Professional Documents

Culture Documents

How To Build A Murphy Bed How-Tos DIY

Uploaded by

scribOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Build A Murphy Bed How-Tos DIY

Uploaded by

scribCopyright:

Available Formats

" MENU

$ #

BUILD IT

How to Build a Murphy

Bed

Part of Bros Before Pros

Build a hideaway bed for a studio apartment

or guest bedroom.

Wade Works Creative

By: Chip Wade

Cost $ $ $

Skill Level

Start to Finish ! 1 Day

TOOLS

tape measure

hammer

safety goggles

drill with 1/8" counter-sink bit, 1/4" bit and 1" Forstner bit

table or circular saw

jigsaw

screwdriver

clamps

stud finder

paint supplies

nailer

MATERIALS

(4) 3/4" x 4' x 8' plywood sheet

(2) 1/4" x 4' x 8' plywood sheet

(12) 1x 2 x 8' solid wood board

murphy bed kit

1-1/4", 1-1/2" and 2" screws

finish nails

wood glue

veneer tape

cabinet handles

desired paint or finish

TABLE OF CONTENTS

Introduction

Step 1:Create Struts

Step 2:Assemble Sub-Frame

Step 3:Round Corners

Step 4:Attach Head and Foot Rails

Step 5:Attach Side Rails

Step 6:Position Panels

Step 7:Attach Panels

Step 8:Assemble Header

Step 9:Assemble Cabinet

Step 10:Attach Veneer

Step 11:Mount Cabinet to Wall

Step 12:Attach Hardware

Step 13:Attach Handles

Step 14:Install Mattress Support Panels

INTRODUCTION

Cut List

See the graphic for component measurements to build the

bed. Since these cuts are all straight and simple, your local

hardware store may be able to cut them for you.

(A1) FRAME STRUTS - (10) 3/4" x 1-1/2" x 60-1/2" solid

wood board

(A2) FRAME SIDES - (2) 3/4" x 1-1/2" x 80" solid wood

board

(B) SIDE RAILS - (2) 3/4" x 5-7/8" x 81-1/2" plywood

(C) FOOT RAIL - (1) 3/4" x 3" x 62" plywood

(D) HEAD RAIL - (1) 3/4" x 7-7/8" x 62" plywood

(E) FACE PANEL - (2) 3/4" x 32" x 81-1/2" plywood

(F) HEADBOARD - (1) 3/4" x 15-7/8" x 64-3/8" plywood

(G) VERTICALS - (2) 3/4" x 15-7/8" x 87-1/8" plywood

(H1) HEADER BOARD - (1) 3/4" x 14-3/8" x 64-3/8"

plywood

(H2) HEADER RAILS - (2) 3/4" x 2-3/4" x 64-3/8"

plywood

(H3) MOUNTING CLEATS - (2) 3/4" x 1-1/2" x 14-3/8"

solid wood board

(I) LEG SUPPORT RAIL - (1) 3/4" x 3/4" x 60-1/4"

plywood

(J) MATTRESS SUPPORT - (2) 1/4" x 31" x 80" plywood

STEP 1

Wade Works Creative

Create Struts

Make sure there is ample room for the bed to extend

before you begin building. Determine the size of the bed

and orientation (pivoting on the long side or short side of

the bed). These instructions are for a queen-sized bed

pivoting on the short side .

Lay out the 10 frame strut pieces (A1), and pair them to

create five struts. For each strut, glue two strut pieces in

an "L" shape using wood glue. Hold the pieces together,

and drill pilot holes 8” apart along the length of the struts.

Secure them with 1-½” screws.

STEP 2

Wade Works Creative Wa

Assemble Sub-Frame

Place the struts 20” apart, perpendicular to the frame

sides (A2). Drill pilot holes, and attach with 2” screws.

STEP 3

Wade Works Creative Wa

Image 1 Im

Round Corners

Round one corner of each side rail (B) to a 2-7/8” radius

using a jigsaw (Image 1). Pre-drill for the hardware, and

follow the instructions included in your particular

hardware (Image 2). The rounded corners should face up

at the foot of the bed.

STEP 4

Wade Works Creative Wa

Image 1 Im

Attach Head and Foot Rails

Drill five equally-spaced pilot holes from the inside of the

sub-frame using a 1-1/4" bit, and attach the head (Image

2) and foot rails with 1-1/4” screws (Image 2).

