Professional Documents

Culture Documents

QC Procedure For Piping Field Fabrication and Erection

Uploaded by

Fouad Oudina0 ratings0% found this document useful (0 votes)

123 views32 pagesHELLO

Original Title

QC Procedure for piping field fabrication and erection

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHELLO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

123 views32 pagesQC Procedure For Piping Field Fabrication and Erection

Uploaded by

Fouad OudinaHELLO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 32

‘SLNo,

10.

Se >

1

2

8

4.

Se &

16.

e

16

”

18.

ed

0,

2.

a.

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

‘TABLE OF CONTENTS

SCoPE

PURPOSE

DEFINITIONS

[REFERENCES

RESPONSIBILITI'S

MATERIAL HANDLING

MATERIAL RECEIVING INSPECTION

MATERIAL STORAGE & PRESERVATION

[MATERIAL IDENTIFICATION AND TRACEABILITY

FIELD FABRICATION AND ERECTION PROCEDURE,

INSTALLATION REQUIREMENTS FOR PIPING CONNECTED TO

EQUIPMENT

PAINTING AND COATING

INSPECTIONS AND TEST PLAN

PRE-TEST PUNCH LISTING

FINAL INSPECTION AND RELEASE FOR TESTING

‘PRESSURE TESTING

REINSTATMENT

PIPING TOLERANCES

INSULATION

DOCUMENTATION

ATTACHMENTS,

Page 29

n

2s

as

”

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

1. score,

AA Ti rocedue aden the vaous sigs of piping ereton and inspeston of metal ing in

Fadi Sulfur Recovery Unit,

2. PURPOSE

‘This quality procedure dseibes the minimum quality requirements to ensure tat ppg ection

stv ae pefoome in accordance with appieable Saud Aranco specifications and inertons

onde

3. DEFINITIONS

rRorct Fadl as Pat Suphr Recover Une Petage3

Company Sz Aa (SA)

{CONTRACTOR Pete Sait Aria intenonl Lined (PSA)

SUBCONTRACTOR Naser Aji Conon (8H)

saes Sao Aamo Bags Spat

sacr Stl Anco EnghoeingPoceue

sanss Sad Anme> Matai Syten Specifeton

i lect an Test Pen

wes Welding ProcedueSpesiteaon

Nor Non Deuce Tsing

wart Post Well Hest Treatent

Pa Positive Mari Leniaion

4. REFERENCES

SAEsi-100 pte Cole Sti or Fe Phe SS

SAESL-105 iia neal Spiieadon) PIPING, LE chee

SAESL-I08 Selon Var

SAESLI09 Seleconot Fags, St Ba and ts

SAEs-100 nition fig Soins nd Conon

sassicisa tel eeton fr Ppa Stes

SABSLA36 Pipe Fig nd ing Mat Reuemets

SAES-150 res Testing of Phat Piping and ples

SAESL-310 Dosgn of Pat Pring

SABS.-350 Conon of lit Ping

SSABSI:200 ——_:Stomgs HndingIislaton nd of exer coned pipe

SAESA2I6 Posie Mat Keon

Page 20029

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

SABS-A.004 General Reguiement fo Prestre Testing

SAES-A.007 Hy ostale Testing ul and Layap Procedires

SAES-W-O11 Wetling Requirement fr On Plot ining

SAES-W-6 Welling of Seca Resistance Materials

O1-SAMSS-010 Fabrice Stel Piping

O1-SAMSS.035—:APILine Pipe

O1-SAMSS013 Carton Stes Pipe for On Pot Piping

OI-SAMSSM6 ——:Stanes Ste Pipe

©2-SAMSS-005 But Welding Pipe Fitngs

SABP-310 Piping en Pipeline Repair

SAEPASI Bolted flange jit srembly

SAEPAI60 Tracking and Reporting of Weldiag, NOT and Presse Testing fo Capital

Projets

SATIPW.OIL01 —: Welding of On Pot Piping

SATIPL350.01 —_: On-Hot Metalic Piping ntlison

SATIPAL350-08 _: Shop Fabrica - Piping & Miscelncous Sel Sct

SATIPL-108.01 Valve Inspection, Testing & Instlaion

SATIP-AGOEO1 — : Paeumatic Pree Testing

SATIP-A04-02 ——:Hydostae Testing of On ot Ping

DH4-A-RESWOI96 — :Pipemisking& color coding

DE-ARE-SE5255 Piping Mati peliaton/

Applicable ITP Iapeton and Tet plan

Schedule “Q” = Qualiy Requirements

ASMESECII Par A :Ferout material speciftion

ASMESEC.UPar'B :Nonferout matt specifction

ASME'SECI PartC : Specifations fr welding os, lode, and filer mals

ASMESECY + Nondestructive Examination

ASMESECIX —_: Welding and Bang Qualicatons

ASMEBSI3 Proce Png

PRLES-43 ‘Stand er proseton of Aastenit Stiles Stel & Nik Aly

Mates

NSILPSAL-FSRU-FQP-QC-0001 = Project Quality Pin

NSHLPSAL-FSRU-PRO.GE-O013: Merit Contol Procedure

NSI-PSAL-FSRU-PRO.GE-OO14 —_: Vera Hindling, Storage & Precrvatin Procedare

Page 0629

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

[NSIEPSAL-FSRULPRO-PL-OO03 _: Welderand WPS quien ani contol & Procedure

NSI-PSAL-FSRU-PROI4006 _: Welding Consumables Handing and Storage Procedure

NSH-PSAL-FSRU-PRO-PLODI6 Prostar for Weld Joint Repair and NDT ientcaton

NSILPSAL-FSRU-PRO-PLOOI7 Bak Purge Poceie

[NSTLPSAL-FSRUPRO-PLOOIS Gasket and Bolt Tightening Procedure

NSHLPSAL-FSRU-PRO-TIG024 Socket Threaded Well Gap Contol Seal Welding

Procedure Shop & Fiekt

[NSHLPSAL-FSRU-PRO-PLOWS = NDT Contol Procedure

NSHLPSAL-FSRUPRO-PLOGT Prete Testing of AG Piping

NSH-PSAL-FSRU-PROPLAE28 Piping nem Clestiness Procedure

NSHLPSAL-FSRUPRO-PA.OOL Procedure for lating, contig and pabting

Chore Consrctin Aplisetione Stare (SUT Deis)

RESPONSIBILITIES

‘SA. Project Manager shall be the respons rte vel implementation af the company sty

& cualty pln and ensre efficient execution of wak la seonlance wth projet peiicaton

and tis procetrs

52 QAQC Manager shall be responsible for enering all sctviics are cried out a8 per the

Drojct quality pln, project specications, and this procedure. He shall ensue inspections,

‘etn, and examinations ae cal out ter the approved TP

53 Construction Manager shale the responsible fo al meckanisl en piping erection atvis

evtsning tts project.

54 Piping Manager sal te esponstie fr easing al piping erosion stivies are caied ou as

sti procedure shall ave cose cooing with pojes quality contol department. He

Shall co-odite with pesomel at fell, plan work sebalule allsate job 10 piping

soperinendens

5. Piping Superintendent shal pln the daily work sede; th job to concer Seprvors

td controling piping works in the eld.

