Professional Documents

Culture Documents

Img - 0200 3

Img - 0200 3

Uploaded by

Katrina Cave0 ratings0% found this document useful (0 votes)

23 views10 pagesOriginal Title

IMG_0200 3

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views10 pagesImg - 0200 3

Img - 0200 3

Uploaded by

Katrina CaveCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

‘Adjusting main relief valve

+ Disconnect high pressure hos

1) Adjusting high pressure setting

a sgean locknut (2) of main rlit valve (1),

then turn holder (3) to adjust.

Turn the holder to adjust as follows.

+ To INCREASE pressure, turn CLOCK-

WISE.

+ To DECREASE pressure, turn COUN-

TERCLOCKWISE.

After adjusting, use the measurement pro-

cedure above to check the oil pressure

again.

Amount of adjustment for one turn of

holder: Approx. 12.6 MPa {128 kg/cm*}

SS Locknut:

53.9 + 4.9 Nm (5.5 + 0.5 kgm)

* When the high pressure setting is ad-

justed, the low pressure setting will also

change, so adjust the low pressure set-

ting also.

2) Adjusting low pressure setting .

+ Loosen locknut (4) of main relief valve (1),

then tun holder (5) to adjust.

* Turn the holder to adjust as follows.

+ To INCREASE pressure, turn CLOCK-

WISE.

+ To DECREASE pressure, turn COUN.

TERCLOCKWISE.

% After adjusting, use the measurement pro:

cedure above to check the oil pressure

again.

* Amount of adjustment for one turn of

holder: Approx. 12.6 MPa {128 kg/cm’)

SS Locknut

39.2 - 49.0 Nm (4-5 kgm}

2. Adjusting swing motor safety valve

* Ifthe swing relief pressure is not normal, ad

just the swing motor safety valve as follows.

1). Loosen locknut (7) of swing motor safety valve

(6), then turn adjustment screw (8) to adjust.

* Turn the adjustment screw as follows.

+ To INCREASE pressure, turn CLOCK-

WISE

To DECREASE pressure, tun

TERCLOCKWisE

* Amount of adjustment for one turn of ad-

justment screw : 14.0 MPa (143 kg/cm?)

91F00261

2) After adjusting, tighten locknut (7).

SS Locknut

:53.9- 73.5 Nm (5.5 ~ 7.5 kgm}

+ After completion of adjustment, use the

measurement procedure above to check

the oil pressure again.

STING AND ADJUSTING OUTPUT PRESSURE

OF PC VALVE (SERVO PISTON

INPUT PRESSURE) 0

Measuring

4 Oil temperature when Mm

ring : 45-55 °C

4. Remove pressure measurement plugs (1) and (2)

(Thread dia.= 10 mm, Pitch=1.25 mm), and install

bil pressure gauge C1 (39.2 MPa (400 ka/emn").

2. Turn the swing lock switch ON.

3, Run the engine at full throttle and measure the

oil pressure when the arm IN circuit is relieved.

[Reference]

if there is any abnormality with problem in the

LS valve or servo piston, the servo piston input

pressure becomes a value close to 0 or the same

pressure as the pump discharge pressure.

ind the engine speed drops,

‘If the engine speed is normal but the work

equipment speed Is slow, adjust PC valve (6) as

fellows if the pump discharge pressure and LS

differential pressure are normal.

4) Remove nut (3) and disconnect hose.

2) Loosen locknut (4), and if the work equipment

‘speed is slow, turn screw (5) clockwise; if the

‘engine speed drops, turn the screw counter-

clockwise.

Adjusting

‘Ifthe load increases @

BRPOIONS.

TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE

{SERVO PISTON INPUT PRESSURE)

AND LS DIFFERENTIAL PRESSURE

$45 ~56 °C

+ Oil temperature when measuri

1, Measuring LS valve output pressure (servo pis-

ton input pressure}

1) Remove prossure measurement plugs (1) and

2) (Thread dia.= 10 mm, Pitch=1.25 mm), and

install oil pressure gauge C1 (39.2 MPa (400

kgicm').

Use the work equipment to raise the track as

sembly on one side

Run the engine at full throttle, operate under

the conditions shown in Table 1, rotate the

track under no load, and measure the oil pres-

sure (the oll pressure when the travel is oper-

ated on one side under no toad}

2)

3)

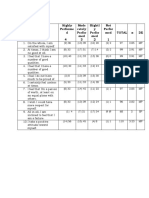

Table 1

Travel

2.94+0.49 |About san

i3i pressure

Neutral

Full

TT

AA

Hh

i!

