training

and funds to implement these rules and program.

Sef a good example.

— 2, ENGINEERS AND FOREMAN

Be aware of the requirements of the Project Safety Plan, Safe Construction Methodologies, and

safely procedures relevant to the individual's specific area of responsibility.

Plan and maintain a tidy and orderly work place such that work can be carried out with minimal

tisk to health and safety.

Ensure that work is carried out as planned and regularly inspect all work areas to ensure the

safety of all activities, equipment and materials in his area of responsibility.

Ensure that other, including the general public, are protected.

Incorporate safety instructions into routine orders and ensure that workers are not required or

permitted to take unnecessary risk.

Respond to the recommendations of the Project Safety Adviser.

Encourage those who perform safety and reprimand those who do not.

Set a good example

3. PROJECT SAFETY OFFICER

Serves as Secretary to the safety health commitiee

Prepare minutes of meetings

Report status of recommendations made

Notify members of the meetings; and

Subrnit the employer a report of the activities .of the committee, including recommendations

made.

Acts in an advisory capacity on all matters pertaining to health and safety for the guidance of

the employer and the workers

Conduct investigation of accidents as member of the Health and Safety Committee and

submits his separate report and analysis of accidents to the employer

* Coordinates all health and safety training program for the employees and employer

e Conduct health and safety inspection as member of the committee

« ‘Maintains or helps in the maintenance of an efficient accident record system and coordinates

actions laken by supervisors to eliminate accident causes.

* Provides assisiance of government agencies in the conduct of safety and health inspection,

accident investigation or any other related programs

e For purposes of effectiveness in a workplace where full-time safety man is required, he shall

report directly to the employer

4, EMPLOYEES

e Attends orientation, toolbox talks, and safety meetings as required.

« Use the right tools for every job and keep them in good condiilon.

e Use the safety equipment and protective clothing supplied

* Avoid taking shortcuts that may lead io unnecessary risk.

e Report any defects at the site, in equipment or any other safety hazard.

¢ Comply with all rules

® Participate in safety program and cooperates actively with the Health and Safety Committee

e Assist government agencies in fhe conduct of health and safety inspection or other program.

VI. ON-SITE SAFETY AND HEALTH AWARENESS AND LEARNING

{t is important that all the employees are aware of the hazards in the work place therefore

Safety Knowledge, atilfude, skills and habits at all levels of the project workforce shall be promoted,

naintained and enhanced b y regular and continuing safety training and learning which are promoted in the

“following manner.

1. Safety Orientation

New workers will be required to attend a Safety Orientation course that is organized by the safety officer

visual presentations is the best way to penetrate the awareness of the new recruits before they are deployed in

“the work place. They will be issued a card that proves the completion of the orientation; a new worker will be

given site ID card. He will then be learning which are promoted in the following manner.

~ Induction seminar of workers will also include the company safety health policy, project clinic

procedures, and the company code of employee discipline. The seminar will be participated by the project

surse or safety officer or first aider and the project administrative officer of his representatives.

2. Tool Box Talks

a Toolbox meetings are essential to provide a forum to discuss Items of safety relevant to the project and

permit an opportunity for open communication between employees and supervisors on the project. Safety

talks will be scheduled on every Monday morning not more that 20minutes to voice out concerns in the work

“place. Such talks will be caried out by the supervisors (project engineer and foreman) with the assistance of

the safety officer.

MEMBERS OF THE TOOL BOX IN THE PARTICULAR PROJECT SHALL BE COMPOSED OF:

- The project Engineer

- Material Engineer

- The Safety Officer

- The Foreman

- (8) Mason Workers

- (4) Carpenters

- (2) Steel Men

- {1} Plumber

- (1) Electrician

- {8} Laborers

3. Safety Seminars for Supervisors and Engineers

The PIC or the project safety officer will arrange safety course for supervisors and engineers. The

seminar shall reinforce the responsibility of supervisors and engineers for their worker's safety and welfare.

= Vil. SAFETY PROMOTION

Safety Promotions involves three steps: preparation, presentation and commitment. Preparation is when

_ the company evaluates the hazards and risks of the job and how the employees do the work. The

company research and observe the job or task determine the safety precautions that apply to the

work, and target the safety efforts to address ihese precautions. Presentation is the use of the job

knowledge to convince the worker of the need for safety. Commitment is when ihe accidents are cut

down due fo fhe preparation and presentation of the safety precautions in doing the work.

1. REQUIREMENTS

a. Safety must be included in the job instruction

b, Safety Bulletin and Posier

Put posters in places where workers linger or sland in line, or entrances and exists. However,

make sure you place them in appropriate areas. Place a poster the use of safety belts, lockers or near an exit

rather than in ihe messy areas. Posters must be clear and simple, if must have bold color to give emphasis and

fo ensure that even from a distance it can be seen, Bulletin boards must be big enough fo catch the attention

of the workers.

2, RESPONSIBILITIES

* Project supervisors shall include the safety aspects when they give job instruction to ihelr workers.

« The project supervisors and the safety officer shall be responsible for ihe conirol of pasting and

the upkeep of their bulletin boards .

e The safety officer shall provide posters and othey safety information materials for the bulletin

boards. ee

— Vill.

ACCEDENT / UNCIDENT INVESTIGATION AND REP G

In compliance fo rule 1054 of the OSHS of DOLE, records of accident and illness shall be kept

_and maintained open at all times for inspection by authorized personnel. All accidents and downgrading

incidents shall be thoroughly investigated to. find the root causes. Measurers to prevent recurrence of the

ccident/incident tend to be more effective if targeted to the root causes; otherwise, treating the symptoms

vould just increase the waste of resources.

An immediate investigation will be completed by crew supervision, foreman. The investigalion process

jall be supervised by the project manager and project safety officer.

3

REQUIREMENTS

The Incident/Accident Investigation Report Form should be used; we can use the forms from the

OSHS manual.

All accident/incident shall be reported on the standard form by the supervisor.

High potential accidents and near-accidents shall be reported fo the attention of upper levels of

management to assure full investigation and action by appropriate authorities.

The safety officer shall ensure that all corective actions listed for major high-potential loss accideni

are implemented.

MAJOR LOSS ANNOUNCEMENTS

Summaries of vital information on major personne! accidents must be wrillen and promptly

submitted to the PIC.