‘6 ping Superstar shal e the responsible to neue safe ad eiclen working eniroetnt

'» monitor plant snd equipment equrements and to ensure that product and ua ae

‘msintained by ter subortnats, They are aso responsible for extring tt the prope mate

{is being used in adston tthe coret welding consumable and he core welling paced

‘87 Planning Englner sil receive all he drawing fom document controle and sae wil be

at updaing a per the lest revisions, Preparation of weekly, monthly asd overall schedale

‘willbe compiled an he sme wll be meitored on dally bis. le shall be the epansible for

9

su

su

‘QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

‘work order appro of fd mater request and progess updating. The Planer wil issue

{he S79 (Ste Teka! Quey) to PSAL ifany enginesing consis are repre

“Material Manager sill be overall responsible forthe consrton material, He shall lease

ll required material to Get after receiving of Held tril request rogue by pipig

supervise and approved by plasng engines. Heal be reposibl fo evn inpeton

otieaton quality deparient preservation of mts,

“Material Controle is responsible foal materi reving& suing ofthe mle ofl es

Per the eld materi request approved by materi manage, Records shal be made fo siting

nd an updated stats of materials tock and transfor to fl wil dete tobe minsined dally

at,

(GC Supervisor shall range and supervise all QC sesvitesenerig that ll inspections are

performed in timely manner end documents. Before siting now acti tol fox shal be

‘conduc

Piping Inspector shall be responsible fr inspection and esting of al piping atv uch

‘materi resin, ping itera lesing St alignment, dinensina check

‘Welding Foreman sal be remoribe fr arangng and checking al welding rested tol and

‘qupment for welder and welling activi. He shall give the practice training to welers

whenever ruled. He dal be respoesible for welder passport (NSH wil isu weler passport

‘0 all quaifled welders for upting progress, weekly rope percentage, oberon ee.)

pdating.

‘Welding Inspector shall be responsible for inpeton attesting. of al piping welding

‘ctvites. He shall be responsible for welding contmsble receiving inspection, ft up, wel

‘sul, welding consmsble sence, and NDT witness The welding report tal be prepared by

welding inspector and submited to PSAL and Saul! Aramco Inspect, Bere string sty

toot box sta be conducted. He shall moltor welder rejection rls, welder passport and

ogresie examination weekly

[NDT Coordinatr sal co-orfnste with welding inspectors and NDT service providers for

‘executing the NDT. He shall corey Hetty an very the NDT selected wel joints before

offering to NDT service provider. He shall ent joints with warming tapes as pe the

‘Amachmest.2. RT oer fr rest joints hal be dove by same NDT servic provider. He shall

ropa weekly welding reedon rate, Welder reecton ree. a8 fe the SAEP-IL@0NDT

Coordinator shall ensure that spotperennge raligrapty Jolt are seleced by PSAL.

Inspector.

A

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

S15 PWHTT tnspecor shall be responsible for cowdiniing wth welding inspectors, PWHT

‘etnician and NDT Coordinator exerting PWT, He shal ides he jos and tag shall

‘putas pertheAtichment2, He stall monitor before, ding, dsr PWHT oats, He shall

be responsible fori caliaton of PWHT machines,

5:16 PMI Taspector shall b responsible for cording with welding inspectors, PMI technician

snd NDT Coordinator for exseting PM

‘547 RTT shll te resposibl ote interprtton of raograhi ns sd to erat th uaisy

‘of weld swells th im qty. He hall sponsible for he preperton of sessment report

asc onthe raiogphi ln ter prope lateeaion with reference to applicable codes

6. MATERIAL HANDLING

6.1 Responsible persone for the wanspraton and handing fall knd of piping matt (pe,

fitiag, ave, Aang, support marr, instrmens an pipe spl) ane ssid to eas ts

salty and quality are assured during eciving, storage, suing, and vansortation to fell and

‘brian sho.

{62 Alleria shal be handled wi care ring fiction and installation to prevent damage,

63 Stans set & hgh ally sta, ings and vais shal handled and sqrestod seprtely

ln accordance with SAES-L-108

64 Stings fr iting pipe shall te nylon or snl mero pevet damage to the pie src,

6.5"" Mito sabe inpected pon delivery wit reurement of he Purchase Orde t ei he

‘tipping documento, cetcation record, material fest cette and delivery noes are

‘oreo. Noifeton tall be gven to Quality department fr reeivng inspection

66 Ping identieaton, color code, labels and making shall be cared out as pe the Piping

marking od color coding speifcaion (DH1-A-RE-$89196)

MATERIAL RECEIVING INSPECTION

LA All otras shal be inspeced on receipt in secardace with procedure no. NSELPSAL-PSRU-

PRO.GE-O013,

72 QCnspecor shal check mati with relevant sproved IP and aly econ

73 Theresponsible QC specter al hes aa verify te ieaifcation aga oa seis

7A tthe materi ar not conforming Yo the loran drawing or speciation, i sabe spurte

om uodamaged mses and tagged with REJECTED matk so those mail can ely

ent.

15 Damaged material shall be documented, photographed and report shall ncate the reson for

he constant mail

A

A

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

176 ‘The stivngispector sal record contin of materi onthe mail receiving 5 tthe

‘mates personal can tke necessary comet measure

‘17 Pipes tings, valves, instruments und bite spots shal be recived by piping supervisor

st el

18 Each soo! sal be stamped or send with spool ication umber ad he responsible

rsa in spool releasing fom shop and esiving at ell sal be verified forthe coeness

spools wit the Inte approved IFC dang and related documents inhng NDT,

79 ‘The spool sal be clean snd dry, all oaeferegn materi and weld spt reinoved ftom

‘he inside ad tse of he po.

710 Flange ices are protected by sible Mange protectors

711 All spool shal te recived at ste shal be wi proper end covers for protecing the enrapment

oF eign materi

‘MATERIAL STORAGE AND PRESERVATION

841, Alt piping mata shall be stored and preserved per th approved Mata Handing

Storage ad Preservation Procedure (NSH-PSAL-FSRU-PRO-GE-0014,

52, Pipe shall not be stored drecty onthe sro. Pie shal be placed on mounds or sesper.

Separate are sal salle wih proper ara Henin fr dient mater

83, Stocking of pipes shall be mde in manera avoid dag fo pipes x cating.

54, Fitngs and valves stall be stored in shipping rales or on rack, Stiles sel pipes and

‘ings must be sept from carbon sel to aol contamination,

483, Alleria hall be andes with care ding Sricton and istallation to grvent damage,

56, od protectors on pipes, anges, weld bevels, eds an socket end shall be fly atch,

1.7. Pipe stall not beled a dropped off ruck

28. Bnd Bevel protectors sal ain on pipes and ftings wl

arnage inter o extral oting.

8.9, Plage face ant trends shal be protec foe rat by aplyng suitable ast prevents.

8.10, Lined and coated pipes and tings sal be ied with wie fare orubtercovered stings nd

dng sal be sed to prevent damp toning o costing, Wire ope slings hl ot wad.

B11, Shines stat mates shall be covered and proteced flom water splath and oer

in storage, protectors stall not

contamination dro shipment an storage,

‘MATERIAL IDENTIFICATION AND TRACEABILITY

8A, All pipe and fitings shall have tho material specication and grate stamped, seni, oF

otherwise clearly marked with penanent marking metho,

92. Spools are stamped, sence or ley marked witha pemaneat making method

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

93, Paint marking sal be dove with watrisolble mail tht contains no subtnces that

rfily act the meal at ambient or elevated tenpesturs, In parila, the marking

‘ail shall be reo ead, sulir, ie cadmium, mercury, borin, o abr halogens.

94. The entiation makings sal be tne to resin itera entiation when a pate

Bs) The cole olin sytem er mae Hemeton senda oe preven ts

10.

Cee >

‘sing incoret lloy material. The pineal pupae of coor coding is fr vse! Metco

turing storage and fer the components has en ctf faction

95% Color coding may be done by the mati manufictrer ot materi suplie. Colo caing eed

rote retained after pining.