HT |

Me ol pressure

SY reiterentil pressure gauge

1) Measuring with shar

i), Remove ot reseure measurement plug! |

‘and (2) (Thread dia.—1omm, Piteh=1.25mnm);

and install differential pressure gauge cs.

% Connect pump discharge pressure

side (1) to the high- prassure side of

the differential gauge and LS pressure

side (2) to the low-pressure side.

Use the work equipment to raise the track

on one side.

ii) Run the engine at full throttle, set to the.

conditions below, and measure the LS di

ferential pressure.

+ US differential pressure when travel le-

ver is at Neutral

2.75 + 0.98 MPa (28 + 10 kg/cm’)

* The LS differential pressure when the

travel lever is at Neutral is the same.

as the unload pressure.

+ LSdifferential pressure when travel le-

ver is at half-way position (track ro:

tating under no load)

2.21 + 0.1 MPa (22.5 + 1ka/cm*}

2) Measuring with oll pressure gauge

+ Themaximum differential pressure is less

than 1.96 MPa {20 kg/cm}, so measure

with the same gauge

i) Remove oil pressure measurement plugs (1)

and (2) (thread dia.x10mm, pitch=1.2mm)

nd install oil pressure gauge C1.

ii) Install oil pressure gauge C1 (39.23 MPa

(400 kg/cm’}) to the plug for measuring

the pump discharge pressure.

* Use @ gauge with a scale in units of 7

0.98 MPa {10 kg/cm”,

iii) Use the work equipment to raise the track

iv) Run the eng

high idling, set to the

iil), and measure E ?

ap discharge pressun

ind directly in front of the indicator Hi

i dit correctly.

: jh idling, set tothe | f

itions in St ra ran

the LS pr

% Stand directly in front of the

Picanto

vi) Calculate the LS differential Pp il

the pump discharge py

pressure,

{Differential pressure) « Pump discharge

Pressure} - ALS pressure) HH

iii), and measure

ssure from,

and the LS

Hidii{t)

iy LUUDLLAAAADIANIARAbiaEAaniaBAatdaaDebAnbialbinbbantenteeiuisdisteaslat uel

& Agustina LS valve

ifthe results show that the LS differential pres-

sure is not within the standard value, adjust

the LS valve as follows.

1). Disconnect hose (8) from LS valve {7).

2) Loosen locknut (9) and turn adjustment screw:

(10) to adjust the differential pressure.

+ Turn the adjustment screw to adjust as

follows.

+ To INCREASE pressure, turn CLOCK-

WISE

+ To DECREASE pressure, turn COUN-

TERCLOCKWISE

* Amount of adjustment for one turn of ad-

justment screw: 1.30 MPa {13.3 kg/cm?)

{LS differential pressure}

After adjusting, tighten locknut (8),

SRE] Locknut: 59+ 10 Nm {6+ 1 kgm)

% After completion of adjustment, repeat the

procedure above to check the LS differ-

ential pressure again.

eg

val

aerate

TESTING ANI

CIRCUIT OIL PRESSURE

Measuring

spacer temperature when measuring : 4 - 85°C

A Lower the work equipment to the ground and

stop the engine. Loosen the oll filler cap slowly

to release the pressure Inside the hydraulic tank.

Then put the safety lock lever in the LOCK post:

tion.

4. Remove the cover at the top of the valve.

2. Disconnect hose (1) going to the solenoid valve,

then install adapter C3 and oil pressure gauge C1

45.9 MPa {60 kg/cm’).

3. Start the engine and measure with the engine at

full throttle.

Adjusting

+ ifthe pressure in the control circuit is not normal,

adjust the control relief valve as follows

1 Loosen locknut (2) and turn adjustment screw (3)

to adjust.

* Turn the adjustment screw as follows.

+ ToINCREASE pressure, turn CLOCKWISE

+ To DECREASE pressure, turn COUNTER

CLOCKWISE

% Amount of adjustment for one turn of adjust:

ment screw : 0.98 MPa (10 kg/cm’)

2. After adjusting, tighten locknut (2)

GrmI Locknut : 19.6 ~ 24.5 Nm (2.0 ~2.5 kgm)

+ After completion of adjustment, rep

procedure above to check the oil pre:

again.

t the

“TESTING SOLENOID VALVE

_ OUTPUT PRESSURE

Oil temperature when measuring : 45 ~ 55

4. Disconnect the output hose of the solenoid valve

tobe measured, then install adapter C3 between

the hose and the measurement point,

2, Install oil pressure gauge C1 (5.9 MPa {60 kg/cm*})

to adapter C3.