STEP 5

Wade Works Creative Wa

Image 1 Im

Attach Side Rails

Place the side rails (B) next to the sub-frame, making sure

the rounded ends (where the leg hardware will be

attached) are at the foot and that the leg hardware is

mounted on the outside. Drill pilot holes from the inside of

the sub-frame on each side of each strut using a 1-1/4" bit.

Attach the rails to the sub-frame with 1-1/4” screws. Next,

drill pilot holes (two holes per corner) from the outside

through the side rails into the head rail and foot rail.

Attach with 2" screws (Images 1 and 2).

STEP 6

Wade Works Creative Wa

Image 1 Im

Position Panels

Lay both face panels (E), best face down, with long sides

butted together (Image 1). Carefully align the bed frame

assembly on top of face panels (Image 2). The panels

should extend 1/4” beyond the side rails on each long side.

The panels should be flush with the foot rail (C), but

extend beyond the head rail (D). Once the sub-frame is in

place, trace between the struts to guide glue application

(Image 3). Next, trace the 1/4” panel reveal on the sides.

STEP 7

Wade Works Creative Wa

Im

Attach Panels

Secure struts by applying a bead of glue to the face panels

(E), following the pencil guide made in the previous step

(Image 1). Carefully reposition the sub-frame on the glue,

and confirm it is flush with the panels at the foot and

centered on the sides. The sequence that you apply the

screws is important to keep the face panels and sub-frame

aligned. First, secure the last strut on the foot with 1-1/4”

screws on the corners. Next, insert two screws in the

center of the foot rail strut. Then, screw the corners at the

head of the bed. Once the corners are secure, screw

remaining struts to the face panels at approximately 6-

inch increments (Image 2).

STEP 8

Wade Works Creative Wa

Image 1 Im

Assemble Header

Attach the mounting cleats (H3) flush with the short ends

of the header board (H1) by drilling pilot holes then

attaching with 2" screws. Make sure the header has the

best face down (Image 1). Next, screw a header rail (H2)

to the rear side of the header board (H1). Leave 1/2” of the

header rail (H2) extending beneath the header board

(Image 2). Align the remaining header rail (H2) with the

front edge of the header board assembly, and leave the

1/2” extension underneath. Because the face will be

visible, secure with glue and a nailer and finish nails

instead of screws (Images 3 and 4).

STEP 9

Wade Works Creative Im

Image 1

Assemble Cabinet

The verticals (G) make up the sides of the cabinet, and the

header makes up the top. Attach the verticals to the short

sides of the header with a drill and 2" screws (Image 1). If

necessary, cut a notch with a jigsaw to allow clearance for

base molding so the cabinet stays flush with the wall

(Image 2).

STEP 10

Wade Works Creative

Attach Veneer

Use an iron to bond the veneer tape to all the plywood's

visible edges for a finished look.

STEP 11

Wade Works Creative

Mount Cabinet to Wall

Find the studs in the wall, and screw through the back side

of the header to attach the cabinet to the wall.

STEP 12

Wade Works Creative Wa

Image 1 Im

Attach Hardware

Follow the instructions provided with your hardware kit.

Make sure all the mechanical parts fit and function

(Images 1 and 2). Then, remove the hardware to make

finishing the surfaces easier. Paint or stain in your desired

finish, and reinstall hardware, including the leg support (I),

according to kit instructions (Image 3).

STEP 13

Wade Works Creative

Attach Handles

Attach handles to the outside surface of the face panels at

a comfortable height for you. Generally, 66 inches from

the floor is a good height. We built a base version, but you

can customize with wooden trim, decorative hardware,

chalk paint, etc. Make sure the decorative additions don't

interfere with the lowering of the bed.

STEP 14

Wade Works Creative Wa

Image 1

Install Mattress Support Panels

Install the mattress support panels (J) to the inside of the

bed to cover the struts using 1-1/4" screws (Image 1).

Next, attach the elastic bands (in the kit) into the struts

and through the mattress supports using 1-1/4" screws

(Image 2).