9.7 ASTM A193, Grade BT stud boks do not rqute color coding ifthe rade of the mae

stamped on on ent of ech bt.

98. Splratovound gaskets shall be color coded in accontnee with ASME B1620. Sheet ype

shes do notruire alr coding.

9, Pipe and Fittings: Each gt of pipe and ing shall ave a $m or lgersrpe runing fl

length One inc NPS and staller my ave 43 mi stipe rng fl enh

9:10, Valves: When require, sbpe ares te bad fom fang fo flanger en toca.

9.11, lange: When equi, stripe arse edge up to ub,

9.12. Boling: When rquted, stripe rend he midpoint ofeach bolt or sud

9213. Mat, Sheet, and Strip Stipe on src nes fo perpendicular ees Fr cai gh

9.4, Tuber and Bars: Strip ence eth

9.18. The materials received witout proper making shall be segrested, marked ad sored in

‘eve items to provet untried wage,

}. FIELD FABRICATION AND ERECTION PROCEDURE,

101 Genera

10.1.1 Constrcton of plant piping shal be in aecorance with SAES-L-350.

10.12 Inspsion for shop fbision of Pipe Spols and miscellaneous Stee Struct sll be

pevfomedas per SATIP-L350-06,

10.13. MetlicPping field estan inspection sal be perfrmed es per SATIPA-380-01

10.14 Pipe spook shal be checked agains ping spinon an dawings proto installation,

10.15 ach spools, pipes and fitngs shall be vill inspected for physical damage prior to

instalation or erection,

10.16 Preise pipe spook shal be taken fo feld only after complation ad septa of a!

Nor.

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

AN 101.27 pwr pig pot wh age instal bpm ete age ey.

[[\ 1088 Wie PET ope ie ee cng We ata ih

soe pert fr nla ns, drmy exes es ad we pd ae be ele

be spool bere tes celevng

40.1.9 Prior to cretion al pipe spooks stall be checked and clean fom ay kind of dso frcgn

material inside the pips.

_A\ 12110 Pee p00 end shal be covered ater inspection to prevent unguried removal of end covers

bere making succeding joins.

10.1 emai on ie crs, el wh be ero se a

sings Det chs os pe cg roe Sra pee

10.12 Paling nei of pi a tated ale a pn Rg

Se mi hb cet 0 wth pn md me et tam

stew fm

101.18 Donates fom hd,

101.1 Vety wf hey sens of pues i eng te al

‘ing iin

[[\ 1880 eto pi 7 tl eae et nin pens

tinge etn, ls pes pr eon, pein ae i a

che vit ea a

(A, tea6T sete mero mie, ie tl oon sine

ves ge he spr di no hs wel ane

mane hc rey we es lm ee a eh oe

ile pr comming cig ges sn pr

101.7 Mee © poe rig mye myo a ner De fl

enh lets on ety ese at es

10248 psn tan wd a aes ane

10119 tg al beta od eho! in wre in pn ‘Ot nd alt

“een Powe QUEPSAL AER PRO-019)

A 101.20 Damaged or rejected spools and items are identified, segregated, controlled and tracked. Such

toms eed RECTED vet Ain bn

esis

A a121 tert mets ee mnt il ml a see wi

sags,

A\ 212210 pgs twa OC don empente aiwenpt eie

Page 90629

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

A\ 104128 Were Chay impact is specified on he WPS (aw Temp Serie), Heat input Ht of each

102

1022

1023,

to2a,

AY 0s

1032,

1033.

103.

035.

1036.

103.9,

production weld is caused (sing formula below) to ont not to exes the het inpat

lis ston the WPS.

HI Giom) = Volt Amp X 6 Tavel Spend mi)

Internal Cleaning

All pipes and spools be neal cleaned 8 per the approved Piping Intl Clessiiness

Procedure’ (NSH-PSAL-FSRU-PRO-I-028),

All pipes and spook sal be inamaly clemed by ai blowing nation, for age dlanete

pies rag cleaning sould be eondaced if food pret

All petite pipe spol shal be val inspected fr cents, and tll ave frien

‘nati moved from the ine,

Spool leminess checks pele to insallaon (best with mor aad nail sunlight) are

enable “len

Pipe Laying, Spoo! Erection & Assembly on Pipe racks and Sleeper ways

Piping rcaon a fet istaaon shall te performed within he tolerance sped in

‘SAES-L-110 (Limitations on pie joint nd componets)

Pipe rack nt sleeper way suppocs have ben completely eee or installed

Cenecties of piping rns re lid out and Pips. ine numbers are marked oo the beam

(cemetins)

Minions ie spacing betwee piping suppored on sleepen or pipe racks i verified and

confined wit Sui Aramco Standard Drawing for pipe spacing AB-36207.

Insult lines & insustion hicks sented per Notes and dtl of Std Drawings AA-

(036911 & AA096919 nd considerations allow proper clesrane betwee piping ta,

ngs spacing consieatios (sagging of Manges may be equed) bee ben incomported

and spocag is adequate

In all cases, a minimum clearnce of 0 man i provided fr inspevon & frexdom of pipe

‘movement batveen stove ground piplag crossing with any sirctre inch pipe support

strstr) This learns slo required fo sbove pound piping crossing with coher pe

00mm piping cleus above Rashed grat clovition i shown on approved dawings fo

hvizntl piping runs and Pipe elevation of vera drsins (lowest pin) slows adezute

clearance for sericea (hae en be atiaced to rn ine)

lar ines and ote ammable and toxic services se lcated on pie ks and sleeper ways

‘These type lines arent routed below ground at ay loaton excep rough an acepabe pipe

hse tat fies alnpeton a ninteance sees.

Page 10029

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

1n3.0Low ion ting 1) syns sal not sw snd oro dei cule on

stg tice

103..P%ar asian he Pips ripe poo sab nelly ne by i: owing nd

lanes is sag ed hen pose.

103.12Pping code mr covee trinpeson even unin removal onl eve etre

alg reign

1013 allenpray felt isn eporry sponsor ope lime halle mgs on

ripe as befor in tation

40314 pecans be kn cringing ad nstlition fie on pie ack Method

of iting Singrod, methook epee)

104 Fitup

AOA. Al op and wong sl eco on in ssn wi

deawing WS.

1042, PreWeling & Weld Jot Fe Up lnpecton sal be permed apr SATIPAVO101,

SAIC-W.205 math repre ope sed on SATIC.2006

1043. Coin sl be cariedouta bw;

+ Cabonstctripes 1s Cating and Ging :

+ Alloy Stet Pipes: Fant Conga prndag A>

+ Stine! : ining ad Pa Catng

+ Nonfat: fining ad Psa Cating

1044, All mate emo! adctingtlfor inks sa and ick alos sal be sinless

stl tnt pv dn ter mata

1045, Mati resi sl ante aie tg pes

1048. Thema oor ge sen forall matting carbon seal be pover ed

or wand pre belting

1047. Thema ut sre of sins sl an mone stl be gous to ght (a

din ster oro welding

1048. A ina fm dp sale eno ty ging or machining om heal a oe

suger ofa dna ati

104 Bevel prepare and hale done mor proved WPS. Ftd bevel ale heck

fer teninton.

