Professional Documents

Culture Documents

306 en

Uploaded by

ahmed0 ratings0% found this document useful (0 votes)

9 views2 pagesThis document describes a testing procedure for gas sensors and gas measuring instruments. It involves generating gas mixtures of defined compositions using mass flow controllers to blend up to four gas components, including an inert carrier gas and humidity. The mixtures are analyzed to ensure accuracy and transferred to test chambers containing the sensors. The sensors are tested over a wide range of conditions, including gas composition from 1x10-6 to 0.99 m3/m3, humidity from 0.05 to 99%, temperature from -40 to +180°C, and impedance, resistance, and capacity. The system aims to calibrate and validate gas sensors and instruments through precise control and measurement of test conditions and mixtures.

Original Description:

Original Title

306en

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes a testing procedure for gas sensors and gas measuring instruments. It involves generating gas mixtures of defined compositions using mass flow controllers to blend up to four gas components, including an inert carrier gas and humidity. The mixtures are analyzed to ensure accuracy and transferred to test chambers containing the sensors. The sensors are tested over a wide range of conditions, including gas composition from 1x10-6 to 0.99 m3/m3, humidity from 0.05 to 99%, temperature from -40 to +180°C, and impedance, resistance, and capacity. The system aims to calibrate and validate gas sensors and instruments through precise control and measurement of test conditions and mixtures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pages306 en

Uploaded by

ahmedThis document describes a testing procedure for gas sensors and gas measuring instruments. It involves generating gas mixtures of defined compositions using mass flow controllers to blend up to four gas components, including an inert carrier gas and humidity. The mixtures are analyzed to ensure accuracy and transferred to test chambers containing the sensors. The sensors are tested over a wide range of conditions, including gas composition from 1x10-6 to 0.99 m3/m3, humidity from 0.05 to 99%, temperature from -40 to +180°C, and impedance, resistance, and capacity. The system aims to calibrate and validate gas sensors and instruments through precise control and measurement of test conditions and mixtures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Chapter 3: Gas Analysis and Gas Measurement Reference procedure

Testing and Calibration of Gas Sensors

Keywords

Calibration, test, validation, gas sensors, gas measuring instruments, characteristic curves, ageing,

reproducibility, cross sensitivity

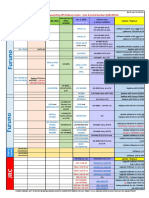

Quantities and items tested

Determination of gas mixture composition (in particular hydrogen-, ammonia-, methane-, sulfur dioxide and

ethanol mixtures), characteristic curves of gas sensors, gas measuring devices

Testing range Uncertainty of results

Volume fraction of gas mixture components

1·10-6 m3/m3 to 0.99 m3/m3 from 2% to 5%

Humidity

0.05 % to 99 % relative humidity from 0.5 % to 2%

Temperature

-40 °C to +180 °C from 0.1 K to 0.3 K

Impedance

10 m to 100 M from 0.1 to 50

Resistance

10 m to 100 M from 0.1 to 50

Capacity

1 pF to 100 nF from 0.1 pF to 2.5 pF

Fields of application

Calibration, testing and validation of gas sensors and gas measuring instruments

Methodology and instrumentation

Generation and determination of gas mixtures with defined composition, complex gas mixing and analysis system

Qualification and quality assurance

The accuracy of the procedure is regularly verified using certified reference gas mixtures.

The measuring equipment and reference standards of the entire system are subject to a rigorous calibration

program providing traceability to the SI.

Contact: Dr. Ulrich Banach Phone: +49 30 8104 3214

E-mail: ulrich.banach@bam.de Fax: +49 30 8104 3255

Division 6.4: Nanomaterial Technologies back to Catalogue

of Reference Procedures

Date: Feb. 2014 1(2) 306en.pdf

Reference procedure Chapter 3: Gas Analysis and Gas Measurement

Further information

General

Gas sensors are calibrated and tested using a test

system where test gas mixtures of defined composition

are generated dynamically from appropriate parent

gases in cylinders. These test gas mixtures are

transferred into test chambers containing the sensors

under investigation. The gas blending system provides

for continuous variation of mixture composition,

including humidification, at a high dynamic range (left

part of figure). Gas blending is performed using mass-

flow controllers (MFC), which control four different gas

streams. The blending process and the resulting

composition are regulated by varying the gas flow

through the MFCs. The system is able to generate gas

mixtures containing up to four components, an inert

carrier gas (synthetic air or nitrogen) and humidity. Two

test chambers have been developed, optimised for a

small and a larger volume, respectively, and accurately

defined gas flow. These test chambers are equipped with five (or up to ten) sensors of different types and provide