Wade Works Creative

Like this? Here’s more:

BEDS FURNITURE BEDROOM

NEXT UP

How to Make a Channeled Headboard

MORE FROM:

Bros Before Pros

WE RECOMMEND

How to Make a Tufted 6 Clever Ways to Hide a

Wingback Headboard 31 Photos Guest Bed 12 Photos

How to Make a Two- How to Make an Upholstered

Dimensional Upholstered Footboard 19 Photos

Headboard 35 Photos

You might also like

- KenmoreWasher PartsDocument8 pagesKenmoreWasher PartslammersgNo ratings yet

- 2012 Shed TechartDocument15 pages2012 Shed TechartMujNo ratings yet

- DIY Skee Ball Machine: InstructablesDocument12 pagesDIY Skee Ball Machine: InstructablesKenneth BoyerNo ratings yet

- Handmade Haven: Farmhouse X DeskDocument15 pagesHandmade Haven: Farmhouse X Deskgunay cakmakNo ratings yet

- Murphy Bed InstDocument20 pagesMurphy Bed InstRobert ParkerNo ratings yet

- Custom Storage Bed For Humans and Pets: InstructablesDocument12 pagesCustom Storage Bed For Humans and Pets: Instructableswagnerprates1608No ratings yet

- Kreg Tool - Innovative Solutions For All of Your Woodworking and DIY Project NeedsDocument5 pagesKreg Tool - Innovative Solutions For All of Your Woodworking and DIY Project NeedsFernandoNo ratings yet

- Vertical DIY InstructionsDocument20 pagesVertical DIY InstructionsDangheliz Tobar UrzúaNo ratings yet

- Diyhuntress Igbc Desk PlansDocument23 pagesDiyhuntress Igbc Desk PlansEdwin Espinoza obandoNo ratings yet

- The Pencil Post BedDocument6 pagesThe Pencil Post BedAnonymous QJ5j94luLmNo ratings yet

- Construction Guide Easy DIY Murphy BedDocument37 pagesConstruction Guide Easy DIY Murphy BeddnvidcNo ratings yet

- The Cutting List Where To Drill The Holes: Item Id Description Stock Size Length Pieces (A) (B) (C) (D) (E) (F)Document2 pagesThe Cutting List Where To Drill The Holes: Item Id Description Stock Size Length Pieces (A) (B) (C) (D) (E) (F)Exartis GeorgeNo ratings yet

- DIY Tutorial Pallet Teenager Cabin 1001palletsDocument10 pagesDIY Tutorial Pallet Teenager Cabin 1001palletscristian fulgencioNo ratings yet

- Folding Workbench - Ana WhiteDocument13 pagesFolding Workbench - Ana Whitejmdzr17No ratings yet

- DIY WorkbenchDocument2 pagesDIY WorkbenchlittleasianmanNo ratings yet

- Construction Guide Easy DIY Murphy Bed PDFDocument37 pagesConstruction Guide Easy DIY Murphy Bed PDFMeda_2011100% (4)

- Bench - Mendocino BenchDocument5 pagesBench - Mendocino BenchvdbrogerNo ratings yet

- Gable Shed Plan: Free Streamlined VersionDocument9 pagesGable Shed Plan: Free Streamlined VersionUdu OgahNo ratings yet

- DIY Outdoor Chair - Angela Marie MadeDocument10 pagesDIY Outdoor Chair - Angela Marie MademrcongamanNo ratings yet

- Lean To Shed Plan: Free Streamlined VersionDocument9 pagesLean To Shed Plan: Free Streamlined VersionjesusdoliNo ratings yet

- Murphy Bed FrameDocument5 pagesMurphy Bed Frameonodi19603469100% (1)

- Kids Crooked House Catalog 2017Document16 pagesKids Crooked House Catalog 2017Joao CarneiroNo ratings yet

- Barn Door Baby GateDocument17 pagesBarn Door Baby GateNovitates1No ratings yet

- How To Make A SOFA That Turns Into A BEDDocument16 pagesHow To Make A SOFA That Turns Into A BEDKalid Kemal100% (1)

- DIY Kitchen Island: Tools ListDocument14 pagesDIY Kitchen Island: Tools ListDanNo ratings yet

- Manual EnderDocument38 pagesManual EnderCarlos Alberto Lima EscamillaNo ratings yet