3. Measure the output pressure under the conditions

in the table below.

Solenoid : ]

Measuring condition Opatating || Adlation [Oil pressure

| valve a ane congition. [of solenoid | IMPs (higkem?

eae i il 324»

: | 2pe Travel operated Pressure rises ONT tees

relie te

| a ar ee Pressure dowd Mat] ore 8

r +

spec in| eirlos lever Lock PeClockactusies | Or | 8)

{ic fock fi — nt A et

Safety lock lever: FREE PPC lack relaased||/ | ON) || 248,949

| Travel speed selection switch at Lo | Travel sped qe feet aash

3 [Travel speea zt ces OR CSL ETT CPT Ee LT 40) [puariearmanicum

i} Travel speed selection switch at Hi | Travel speed Hi ON) |) 928 0349 el past a

= mM il (33:8) [Heaedosnmem

|Swing holding

Swing lock switch: LOC

8 x | brake: Applied

Swing pols

fiat

Swing holding

brake: Relwssed

‘Swing lock switch: OFF

MEASURING PPC VALVE

OUTPUT PRESSURE

Oil temperature when measuring : 45 — 65°C

1. Measuring PPC valve output pressure

4) Disconnect PPC hose (1) of the circuit to be

measured.

2) Install adapter C3 between the hose and el

bow.

3) Install oil pressure gauge C1 (5.88 MPa (60

kg/cm’) to adapter C3.

4) Run the engine at full throttle, operate the con-

tro! lever of the circuit to be measured, and

measure the oil pressure.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TH THDocument19 pagesTH THKatrina CaveNo ratings yet

- Maternal and Child Nursing: ST TH ST ND THDocument15 pagesMaternal and Child Nursing: ST TH ST ND THKatrina CaveNo ratings yet

- (Zerrudo) OB Refresher NotesDocument13 pages(Zerrudo) OB Refresher NotesKatrina CaveNo ratings yet

- Reaction Paper (Self-Awareness)Document2 pagesReaction Paper (Self-Awareness)Katrina CaveNo ratings yet

- 1 Scrub 2 CircuDocument2 pages1 Scrub 2 CircuKatrina CaveNo ratings yet

- Entrep Act - QuizzesDocument22 pagesEntrep Act - QuizzesKatrina CaveNo ratings yet

- Proposed Strategies To Enhance The Self-Esteem of The Student NursesDocument10 pagesProposed Strategies To Enhance The Self-Esteem of The Student NursesKatrina CaveNo ratings yet

- Print Ko BukasDocument3 pagesPrint Ko BukasKatrina CaveNo ratings yet

- Entrepreneurship ExamsDocument15 pagesEntrepreneurship ExamsKatrina CaveNo ratings yet

- 2 Scrub 1 CircuDocument3 pages2 Scrub 1 CircuKatrina CaveNo ratings yet

- Jestian Ryll B Delacruz Bsn-IvDocument3 pagesJestian Ryll B Delacruz Bsn-IvKatrina CaveNo ratings yet

- A. Malpractice, Negligence, Torts and CrimesDocument7 pagesA. Malpractice, Negligence, Torts and CrimesKatrina CaveNo ratings yet

- Return Demo GuideDocument1 pageReturn Demo GuideKatrina CaveNo ratings yet

- Highly Performe D 4 Mode Rately Perfor Med 3 Slightl y Perfor Med 2 Not Perfor Med 1 Total X DEDocument4 pagesHighly Performe D 4 Mode Rately Perfor Med 3 Slightl y Perfor Med 2 Not Perfor Med 1 Total X DEKatrina CaveNo ratings yet

- References AnalyzationDocument4 pagesReferences AnalyzationKatrina CaveNo ratings yet

- Jerome RepatoDocument4 pagesJerome RepatoKatrina CaveNo ratings yet

- Control of Diarrheal Diseases (CDD) : ObjectivesDocument39 pagesControl of Diarrheal Diseases (CDD) : ObjectivesKatrina CaveNo ratings yet

- Anatomy and Physiology The Spinal CordDocument11 pagesAnatomy and Physiology The Spinal CordKatrina CaveNo ratings yet

- Hiatal Hernia: No SymptomsDocument2 pagesHiatal Hernia: No SymptomsKatrina CaveNo ratings yet

- Research SELF ESTEEM Grp4. 2Document47 pagesResearch SELF ESTEEM Grp4. 2Katrina Cave100% (2)