Professional Documents

Culture Documents

2 Response Surface Optimization of Dye Removal Using Waste Prawn Shells

2 Response Surface Optimization of Dye Removal Using Waste Prawn Shells

Uploaded by

saiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Response Surface Optimization of Dye Removal Using Waste Prawn Shells

2 Response Surface Optimization of Dye Removal Using Waste Prawn Shells

Uploaded by

saiCopyright:

Available Formats

International Journal of Chemical Sciences and Applications ISSN 0976-2590.

Vol 2, Issue 3, 2011, pp 186-193 http://www.bipublication.com

RESPONSE SURFACE OPTIMIZATION OF DYE REMOVAL BY USING

WASTE PRAWN SHELLS

Narayana Saibaba K.V1 , P. King2, R. Gopinadh3, V. Sreelakshmi4

1,2 Environmental Pollution Control Engineering Laboratory, Department of Chemical Engineering, Andhra

University, Visakhapatnam -530003, Andhra Pradesh, India.

3,4 Bioprocess Engineering Laboratory, Department of Biotechnology, GIT, GITAM University, Visakhapatnam -

530453, Andhra Pradesh, India.

ABSTRACT

A simple, highly efficient, locally and abundantly available, adsorbent was studied for removing dyes from synthetic

industrial effluents. Experiments were conducted to study the efficiency of carbon prepared from waste prawn

shells for removal of crystal violet (CV). The effect of various process parameters such as temperature, initial pH,

contact time, adsorbent dosage and initial dye concentration of the solution were studied by running batch

experiments in Erlenmeyer flasks. Response Surface Methodology was used to optimize the process parameters.

ANOVA analysis was also studied to know the interaction effect of dye and adsorbent.

Key Words: Response Surface Methodology; Optimization; Prawn Shell Waste; Crystal Violet; Dye; ANOVA

1. INTRODUCTION filtration, etc. are generally expensive and also

Dyes are extensively used in textile, plastic, produces large amount of sludge; disposal of

leather, food, paper, cosmetics and which creates environmental problem. Hence,

pharmaceutical industries. Effluents from such biosorption is used in this study which is simple,

industries are important sources of color efficient, easy to run and cheap [8-10].

pollution. Dyes present in water streams do not Researchers investigated the feasibility of using

allow the passage of light through them and various materials as adsorbents such as orange

cause damage to the aquatic life. Disposal of peel, bentonite clay, bamboo dust, coconut shell,

dyes into water streams cause skin allergies, wheat bran etc. But still there is a need to

cancer and eye irritation in human beings. develop cheap and effective biosorbent [11-17].

Among the various frequently used dyes crystal In this study, activated carbon prepared from

violet(CV) is important one which is used as prawn shell waste (PAC) was used as sorbent for

biological stain, finger printing, veterinary the removal of crystal violet dye from synthetic

medicine, poultry feed additive, dying and industrial effluent. The various experimental

paper industries. Crystal Violet dye also causes parameters affecting the dye removal process

mutagenic effects to human being hence it needs such as temperature, initial pH, contact time,

to be removed before discharging into water adsorbent dosage and initial dye concentration

bodies [1-7]. of the solution were also studied.

Dyes in waste water are easily detectable and Designing of experiment and standardization of

difficult to remove as they are not easily variables affecting the system is very critical in

biodegradable, stable to oxidizing agents and optimization process. Generally this

light. Normal methods of dye removal such as optimization is carried out by using traditional

flocculation, precipitation, coagulation and one factor at a time method, which is simple,

RESPONSE SURFACE OPTIMIZATION OF DYE REMOVAL BY USING WASTE PRAWN SHELLS

time and chemicals are consumed in large Appropriate amounts of adsorbent were added to

quantities. Moreover this method neglects the the flasks and placed in orbital shaker for

interaction effects of process variables. Hence, appropriate times at 120 rpm speed. Solutions

in the present study statistical approach such as pH’s were maintained at different values by

Response Surface Methodology (RSM) was using 0.1N HCl and 0.1N NaOH.

adopted to study the correlation among the Concentrations of dye were measured by using

process variables affecting the process and to UV-Vis Spectrophotometer at a wavelength of

optimize the process variables to give higher 590 nm.

color removal [18-27].

2. MATERIALS AND METHODS: The percentage removal of color from solution

2.1 Chemicals and Materials was calculated as

The chemical HCl and NaOH used in this study % Removal of CV = = * 100

were purchased from lotus enterprises,

visakhapatnam, India. Analytical Grade Crystal Where, Ci and Cf are the initial and final

violet (mol. formula C25H30ClN3, mol. wt. concentrations of the CV dye in liquid, mg/l.

407.99, λmax =590 nm) was procured from Fisher 2.4 Experimental Design and Data Analysis

Scientific. All the solutions were prepared by

using deionized water in this study. The effect of various process parameters such as

The prawn waste was collected from the fish temperature (x1), pH (x2), time (x3), adsorbent

market at poorna market, Visakhapatnam, dosage (x4) and initial dye concentration (x5) on

Andhra Pradesh, India. The waste prawn color removal was studied by using half fraction

material was subjected to shell removal by hand factorial Central Composite Design (CCD). A

and washed thoroughly with demonized water CCD with 32 experiments was used for the

till no color is observed in effluent. This optimization of process parameters for removal

material was dried in sunlight for one day and of CV dye from synthetic industrial effluent

grounded to powder using roll crusher. The solution. All independent variables were coded

crushed prawn shell powder was placed in to five levels as Xi according to equation-1.

muffle furnace at the temperature of 5000C for 5 Xi = , i = 1,2,3,……k ------------ (1)

hours. Then it was screened to different particle

sizes by using sieve shaker. The prawn shell

Where Xi is independent variable, xi is the real

powder retained on the mesh no-52 is collected

value of an independent variable, xoi is the real

as used as adsorbent through out in this study.

value of the independent variable at the centre

point, and ∆xi is the step change. A polynomial

2.3 Experimental procedure

(Equation-2) was developed to estimate the

behavior of the percentage removal of color.