Prompt summaries of major property loss or damage and fires must be written and circulaied fo the

PIC,

These reports must contain key information pictures must be taken to documents the hazard and to

prevent such hazards to occur.

CONTENTS

The project manager will report in writing to the general manager. A narrative of the accident

etails and what was done or is being done io prevent the hazard. This written report may be preceded by a

elephone call for possible representation of the general manager. The narrative report will include ihe

following information;

«Injured employee(s) name(s}, occupation. length of employment, age, sex, date and time of

accident.

» Description of accident; detail of what the employee was doing and what tools, equipment,

structures or fixtures were involved.

e Nature of injuries and iliness

¢ Accident causes that contriouted fo the incident

e Steps to be taken to see that this is done

e Provide a detailed skeich, if needed to explain ine accident scene.

Photograph shall accompany the written report for seriaus accident which results to lost time injury.

After the’ conduct of investigation, the employer thru the project safety officer shall submit a report io

DOLE Regional Office on or before 20'" of Ihe month following the date of occurence of accident using

the DOLE/BWC/HSD-IP-6 form.

4, RECORDKEEPING PROCEDURES

The first aid personnel/company nurse with the assistance of the project safety officer must maintain a

variety of records for protection of the employees, the company and client.

1. First Aid Log

This is a chronological listing of all visits to the clinic or first aid station. Every injury illness reported, no

matter how slight mus! be recorded. A copy of the logbook and necessary forms shall be provided fo

the clinic or first aid station.

2. Individual Medial Record

This is a confidential record of the employee's illness and injuries reported to the clinic or first aid station.

The first aider is responsible for keeping the medical record of every employee in the site. Al the end of

the month, he/she shall submit to the project manager and project safety officer a summary report of

all cases treated in the clinic.

IX. PROTECTION OF THE GENERAL PUBLIC

To avoid hazard to the general public L and L Construction give emphasis on ihe placement of

the warning signs and barricades if needed a guard to ensure the safety of the general public. We

believe that in doing so not only is the company protecting the people but if also prevents possible law

sulls to unsuspecting victims.

1, REQUIREMENTS

@. Standard warning signs, traffic signs and barricades shall be installed as required by the government

regulations and by the OSHS for building projects.

b. Safety nets, inverted umbrella and covered walkway shall be Installed as required to protect the

public from falling debris. .

c. Signs, barricades and other safeguards installed shall be protected from misuse, abuse, damage or

interference. .

2. RESPONSIBILITIES

a. The project manager shall anticipate the project needs and order the preparation the required

devices.

b. Ihe project engineer shall install barricades, and safety nets as required by the project. They shall

also protect these devices and public safeguards from misuse, abuse, damage or interference.

1.

c. The project in charge shall strictly enforce the assignment of qualified personnel to do certain jobs

as stated above.

d. The project safety officer shall conduct daily inspection of the installed safeguard.

CONSTRUCTION SAFETY PRACTICES

EXCAVATION

Excavation is defined as making a depression or cavity in the earth's surface including the removal of

—previously installed roadways, slabs or foundations af and below the surrounding ground level. The

principal hazards associated with excavation are:

Suffocation, crushing or other injury from falling material.

Damage/failure of insialled underground services and consequent hazards.

Tripping. slipping or falling.

Possibility of explosive, flammable, toxic or oxygen-deficient atmosphere in excavation.

“Prior to starting excavation, proceed as follows:

2:

Determine the presence and location of any underground oil, chemical or gas.

Areas to be excavated shall be identified and segregated by means of baricades,

ropes and/or signs to prevent access of unauthorized personnel and equipment.

Suitable means shall be provided to make baniers visible at all times.

Provide means of diverting surface water from excavation.

Sloping, shoring or bracing that may be required to stabilize the soil shall be designed

by a competent engineer and installed as designed. Special aitention shall be paid to

bracing design when ihe excavation is near operating equipment.

CONCRETE. FORMWORK AND SHORING

Some of the hazards associated with concrete installations are:

* Failure of inadequately designed/installed forgns and shoring.

Awkward confined workspace while forming and placing.

Rebars, wire mesh and tie wire pose puncture and culling hazards.

Falling or flying concrete and gunite while placing.

—Pre-siressed concrete includes use of exposed steel bars or strands with much latent energy.

Safety for the installation of a finished concrete structure starts with its design. A competent engineer

should design the formwork for all structures requiring the use of shoring and for large pours to.be

made at and below ground level.

Provide adequate bearing capacity, {a function of soil conditions), for formwork

vertical support members.

Provide bracing of formwork lateral for loads fo be imposed during form erection and

the pour. .

Provide support for and anchor reinforcing steel as if is installed.

Sequence of form erection should minimize exposure of workmen to installed

reinforcing steel. Provide covers as required to prevent possible impalement or cutting

by workers by exposed steel.

Adequate work platform with guardrails should be provided for workmen during form

erection. Use safety belts when platforms cannot be provided.

For placing concrete in approved forms:

Provide adequate means of access for equipment and men to be used for placing and

finishing concrete.

If buckets are used for pour, riding the bucket is prohibifed.

Electric powered trowels, floats and vibrators shall be double insulated or grounded for

operator protection.

For gunite work, head and face protections must be used by nozzle men.

Eye protection is required for labor crews placing concrete.

—emoval of forms and shores should follow approved scheme of the Structural Designer. All nails,

exposed tie wires, efc. are to be removed or bent over as forms are removed. Form materials shall be

yeatly stacked for reuse or disposal.

3. SCAFFOLDING AND LADDERS

iii.

iv.

The major hazards associated with the use of scaffolding and ladders are falling

men, material or tools.

Scaffolding are generally classified by the loading of work platforms as light,

medium or heavy duty with design platform loading of 25{122), 50(224) and 75(366)

psf (kg/m2), respectively:

The following requiraments are applicable to all scaffold work platforms.

A guardrail shall enclose all working platforms more than 10 ft. (3m) above ground or

floor level. Guardrail shall be located 42 in. (1,050 mm} above platform.

Work platform shall be completely decked with no opening.

Adequate access to each work platform shall be provided. If ladders are used they

shall be securely tied to scaffolding.

Planks shall be fastened/secured and kept clean.

AS applicable, continuous scaffolding is io be tied and secured fo structure being

scaffolded at 25 ft. intervals horizontally and 25 ft. vertically.