for measurement of gas temperature between -40 °C and +180 °C. The gas mixtures generated are analysed

using a dew-point mirror and a quadrupole mass-spectrometer to check the accuracy of the pre-determined

mixture composition and humidity. The humidification of the gas mixture is based on the saturation method using a

glass bubbler. The humidified carrier gas is cooled down in a gas cooler to adjust the dew point. Finally, the

humidified carrier gas is mixed with the test gas, and dry inert carrier gas is added. A personal computer controls

all parts of the system via an IEEE-bus net. The right part of the figure shows a schematic plan of the measuring

system.

Operating principle

Date: Feb. 2014 2(2) 306en.pdf

You might also like

- Transverse Disciplines in Metrology: Proceedings of the 13th International Metrology Congress, 2007 - Lille, FranceFrom EverandTransverse Disciplines in Metrology: Proceedings of the 13th International Metrology Congress, 2007 - Lille, FranceNo ratings yet

- Furnace Design and OperationDocument36 pagesFurnace Design and OperationkINGNo ratings yet

- New Developments in Continuous Emissions Monitoring CEMS)Document8 pagesNew Developments in Continuous Emissions Monitoring CEMS)Bill WorthingtonNo ratings yet

- Method 25A - Determination of Total Gaseous Organic Concentration Using A FlameDocument7 pagesMethod 25A - Determination of Total Gaseous Organic Concentration Using A FlameThiago SantosNo ratings yet

- Measurement of Hydrogen Chloride GfcirDocument15 pagesMeasurement of Hydrogen Chloride GfcirIsabel MorenoNo ratings yet

- Tin Oxide Gas Sensing: Comparison Among Different Measurement Techniques For Gas Mixture ClassificationDocument5 pagesTin Oxide Gas Sensing: Comparison Among Different Measurement Techniques For Gas Mixture ClassificationMohammad Kabir HossainNo ratings yet

- Method Epa 25a FidDocument14 pagesMethod Epa 25a FidErick HidalgoNo ratings yet

- Flare Gas Measurement Using Ultrasonic Transit-Time Flow MetersDocument13 pagesFlare Gas Measurement Using Ultrasonic Transit-Time Flow MetersAlvaro Andres Blanco Gomez100% (1)

- Untitledyvhyfrc 6Document18 pagesUntitledyvhyfrc 6Lsk MatammuNo ratings yet

- Presented By:: Satabdy Jena Mtech (Power and Energy Systems) ROLL NO.: T14EE003 Nit MeghalayaDocument23 pagesPresented By:: Satabdy Jena Mtech (Power and Energy Systems) ROLL NO.: T14EE003 Nit MeghalayaHamza Ali MinhasNo ratings yet

- 10 SPWLA D 11 00183 Improved Formation Evaluation While Drilling With A New Heavy Gas DetectorDocument12 pages10 SPWLA D 11 00183 Improved Formation Evaluation While Drilling With A New Heavy Gas DetectorpendexxNo ratings yet

- CTM 030 PDFDocument19 pagesCTM 030 PDFwalaaiNo ratings yet

- Cable Tray Manual For Electrical Engineers and Designers 2014Document16 pagesCable Tray Manual For Electrical Engineers and Designers 2014zaffarNo ratings yet

- Ps-8a.pdf2 PDFDocument9 pagesPs-8a.pdf2 PDFdevsadNo ratings yet

- Materi Webinar CompressedAirQualificationforPharmaceuticalIndustry ArjunaSolusiSejahteraDocument43 pagesMateri Webinar CompressedAirQualificationforPharmaceuticalIndustry ArjunaSolusiSejahteraDavid Alberto ChristianNo ratings yet