The Crystal Violet stock solution was prepared

by dissolving 1000mg of CV dye in 1000 ml of

Y = β0 + iXi + ijXiXj +

deionized water in volumetric flask. Different

2

concentrations for CV dye (50 ppm -150 ppm) iiXi -----------------------(2)

were prepared by diluting the stock solution with

appropriate amounts of deionized water and Where Y is the response, β0 was the intercept

stored in volumetric flasks. Different term, β i were linear effects, β ij were the squared

concentrations of dye solutions of 50 ml ranging effects and βij w-ere the interacting effects.

from 50ppm-150ppm were transferred

separately to different Erlenmeyer flasks. 3. RESULTS AND DISCUSSION

Narayana Saibaba K.V, et al. 187

RESPONSE SURFACE OPTIMIZATION OF DYE REMOVAL BY USING WASTE PRAWN SHELLS

The statistical analysis of the experimental It is noticed from the figure-1that percentage

results shows that percentage of dye removal removal of CV has increased significantly with

was a function of temperature, pH, time, increased adsorbent dosage up to 0.6 g however,

adsorbent dosage and initial dye concentration beyond the dosage of 0.6 g changes in

of the solution. The levels of independent percentage removal of CV was marginal. This is

process variables used in a Central Composite in accordance with the reports available on other

Design and the design matrix used with the dye removal processes [24, 29]. The percentage

observed responses obtained were shown in removal of CV dye increased slightly up to the

table -1 &2. Responses shown in table-2 were concentration of 100 ppm after that removal

the average values of three replicates for all the again decreased as shown in figure. This might

experimental runs. be due to the non availability of active sites on

The main effects of all parameters on percentage the adsorbent surface [30].

dye removal were determined and shown in ANOVA gives the information about quadratic

figure -1. A plot of temperature versus and interaction effects along with the normal

percentage removal of CV shows that the linearised effects of the parameters.

percentage removal of dye increased with Model was developed from ANOVA to

increased temperature up to 300C and thereafter represent the effect of above parameters on

it showed a decrease in percentage dye removal. percentage removal of crystal violet dye and was

This might be due the exothermic nature of the shown in equation-3.

process. At higher temperatures low percentage

removal efficiency might be due to desorption of Y1 = - 640.427 + 28.169X1 - 18.601 X2 +

adsorbed dye particles from the adsorbent 4.737X3 + 146.959X4 + 2.791X5 - 0.434

surface. Similar temperature effects were X12 + 1.729X22 - 0.009X32 -

obtained with other adsorbents also [28]. The 100.261X4 - 0.009X52 + 0.227X1X2 -

2

effect of pH on CV removal was studied in the 0.072X1X3 + 4.283X1X4 -0.024X1X5 +

range of pH 2-12. It is apparent from the figure 0.032X2X3 -13.699X2X4 - 0.064X2X5 -

-1 that percentage removal was decreased with 1.339X3X4 - 0.006X3X5 + 0.648X4X5 ------

increased pH and reached minimum at pH range ------ (3)

of 4.5 to 9.5. At normal pH values electrostatic

repulsion between protonated PAC and crystal Experimental data along with the predicted

violet dye might result lower removal results obtained from the above model were

efficiencies where as at higher pH conditions shown in table-2. The proposed model was

electrostatic attraction between CAC and basic evaluated by regression coefficients, standard

dye may be resulted higher efficiencies. Similar error, t-values, p-values and correlation

observations were noticed for biosorption of CV coefficient (R). The model indicates that the

from aqueous solution [8, 25]. Percentage adsorbent dose, temperature and pH had a strong

removal of dye was increased with time up to effect; linear and quadratic terms had more

52.5 minutes beyond that the change in influence in comparison to the interaction terms.

percentage dye removal was slower. This might From the tale-3 it is clear that all parameters

be due to the fact that increased time allowed the effects were significant at 95% confidence

particles to reach equilibrium hence, removal levels. Here, the value of correlation coefficient

efficiency was increased. These results agree (R= 0.999), R2 ( 0.999) indicates a high

with the results obtained by other researches on agreement between the experimental and

dye removal [9,13]. predicted values and its significance. The model

adequacy was tested by using ANOVA (Table-

Narayana Saibaba K.V, et al. 188

RESPONSE SURFACE OPTIMIZATION OF DYE REMOVAL BY USING WASTE PRAWN SHELLS

4). Lower P values for regression model REFERENCES

equation imply that the second-order polynomial [1] C. Pradeep Sekhar, S. Kalidhasan, Vidya Rajesh,

model fitted to the experimental results well. N. Rajesh (2209). Bio-polymer adsorbent for the

removal of malachite green from aqueous

The graphical representations of the regression

solution. Chemosphere, 77: 842-847.

equation (3) were shown by the 3D response [2] Ali Riza Dincer, Yalcin Gunes, Nusret Karakaya

surfaces and 2D contour plots in figures 2-12. (2007). Coal-based bottom ash (CBBA) waste

The optimum combination of all parameters material as adsorbent for removal of textile

dyestuffs from aqueous solution. Journal of

effecting the percentage removal of dye was hazardous materials, 141: 529-535.

predicted by using prediction profiler of the [3] Ming-Shen Chiou, Guo-Syong Chuang (2006).

software. The maximum removal efficiency was Competitive adsorption of dye metanil yellow

predicted to be 92% which was obtained at a and RB15 in acid solutions on chemically cross-

linked chitosan beads. Chemosphere, 62: 731-

temperature of 200C, pH of 12, contact time of 740.