— v. All materials used for scaffolding shall be periodically inspected to confirm condition

satisfactory for continued use.

vi. Suitable footing shall be provided to prevent uneven setilement and loading of

= vertical support for scaffolding.

vil. If adjusting screws are used, they shall be installed only at baseplates. They shall

never be used on scaffolds with casters.

viii, © When erecting using rolling scaffolds, casters shall be locked in position. Personnel

are not permitted on rolling scaffold while it is being moved. Any tool or material on

scaffold to be moved shall be secured.

ix. Straight or extension ladders shall be used at an angle of about 75 degrees with the

horizonial (4 fo | rise) with the top extending at least 3 ft. (700 mm) above the point

of fop support and securely tied at that point.

x. Personnel shall have both hands unencumbered when climbing ladder. All climbing

and descending shall be done facing the ladder.

xi. Metal ladders shall not be used in the vicinity of electrical equipment or circuits.

xii. When using stepladder considerations should be given to tying off or holding to

stabilize. :

xiii. Scaffolds must be plumb and level at all times.

xiv.

4. WELDING, BURNING AND CUTTING

The major hazards associated with burning and welding operations are:

= -@ Heat and fire

e Electrical shock

e Toxic gases and fumes

» Intense light, ultraviolet or infrared rays

e Restricted visibility while working

it

i

“Proper care of welding and buming equipment is a requisite for minimizing hazards.

» All gas cylinders shall have their contents clearly labeled.

e Gas cylinders shall always be stored, transported, used and secured in an upright

position. Valve keys must be on cylinder when in use.

e Gas hoses shall be regularly checked for abrasion, cuts, leaky joinis or other damage.

Welding cable shall be similarly checked for external damage and for properly

connected and insulated joints. In running hoses and cables to work, preferably they

should be located overhead. If not possible, ahd particularly in heavy traffic areas,

protective cover should be provided when run on the ground.

a} Never use grease or oil on equipment (cylinders, hoses and torches} handling

oxygen

b) Oxygen shall nat be used for ventilation or cooling, blowing dust or cleaning

work. .

c) Frames of electric welding machines are fo be grounded.

In preparing for welding and burning, it shall be ensured that:

a} Sparks or molten metal will not fall on people or combustible materials particularly from

work at elevated location. /

b] Work screened or isolated to preclude exposure of adjacent workmen to welding flash

c] Work is properly grounded for electric welding. Pipe containing oil, gas or other

combustible material and conduits and structures for electricity transmissions shall not

be used for grounds.

d) Fire extinguisher is available within 50 ft (15 m) of work. For work al elevated location or

in confined space, extinguisher shall be at work locations.

e] Work location is adequately ventilated for welding or burning materials containing zinc,

lead, cadmium, chromium or beryllium, respirators or fresh air masks are required for

poorly ventilated ar confined workspace.

_ f|_ Work pieces shall be properly supported for the operation to be done

Nhile doing the work, welders and burners must use the personal protective equipment required for

_he job. Normally this will include tinted eye protection, which greatly restricts the user's visibility. For

this reason, thorough preparation for the job is important before starting ihe work, Hand or power

ools are frequently used in conjunction with welding.and burning operations requiring additional

protective equipment.

— 5, HAND AND POWER TOOLS

‘he hazards associate with the use of hand and power tools are:

® Failure or disintegration of tool.

e Proximity to moving or cutting parts of tool

e Flying particles from tool and work

» Heat and sparks

e &Glectrical shock

e Crushing or pinching

_Tools that are right for the job, in safe condition and used properly will provide productivity as well as

safe work conditions.

« Wood handles on tools shall be free of splinters, cracks and solidly attached to their working

heads.

_ Electric powered tools shall be double insulated or properly grounded. Electric cords shall be

maintained free of cuts, abrasion and kinks. Cords shall not be used for hoisting tools.

e Tools with exposed moving parts shall be provided with guards fo minimize exposure of tool

= operator. ,

» All powered tools shall be stopped and as applicable, air or electric supply disconnected, lo

make any adjustments to tool. Fuel powered tools shall be shut down for refueling.

e impact-type (percussion) fools shall have suitable relainers to hold tool bits in place during

operation.

e Extension or leverage increasers shall not be used on tool handles.

» Tools with “mushroomed” striking faces shall be used. If these faces are to be dressed, tool

shall be inspected for cracks and proper temper restore before reusing.

s “Deac-man” controls on tools so equipped shall not be rendered ineffective.

s The rated grinding wheel and cutting blade speed shall be compatible with the speed and

power capability of the driving shaft.

« All fools shall be regularly inspected, repaired and lubricated as required fo maintain them ina

safe condilion.

« Power-actuated tools shall include safety features that minimize possibilily of accidental firing.

These tools are to be handles and treated as firearms with strict control of cartridges, and shall

be used only by qualified operators.

* Personal protective equipment requirements for each type of fool shall be established and

enforced. 5

e Air hoses and electric cords leading to tools at work area shall be located or covered to

protect them from external mgchanical damage. \

6. MATERIALS HANDLING

the hazards associated with materials handling are:

e Falling or moving material and equipment.

e Pinching or crushing.

e Cuts, punctures and abrasions.

e = Strains.

Proper storage will reduce potential for damage and assist in the safe handling of materials.

* Material shall be stored to provide access for men and equipment when handling and

moving, Aisles and access ways shall be kepi free.

® Material shall be stored off the ground by use of pallets, chocks or dunnage.

» Flammable or combustible materials shall be segregated and potential hazards identified.

Suitable fire protection equipment shall be provided at storage areas for combustible

materials and potential sources of ignition shall be restricted from jhese areas.

Mobile equipment is frequently used for handling materials.

* When moving, material sho__ e secured to the vehicle. .

¢ During transportation any overhanging material shall be tagged or marked for easy visibility.

— * For heavy or bulky material, routes of movements shall be checked for clearance and load

carrying adequacy.

* Passengers are not permitted to ride on material handling equipment.

Uncrating of material poses hazards.

* Care must be exercised in removing straps or bands by using the proper tools and protective

equipment.

e When dismantling wooden crates, nails shall be removed or bent over and lumber neatly

stacked for disposal.

7. INDUSTRIAL MOBILE EQUIPMENT

Inherent wilh the use of productive mobile equipment are the many potential hazards that can result

from:

e A large mass in motion.

e Possible malfunction of the equipment.

e Response of operator to constantly changing condifjons.

eee

Prior to work assignment on any pieces of equipment, all operators shall be given the necessary

instructions, practice time, and tested by a competent observer for capability to operate the

equipment safety.