- Det CO Epa MetodsDocument8 pagesDet CO Epa MetodsCharlie CarranzaNo ratings yet

- Co MSDSDocument26 pagesCo MSDSnaidu60606No ratings yet

- MQ Sensors SyngasDocument14 pagesMQ Sensors SyngasGeorge PerakisNo ratings yet

- Gas Chromatography and Mass SpectrometryDocument13 pagesGas Chromatography and Mass SpectrometryMadeeha HassanNo ratings yet

- Fundamentos Cromatografia de GasDocument4 pagesFundamentos Cromatografia de GasNicolassalgueroNo ratings yet

- Keywords: Gas Content, Speed of Sound, Micro Bubbles, Macro BubblesDocument7 pagesKeywords: Gas Content, Speed of Sound, Micro Bubbles, Macro BubblesAshish ChourasiaNo ratings yet

- Real Time Wireless Air Pollution Monitoring SystemDocument6 pagesReal Time Wireless Air Pollution Monitoring SystemramyadeviNo ratings yet

- Amt 2020 199Document23 pagesAmt 2020 199161 Nurul BaitiNo ratings yet

- Amt 2020 199Document23 pagesAmt 2020 199161 Nurul BaitiNo ratings yet

- WMD - Sepcifications For The CHNS Analyzer PDFDocument6 pagesWMD - Sepcifications For The CHNS Analyzer PDFAngel Miguel Mejia RodasNo ratings yet

- Method 3C - Determination of Carbon Dioxide, Methane, Nitrogen, and Oxygen From Stationary SourcesDocument4 pagesMethod 3C - Determination of Carbon Dioxide, Methane, Nitrogen, and Oxygen From Stationary SourcesdevspacebrNo ratings yet

- Mine GasesDocument10 pagesMine GasesMelford LapnawanNo ratings yet

- Qualification of Hvac SystemsDocument58 pagesQualification of Hvac SystemsOsama kamelNo ratings yet

- GCMS Lecture On 14 Oct 2023Document57 pagesGCMS Lecture On 14 Oct 2023Shaivya BajpayeeNo ratings yet

- Astm Astm d2887Document20 pagesAstm Astm d2887Orlando Rojas100% (1)

- 4 - Report On Gas Analysis in Cement Plant PDFDocument77 pages4 - Report On Gas Analysis in Cement Plant PDFTin Nguyen0% (1)

- The - Road - To - A - Mass - Laboratory - e (Hitendra)Document8 pagesThe - Road - To - A - Mass - Laboratory - e (Hitendra)Indra RicatNo ratings yet

- ASTM D2163 GLP CromatografiaDocument5 pagesASTM D2163 GLP Cromatografiaalejandrogrande100% (1)

- Gas Chromatography, GCDocument85 pagesGas Chromatography, GCShaise Jacob67% (3)

- Carbon Monoxide in The Atmosphere (Continuous Measurement by Nondispersive Infrared Spectrometry)Document6 pagesCarbon Monoxide in The Atmosphere (Continuous Measurement by Nondispersive Infrared Spectrometry)Any DBs'uNoNo ratings yet

- Method 21 - Determination of Volatile Organic Compound LeaksDocument7 pagesMethod 21 - Determination of Volatile Organic Compound LeaksCésar Oswaldo Aguilera Ojeda100% (1)

- Epa Ctm-022 Nox by Electrochemical AnalyzerDocument16 pagesEpa Ctm-022 Nox by Electrochemical Analyzeryuber14102No ratings yet

- Paper 02Document11 pagesPaper 02ext.diego.paulinoNo ratings yet

- CTM 034 PDFDocument23 pagesCTM 034 PDFSantiago MontalvanNo ratings yet

- Innovative Instrumentation and Analysis of The Temperature Measurement For High Temperature GasificationDocument41 pagesInnovative Instrumentation and Analysis of The Temperature Measurement For High Temperature GasificationMohammed Al-MislimmawwyNo ratings yet

- Tanker Familiarisation - Gas Detecting Instruments - 2006Document27 pagesTanker Familiarisation - Gas Detecting Instruments - 2006brain_ring100% (1)