90 min, adsorbent dose of 0.41 g and initial dye [4] Chiang Hung-Lung, Lin Kuo-Hsiung, Chen

concentration of 53 ppm (figure -13). Shih-Yu, Choa Ching-Guan, Pan San-De (2007).

Dye adsorption on biosolid adsorbents and

commercially activated carbon. Dyes and

4. CONCLUSIONS Pigments, 75: 52-59.

[5] Xubiao Yu, Chaohai Wei, Lin Ke, Yun Hu,

In this work, the optimum levels of process Xiaoqu Xie, Haizhen Wu (2010). Development

variables were determined by using statistical of organovermiculite-based adsorbent for

removing anionic dye from aqueous solution.

methods. A high percentage of color removal Journal of Hazardous Materials, 180: 499-507.

design was developed by using Central [6] A.R. Binupriya, M. Sathishkumar, K.

Composite Design. A highly accurate model Swaminathan, C.S. Ku, S.E. Yun (2008).

was developed which showed that the Comparitive studies on removal of Congo red by

native and modified mycelia pellets of Trametes

percentage removal of CV dye was highly versicolor in various reactor modes. Bioresource

influenced by temperature, initial pH and Technology, 99: 1080-1088.

adsorbent dosage. However the effects of [7] Chih-Hung Chen, Chin-Feng Chang, Chuan-

Hsin Ho, Tsai-Ling Tsaum Shiu_Mei Lie (2008).

contact time and dye concentration were

Biodegradation of crystal violet by a Shewanella

marginal. sp. NTOU1. Chemosphere, 72: 1712-1720.

The optimum temperature of 200C, pH of 12, [8] Santhi Thirumalisamy, Manonmani Subbian

contact time of 90 min, adsorbent dose of 0.41 g (2010). Removal of methylene blue from

aqueous solution by activated carbon prepared

and initial dye concentration of 53 ppm were from the peel of cucumis sativa fruit by

obtained by using Response Surface Method, adsorption. Bioresource Technology, 5: 419-437.

which resulted 92% of removal of CV dye from [9] Rajeev kumar, Rais Ahmad (2011).

solution. This method produced 250% higher Biosorption of hazardous crystal violet dye from

aqueous solution onto treated ginger waste

removal of CV dye efficiency as compared to (TGW). Desalination, 265: 112-118.

that in original values. The above results [10] Xudong Li, Rong Jia (2008).

suggest that activated carbon prepared from Decolorization and biosorption for congo red by

waste prawns could be used to remove the CV stystem rice hull-Schizophyllum sp. F17 under

solid state condition in a continuous flow

dye from aqueous solutions effectively. This packed-bed bioreactor. Bioresource Technology,

method may results in reduction of 99:6885-6892.

environmental problems without compromising [11] V. Jaykumar (2009). Statistical Analysis

and Optimization of acid dyes biosorption by

plant productivity. This method can also

brewery waste biomass using response surface

generate income to the fishermen and reduce the methodology. Modern Applied Science, 3: 71-

effluent treatment cost to the industries. 84.

Narayana Saibaba K.V, et al. 189

RESPONSE SURFACE OPTIMIZATION OF DYE REMOVAL BY USING WASTE PRAWN SHELLS

[12] F. Ferrero (2007). Dye removal by low [23] Gregorio Crini (2008). Kinetic and

cost adsorbent: Hazelnut shells in comparison equilibrium studies on the removal of cationic

with wood saw dust. Journal of Hazardous dyes from aqueous solution by adsorption onto a

materials, 142: 144-152. cyclodextrin polymer. Dyes and Pigments, 77:

[13] C. Pradeep Sekhar, S.Kalidhasan, Vidya 415-426.

Rajesh, N. Rajesh (2009). Bio-polymer [24] Javad Zolgharnein, Zhaleh Adhami, Ali

adsorbent for the removal of malachite green Shahmoradi, and S. Norollah Mousavi (2010).

from aqueous solution. Chemosphere, 77: 842- Optimization of removal of methylene blue by

847. platanus tree leaves using response surface

[14] Gudrun Petzold, Simona Schwarz (2006). methodology. Analytical Science, 26 : 111-116.

Dye removal from solutions and sludges by [25] Box GEP, Wilson KB (1951) . On the

using polyelectrolytes and polyelectrolyte- experimental attainment of optimum conditions.

surfacant complexes. Separation and purification J R Stat Soc (Ser B), 13 : 1–45.

technology, 51: 318-324. [26] S.Jain, R.V. Jayaram (2010). removal of

[15] Eltaief Khelifi, Lamia Ayed, Hassib basic dyes from aqueous solution by low-cost

Bouallagui, Youssef Touhami, Moktar Hamdi biosorbent: wood apple shell (Feronia

(2009). Effect of nitrogen and carbon sources on acidissima). Desalination, 250 :921-927.

indigo and congo red decolourization by [27] Meng Nan chong, Shaomin Lei, Bo Jin,

Aspergillus alliaceus strain 121C. Journal of Chris Saint, Christopher W.K. Chow (2009).