1040 er ss with infringe oe stichnet wel sale comple an peed

proved TFC omatre

‘QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

104.11 iting tht are rector r-Seoled sal ave he et sie exited for laminations before

‘welding. The NDT method tobe ued shal be determine by Saul Ara Inspector,

104.12.4neral misalignment of tut jolts shall ot excel Sm. later tpeing in accordance

with ASME 31.3 by machining, back welding of «combination may be wed cme the

risallnmest,

4104.13.01, moisture, ran see, snd, pin(excpt welable pines fer approved eppiaons)

‘metalic costings. ne) or other foreign mater shal be removed fom the weld surfice and

st east 25mm of aacont base metal pie to weld, nctiding any sch coating on temposry

tachment or sport.

10.414 we ints shall be marked for ientieston maim floms

104.151Use sulle permancar weather proof makes, and mates fr Jen max Kstifeaton

Cerf ow chlorite 0 pp) markers hall be wed forsee tesa eal alo el

104.16 material moval & ening tos hl be sinks se! it shall a eviowy used on CS

materials for SS and N los and ae market emit hat they ate o be ween attic

{nick ally mates only. Markings sible wil ato isin ute, (Yeo lor cose)

TOA.ITANI WPS6, PORS, snd Weld and line description tbl shall be aval a the work sit or

‘esifleaton t anytime forte auhosaed Saud Ara Ieper.

1O4.18All tack weds shall be made by qulifed weldes, All tacks or teporacy wells shal be

formed with he sane ue, materi lestroes, minim preheat and prose tht re

ed for permanent welds

104.19-tack wels sall be sulicent size to msn joint alignment. The recomended tack

thickness is 3.2~4.8 mm a length i 125254 sm

‘The minimum number of ack welds are:

Pipe damster of 016mm orless: Three epullyspsed ats

Pipe dameer above 101.6mm : minimim of foer eqully spaced tacks, The

designated inspector should determine if more aks

se noaded

104.20A8S-W-016 Corrosion resistance alloy sal be tsked with minimum equally spaced fur

tacks.

104.21.Brdge tts (oct above the root area) are acceptable bt such tacks mutt be completly

removed pie to completion ofthe weld

Pee

Pee

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

105 Welding

10.3.1 The wind velocity inthe sea for GTAW, MAW, oF gs shield FCAW shall ot exceed pt

(2-2. Necessary shielding snd wind protection shall be asl if wind velocity exceeds

8iph,

105.2 Welding shall not be dove when sures area wet dap or expt fo anor sow oF when

‘the welders ane expose to inclement contons

10.33. All WPSs, PQRS sal e avaible th work sto alte, WPSs shal be played ats

10.54, Welding inspection (Btore welling, ring welig and fer woking shall be performed as

px SATPAW.O1L,

10.55. Contamination rom the environment, ssh 8 win st som and noise hal be prevented

by nae of adequt shielding or pret,

105.6, Welding shal ot commence before lesranse fom NSH & PSAL Quality aspen. Welds

all have qulieaon spate in ASME SEC IX o cover te typeof mati cone in

the piping work, and the welder quails test in scordance with ‘Welder and WPS

(Quuiscaon and Control Prod’ (NSIPSAL-FSRU-PRO-PL-0003)

10.5.7. All welding sal be aed oly by quale welders with valid Job Cltrancs Card JCC) and

2s pr eprored Welding Procedure Speifiation (WPS),

1053, All pressre containing welds shall be mde wit maple passes

10159, Adjacent bends ofa weld shallbe stagere and ot stated the same location.

10.5.10.i1 nozales, ranch, and ee enncctions shale made wih il peeation groove welds only

sod spec approved PMS,

105.1 1.Preeatng shal be card outs per he approved WPS a the ceptable methods are

Oxy fel gas toch with eating ti.

1. Aieful gator

Fle cera mats (For low allo tl)

10.5.12Post weld heat estment sal be cared ou per the approved WPS and he soceptble

methods ae:

‘Flori esistance este.

1b, ndtin eter.

105.13.Preeat temperature sal be exalted over amin tance of nun on each sie ofthe

Weld. If wal thickness exceeds 25 mm and preheating Lo be dooe fom the sme side as

welding then the heat source shall be removed for I minute t allow fer temperture

‘qualiato prior measuring the temperate,

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

105.14Temperaur inficating crayons shall not be used or deposed weld meal o onthe joint

surfs to be covered by weld metal

10.5.5. socket and seal welding shal be cared ot in aecrdance with rocsture‘Socke/Treaded

Wild Gap Coro! & Seal Welding Procetire-Shop & Field’ (NSILPSAL-FSRU-PRO-PL

02s)

105.16For FNo.S and high maneas, Sack purging shall be mnie val test nim

‘0mm of the weld depos thickness has been completed. Bak pring sal be dane as per

“Back Purge procedure’ (NSH-PSAL-FSRU-PRO-PI-O017).

105.171 Welding Consumable storage and handing shall be accordance withthe “Welding

consomablehniling and sorage procedure (NSH-PSAL-FSRU-PRO-PI0006

105.18.Are sites, gous, and oer actions of celess workmanship (uch a surface porosity,

uneven weld proies and andre sal be eave by ering el etd by MPT,

105.19Any temporry welled sticheals or ternporry tack shall be goin off. Atackments may

bbecutoffno close tha iim the rem surie, print the required grinding

10.5:20.terng of Weld Joint

1. Butering or wed bul-upon the prepared sures shi ot exceed he st of 19 of

{he bas sta tikes or 10 rum without th approval of CSD. Ifthe buster bil

up excess, then he following requires sal apply,

‘+ Specie ppovalis required fom PSAL- QC. If at approved te spool pipe

shal be ele to length ape by PSAL. QC.

‘+ Thebutting operation shall be wimessod ty Saudi Anco Inspection

+ ‘Thebuting shall te inspected by RTLPT or MT afer completion of te bik

put before fal wel of joint

1, Buterng oot heawen ania metal jin sure ir approval by CSD.

105:21,For all mates, inspection by MPT metiods of ae shal be performed wire temporary

‘welds ave been removed or weld repair to ground ares ofthe base mail hove ben made

orate sik afer epi by grinding

105.22.cep for ASME Pod though PNo.SA/SB/SC base teria ll anual GTAW sal se

‘high equeny start and post pure gs low fr the torch.

10.5.23.Bach weld pass stall be throughly leaned aad slag ree faregn mater removed bef the

next pass depesited.

10.5.24.A slg, ax and pute sal be removed fiom he completed wel and surrounding re

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

105.25.The heat iput (HI ofeach prodstion weld must b elo if noch foughoes est ae

‘pei and then confined not exceed th est pt is ted inthe welding procedure

specications, Heat inp sal Ye calculate with format ‘Hest apt clelton see”

PSAL-PSRU-AM-PL0)

10526:The minimum distance between parallel fut welds sal be 20m ce tes fines the wa

thickness ofthe joint, whichever rete

10.5.27.Pressare conning Wels (eg, nozles and otberatachmects) sal be spared rom other

prestre conning welds by no les han 20mm thre tines th joint thks, whichever is

excoer. Contactor aproval it required if the miniman separation snot mt. Radiography of

the butt weds requ or sitions in Which th nium parton ent aciove, For

Joints other than bat welts, ote appropri inspection methods ble se, depending

the geometry ad materia The flowing ar exenton:

I, Simctraeomponets and enfrcing pads

T, Hotta spite end weds which cou the pipe longiinal seam,

105.28.dentifeaton tg shall be followed as per ‘Waring tape Color ode fo spl & ints ind

Abtacment2)

105.29,When a circu weld with an intersecting longticinn weld) i examined, tes the

sdjacent 38 mmo (112 ino each intersecting wld shal be examine

105.304 any grinding educs the base metal thickness to les than the design minimum, he ground

axea shal be reweldd snd ground fash withthe oil bse etl sere followed by

[PUIMPT or the compeneat shal be replied, Rewelding sll be done only wih the pear

approval of PSALIaudl Aramco,

106 Nondestructive Testing

106.1. All welds shal be visually Inspected and acepe prior to performing NDT.

1062. NDT sal wines ty proved welding inspesior.

106.3. All NDT shal be could in scardnes with NDT contl procedure (NSEL-PSAL-PSRU-

PRO-PL-0025)

106.4. NDT shall be performed ss required by SAES-W-01|, ASME D313 & Approved tomers

drawing. After NDT clearance, spol shall eles for lating & pining a eid,

106.5. Joint repair wll be dove ined an aon! penalty shots spud wiki SAES-

W-011 shal be aiographe.