Prior to starting work each day, operator shall check proper functioning and condition of hom, lights,

tires, brakes (service and emergency), windshields, mirrors and make a visual and operational check

of engine and functional devices of the equioment. Any defects shall be rectified of logged for

correction as judged necessary by the operator or his supervisor.

“All equipment shall be periodically inspected and serviced by a competent mechanic. Records of

this maintenance shall be kept for each piece of equipment.

The load capacity and any operational restriction for each piece of equipment shall be posted at

the operator's station. As applicable, the capacity and requirements for any equipment to transport

dersonnel shall be posted also.

Safe means of access to operator's station shall be provided on each piece of equipment.

_?ermanently mounted fire extinguishers shall be provicled on alll industrial mobile equipment.

The engine shall be shut down and parking brake set each time.

e The equipment is being refueled.

* Any maintenance work is being performed.

* The operator leaves his station tor any reason.

Any load exiending beyond the confines of the equipment shall be marked or lagged for easy

visibilily.

—Loading of container-type equipment shall be limited io a capacity that will avoid spillage along the

route of travel.

“When operator's visibility is restricted in direction of travel, or when working in a congested or

confined space, a signalman on the ground with clear visibility shall direct the movement of the

2quipment.

For best control, mobile equipment shall always be operated in gear, i.e., never “coast” downhill.

‘Nhen equipment is shut down with any reason and at the end of the workday all appurtenances

uch as blades, buckels, fork hooks shall be grounded or placed in their lowest position.

“In areas of heavy traffic or congestion, it may be desirable to install traffic signs to control the

novement of vehicles as well as baricades to restrict fodt traffic. (Note: a fatality could occur if a

_vorker walks out from behind a truck and be run over.) Condition and capability of roads or routes of

travel for mobile equipment shall be ascertained prior to starting work. Weather will affect these

conditions, and they shall be rechecked as appropriate.

8. ELECTRICITY

he major hazards of electricily are electrical shock and the accompanying possibility of death. Fatal

electrical shock can be sustained with volfages of 120 or less with current as low as 50 — 200 mill

imperes. These numbers indicale that care must be exercised with any work utilizing electricity since

me hazard is present over the range of currents and voltages in service at construction site. Because

the distribution system is temporary and because of conditions inherent with a construction site -

nuch activity, many people, water and dust - care in the layout and installations of the temporary

‘electrical system is required.

e The major source and distribution equipment (generators, transformers and switch racks} shall

- be isolated by fences or in building with access restricted to authorized personnel only.

e All temporary circuits at the construction site shall be grounded with the ground circuit

having a resistance no greater than 25 ohms.

« All circuits shall be provided with fuses or circuit breakers sized to prevent overloading of the

wire and equipment in the circuit.

e All non-current carrying metal frames or containers of electrical equipment shall be

grounded.

e The conductors for the temporary electrical distribution system shall be located to minimize

/possible external damage and/or contacts by people and equipment. Conduits or

— protective covering may be required in areas of heavy traffic or congestion. Only qualified

electricians shall do any alteration or extension to the system.

« The use of a 12-valt temporary lighting system is recommended for work inside towers, vessels

= or other confined moist or dusty areas.

A tag and lock oul procedure shall be established or subslations with energized buses, barriers shall

~ be provided and identification signs installed to segregate workers from “live” equipment.

All portable electric powered tools shall be grounded or double insulated. Cords for these tools shall

be run and located to minimize possible damage to cord. Cords shall not be used for hoisting tools.

Where more than-one voltage level is in service at a site, each receptacle shall have its voltage

_ Identified.

9. PAINTING Y

“The hazards associated with painting are:

e Toxic Fumes

e Flammable materials

e Falls

— « Dust and Flying particles

?ainting frequently includes the use of toxic and/or flammable materials. Prior to starting work,

workmen shall be made aware of the hazards of the materials they are using and the protective

equipment required. When using flammable or combustible materials in confined spaces, adequate

ventilation must be provided. Respiratory equipment shall be used as the conditions and materials

‘dictate.

aurlace preparation for painting can present a variety of hazards dependent on ihe method used.

— e When solvent cleaning, the toxic and combustion characteristics of the solvent shall be

determined, and appropriate protection provided.

e When mechanical cleaning, such as chipping, scraping or wire brushing, an eye protection is

mandatory.

e If sandblasting is done, workmen doing the work shall be equipped with fresh air masks with

the source of air supply monitored for suitability for breathing purposes. Eye protection is

required for those doing the blasting and other persons exposed in the area.

® During any surface preparation involving the use of heat or fire, fire extinguishers shall be

located within 25 ft. (7.5m) of the work.

he use of safely belts or safely hamesses is mandatory for all work than 10 ff (3m) above grade,

_vhich is not done from a fixed platform with guardrails.

_ Pressurized spray guns are frequently used for paint application.

e [f spray printing is done in an enclosed area, adequate ventilation and/or means of safely

exhausting fumes must be provided.

* Spray gun nozzle shall be grounded to minimize possibility of static electricity build-up and

discharge.

— e Care must be exercised in the use of spray equipment employing high pressure. Trigger guards

shall be provided on these sprays.

~ 10. MASONRY

_The hazards associate with masonry and insulation are: | 4

® Dust and fumes sO

« Cuts, abrasions and punctures

e Falling Materials

e Personnel falls

For work at an elevated location, in addition to having a work platform with guardrails, care shall be

exercised to insure that materials to be handled do not exceed allowable scaffold loading. Bricks

and blocks shall be neatly stacked. They shall be passed by hand, not thrown, when moving.

Hand and eye protection shall be worn when installing wire mesh and sheet metal that requires

cutting and/or trimming. Eye protection shall be worn when shaping bricks with hand tools.

When mixing and installing mortar or insulating cement mixes, protective equipment shall be used as

ndicated by the material supplier.

When cutting brick with a power saw, dust shall be controlled, preferably by use of an exhaust hood.

Dust may also controlled by wetting the brick and/or providing baniers to limit dispersion. Operator

~shall wear eye and face protection while cutling and respiratory equipment if exposed to dust.

3asic safety practices forbid to use of any installation containing asbestos.

Excess scrap materials must be promptly cleaned up and disposed of at least daily.