Hazardous Materials, 163: 1056-1062. Optimisation of an annular photoreactor process

[16] Abbas Afkhami, Mohammad Saber- for degradation of Congo red using a newly

Tehrani, Hasan Bagheri (2010). Modified synthesized titanium impregnated kaolinite nano-

maghemite nonoparticles as an efficient photocatalyst. Separation and purification

adsorbent for removing some cationic dyes from technology, 67: 355-363.

aqueous solution. Desalination, 263: 240-248. [28] K. Ravikumar, B. Deebika, K. Balu (2005).

[17] Khanidtha Marungrueng, Prasert Pavasant Decolourization of aqueous dye solutions by a

(2007). High performance biosorbent ( Caulerpa novel adsorbnet: application of statistical designs

lentillifera) for basic dye removal. Bioresource and surface plots for the optimization and

Technology, 98: 1567-1572. regression analysis. Journal of Hazardous

[18] Duff, R.J., Defeo, J.A. & Robinson, R.A Materials, 122: 75-83.

1973. Abstracts of papers, 166th American [29] Chellapandian Kannan, Thiravium

Chemical Society National Meetings, Chicago, Sundaram, Thayumanvan Palvannan (2008).

Micro, pp. 28. Environmentally stable adsorbent of tetrahedral

[19] V. Ponnusami, S. Vikram, S.N. Srivastava silica and non-tetrahedral alumina for removal

(2008). Guava (Psidium guajava) leaf powser: and recovery of malachite green dye from

novel adsorbent for removal of methylene blue aqueous solution. Journal of Hazardous

from aqueous solutions. Journal of Hazardous materials, 157 :137-145.

materials, 152: 276-286. [30] F. Doulati Ardejani, Kh. Badii, N. Yousefi

[20] Yujie Shi, Xiangqun Xu, Yang Zhu (2009). Limaee, N.M. Mahmoodi, M. Arami, S.Z.

Optimization of Verticillium lecanii spore Shafaei, A.R. Mirhabibi (2007). Numerical

production in solid-state fermentation on modeling and laboratory studies on the removal

sugancane bagasse. Applied Microbial of direct red 23 and direct red 80 dyes from

Biotechnology, 82: 921-927. textile effluents using orange peel, a low-cost

[21] M. Mohammadian Fazli, A.R. adsorbent. Dyes and pigments, 73: 178-185.

Mesdaghinia, K. Naddafi, S. Nasseri, M.

Yunesian, M. Mazaheri Assadi, S. Rezaie, H. Factor Symbo Level

Hamzehei 2010. Optimization of reactive blue 19 l -α -1 0 1 +α

Temperature,

decolorization by ganoderma sp. Using response 0

C

x1 20 25 30 35 40

surface methodology. Iran. J. Environ. Health. pH x2 2 4.5 7 9.5 12

Sci. Eng., 7: 35-42. Time, min 33.7 52. 71.2

x3 15 90

[22] S. Kara, C. Aydiner, E. Demirbas, 5 5 5

M.Kobya, N. Dizge (2007). Modeling the effects Adsorbent 0.

x4 0.4 0.6 0.8 1.0

dose, g 2

of adsorbent dose and particle size on the Initial dye

adsorption of reactive textile dyes by fly ash. 15

concentration x5 50 75 100 125

0

Desalination, 212: 282-293. , ppm

Table-1: Levels of different process variables used

in CCD for removal of CV dye

Narayana Saibaba K.V, et al. 190

RESPONSE SURFACE OPTIMIZATION OF DYE REMOVAL BY USING WASTE PRAWN SHELLS

% Removal of dye b1* b3 -0.072 0.0038 -18.783 0.000

Run

X1 X2 X3 X4 X5

Order Observed Predicted b1* b4 4.283 0.3602 11.888 0.000

1 0 0 0 0 0 43.2849 43.3053 b1* b5 -0.024 0.0029 -8.379 0.000

2 -1 -1 1 -1 -1 43.0642 43.9253 b2* b3 0.032 0.0077 4.13 0.002

3 -1 1 -1 -1 -1 10.0890 10.0775 b2* b4 -13.699 0.7205 -19.014 0.000

4 -1 -1 -1 -1 1 2.9755 3.3199

b2* b5 -0.064 0.0058 -11.086 0.000

5 0 0 0 0 0 43.4041 43.3053

6 0 0 0 -2 0 5.6292 5.7661 b3* b4 -1.339 0.0961 -13.941 0.000

7 1 1 -1 1 -1 47.2262 47.3290 b3* b5 -0.006 0.0008 -7.765 0.000

8 1 -1 -1 1 1 57.0714 57.5301 b4* b5 0.648 0.072 8.997 0.000

9 -1 -1 1 1 1 58.7795 59.4130 Table- 3: Response Surface Regression of percentage

10 1 1 1 -1 -1 50.6919 50.5016 removal efficiency of CV dye

11 2 0 0 0 0 0.6292 0.5376 Source DF

SS MS(Adj) F p

12 0 0 0 2 0 49.7882 48.7609

Linear 5 5311 958.15 461.48 0.000

13 0 0 2 0 0 49.5366 49.0954 Square 5 9096 1819.2 876.19 0.000

14 0 0 0 0 0 42.7816 43.3053 Interaction 10 3038.1 303.81 146.32 0.000

Residual

15 0 0 0 0 -2 30.7436 29.2610

Error 11 22.8 2.08

16 -1 1 1 -1 1 37.2184 36.6862 Lack of Fit 6 16.7 2.78 2.27 0.193

17 -1 1 1 1 -1 42.6715 42.9490 Pure Error 5 6.1 1.23

18 -1 1 -1 1 1 13.7097 13.4706 Total 31 17468

19 0 0 0 0 2 9.6119 10.2041 S = 1.441 R= R-Sq = R-

0.9995 99.9% Sq(adj)