- Pogany Et Al-2016-Measurement Science and Technology-AMDocument23 pagesPogany Et Al-2016-Measurement Science and Technology-AMlaoying qdNo ratings yet

- Real Time Machine Olfaction For Mobile Robot ApplicationsDocument8 pagesReal Time Machine Olfaction For Mobile Robot Applicationsjorge_tristNo ratings yet

- Experiment 10Document59 pagesExperiment 10Karina NarcisoNo ratings yet

- Use of Salt Solutions For Assuring Constant Relative Humidity Conditions in Contained EnvironmentsDocument33 pagesUse of Salt Solutions For Assuring Constant Relative Humidity Conditions in Contained EnvironmentsFamiloni LayoNo ratings yet

- Protocol: Practice: Investigation of Different Methods To Study Thermal AnalysisDocument16 pagesProtocol: Practice: Investigation of Different Methods To Study Thermal AnalysisjuansanninNo ratings yet

- Method 21 8/3/2017: Method 21 - Determination of Volatile Organic Compound LeaksDocument7 pagesMethod 21 8/3/2017: Method 21 - Determination of Volatile Organic Compound LeaksBounty HunterNo ratings yet

- InTech-Electronic Nose System and Artificial Intelligent Techniques For Gases IdentificationDocument26 pagesInTech-Electronic Nose System and Artificial Intelligent Techniques For Gases IdentificationGovind Singh ThakorNo ratings yet

- 01 Fundamentals of GCMS PDFDocument41 pages01 Fundamentals of GCMS PDFKakaDewi75% (4)

- Metodo Epa 18Document40 pagesMetodo Epa 18Luis TrejoNo ratings yet

- Certification of AMS Acc. en 15267, Part 3 - Overview and First ExperienceDocument11 pagesCertification of AMS Acc. en 15267, Part 3 - Overview and First Experiencesalekojic5332No ratings yet

- The Ultimate in Dependability and Reliability: Stack-Gas Analysis SystemDocument6 pagesThe Ultimate in Dependability and Reliability: Stack-Gas Analysis SystemsunitbhaumikNo ratings yet

- Standard Test Method For Vapor Pressure of Liquefied Petroleum Gases (LPG) (Expansion Method)Document7 pagesStandard Test Method For Vapor Pressure of Liquefied Petroleum Gases (LPG) (Expansion Method)José Hernández VázquezNo ratings yet

- 1A Comprehensive Review of Ultrasonics Application in Detection of Fuel AdulterationDocument6 pages1A Comprehensive Review of Ultrasonics Application in Detection of Fuel AdulterationInternational Journal of Innovative Science and Research Technology100% (1)

- Trace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCDocument6 pagesTrace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCgoodcharacter1No ratings yet

- EMR Standard #3 2017Document10 pagesEMR Standard #3 2017Hasnaoui SamirNo ratings yet

- Measurement of Temperature and Chemical Composition: Jones' Instrument TechnologyFrom EverandMeasurement of Temperature and Chemical Composition: Jones' Instrument TechnologyNo ratings yet

- Ultrasound in Food Processing: Recent AdvancesFrom EverandUltrasound in Food Processing: Recent AdvancesMar VillamielNo ratings yet

- EditingDocument1 pageEditingahmedNo ratings yet

- ASMAR VesseReportDocument1 pageASMAR VesseReportahmedNo ratings yet

- File MenuDocument1 pageFile MenuahmedNo ratings yet

- Edit Menu: "Model"Document1 pageEdit Menu: "Model"ahmedNo ratings yet

- Zaratos RreportDocument1 pageZaratos RreportahmedNo ratings yet

- SWP05 - Form 10 PDFDocument3 pagesSWP05 - Form 10 PDFahmedNo ratings yet

- SWP05 - Form 06Document10 pagesSWP05 - Form 06ahmedNo ratings yet

- Ssas Test MSG - 08.12.2022 - Mariona StarDocument1 pageSsas Test MSG - 08.12.2022 - Mariona StarahmedNo ratings yet