11. HOUSEKEEPING

« Inherent with good housekeeping is the elimination of many hazards that could result in falls,

trips, cuts, fires and many other potential accidents. Good housekeeping is a visible

advertisement and promotion of safe working conditions.

12. SAFETY SIGNS a

Containers for trash and debris shall be deployed throughout the site. Schedule of pick-up and

disposal of trash shall be sel fo prevent overfilling containers and large accumulations at any

location.

It work restricts traffic on roads, barricades to divert traffic shall be used. Similarly, clear

walkways for access to site shall be maintained. Hosed and electric cords shall be laid to

minimize road and walkway crossings. Where necessary, these shall be run overhead, or

provided with protective covering if run at ground level.

Clean up is a part of every job to be done. Excess and scrap materials shall be stored when

not in use. Working platforms on long-standing scaffolds shall be periodically cleaned of debris

if

~ Safety signs should be provided in order fo wam the workers and the public of hazards existing in the

workplace. It shall be posted in the appropriate areas, strategic locations and should be

_understandable. The size should conform with the OSHS manual and same wilh color. All signage's

should be kep! clean and be inspected regularly. It should be in good condition, damage signages

should be removed or replace.

_ Signage's shall include but not limited to the following.

The use of personal protective equipment.

Areas where there are potential risk of falling and falling objects

Areas where explosives and flammable substance are stored

Areas where there are tripping and slipping hazards

Place of electrical facility or equipment

Places where dangerous moving parts of machinery

Location of fire alarms and firefighting equipment

Periodic updating of man-hours lost

XI. ENVIRONMENTAL CONTROL PLAN

Waste in the work place poses a great threat to the environment, in the construction site

however

waste could not be avoided but it can be minimize thru recycling or even good housekeeping

therefore it is essential to create environmental control plan not only will it minimize the waste it could

also minimize the expense as well.

. RESPONSIBILITIES

. The project manager shall be responsible for the implementation of this environmental control

plan.

. The project manager ensures that after the work is done all waste in the work site must be

collected and properly disposed of.

_ The project manager shall ensure that the plan conforms to the project risk assessment done

for the project.

. The project safely officer shall assist the PIC in the implementation of this plan. He shall

conduct daily inspection of the sife fo identify non-compliance with this plan and to

determine other hazards and concerns not identified by previous risk assessment and hazard

analysis. . it

‘

. HAZARDS AND ENVIRONMENTAL CONCERNS

e Dust

e« Noise

e Exhaust Emission

e Muddy Roads

_ SPECIFIC CONTROL MEASURES

a, DUST

Sprinkle dry ground wilh water

Place gravel around field office areas

Implement site speed limit at 20 kph or as required by the owner for all vehicles

b. NOISE

Mount equipment so that vibration will be reduced

Position equioment as further away from the field offices and active areas as practicable

Install muffler to exhaust systems of machines and equipment

Provide ear protection for workers exposed fo noise

c. EXHAUST EMISSION

Direct exhaust of stationary equipment away from the work areas and field offices

Position machine or equipment in open areas

Do not run any gas or diesel engine inside confined spaces

Implement preventive maintenance schedule

d. MUDDY ROADS

Provide tire washing facilities near exil gate

Require all outgoing vehicles to wash tires before going out to the project

. MONITORING

. The project manager shall require strict monitoring of compliance with the requirements of this

environmental control plan.

. The projeci safety officer shall continuously monitor on-site conditions; detect changes and

new hazards not previously identified in this plan. He shall require immediate actions fo control

= the hazardous conditions or where there is need for using such equipment to reduce the

hazard fo the employees. . 1

+

o Xl. PERSONAL PROTECTIVE EQUIPMENT

All employees are required to wear appropriate personal protective equipment in all operations

—where there is exposure lo hazardous conditions or where there is need for using such equipment to

reduce the hazard to the employees.

Once issued, it is the responsibility of the employee to see that the issued PPE's are maintained in safe

condition and inspecied daily.

— 1, MINIMIUM REQUIREMENTS

e Safety Helmet

Safety Shoes

Pants (trouser) maong. No worn out pants

Long sleeve T-shirt

2. GUIDELINES IN THE USE OF P.P.E.S.

in providing safe working conditions, the use of personal protective equipment is the last line of

defense against possible injury. If musi be recognized that the use of personal protective equipment

requently reduces or restricts some of our normal senses that contribute to our safety awareness, for

~ example.

e Wearing safety glasses with side shields, goggles or tinted goggles restricts normal vision.

e Earmuffs or plugs equipment frequenily restrict vision

e Wearing gloves reduces the sense of feel

e The discomfort of wearing many protective items is detracting to users

a. HEAD PROTECTION

secause of the danger of falling or flying material or impact with fixed or moving objects, the

wearing of non-conducting safety hats throughout the construction site are normally mandatory.

~ b. EYE AND FACE PROTECTION

xposure to airborne physical, chemical or radiation agents that could injure the eyes or face

Tequires protection. Refer io Rule 1082 of the OSHS. At each construction site consideration should be

aiven lo mandatory eye protection for certain areas or the entire site if conditions warrant and eye

juries will be reduced. Contact lenses do not constitute eye protection and actually pose a hazard

7O the user in some situations. Consequently, their use on site is strongly discouraged.

i%

= c. RESPIRATORY PROTECTION

‘ 1

4

Physical or chemical contaminants in the air that are harmful if ingested by breathing and/or possible

—oxygen deficiency require the use of respiratory equipment. This equipment that fits over the nose,

nose and mouth, or entire face can be broadly classified by its intended function.

~The suppliers of canisters and filters identify them for the types of environment they are effective in

and limit their use. These instructions must be observed for proper protection.

~ Anybody excepted to use fresh air masks in the course of their work shall be given training and

‘oractice in the proper methods of wearing and operating this equipment. —

d. HEARING PROTECTION

__digh noise levels pose the long range health hazard of loss of hearing to exposed workers. Permissible

noise exposures are given in table 8b of the OSHS, because of the changing activities and conditions,

xeriodic monitoring for the noise levels throughout the construction site are required. When noise

_evels above permissible level are observed, the preferred course of action is io control or isolate the

noise source thus reducing it to a permissible level for exposed workers. If it is impractical to do this,

rearing protection shall be provided for exposed employees. Earmuffs or plugs of material designed

__or sound muffing shall be used.

e. BODY PROTECTION

For most works in a construction site, work clothing that covers the body, legs and arm is adequate.