20 0 0 0 0 0 42.7816 43.3053

= 99.6%

21 1 1 1 1 1 28.0929 27.6750

Table-4: Analysis of Variance for Removal of CV dye

22 -2 0 0 0 0 0.0225 -0.7762 using CCD

23 1 -1 -1 -1 -1 5.0222 5.7085

24 1 -1 1 1 -1 49.1167 50.0921

25 0 -2 0 0 0 91.4121 89.2178

26 -1 -1 -1 1 -1 28.7511 29.9052

27 1 1 -1 -1 1 3.6714 2.9644

28 0 0 0 0 0 45.0333 43.3053

29 1 -1 1 -1 1 3.0357 3.2013

30 0 0 0 0 0 41.6558 43.3053

31 0 2 0 0 0 82.5532 83.8573

32 0 0 -2 0 0 13.5100 13.0608

Table-2: CCD plan matrix in coded values and Responses

Term Constant SE T P

Fig-1: Main Effects plots of % Removal of CV Dye

b0 -640.427 20.305 -31.54 0.000

b1 28.169 0.7889 35.707 0.000

b2 -18.601 1.341 -13.871 0.000

b3 4.737 0.1788 26.492 0.000

b4 146.959 16.8947 8.699 0.000

b5 2.791 0.1414 19.745 0.000

b1 * b1 -0.434 0.0106 -40.805 0.000

b2 * b2 1.729 0.0426 40.624 0.000

b3 * b3 -0.009 0.0008 -11.49 0.000

b4 * b4 -100.261 6.6512 -15.074 0.000

b5* b5 -0.009 0.0004 -22.151 0.000

Fig-2: Surface plot of percentage removal of CV

b1* b2 0.227 0.0288 7.863 0.000

dye,Temperature and Adsorbent dose

Narayana Saibaba K.V, et al. 191

RESPONSE SURFACE OPTIMIZATION OF DYE REMOVAL BY USING WASTE PRAWN SHELLS

Fig-3: Surface plot of percentage removal of CV dye, Time Fig-6: Surface plot of percentage removal of CV dye, Dye

and Adsorbent dose concentration and pH

Fig-4: Surface plot of percentage removal of CV dye,

Fig-7: Surface plot of percentage removal of CV dye, Dye

Adsorbent dose and Dye concentration

concentration and Temperature

Fig-5: Surface plot of percentage removal of CV dye,

Fig-8: Surface plot of percentage removal of CV dye, Dye

Adsorbent dose and pH

concentration and Time

Narayana Saibaba K.V, et al. 192

RESPONSE SURFACE OPTIMIZATION OF DYE REMOVAL BY USING WASTE PRAWN SHELLS

Fig-9: Surface plot of percentage removal of CV dye, Fig-12: Contour plots of removal of CV dye

Temperature and pH

Fig-10: Surface plot of percentage removal of CV dye, pH

and Time

Fig-13: Response surface optimization plots for percentage

removal of CV dye

Fig-11: Surface plot of percentage removal of CV dye,

Temperature and Time

Narayana Saibaba K.V, et al. 193

You might also like

- 1930s Cocktail MenuDocument5 pages1930s Cocktail MenuLipeKatieNo ratings yet

- Overview of The DSM 5Document68 pagesOverview of The DSM 5khalpopoNo ratings yet

- Avocados in Love PatternDocument10 pagesAvocados in Love PatternTu Anh Nguyen100% (2)

- The Spiritual Teaching of Saint John EudesDocument137 pagesThe Spiritual Teaching of Saint John EudesAnonymous D83RFJj34100% (2)

- Removal of A Basic Dye From Aqueous Solution by Adsorption UsingDocument6 pagesRemoval of A Basic Dye From Aqueous Solution by Adsorption Usingseranim22100% (1)

- Dye Removal ProposalDocument15 pagesDye Removal ProposalnorsiahNo ratings yet

- A Comparative Evaluation For Adsorption of Dye On Neem Bark and Mango Bark PowderDocument9 pagesA Comparative Evaluation For Adsorption of Dye On Neem Bark and Mango Bark PowderdivNo ratings yet

- RPM5Document4 pagesRPM5mmak946.lkiNo ratings yet

- Microchemical Journal: Abdelmajid Regti, My Rachid Laamari, Salah-Eddine Stiriba, Mohammadine El HaddadDocument8 pagesMicrochemical Journal: Abdelmajid Regti, My Rachid Laamari, Salah-Eddine Stiriba, Mohammadine El HaddadhendrynordanNo ratings yet

- Removal of Methylene Blue From Aqueous Solution by Bioadsorption Onto Ricinus Communis Epicarp Activated CarbonDocument5 pagesRemoval of Methylene Blue From Aqueous Solution by Bioadsorption Onto Ricinus Communis Epicarp Activated CarbonLuisa LouisaNo ratings yet

- Use of Renewable Adsorbent (Peanut Husk) For The Treatments of Textile Waste WaterDocument8 pagesUse of Renewable Adsorbent (Peanut Husk) For The Treatments of Textile Waste WaterchemistryjournalNo ratings yet