106.6, Rejected welds sal Ye reared in accordance with pprovd epi procedure (NSHE-PSAL-

[FSRU-PRO-PI-0016) and WPS by qualified welders and inepeed s a minim wing the

orginal test metod of he join.

Can

QUALITY CONTROL PROCEDURE FOR,

PIPING FIELD FABRICATION AND

ERECTION

A\ 1967. Pi to st of post weld heat acatneat work, NSH stall prepare a table Hsing etch

Joinispoolequiing eat treatment nd bal be submited to contactor &commay for eview.

‘The table shal include joint no. / location spool no, drawing no, diameter, wall ines,

mate heing rt, cooing a, soaking temperate, soaking time

A\ 1068. Harassing sal be whore apt, sal e peremned by tne and aprved

etonnal pe approved tid pry hares ttn procedure

{\ 106% Pst Mast Keeton (PMD, se apples be peromed by tind and

‘proved pesonel sper approved Thin party PMI procete

A\ 105:10.Ferit west where apliabi, tll be performed by tine and approved persone and per

snproved hid party Fete est procedure.

107 Austonltie/Duplex Stantess Steels

10.7.1, Abrasive teting ano rinsing ie shal nt be wed on eter carbon tel or other ead of

tines sel materi. The seletion of ginding and ceanag tos shal be appropriate forthe

‘se atrial Es, carbn tel rashes sal not be ted on anes tel mater.

107.2, Al lee materiale should be invidly and ely stamped, aged or senile wo ee

treba comet sage onsite

10.7.3. The GTAW process sl be used forall psses for wall ike lt ban 9S fr duplex

sinless ofr wall hikes less than 68 men fr ther comorion rita lloys (CRA)

(0.74, Allman CTAW sal se abigh requney tarts pope as lw forthe toch,

10.75 The maximum trys enperatare for dopo tassel shall no exceed 100°C

1026. Unless speed oteis, the maxim interpas tempera shill be 177°C for PN. &

teri

10.7. The ange sal achieve atl oxygen lees inside or exing the oi (va the vent) 0 gree

rior oan daring welding,

10.7.8. Feo messarmens bl be performed a accordance with AWS AS2

10.7.9. For production weds, the fertite content sal be checks in the ae Welded coniton, The

Aerie number sal be twee 3a 10FN,

10.7.102uge dam instalistion and removal shal be controled by acardance with prose for back

paring of pie welding (NSHLPSAL-FSRU-PRO-PO017)

107.11 Special equbemons or duplex stiles tes

8) GUAW proces mast be sed forthe root and ht pstes ifthe wal tines f eget

‘oor greterthan 9mm,

1) Repair of tecive wads regu separate epi welding procedure gulifcaions i

poe tins stl was wed fer coreion reise

ee

‘QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

©) Theft conta of competed wel sl be checked in sccordance with AWS 2

1 shall be within range 0f 30 to 60 % frit sing the appropriate fete number

tase onthe corto estibished byte PQR messiremet

4) The welding prams stall be mond in ore to cafarm compliance to the

‘minum and maximim het input estos

©) Hardness testing sal be conducted on 820% random supling of all production

weds Both he wel mot nd HAZ sal betes

108 Orifice Plate & Restriction Orifice Installation

10.81. Orifie plates shall ba afin ish Gone, lapped, pols or bf. Orifice plats shal be

feof sic fe and bore edges are m0

10.82.0Fic plates toes shal be in center of plate ad th pl ain at,

10.83.0rice Paes shllbe ee fom mechs damage end eligi

10.84, Welded bane stall be paral ote plates wih welds ground Fash

10.85.Phtes are fie om echnical damage and weling diorton.

108.6 Oriie anges ae to be wel-neck with an internal bore to mish the iter dametr of the

ie. Any distortion resuing from he bat wo bl be removed and ground Mish wth the

Inside imate of te pipe

108.7.Psort instalation Orifice Plat Oietation shal be confimed with the SASD AD-036004,

1088.The inspection of Ventul, Flow Orifice Pte & Resco orifice installation shall be

performed spor SAIC-L-2046

103 Installation of Pipe Supports

109.1.A11sapors, anchors, guides and other suport stachments hall be vce in accordance

ith details indo in the pipe suppor drawing, approved some reins and contrac

specication requirements et

10.9.2.tnspestion of pipe supports ad anchor italien sal be performed a er SAIC-L 2018,

1093.Reinfrcing pad material shall be ofthe same pipe materia per suport standard ules

‘otbernt spprovedin writing bythe SAPMT,

109.4.Fi-up and welding shal be done as pe th approved WP' and approved dawing,

10.95. All welds of pipe supers th ip wll sal be continous with smoot fish

109.6. tntaling additional dammy supports ar than those in the design eawings sal ot be

installed without prior review an approval om the chirmas of pig stars commit of

is representative

‘QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION,

10.97. Goum weep he shall be elo forall dary support. The weep hole ssl be ost neat

‘he bse pte oral veea dun supports, aed ner there pipe a6 lock posto fo all

horizontal dummy supe.

10.9.8, Separate sage fry sal be made to sore fabricated sports in are wise and trial

1099, Fabricated CS, LCS, $8 & Nenferous supports shall be paced sepately with proper

‘entiean ike pe of supp, sequence nanter ets with legible marking.

109.101 west the pipe shall be continuous with smooth nish spot weting i nat accept,

109.11. Minima ilet weld siz i shal be 31 nc (Sra) for strstr Wels.

10.9.12Pipe suport sl be ul contc wit seppors bat cry the oad.

109.13Low fivton sippere sling surfices shall be protected dorng all consrtion stvites

ncn plang ed sandblsting.

109.14. Speag support

| Thespring sng shal be verted tht they are matting the design requlements,

The spring suport sabe fal engagement wit pipe.

[LA ping shal bein compression, so that ilu wl not rsa de complete reese of

toad

10.9.5. Hanger rods

1 Rod hanger sal nt be wed fr ines

fw.

1, All hangers sallbe proved wid mean for veel aust

I, Sutble locking devices shall bo wed tall threaded connections of hanger sstembly

(ovbie mis).

1V, Rod innges hl be sbjoted ttn lon only.

10,10. Threaded Connection Requirements

10.10. Allred joins shal be taper pipe head (NPT) canon o ASME B12.

10.102, All headed comcions shall be performed as pe NSILPSAL-FSRU-PRO-F-OI24

(GockeTizeaded Weld Gep Control & Sel Welding Procedure)

10.103, Sit tueadng option se monitared in process for cde quay per ASME B120.1 se

fallow:

b>

"NPS and lager in iid serie mslphase

4) Pipe eds are rexmed clean ate threading

+) Oi nd residual shavings are removed fom nse pping

©) OD threats are chased and cleaned of devs and dba,

10.104.

ro105.

10106.

A tom

A wna

A ous.