Norkers that are exposed to heat, sparks or molten metal should be aware that some clothing

materials are more flammable than others, i.e. some synthetic fibers ignite and burn more readily

than natural cloth fibers. Suits or aprons suitable for the exposure fo extreme heat, toxic chemicals, or

~ 1cids shall be provided if work conditions require.

f. FOOT PROTECTION

“Tt is advisable for all workers on a construction site to wear safety shoes because of the many hazards

axposing feet to injury in-addition, used of boots may be required when works is in water or feet are

_2xposed to chemical or acids.

g. HAND PROTECTION

“Various types of gloves shall be available and used to protect the hands from cuts, abrasions and

sunctures, sparks, heat, cold and molten metal; contact with electricity and exposure to toxic

~hemical and acids.

materials shall be restricted, and sources of ignition forbidden in the area. As these

materials are removed from storage for use, the precautions required to prevent ignition for

each type of materials shall be observed.

c. Sources of fire ignition exist throughout a construction site with welding, flame burning,

grinding, heaters and exhaust from engines or sparks from electrical equipment.

= Scheduling shall minimize work with combustible materials in the vicinity of ignition sources.

When this is impractical, fire protection equipment shall be provided and consideration

given to providing a fire watchman to initiate action should a fire occur when the fire

_ hazard is large.

d. Only approved containers should be used to store or transport fuel.

e. Fuel storage tanks, hoses, etc. should be grounded

f. No smoking rules must be established and enforced without exception

g. Fire extinguishers should be available to all welders

= h. Fire drills should be considered especially if ihe project is in or near an existing operating

facility.

2. FIRE PROTECTION JNSTALLED

First aid/fire fighter equipment shall consist primarily of portable fire extinguishers. Refer to Rule

1944.05 of the OSHS. Extinguishers to be permanently mounted shall have their location clearly

marked and be accessible at all times. The necessary instructions for using extinguishers shall be given

© all personnel who may be required to use them,

XVII FIRST AID & HEALTH CARE MEDICINE, EQUIPMENT FACILITIES

The first aid station or clinic should consists the following equipment and medicines as a

requirement of D.O. 13. :

e Equipments

Washing Area

First Aid Cabinet

Stretcher

Examining Table and Chair

a First Aid Pamphlet

y Cotton

« Dressing Pads

4464

¥ Gauze pads, finger size

v ‘Gauze swabs, medium size

vy Gauge swabs, large

¥ Adhesive dressing

vo

Eye pads

e Plasiers

— e Bandages

« Eyewash solution

e Thermometer

« Stethoscope

e Spygmomanometer

e Safety pins

Medicines for the station should be taken from Table 47 of the OSHS manual based on the number of

workers, And it should be noted for hazardous and non-hazardous workplace.

XVIII. WORKERS WELFARE FACILITIES

1. Adequate toilet, washroom and change facilities shall be provided for the work force

2. Portability of drinking water used on the site shall be checked regularly. Coniainer for drinking

water shall be identified for that use only, tightly covered when in use and not user for any

purpose.

3. If eating facilities are provided on site, sanitary conditions shall be monitored periodically.

Garbage shall be kept in sealed containers and should be disposed daily.

4. Control of vermin, pests and insects is required if they pose a hazard to health of workers while

on the site.

5. A temporary bunkhouse for the workers, this will serve as a temporary shelter complete with

lockers, storing of personal belonging of worker.

XIX. PROPOSED HOURS OF WORK AND REST BREAKS

The work schedule will be from Mondays to Saturdays, 8:00 am - 5:00pm, with 15 minutes break

in the morning and afternoon and one (1) hour break for lunch.

~ XX. | CONSTRUCTION WASTE DISPOSAL

1, OIL LEAKS AND SPILLAGE

e implement proper storage and handling of fuel and lubricants

‘

e Provide oil catch or drip trays.

e Clean up immediately any spillage and leak

e Utilize only equipment in good condition, Disallow entry of equipment with leaks into the

project

e Deploy fire extinguisher in fuel and oil storage areas

2. GARBAGE

¢ Designated garbage collection area

e Clean up the site daily

e Dispose garbage off site regularly and frequently

« Disallow eating in the work areas

e Designate mess hall area away from the work areas

XXI. EMERGENCY ACTION PLAN

The objectives of this Emergency Action Plan are:

e To ensure readiness to cope with emergency that may result in the loss of life and property.

* To be able io effectively carry out an orderly, timely and safe evacuation of all personnel in

affected areas of the emergency when necessary

¢ To prevent further injuries/casualties, and more damage to properly in times of disasters, or

natural calamities

« To facilitate first aid response to an injured worker and immediate access to Emergency Room

facilities or first aid station.

1. EMERGENCY PROCEDURE

should emergency occur, the Project manager on site shall.

e Immediately secure the area and implement the emergency action plan. According to the

situation, the person in charge will delegate authority and assure the safety of those

responding.

e Ensure notification of the project safety officer.

« Provide information regarding the emergency to rescue personnel and project management

representative only. Question from the press and media will refer to the project management.

After the project, dismantling and demolition of temporary structure, scaffold, temporary

electrical wiring, transport of heavy equipment must be under the supervision of a competent

person and the project safety officer. It must be accordance with OSHS manual and D.O 13

especially for heavy equipment.

‘

XXII. JOB HAZRD ANALYSIS

The objective of job hazard analysis is to develop a preliminary hazard analysis on work

operations as fo their potential for injury, property damage or both. Once potential hazards have

been identified, procedures can be developed to eliminate or mitigate their potential for

occurrence.

Land L CONSTRUCTION shall conduct tool box meeting every moming for 20minutes, they will

identify hazard in every scope of work and give corrective action in order to avoid accidents.

1, BENEFITS

- e Potential for injury property damages could be prevented and eliminated

e Identified hazards could be used as a tool in the foresight of schedule activities

e Necessary safety precautions could be planned

e Job procedures and consiruction methods could be adjusted or improved

* Provides training

e Increase awareness

e Ensures the employees thal their safety is one of our concems which will give them

encouragement to use their common sense in while in the working area

* Eliminate cost or possible law suits due to the accident that has occurred

* Eliminates the possibility that there might be delays in the construction project due to the

injuries that has happed to the worker.