- Biosorption Behavior of Basic Red 46 and Violet 3 by Dead Pleurotus Mutilus From Single - and Multicomponent SystemsDocument13 pagesBiosorption Behavior of Basic Red 46 and Violet 3 by Dead Pleurotus Mutilus From Single - and Multicomponent SystemsChern YuanNo ratings yet

- Studies On Removal of Methylene Blue Dye by A Novel Activated Carbon Prepared From Thespesia Populnea Waste BiomassDocument21 pagesStudies On Removal of Methylene Blue Dye by A Novel Activated Carbon Prepared From Thespesia Populnea Waste BiomassABDULAJIJNo ratings yet

- Ion of Basic Dye Using Industrial Waste Spent Brewery YeastDocument26 pagesIon of Basic Dye Using Industrial Waste Spent Brewery YeastS Bharadwaj ReddyNo ratings yet

- Removal of Yellow 2G Dye From Aqueous Solutions Using Activated Carbon Prepared From Mosambi and Cotton An Agricultural WasteDocument6 pagesRemoval of Yellow 2G Dye From Aqueous Solutions Using Activated Carbon Prepared From Mosambi and Cotton An Agricultural WasteInternational Organization of Scientific Research (IOSR)No ratings yet

- 2007 2 BiomassDocument12 pages2007 2 BiomassSeptian Perwira YudhaNo ratings yet

- BATCH ADSORPTION STUDIES ON REMOVAL OF DYES FROM WASTE WATER USING MODIFIED SEASHELLS AS ADSORBENTS Ijariie5776Document7 pagesBATCH ADSORPTION STUDIES ON REMOVAL OF DYES FROM WASTE WATER USING MODIFIED SEASHELLS AS ADSORBENTS Ijariie5776Karthik Kalasipalya Vinod KumarNo ratings yet

- 2222 PDFDocument13 pages2222 PDFhshobeyriNo ratings yet

- Mayerly J. Puchana-Rosero, Eder C. Lima, Bianca Mella, Dimitrius Da Costa, Eduardo Poll, Mariliz GutterresDocument9 pagesMayerly J. Puchana-Rosero, Eder C. Lima, Bianca Mella, Dimitrius Da Costa, Eduardo Poll, Mariliz GutterresJuan Carlos ZavaletaNo ratings yet

- Congo Red Dye PDFDocument6 pagesCongo Red Dye PDFkiranpatil1014532No ratings yet

- Chemical Catalytic Reaction and Biological Oxidation For Treatment of Non-Biodegradabletextile EffluentDocument7 pagesChemical Catalytic Reaction and Biological Oxidation For Treatment of Non-Biodegradabletextile EffluentIrina Natalena OsantiNo ratings yet

- Model Published Paper3 - May Refer ThisDocument9 pagesModel Published Paper3 - May Refer ThisUSHA JAIGANESH GTAVMNo ratings yet

- Effective Removal and Recovery of Fast Green FCF Dye From Wastewater Using Green AdsorbentDocument12 pagesEffective Removal and Recovery of Fast Green FCF Dye From Wastewater Using Green AdsorbentSandip LabadeNo ratings yet

- Agricultural Residue Anion Exchanger For Removal of Dyestuff From Wastewater Using Full Factorial DesignDocument8 pagesAgricultural Residue Anion Exchanger For Removal of Dyestuff From Wastewater Using Full Factorial Designhafsaoui younesNo ratings yet

- The Use of Rice Straw As An AdsorbantDocument4 pagesThe Use of Rice Straw As An AdsorbantgobinathdpiNo ratings yet

- Application of Treated and Untreated Cucumis Sativus Peels For Elimination of Congo Red Dye From Aqueous Solutions: An Adsorption StudyDocument13 pagesApplication of Treated and Untreated Cucumis Sativus Peels For Elimination of Congo Red Dye From Aqueous Solutions: An Adsorption StudyMuhammad Muneeb AhmadNo ratings yet

- Removal of Methyl Orange From Effluent Water by Silver/Copper Nanoparticles Deposited On Antigonon Leptopus Leaf Powder An AdsorbentDocument7 pagesRemoval of Methyl Orange From Effluent Water by Silver/Copper Nanoparticles Deposited On Antigonon Leptopus Leaf Powder An AdsorbentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Use of Palm Oil Fiber An Agricultural Waste For Removal of Methylene Blue From Aqueous Solution - FairusDocument8 pagesUse of Palm Oil Fiber An Agricultural Waste For Removal of Methylene Blue From Aqueous Solution - Fairusfairus100% (6)

- Removal of Methylene Blue Dye From Aqueous Solutions Using Lagerstroemia Indica Seed (LIS) Activated CarbonDocument10 pagesRemoval of Methylene Blue Dye From Aqueous Solutions Using Lagerstroemia Indica Seed (LIS) Activated Carbonsagar dasguptaNo ratings yet

- Chaibakhsh2014.PDF BuenazoDocument7 pagesChaibakhsh2014.PDF BuenazoabnerNo ratings yet

- Removal of Some Reactive Dyes From Synthetic Wastewater by Combined Al (III) Coagulation Carbon Adsorption ProcessDocument8 pagesRemoval of Some Reactive Dyes From Synthetic Wastewater by Combined Al (III) Coagulation Carbon Adsorption ProcessArif HidayatNo ratings yet

- 1648-Article Text-4967-1-10-20131025Document10 pages1648-Article Text-4967-1-10-20131025katagelombangNo ratings yet