A coma

oats.

ots

oats,

‘oun

A ons

A one,

A vos

A one

A wns

(\ wns

‘QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

4 Staring heads and runout trois sre chamfred and rounded

) Tends ae fe of burs, at pos, chat, eas eu 6)

1 Dis rein good coadkian and produce smooth quality heads.

The engaged ppe thread shal be vr ove «minimum thea engagements flows

Noinalsinesie: Number oftieads saad

waw 6

trough 112" 7

2 rough 3” 8

In harrdous svies, maximum sie of treed connestions sal be inc for standard

{iting & valves In on-bzardvs services, maximum snes"

PTFE (Teflon tape sal not be ued for seve tape restr han 204°C on read

ta

Ensure tht al valves ae hyo tte snd test eports are alba,

‘Valve lepton, Testing & lntalaton shal be perfoed wer SATIP.L 108-0

ion of Valves

‘Valves re completely dine of et fd & Borouhly eed ar the completo of etng,

Machined sures are costed with light fim of high scsty rast db ol hat wil not

become Hid & rm oat temps below 30°C.

‘Valves shall be purchased from manaecures approved in accordance with SAES-102,

rot insalition esue that valve eal opeingand closing il oko

Valve dsction shall be checked and conte for diretonal valve like check valves, lobe

‘lve te. and valve handle rientaton sal be sper approve isometric dang

‘Valve ideation shal be checked a perth approved isonet drawing.

‘Valve shall be cheska fer any mage and Mage aig shal be check Before instalation,

(Cain wheel operation sal ot be povided for emergency oon valves or vals tang

treed ody connection

Amospvsic dain al vent valves stall be povided ith pig or bint onthe charge

site

‘Chek valves in snes NPS 3 iach ond above shall not installed in vertical tines, unless

spproved by company.

‘Conrol valves shall ot used as emergecy shutdown vals.

Valve had whee shal be uly esse fo peatin

All valves in serves below 45 shal be fll asteniS.

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

re

be &

e

10.115. All bolting tn tow temperntue sevice valves shall be ASTM A320, Grade L7. The

crsponig nuts shall be ASTM A194, Grae 4.

10.1.6. For cock valves sass NPS 4 loch & above, a turbulence minimum distance of 5 pipe

dames wpstean & 2 pipe diameters downstream of vey check vale shal to malatulned,

1No pine fines er devices tat rent ow (elbows edier, tees, orcs, and conta

‘ave hl be inte in deve zone, Noe: Exempted are chock valves i intermitert

service & valves in skint yes

10.1117. Swing Chests (aids) ae install with fw arow pointing downs. Verity

Flow direction and core insiallson

10.1.8, Cont vale are nse in the direction of flow cased or stelstamped on he valve body

tod shal be neta in horiont ins

10.41.19, Contok ves and heir acting systems ae mounted such that all adjments ae

accesible and all insoles are real) from ead, permanent plato, walkay

x xed ndier,

10.11.20, Rett vale lt & out piping main lane aeament i within tolerance:

5) Rottion of flanges, meaared atthe ff betwen elevatlons of Blt hols 0a

opposite sides ofa flange centering, sl not exceed 2.4 mam.

1) Thetitofa ange messed at the periphery soos ny diame hall not exceed L.6

‘nm fom the square postion

10.11.21, Flange vives shal be tightened in accordance wth procafure ‘Gasket snd Bolt Tghening

Procedure’ (NSHLPSAL-FSRU-PRO-PL-OOIS)

10.12, Flange Joint Antembiy and Bolt Tightening

10.2.1, All angeditens shal installed and ightned in accordance with SAEP-381 and procedue

“Gasket and Bolt Tightening Procure’ (NSH.PSAL-FSRU-PRO-PL-O13).

10.22, Inspection oblige assembly sal be perfume as pr SAICAL2014,

1012.3. Flange bol oes sal be orient follows, ule ethers indicated onthe constuction

ings

> Thetit o2flange measured tthe periphery serost any diameter sal ot exceed 1.6

‘nm fom the gure poston andthe flange face parallel sal not excel 0.8 mam.

> Theflane fc cee line tolerance sal nt exceod 1S mm

‘The emp between ming Manges aball be minima“? (Gaskee tiknes) and

maximum to ties the ake hlcness.

> Thebolthole ational oft shal ot exceed 3mm,

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

10124, Gusset beste arte etre ad compete wi the fan ing. ng

—

10125, Gust al ote dana or srl ale ofl oon ares he sive pte

shall beret

10126, Theol maz tal select in aca with SAES-109,See-13

10127, Bot, au and wate sal bev cic or rope, gee dneson sn for

sey paple anag ch scores, st an as Ao th subi of sd ois

se ats mel rh ec emg ecm with th ans mata

sha be chct.

10128, Boks anda stall bee! wien reassembling xsi mes

10129, Thenustal vel eel ngage aster anges.

10.2.0 Wie esembngthoge ot, al ndcatons of te pevons gkt nso sal be

revere,

10,21, Laem sant be went pth gs sein a.

1012.12 Hammon fase mat permite ire tong or teen

10.2.1. Maal org wees hl tbe td fr lsd ar.

10.214, Tieening tos sa be cated fr aay, permanent alten, The oe

song shoul nts 2%

101215 Tgexng sal ave a mina of four pases 4-6 100%100%) techie he

sequin

101216 Afr complain of Sage seably inesion fans jit ening ngecion Report

(ATIC 2001 stale prepared and document

11.0 Installation Requirements fr Piping Connected to Equipment a8 P2X A°7696 Chosen 206

111A ping sal erste nd prt alow cso maize fr oan pion

tod ner, nt made lon Hck vex sind mackie sl be able

fom glen mtn.

1.2, taton Wok ves a ee inte it and ut oes ing 6 and tow al

roca A chek vale tal bens fe the char ieof al pumps. Teck rae

‘hl be ote Bete he machin dcr ge andthe dcr blk vate

115, Pamp sion pn be araged ch tht Be ow isnot sd no rae

step etn pz

114, Recor ton Recital on ne hl be exente wih eft sion Bsn

‘acer wi eft ide on op sal be tie for ova ping in a op ston pomp.

Conese desta be wed nthe ei in in red

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

113, Suction a dchareppng or veri ise pepe sl be adjustable spp

116, Suction ping to wet compress shal be it ced nd inst

1.7 The fot ined on tthe equipment ol ef a mislgament fe ppe wi eglpnect

son. an conti fe lowing:

ovina exten oft

Flange fic vert et

Ags misligest ween wo lange hes

Inaqate svpos

Wrong pir ports seid (sed stably) andlor nt emus separ used.

"1A, Ping shal not be atch unl rotting esipmen is bon gout ad nal algamt fas

een compe nd scope

11.3, Allipn ote equipment coms sil eds a ino ser ha

sanufatue neomnendtons, AS PP APT C96 CHAPTER 6B

2110 Fog sl nt bese wilco pment Apek APL 6 jchnglen 206

11. All spring suport sal e securely chock in poston and any tempor spas eg

yo testing shal bent prio he st.

1.12 Peo gong» realign: check lb condeted ty ensure prin linen canbe

tied 3 7X APL OES, Clangler OF Change srt

21 ter aa a po i af pet ees

11.6, Feld inated auxiay pig eestor Seco Wal 8 ool para

foe eqipmet, hse ites dont ner with he renova istaton of pnt ot

seco fr noma open sd manta,

11.15, Checkand ens the couplet and proper intlation ofthe olin ping end somes

scape approved drawings nd pce

11.16, nr comectg piping shal oly be stich the supe! er anchor bls eine,

{leh eigenen compte fil welling an ng inner have ben compe

1.17. Al oss ping shal ot be cme he quent unl secs eng adspporing

seve ae comple a cet.