XXIII. PENALTIES AND REWARDS

1. REWARD

L AND L Construction have less than50 employees therefore we propose that the reward in our

—zompany is recognition. The praject manager shall post poster that recognize the employee with

“NO” accidents during the project duration if he has been recognize in 3 consecutive projects then

ris miscellaneous budget will then be rewarded to him.

2. PENALTIES / SANCTIONS

—Description of offenses violation of any safety rules, regulations and general practices promulgated

by the project and/or the company.

~ Direct Action on the Offense:

i

'

1. Failure to wear Personal Protective Equipment at construction site or where specified

A. Safely Helmet and Safety Shoes

First offense — Verbal reprimand

Second Offense ~ 5 pesos salary deduction

Third Offense — 10 pesos salary deduction

se and so on ----------

Eye and Face Protector

Spectacles ~ Required for steelmen and those engage in chipping works

Goggles ~ Required for welding works

Dusk Mask — Required for cement handling and housekeeping operations

Respirator — Required in confines areas (cleaning of tanks etc.) painting, handling chemicals

especially toxic matter

First offense — Verbal reprimand

Second Offense — 5 pesos salary deduction

Third Offense ~ 10 pesos salary deduction

mannnnee and so on —--------

c. Safety belt and Life Lines - Required for employees doing above éff. that has a great

danger for falling (ex. Perimeter of building being constructed, column and rebars

installation, formworks, plastering works outside the building painting crane installations and

repair and other that may be required by the project safety engineer:

First offense — Verbal reprimand

Second Offense — 5 pesos salary deduction

Third Offense - 10 pesos salary deduction

aa and so on ------=--

d, Ear Muff — required for employees engaged in usual noise exposures such as generator

tending, heliports, tinsmith work (air conduct assembly).

First offense —- Verbal reprimand

Second Offense — 5 pesos salary deduction

Third Offense — 10 pesos salary deduction

sre GN SOON we \

e. Rain Boots [Rubber boots) - required for employee engage in masonry works especially

those belonging to pauring and concreting crew those assigned in dewatering works and

ihose operation that-wearing of safety shoes in unlikely deterrent.

First offense — Verbal reprimand

Second Offense - 5 pesos salary deduction

Third Offense - 10 pesos salary deduction

sear — and so on --—---—-

f. Rain Coat --required: during rainy season ( a must for all employees working at active

level/floor) site supervisors may opted to send the workers home (discretion of site

operations).

First offense — Verbal reprimand

Second Offense — 5 pesos salary déduction

Third Offense — 10 pesos salary deduction

—------- and so on --------

g. Hand Gloves - required for those employees engaged in material handling, steelworks,

welding operations, tinsmith and chipping works.

First offense — Verbal reprimand

Second Offense — 5 pesos salary deduction

Third Offense — 10 pesos salary deduction

. Smoking at Restricted Area

First offense - Verbal reprimand

Second Offense - 5 pesos salary deduction

Third Offense — 10 pesos salary deduction

-—-——- and so on +---------

. Unauthorized used/tinkering playing of fire fighting equipments

First Offense -Verbal reprimand

Second offense - Dismissal

. Driving under the influence of Liquor that result into a vehicular accident

First Offense — Dismissal

. Failure to report his/her pergonal accident (work lLonneeted within 24 hours at the project

clinic

and/or advise his/her immediate superior.

First Offense — the cost of his personal accident will be charges to his salary

---QNd SO ON----------

. Failure fo observe the 20 KPH speed limit at the construction site

First Offense -Verbal reprimand

Second offense - dismissal

Deliberate removal/tampering of safety signs and foster including traffic signs on site

(Unauthorized).

First Offense -Salary deduction to the cost of sign

Second offense - Dismissal

Unhygienic Practice (Urinating, removal or vowel elsewhere on sile other that the prescribed

area}

First Offense ~Clean the area where he is doing his act

Second offense - Verbal reprimand

Third Offense — Dismissal

Tampering of electrical wiring connection and fuse boxes (breaker)

First Offense —Verbal reprimand

Second offense - Dismissal

. Allowing other workers/employees to ride in heavy equipment other that the operator and

outside cab of vehicles.

Driver shall given ;

First offense - Dismissal

OHSO woInssiG eaqnoexa

(fd

‘Wl OS39 ‘GIN ‘ooanong fife

“oul OL ys

py “WIN Vd “Sl

“yL0% AeWso Aepyg siuj uenls

OLO

I O39 * OVIN IN NWTY ALLY

vLOz ‘6-G Aew uo Aud 019 ag ueAeBed ‘AemyBiy UeBemsney

BZE}d [EOSIN OIPSWA JO SU} IE pjay ‘SANOY OF JOL

SULUWAT, AJafog uoljonssuo)

eu payejduuas Aljnysseoans Burney JO}

ueyeing "3 yeioqeq

wongegyuog) fo

siyj pueme

‘OU ‘OL DHOMION UZTBOH pure Ajajesg yeuotednso9

pue

OF “ON B31 feuo!Bey 3700

yum uore1edooo Ul :

491089 YYESH pue Ajoses peuonedns90 /

LNAWAOIdINA ONY YOdVT dO LNAINL Yd

saulddiiud eur Jo ayjandey

Os Jomo ef one

NO FEES REQUIRED FOR THE FILING, EVALUATION AND APPROVAL OF CSHP

Revised Form.: CSHP-DO13-98:

Date of Revision: June1, 2011 Page 1of3

REVISED APPLICATION FORM for

ve Department of Labor and Employment EVALUATION/ APPROVAL OF

ex a.

REGIONAL OFFICE NO. XIII-CARAGA | CONSTRUCTION SAFETY & HEALTH

PROGRAM (CSHP)

Legal Basis: Section 5 of Department Order No. 13 s 1998

(Guidelines Governing Occupational Safety and Health In Construction Industry)

Instructions: This form shall be duly accomplished and submitted by the MAIN/GENERAL

CONTRACTOR in applying for an approval of a Construction Safety and Health Program intended for

a specific construction project.

Note: A CHECKLIST OF REQUIREMENTS shall be used in receiving the application.

Only an application form with complete requirements and attachments will be processed,

Application found with incomplete requirements will be given 15 calendar days to comply. Failure to

comply within the prescribed period, the application will be deemed disapproved.