- Optimization of Process Parameters For COD RemovalDocument6 pagesOptimization of Process Parameters For COD Removalla sourceNo ratings yet

- Articulo 1 Inmovilización Alginato PDFDocument6 pagesArticulo 1 Inmovilización Alginato PDFCarolina MorenoNo ratings yet

- Kinetics and Thermodynamics of Adsorption Process Using A Spent-FCC CatalystDocument4 pagesKinetics and Thermodynamics of Adsorption Process Using A Spent-FCC CatalystDrZakir HussainNo ratings yet

- Miaz CopsDocument5 pagesMiaz CopsMelese DagnawNo ratings yet

- 11.19 Indian Journal of Chemical Technology, Vol. 26, November 2019, Pp. 544-552Document9 pages11.19 Indian Journal of Chemical Technology, Vol. 26, November 2019, Pp. 544-552Sathyabama University BiotechnologyNo ratings yet

- Extraction of Methyl Red From Industrial Wastewater Using Xylene As An ExtractantDocument6 pagesExtraction of Methyl Red From Industrial Wastewater Using Xylene As An ExtractantUmi Dwi JayantiNo ratings yet

- Removal of Reactive Yellow Dye Using Natural Coagulants in Synthetic Textile Waste WaterDocument7 pagesRemoval of Reactive Yellow Dye Using Natural Coagulants in Synthetic Textile Waste WaterVittal PiseNo ratings yet

- Decolorization of An Acidic Dye From Synthetic Wastewater by Sludge of Water Treatment PlantDocument6 pagesDecolorization of An Acidic Dye From Synthetic Wastewater by Sludge of Water Treatment PlantCarlos Kirela E. RaquelNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument7 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyRosa CoronadoNo ratings yet

- Chrysanthemum Indicum Microparticles On Removal of HazardousDocument12 pagesChrysanthemum Indicum Microparticles On Removal of HazardousShantha Kumar SNo ratings yet

- Oriental Journal of Chemistry 28 (3) 1091-1098Document8 pagesOriental Journal of Chemistry 28 (3) 1091-1098Noureddine BarkaNo ratings yet

- Art 23Document3 pagesArt 23Fahra Aqilla AzzurahNo ratings yet

- Artículo JournalofHazardousMaterials 2007Document10 pagesArtículo JournalofHazardousMaterials 2007ANA BELEN PEREZ MARINNo ratings yet

- Journal of Hazardous Materials: Sílvia C.R. Santos, Rui A.R. BoaventuraDocument9 pagesJournal of Hazardous Materials: Sílvia C.R. Santos, Rui A.R. BoaventuraJefersonCorreiaNo ratings yet

- Adsorption of Selected Pesticides From Aqueous Solutions Using Cost Effective Walnut ShellsDocument14 pagesAdsorption of Selected Pesticides From Aqueous Solutions Using Cost Effective Walnut ShellsIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Studies On The Batch Adsorption of MethyDocument17 pagesStudies On The Batch Adsorption of MethyLigma BowlsNo ratings yet

- 3.isca RJCS 2015 017Document5 pages3.isca RJCS 2015 017Igbinwole Kehinde SolomonNo ratings yet

- Dye Industry Wastewater Treatment by Coagulation Process: Review PaperDocument8 pagesDye Industry Wastewater Treatment by Coagulation Process: Review PaperAndiGunawanNo ratings yet

- Removal of Rhodamine-B by Adsorption On Walnut Shell CharcoalDocument15 pagesRemoval of Rhodamine-B by Adsorption On Walnut Shell CharcoalAriev BudiManNo ratings yet

- International Journal of Green and Herbal Chemistry: Decolorization of Textile Waste Water Using Low Cost AdsorbentDocument6 pagesInternational Journal of Green and Herbal Chemistry: Decolorization of Textile Waste Water Using Low Cost AdsorbentFarrukh JamilNo ratings yet

- Surfaces and Interfaces: SciencedirectDocument9 pagesSurfaces and Interfaces: SciencedirectygNo ratings yet

- Journal of Environmental Chemical Engineering: SciencedirectDocument8 pagesJournal of Environmental Chemical Engineering: SciencedirectSushanta Kumar BeheraNo ratings yet

- Adsorption Science and TechnologyDocument17 pagesAdsorption Science and Technologydeepika snehiNo ratings yet

- Siva Raj 2001Document6 pagesSiva Raj 2001Alexsandro Nicolay PontoanNo ratings yet

- Potential of Neem Leaf Powder As Bio Adsorbents For Dye Colour RemovalDocument4 pagesPotential of Neem Leaf Powder As Bio Adsorbents For Dye Colour RemovalEditor IJTSRDNo ratings yet

- 1 s2.0 S0143720822009469 MainDocument7 pages1 s2.0 S0143720822009469 MainAnna María KNo ratings yet

- ViewFreeArticle PDFDocument8 pagesViewFreeArticle PDFHury GaldámezNo ratings yet

- Adsorption of Dye From Wastewater by Zeolites Synthesized From Fly Ash - Kinetic and Equilibrium StudiesDocument9 pagesAdsorption of Dye From Wastewater by Zeolites Synthesized From Fly Ash - Kinetic and Equilibrium StudiesPietro FigueiredoNo ratings yet

- Cucumis Sativus Used As Adsorbent For The Removal of - 2017 - Arabian Journal ofDocument8 pagesCucumis Sativus Used As Adsorbent For The Removal of - 2017 - Arabian Journal oflucian_lovNo ratings yet