A\ 29 vawnncicoatine

121, Sutiepeprton halt dane ri apy he pat on te oe

122, Plaga coving ahold be rope overt

123, orto coming, ang fs vate ems sigh ies same pas machines surest 9e—

teed y mag

124, Ava ocoing opeaton sale ety maa ta

Ame Meceskory to akinen piping fo macs goR

18 ned MT et wating ahr ete GS acd guns aig |

Puspole Be ape in of a %

pigeon, Wacktrony Balko utlabd gone Pe gone

Pies gO gull Oidla Simm MICK “ Comphtior “Gaakets as pA

rene oF|

fe distance tom the ober Woks,

13.4

‘QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

125. All paltnglaating sal be peor in accordance with procedure fer blasting, costing and

punting (NSILPSAL-FSRU-PRO-PA-001)

126, Repair Procedure for Atmospheric Coatings - Follow te surfice preparation and aplication

requremecsin the applicable APCS andthe manufacture?’ echnical dita shot

INSPECTION AND TEST PLAN

13. General

13.1..No aia spot al be released fim fieston shop o aye yr, pining ot site

efor fly inspected and released by QuallyContol depres ofboth NSH & PSAL.

13.4.2.Saudi Aramco representative shall have fe ccs othe work tal ime

13.1.3. Piior to star, NSH shall ensue that ll eguied Welding Procedure Spsificton (WES) ae

spprved and have evidence of approval a eck pages of WPS

13.14, Ensue th al weber have valid JCC qualified forthe welding proses, thine ngs,

inmeter range and welders having valé CC for parc welding

18.15. Inpestin & Tes fre Pping stallion shall be cared spr the approved IT,

13.16, NSH Consrction representative shall aise request for inpston (RE) a per the approved

ITP to NSH Quality taser

"NSH Qualiy Inspector shal forward inspect and acozped te RF to PSAL/Sa Aram,

Allqalyeportstcords sal be writen as pe th approved ITP and tached wth RFT

[FT shall cord and contol on taba App

[NSH shal cord an contr! al piping rested activi on database App’

[SH shall imely record al quality contol reports on database “Apps ike ft wp, welding

NDT repueset

15.112. CApps is softare package designed and developed for NSH to mect Hs complet

reuiement for project executoe. CApp it developed as ps the SAEPCI60 “Ticking ad

reporting of welding. NDT a presse tating for xpi projt

152, Poste Matera entiation (PMT)

13.2.1. PMI testing shall be caved ou st per SAES-A-206 for vs he stunless eel and alloy

mate

13.22. PMI Testing of welding consumables sill be perfemad in aecordance with SAES-A206,

13.23. PMI Testing shal be performed by thd paty NDT service provider with approved procedus.

13.24. Inspection fr PMI of Ally Piping & Alloy Components (All Appisaons) sll be a per

SAICL-2000

Page 25029

‘QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

(228, Mt ded ln mpl a tie pi nyo

ee eee

1326, Catan men te PA one re ct eid by

eee

1827, Puttwingot we btn me nde defo ei re,

eersecaercren

1331, Poti rams WE st a ee i AMEE

1332, FW te pte pps NSPOAL RPO ME

1353, Pte sf enc al pre al rn Th

thle tx ave nema ences ermageese anes en

eae ee caer

1235, ePaper 16h ate Ce

1338, Thomann Petron al haw

Neg es

34, Pl es tw iid rely ASME.

1342, Hes sng le et ep NSEEAL FSR RO

1343, Pee ein cre ns PN eel

tepetenl Wireman age Tn tn tre sae

as

1344 tay aig exe ln om OR he sae tre

Gates nts ae mee ex petite alto Gone

sm eve sete! ni ent at oie oy ft ma ede oo

eee eee

ornenest runeausing

14, Rotating been pe AIO md SATA

142. Al pment gs sal pce putt mal i ete & ppt

met

Ue, Atop ened pp oi

144 Yen eat ne bt map tone ls nme pg ea

oe

MAS pent ae i ange i prs pel wih ge

career gre oe cera

Page 029

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

146, Are ses and ote incutons of caves worknatship (uch a ors, uneven wel profiles

tnd undead) shall be removed by grinding and inspected by magostic pale oF Tiga

ponewant method

14.7. Temporary welded tachment ote ppe shal be round off and ingested by tanec particle

oF Bqud peneran metho.

14.8. Process instramens and equipment tat may be das by the stength presse st shall be

Axcontectet

"49. Daring pre-test punch listing he punch tems to be clare resid before pesue esting ant

fer pressure testing shal be erty identi,

15.0. FINAL INSPECTION AND RELEASE FOR TESTING

A\ 1S! Preston and welding complet piping packages sll be veifed by NSH conscton

eparnent art noi (ough RED QC deparnent comple piping est packans,

152. NSH Construction accepted piping tet packages pre-test punch listing sal bo eared out by

as

153, MOT Contech Iganga ey i yt

pone

fj 1se Atoms peg nin PEL Ae peg

7 ‘package and release for testing.

A155. poset enh tty SH Cm FEAL Reh at lpr

184. Along pec al coe! og pate

[A's Pig pts tae ry al ne

sree wth poi rr Tig Pn tA Pe AL RU

mora

A\160.rnessune teste

1S Are pS ni a es er comeing yp ag

one

162A ppd

cea

16, ny od ila apt ee ni

segues pte rst ret omen pene

14 Str sing ma tt a A pce ab ces poe et

pas ype! dled Tg ps hl rd te

Neverfail et eet ra oo

‘be viswaly inspects for damages tht may have oscred during

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

165. Aine te mae ups (Cad id ete On pe

paso ha de eon a Toe

‘tn. Sofoww We le pen apse ol er

tet ein gs

166 Allan a oh ue em Who tee

15). Alin et att uot eae oppo

168 Tees ntfpesn al eppee epee one

159. rtm ak igh nl pe li aj eno

smicme Se fest.

Ist Teepe bmn! rs fin hh nto 0 i

161 ey lore opm dt! ene oy won

1st Poprtre ay te al row rita! eye

16 Ateneo tp alpen oes

170. REINSTATEMENT

V2, Pete tg opt ping tt pag ale ltt os wh

rocoe rv Tein Por AG Pig SHOAL FORO ey

112 Kao i det coin aot

173 Almelo poe tg alerted er ptf vn

174 A pt ts line ine ene wih pe Ga

The Peet (PEA aR ERO O1)

(A, 1, Aten pent tenet Hk ce na wn a

te FAD nt tigi, ow mre, Poe

ne, Tepe trp pb)

196 Clot pig ween a

{idea eon

‘i etn ety i cha pein

17, Nein cl nm oe of PEIN sh ett a

(ian al so xt enti mb ete al)

1 Hen tr min

Sommer

«Poem nee

4 Cra Varo

© Movs

3,

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

f Rete Valves

Installed le aves shal be alate and reports signed as per SAEP-I9 ‘Prese Relit

Devices-Testing and inspeton Requirement?

Pressure gauss & temperature gxups installed are of the same range a shawn nthe PD,

1710, low dietion of Contol valves, cack vahes aad globe valves follow the proces: ow

Astin

‘TAL. Pips are in fl conte wt the suppor. (Ply Resin)

17.12, Weld etachnent ote pipe asl welded,

1713 Jack crew bls installed in ages with spots plats.

1744. A mm weep hole shall edie al dummy suppt a sal be ose near he pte

for ll versal dummy supports, and rea the run pipe at 6 oock poston fr al rion

oy spp

1715, All vents and dans are povided with bar sac plugs or in,

1716, All usand bls of ange coonetons ar fly engaged.