- Abs Solas Imo CheckDocument1 pageAbs Solas Imo CheckahmedNo ratings yet

- SWP05 - Form 11Document2 pagesSWP05 - Form 11ahmedNo ratings yet

- 17 - Anita A - Annex 4 To SBMA Ship's Installation ReportDocument2 pages17 - Anita A - Annex 4 To SBMA Ship's Installation ReportahmedNo ratings yet

- Photo No 2. Concern - No Chart Display-Med Baltic (Ecdis Display)Document2 pagesPhoto No 2. Concern - No Chart Display-Med Baltic (Ecdis Display)ahmedNo ratings yet

- Base Media Week 3, 2021Document1 pageBase Media Week 3, 2021ahmedNo ratings yet

- Jo Vos Princess PDFDocument1 pageJo Vos Princess PDFahmedNo ratings yet

- Gryo No. 1 ServiceDocument1 pageGryo No. 1 ServiceahmedNo ratings yet

- 700 SPA D V2 Connection DiagramDocument4 pages700 SPA D V2 Connection DiagramahmedNo ratings yet

- SWP05 - Form 09Document3 pagesSWP05 - Form 09ahmedNo ratings yet

- Solas V Reg19Document7 pagesSolas V Reg19ahmedNo ratings yet

- Iridium lt3100sDocument83 pagesIridium lt3100sahmedNo ratings yet

- Danelec Apt AsmarDocument1 pageDanelec Apt AsmarahmedNo ratings yet

- LT 4100 Accredited Solution OnSatMail Rev. 1.00Document1 pageLT 4100 Accredited Solution OnSatMail Rev. 1.00ahmedNo ratings yet

- Panama Shipping Registrar Inc.: Safety Radio Survey Report For Vessels Under The GmdssDocument11 pagesPanama Shipping Registrar Inc.: Safety Radio Survey Report For Vessels Under The GmdssahmedNo ratings yet

- Lookup Table - Mackay GPS Rollover 2020 22 PRODUCT Impact Core Serial No. Detail APR 27 JAN 2022Document1 pageLookup Table - Mackay GPS Rollover 2020 22 PRODUCT Impact Core Serial No. Detail APR 27 JAN 2022ahmedNo ratings yet

- Noris NMEA SentenceDocument2 pagesNoris NMEA SentenceahmedNo ratings yet

- Update Drivers DMM Mod2Document3 pagesUpdate Drivers DMM Mod2ahmedNo ratings yet

- 56Document3 pages56ahmedNo ratings yet

- Annual Testing of Two-Way On-Scene Radio Communications in Accordance With: Resolution MSC.80 (70) Relating To SOLAS Reg. IV/7.5Document1 pageAnnual Testing of Two-Way On-Scene Radio Communications in Accordance With: Resolution MSC.80 (70) Relating To SOLAS Reg. IV/7.5ahmedNo ratings yet

- Annual Testing of Two Way VHF Radios (GMDSS) in Accordance With: ( (SOLAS Reg. III / 6.2.1 & Reg. IV/14) )Document1 pageAnnual Testing of Two Way VHF Radios (GMDSS) in Accordance With: ( (SOLAS Reg. III / 6.2.1 & Reg. IV/14) )ahmedNo ratings yet

- Z10mk4-Ku NewDocument2 pagesZ10mk4-Ku NewahmedNo ratings yet

- Drager Vapor 2000Document76 pagesDrager Vapor 2000Vinicius Belchior da SilvaNo ratings yet

- Deepwater ArchaeologyDocument193 pagesDeepwater Archaeologyzrinka_vekic100% (2)

- Model-Ec 7 Map. For: Modified Atmosphere PackagingDocument1 pageModel-Ec 7 Map. For: Modified Atmosphere PackagingRonak PanchalNo ratings yet

- BS en 1089-3 - 2011Document20 pagesBS en 1089-3 - 2011Luís Silva100% (1)

- Chapter 17 MK 16 MOD 0 Closed Circuit Mixed-Gas UBA DivingDocument70 pagesChapter 17 MK 16 MOD 0 Closed Circuit Mixed-Gas UBA DivingHan TunNo ratings yet