- Borhade 2017 Calcined Eggshell As A Cost EffectiDocument14 pagesBorhade 2017 Calcined Eggshell As A Cost EffectiRalucaNo ratings yet

- 5 Ijcms-V3i2-2012-02Document6 pages5 Ijcms-V3i2-2012-02saiNo ratings yet

- Novel Approach in Validation of Adventitious Virus Removal by Virus FiltrationDocument1 pageNovel Approach in Validation of Adventitious Virus Removal by Virus FiltrationsaiNo ratings yet

- Optimization of Process Parameters of Hydraulic Press For Coconut Oil Yield Using RSMDocument1 pageOptimization of Process Parameters of Hydraulic Press For Coconut Oil Yield Using RSMsaiNo ratings yet

- Design of Experiment For Production of Citric Acid Using 2-Level Factorial MethodDocument1 pageDesign of Experiment For Production of Citric Acid Using 2-Level Factorial MethodsaiNo ratings yet

- Application of Genetic Algorithm and Artificial Neural Networks in Bioremediation ProcessDocument1 pageApplication of Genetic Algorithm and Artificial Neural Networks in Bioremediation ProcesssaiNo ratings yet

- Modeling and Optimization of Dye Removal Process Using Response Surface MethodologyDocument1 pageModeling and Optimization of Dye Removal Process Using Response Surface MethodologysaiNo ratings yet

- 5 Ijcms-V3i2-2012-02Document6 pages5 Ijcms-V3i2-2012-02saiNo ratings yet

- 4 JPRonlineDocument3 pages4 JPRonlinesaiNo ratings yet

- English Lesson Plan - Week 3Document11 pagesEnglish Lesson Plan - Week 3Chender DadangNo ratings yet

- Charge Coupled Device (CCD) : Presented byDocument18 pagesCharge Coupled Device (CCD) : Presented byBE CAREFULNo ratings yet

- Chemical Kinetics AssignmentDocument15 pagesChemical Kinetics AssignmentVanshdip RawatNo ratings yet

- LP JusticeFairness CC 002Document8 pagesLP JusticeFairness CC 002jijijijiNo ratings yet

- Agriculture4 0-IEEETIIDocument13 pagesAgriculture4 0-IEEETIIAmanda FNo ratings yet

- Beginner's Health and Fitness GuideDocument19 pagesBeginner's Health and Fitness GuideDiana IonescuNo ratings yet

- Class 6 Social PaperDocument5 pagesClass 6 Social PaperManav RachchhNo ratings yet

- Sf2460i Line 163Document123 pagesSf2460i Line 163Santiago SilvaNo ratings yet

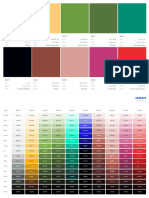

- Color 1 Color 2 Color 3 Color 4 Color 5: RGB Cmyk Name RGB Cmyk Name RGB Cmyk Name RGB Cmyk Name RGB Cmyk NameDocument4 pagesColor 1 Color 2 Color 3 Color 4 Color 5: RGB Cmyk Name RGB Cmyk Name RGB Cmyk Name RGB Cmyk Name RGB Cmyk NameValentina TorresNo ratings yet

- A SeriesDocument16 pagesA SeriesAngel MontoyaNo ratings yet

- 9037HG32LZ20: Product DatasheetDocument2 pages9037HG32LZ20: Product DatasheetNarcisse AhiantaNo ratings yet

- Interpreting Medication OrdersDocument11 pagesInterpreting Medication Ordersmedgeek nmeNo ratings yet

- Manual Call Points: GeneralDocument2 pagesManual Call Points: GeneralAnugerahmaulidinNo ratings yet

- Valley Metro System MapDocument1 pageValley Metro System MapLục Ẩn ĐạtNo ratings yet

- Aristotle Great ChainDocument11 pagesAristotle Great ChainPaul Ng WaiNo ratings yet

- DFT Notes PDFDocument4 pagesDFT Notes PDFkrishna prasad ghantaNo ratings yet

- Crafting The Brand Positioning: Marketing Management, 13 EdDocument21 pagesCrafting The Brand Positioning: Marketing Management, 13 Edannisa maulidinaNo ratings yet

- Honey Encryption New Report - 1Document5 pagesHoney Encryption New Report - 1Cent SecurityNo ratings yet

- Old Offshore Scheme: Frequently Asked QuestionsDocument18 pagesOld Offshore Scheme: Frequently Asked QuestionsIgorNo ratings yet

- Workshop 3 - MathsDocument5 pagesWorkshop 3 - MathsJuan David Bernal QuinteroNo ratings yet

- Material Downloaded From - 1 / 6Document6 pagesMaterial Downloaded From - 1 / 6Omprakash ChandrakarNo ratings yet

- Phantom Testing - Mammography (Revised 12-12-19) - Accreditation SupportDocument6 pagesPhantom Testing - Mammography (Revised 12-12-19) - Accreditation SupportMohammad Ahmad AyasrahNo ratings yet

- Ann. Anim. Sci., Vol. 16, No. 2 (2016) 507-519 DOI: 10.1515/aoas-2015-0087Document13 pagesAnn. Anim. Sci., Vol. 16, No. 2 (2016) 507-519 DOI: 10.1515/aoas-2015-0087Cristian José CardozoNo ratings yet

- 13 Vassileva Pediatric DRLDocument57 pages13 Vassileva Pediatric DRLLavinia BaracNo ratings yet

- LP Expert Detective Class 6Document5 pagesLP Expert Detective Class 6Abhishek SumanNo ratings yet