A. Company Profile/License/Registration of Main/General Contractor

Complete Name of the Company/ Complete Address:

Main /General Contractor ZONE 1, KAUSWAGAN, CAGAYAN DE ORO CITY

L&L CONSTRUCTION Tel. No: 880-2721

Fax No. (088) 880-2721

Name of Project Manager/Contact Person: Email:

MA. ZENITH L. PAMA landlconst .bo@gmail.com

= aa 20

Main Contractor PCAB License Main Contractor Total employment

No._15108 __._-Male_18 Female _2

Date of Validity:

DOLE Registration of Main Contractor ( Pls. attach photo copy of Registration forms received and approved by

the concerned DOLE Regional Office)

Date Reaistered/Approved DOLE-RO-

a. per DO 18-02 (requires yearly renewal)

b. per Rule 1020, OSHS (one time registration) December 6, 2014 RO No. 10

Sub-contractors’ Profile/License

No. of PCAB | Validity Date of

Name of Sub-contractors (If , any) Scope of Work and Workers | License Date DOLE

Project Cost Registration

———

1. N/A

: = a a

33

q |

5:

(Use separate sheet, if necessary) 7

A. REVISED APPLICATION FORM for

f%, Department of Labor and Employment | EVALUATION! APPROVAL OF

Ww ¥. REGIONAL OFFICE NO. 4: !1-CARAGA | CONSTRUCTION SAFETY & HEALTH

y : PROGRAM (CSHP)

8. Project Profile/Description

Name of the Project: (Please attach copy of invitation to Bid/other documents indicating name and details of the

pigject)

NHA-PROSPERIDAD DREAM VILLAGE

Complete Project Address/Location

PUROK 28, POBLACION, PROSPERIDAD, AGUSAN DEL SUR

Name of Project Owner

| Tel. No:

1

NATIONAL HOUSING AUTHORITY | Fax No:

Email :

Project Classification: Date of Estimated Start/Execution of

Estimated No. of Workers to | the project:

LAND DEVELOPMENT be deployed in the project: -SUNE 17 2017

Month Day Year

| 20 WORKERS

Duration of the project (Pls.

state the number of calendar days

Total Project Cost,_P_10,855,610.64 | (Workforce of the project to

include workers of the sub-

192 C.D.

Descrishon of Aste

Bescripusn oF Ach

1al sheet, if necessary)

Bret

MAJOR ACTIVITIES FOR THIS PROJECT INCLUDES BU NOT LIMITED TO:

-EARTHWORKS

-ROADWORKS

-DRAINAGE SYSTEM

WATER SUPPLY overrm

ee

“pacer over overs {DOLE-CARAGA

APPROVED

CERT.NO BAS Se |

DATED: —-——

Revised Form.: CSHP-DO 13-98

Date of Revision: Junei, 2014 Page 2of 3

ms A. PROJECT DESCRIPTION

Specific Name of Project

Location of Project

Scone of Wort

Project Owner

Name of Contractor

Total Project Cost

8. NAME OF PROJECT-IN-CHARGE £

C. SsTinzaven NUMBER OF WORKERS :;

= D. START-UP DATE :

E. PROJECT DURATION 3

NHA-PROSPERIDAD DREAM VILLAGE

PUROK 28, POBLACION, PROSPERIDAD. AGUSAN DEI cur

LAND DEVELOPMENT

NATIONAL HOUSING AUTHORITY

L&L CONSTRUCTION

P 10,855,610.64

ENGR. LOCHINBAR R, BULAHAN

20 WORKERS INCLUDING STAFF, SKILLED AND UNSKILLED

Juz | 17, 2017

192 CALENDAR DAYS

F. ESTIMATED NUMBER OF HEAVY EQUIPMENT

|

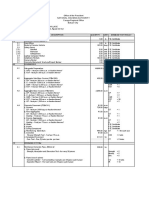

Table 47 of medicines

Topical antiseptic

Eyewash

1 70% isopropyl Alcohol |

Analgesic

Antipretic tablet

Antihistamine

Antacid

Anti-diarrhea

1 Anti-nvpertinsive i

Guaze bandage, roli

Adhesive tape

Cotton

Anti-asthma

TOTAL 21,555.00

1.00 | 50.00

40.00 2.00

40.00 1.00

40.00 2.50

40.00 1.50

40.00 2.00

STATEMENT OF COMMITMENT

\/WE the L&L CONSTRUCTION by accomplishing this Construction Safety and Health Program do hereby

commit and bind ourselves to comply with the requirements of the Department Order No. 13, series of

1998 — Guidelines Governing Occupational Safety and Health in the Construction Industry and the

applicable provisions of the Occupational Safety and Health Standards (OSHS).

We also acknowledge our obligation and responsibilities to provide throughout the course of the project

the appropriate Personal Protective Equipment (PPE) as added protection for our workers and employees.

We also hereby commit to implement the necessary job safety and health instructions and training to all

our workers for the entire duration of the project, as well as the safety of the general public.

L&L CONSTRUCTION

Represented by:

VG\VISAYA

d Area Manager

RHE,

Auth

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Construction Estimate by RN TolarbaDocument77 pagesConstruction Estimate by RN TolarbaGAhr Ceredon100% (1)

- Construction Estimate by RN TolarbaDocument77 pagesConstruction Estimate by RN TolarbaGAhr Ceredon100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Ref - Construction P2P RoadshowDocument83 pagesRef - Construction P2P RoadshowGAhr CeredonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Binder 1Document20 pagesBinder 1GAhr CeredonNo ratings yet

- QCP Dream VillageDocument3 pagesQCP Dream VillageGAhr CeredonNo ratings yet

- Annex A - Technical SpecificationsDocument50 pagesAnnex A - Technical SpecificationsGAhr CeredonNo ratings yet

- Productivity 7-17-14Document23 pagesProductivity 7-17-14GAhr CeredonNo ratings yet

- Citp Final - For ExcavationDocument39 pagesCitp Final - For ExcavationGAhr CeredonNo ratings yet

- 21dj0020 PowDocument47 pages21dj0020 PowGAhr CeredonNo ratings yet

- 21DJ0005 PowDocument51 pages21DJ0005 PowGAhr CeredonNo ratings yet

- ACAP FactorDocument2 pagesACAP FactorGAhr CeredonNo ratings yet

- Manpower Productivity Rate For ConstructionDocument10 pagesManpower Productivity Rate For ConstructionGAhr CeredonNo ratings yet