- The Mole Volume Relationships of GasesDocument15 pagesThe Mole Volume Relationships of GasesMaku MichaelNo ratings yet

- 6.9 Partial Pressure (Dalton's Law) : Chapter 6 The States of MatterDocument17 pages6.9 Partial Pressure (Dalton's Law) : Chapter 6 The States of MatterNaHuynJungNo ratings yet

- BCGA CP4 - Industrial Gas Cylinders and Gas DistributionDocument70 pagesBCGA CP4 - Industrial Gas Cylinders and Gas Distributionallokot100% (2)

- Engineering Encyclopedia: Compressor Performance CharacteristicsDocument60 pagesEngineering Encyclopedia: Compressor Performance CharacteristicsAfzaalUmair100% (1)

- Awisco CatalogDocument319 pagesAwisco CatalogsalcabesNo ratings yet

- PC01040201 0416 en Viking ProductCatalogue Gas OXEODocument332 pagesPC01040201 0416 en Viking ProductCatalogue Gas OXEOioan cristian cotorobai100% (2)

- Commercial DivingDocument45 pagesCommercial DivingSimon Woods100% (2)

- ESO2 Emergency Ventilator Service Manual 5009585 BDocument100 pagesESO2 Emergency Ventilator Service Manual 5009585 Btech.consultantNo ratings yet

- Blue Shield 9, 19, 20,21Document7 pagesBlue Shield 9, 19, 20,21salcabesNo ratings yet

- Anesthesia Equipment - Principles and Applications - Ehrenwerth-Eisenkraft-Berry - 2ed. - 2013 - 714 PáginasDocument705 pagesAnesthesia Equipment - Principles and Applications - Ehrenwerth-Eisenkraft-Berry - 2ed. - 2013 - 714 Páginasmaria lacayo80% (5)

- O2 Sensors Pi 9049119 en GBDocument6 pagesO2 Sensors Pi 9049119 en GBمعاذ شوقي العبسيNo ratings yet

- 306 enDocument2 pages306 enahmedNo ratings yet

- PressureDocument84 pagesPressureHangloque GabanoNo ratings yet

- Mixed Gas Law Worksheet AnswerDocument4 pagesMixed Gas Law Worksheet Answeryiwuwi chiduNo ratings yet

- GB500DDocument16 pagesGB500DMiguel BrocaNo ratings yet

- IOGP 411 Diving Recommended Practice PDFDocument52 pagesIOGP 411 Diving Recommended Practice PDFmatrixianuNo ratings yet

- Manuale Computer SIRIUS ENGDocument26 pagesManuale Computer SIRIUS ENGmercurius.ermesNo ratings yet

- Ideal Gas MixturesDocument14 pagesIdeal Gas MixturesNigel FaranandoNo ratings yet

- Murray and Nadel's Textbook of Respiratory MedicineDocument14 pagesMurray and Nadel's Textbook of Respiratory MedicineMirtel Mongi100% (1)

- 2720 Anaerobic Sludge Digester Gas Analysis : 1. Selection of MethodDocument5 pages2720 Anaerobic Sludge Digester Gas Analysis : 1. Selection of Methodpollux23No ratings yet

- AIGA 058 - 13 Safe Preparation of Compressed Oxidant Gas MixturesDocument40 pagesAIGA 058 - 13 Safe Preparation of Compressed Oxidant Gas MixturesVan SotNo ratings yet

- Oxymixer High Flow Without Monitor - FINAL Technical DataDocument2 pagesOxymixer High Flow Without Monitor - FINAL Technical Dataluqman elektromedisNo ratings yet

- SDI Diver Standards - 07 - Open - Water - Scuba - DiverDocument8 pagesSDI Diver Standards - 07 - Open - Water - Scuba - DiverEllie TohNo ratings yet

- Enhanced Oxidation of The 9%Cr Steel P91 in Water Vapour Containing EnvironmentsDocument27 pagesEnhanced Oxidation of The 9%Cr Steel P91 in Water Vapour Containing EnvironmentsAleš NagodeNo ratings yet

- The Production of Urea Chemical ProcessDocument80 pagesThe Production of Urea Chemical Processady joffriyNo ratings yet