1717, A minimum clearance ot 50mm shall provided fo iepecton and sda of pipe movement

‘beewees above grn piping crossing with any ttre Gncig pipe suppor strstr). This

clearance sal equ for sbove ground piping eosin With enter pp.

1718, Pipe guides are nse estos shown athe approved eometre drawings.

1719, Dts ofthe insted pipe support conform othe Pipe Suppot Deal per project specication,

1720, Travel stops of sing suppor are removed afer press tt

1721, The pipe shal ot be seo support ker pipes and srs,

1722, All oustanding B-Caegory punch ns hl be completed before reise

PIPING TOLERANCES

i,

3.

Ws.

185,

All fbricaton and erection shall be performel within the tole specified in he approved

[WPS andthe project equemens,

‘Where intel misligumentexeeds Si, intraltrinminglloping sil bein scondance

ih ANSUASME B33 Fig: 328.43 ater sprecng with PSAL QC,

‘The maximum tolerance for axial dimeasions, faootoice,censto-ice and Ipetion of|

tachment shal be +3 mn maxima,

‘ater renstion of branches and connections fom center of i shal et exceed 1.5mm

lage bolt hos shall be oriented as follows, unless otherwise indicated onthe seasmtion

devings

2) Fangs ice ver bot hols to sradle vertical centins,

1) Flange fice orzo bolt ols to seaddle rion eateries,

‘QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND

ERECTION

©) Rotation of flange, measured asthe oft twoun elevations of bal leon opposite

sides of Dane enti sal nt exc #24 ra

) The tt ofa ge measured atthe periphery aos any diameter shall not exceed

16am fom he spoon,

186, For Socket welds, to voi cracking of the let wel, the pipe shall sep atleast 1.5mm fo

‘te botom of he socket fee welding

187. Forpiping ove 3” NPS and comected to machinryloqulpment, lange alignment shal be witha

‘he following is

2) Vera bolle office 424mm

1) Horizontal blthoe oft 224mm

©) Rotational Offet 240m

4) Flange fice spration gute tisk 160m

vinta and otal oft 320m

18.8. lange face tt across diame: 0.025 man per 25 mm of fang ouside daneter upto a

oxi of 0.672 mm, and 0.24 mm forall anges with nousde diameter est than 10".

189. In case whee as spectacle pe i inutlled etwsen two flanges thee folernces can be

‘eereased 30% except for tolerance fr flange fice i sree ameter and fangs seperation,

18.10. Ifthe slope is species in the tet IFC drawing, the slope shall be verified with reference to

spe survey report,

©) Combination of erica

) INSULATION

19,1, Industral insulation for piping and equipment shall be as per SAES-N-001

192. Insulation shall not be installed in pumps, aisooled equipment, compressors, steam

‘naps, nameplates, expansion joints, rotating joins and other applications where the

Intended use would be compromised

193. Carbon steel in contact with insulation shall be coated according to SAES-H-ODI, SAES-

1002 and SABS-H-101

19.4. Fireproofing shall be in accordance with SAES-B-006 or SAES-B-009, es appropriate,

19. All equipment, vesiols, and piping shall have been tested, Painted and inspected as

required by the relevant specitiation pio othe istlition of insulation

19.6, Manufsctureré instructions and recommendations of insulation and vapor bariet

rmanufictrers shall be followed,

193. Inspection for Cold Service inslaton shall be as per SATIP-N-001-O1

198. Inspection for Hot Service Insulation stall be as per SATIP-N-001-02

QUALITY CONTROL PROCEDURE FOR

PIPING FIELD FABRICATION AND.

ERECTION

20.0, DOCUMENTATION

20.1 bration ant erection of piping record book shall consi the folowing minima records for

ach lpg et packages,

2) Mari Receiving Inspestion Report

») tap Inspection Report

©) Daly Welding Inspection Report

4) tana Cesing Report

©) NDTRepers

Pail epors

(© Hides reperts

ioe

3 Png Bo Tang eet

© ont aoe

0 lovee

1) Pee Tee

2 Fg Big Do Rape

©) Rahnsoeraet

A 2 ts

© nei! pn me

A 9 varewsngepe

aia. arTactitenrs

‘tachment #1: Ppng Boston Flow Chart

‘Aachen: Waring tape Color code for spats & joins

‘Atachment!3 = Heat input elution shet

is/Components Erection Flow

Paring Project] ‘NSH Feorcaten|

[_ conte Oeeamert ["Spcaormrgea—“}

‘rk Oraere sued

‘eproves cir

180 Drawn fom {or Ferication [ry

& 32

2 a

HW ely

ie Hol

B pry i

a SS

ee ecton Request

NSH Condon Ds

coon

Cameo]

[Cisreiom monnrron]

eee

>

>

SS

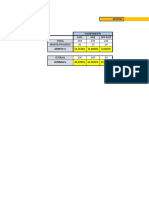

Armcnment. 2

‘Wamning tape Color code for spools& joints

Description ‘Warning tape Color code Remarks

RT joint Yellow &Black tag

RT repair joint Red tag

PWHT Joint Blue tag

‘Spool released for Painting Red &white tag

Rejected Material

Yellow tog.

ATTACHMENT 2,

1

Fe

Ft

ie

ee

jen ome

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- Api 1104 PDFDocument178 pagesApi 1104 PDFAhmad Rizki100% (13)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- RT Interpretation-SignedDocument88 pagesRT Interpretation-SignedFouad OudinaNo ratings yet

- Basic Valve and Testing Method - 1Document37 pagesBasic Valve and Testing Method - 1Fouad OudinaNo ratings yet

- AWS D1.1 (2020) - Essential Variable For WPS & WeldersDocument7 pagesAWS D1.1 (2020) - Essential Variable For WPS & WeldersFouad OudinaNo ratings yet

- ASME B31.3 QuestionsDocument37 pagesASME B31.3 QuestionsFouad Oudina100% (1)

- Piping QuestionsDocument23 pagesPiping QuestionsJlkKumar100% (3)

- API 570 PresentationDocument36 pagesAPI 570 PresentationMohamed El Sayad100% (1)

- Asme Section V Asme 16.5 Asme b31.3 - Questions and AnswersDocument29 pagesAsme Section V Asme 16.5 Asme b31.3 - Questions and AnswersAmr Elsayed100% (4)

- B 31.3Document3 pagesB 31.3MohammedBujairNo ratings yet

- ASME V QuestionsDocument25 pagesASME V QuestionsAshish PatelNo ratings yet

- API 571 - Damage & Failure SummaryDocument6 pagesAPI 571 - Damage & Failure Summarybramo96100% (1)

- Certified Welding Inspector Preperatory Training For CWI and CSWIP-3.1Document4 pagesCertified Welding Inspector Preperatory Training For CWI and CSWIP-3.1Estefano EspinozaNo ratings yet

- Equipements Sous Pression - Equipt Electriques (1) .FR - enDocument14 pagesEquipements Sous Pression - Equipt Electriques (1) .FR - enFouad OudinaNo ratings yet

- Classification of Welding MethodsDocument1 pageClassification of Welding MethodsFouad OudinaNo ratings yet

- ASME IX QuestionsDocument19 pagesASME IX QuestionsptssoftNo ratings yet

- ASME IX QuestionsDocument19 pagesASME IX QuestionsptssoftNo ratings yet

- Monthly Progress: Month %Document2 pagesMonthly Progress: Month %Fouad OudinaNo ratings yet