- Thinking Wood - Project 2 - DIY Portable 3-In-1 Workbench - Table Saw - Router Table ComboDocument8 pagesThinking Wood - Project 2 - DIY Portable 3-In-1 Workbench - Table Saw - Router Table ComboAldrin DejumoNo ratings yet

- EASY To ASSEMBLE Complete Wall-Bed CabinetDocument24 pagesEASY To ASSEMBLE Complete Wall-Bed Cabinetmexicano05100% (4)

- Planos Casa de JuegosDocument47 pagesPlanos Casa de Juegosdaniel estrada0% (1)

- DIY PottingBench 1110Document2 pagesDIY PottingBench 1110TheOwlReadsNo ratings yet

- Chicken Run Plans 4x8Document21 pagesChicken Run Plans 4x8Ivan RochfordNo ratings yet

- Operator'S Manual: 5-1/2 In. 18 Volt Circular Saw P501Document40 pagesOperator'S Manual: 5-1/2 In. 18 Volt Circular Saw P501jahemscbdNo ratings yet

- How To Make A Stopped Dado Jig For Any Router: InstructablesDocument11 pagesHow To Make A Stopped Dado Jig For Any Router: InstructablesTroy100% (1)

- Wooden Bench-Vise 6 InchDocument12 pagesWooden Bench-Vise 6 InchKates SimaduNo ratings yet

- RoutertableDocument5 pagesRoutertablesenthil karthik100% (1)

- Diy Drill Storage CabinetDocument18 pagesDiy Drill Storage CabinetjohnNo ratings yet

- Lean ToToolShedDocument17 pagesLean ToToolShedJeremy Smathers100% (2)

- DIY Kitchen IslandDocument17 pagesDIY Kitchen IslandJurica PrimoracNo ratings yet

- DoubleChairBench DIYPETE PDFDocument20 pagesDoubleChairBench DIYPETE PDFRostocanieNo ratings yet

- Panel Saw Plans: © 2005 by Robert E. Reedy All Rights ReservedDocument16 pagesPanel Saw Plans: © 2005 by Robert E. Reedy All Rights Reservedcorneliu.modilcaNo ratings yet

- Rotating Barrel ComposterDocument3 pagesRotating Barrel Compostertraction9261No ratings yet

- Plans Ladder ShelfDocument6 pagesPlans Ladder ShelfMúsica viajera MXNo ratings yet

- Cruise ControlDocument5 pagesCruise Controlinval78No ratings yet

- Workshop Tote Box: Project 20466EZDocument3 pagesWorkshop Tote Box: Project 20466EZBSulli100% (1)

- Sassy Sparrow - DIY Outdoor Patio Furniture From PalletsDocument43 pagesSassy Sparrow - DIY Outdoor Patio Furniture From PalletsFachransjah Aliunir0% (1)

- Diy - Popular Woodworking PlansDocument108 pagesDiy - Popular Woodworking PlansMSavic100% (1)

- Mission Style Open Shelf Bathroom Vanity: AdvancedDocument22 pagesMission Style Open Shelf Bathroom Vanity: AdvancedMaricruz Valdivieso de PalaciosNo ratings yet

- ParquetDocument4 pagesParquetFernando FrayreNo ratings yet

- Occasional Table: Woodworks: Intermediate ProjectDocument7 pagesOccasional Table: Woodworks: Intermediate ProjectEucap MdzNo ratings yet

- Backyard ProjectsDocument5 pagesBackyard Projects- yAy3e -No ratings yet

- Swing - Garden Swing 2Document1 pageSwing - Garden Swing 2Daniel LourençoNo ratings yet

- Insignia Ns-46e480a13a Ns-55e480a13a LCD TVDocument109 pagesInsignia Ns-46e480a13a Ns-55e480a13a LCD TVJose Luis Montejano GarciaNo ratings yet

- Intermediate Project Storage BinsDocument10 pagesIntermediate Project Storage BinsTyler BassNo ratings yet

- Wall Mounted Shoe RackDocument7 pagesWall Mounted Shoe RacksyafiqNo ratings yet

- Double Chair Bench PlansDocument9 pagesDouble Chair Bench PlansMark KozubackNo ratings yet

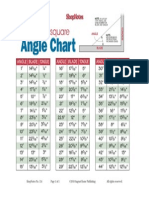

- Framing SquareDocument1 pageFraming SquareflerziNo ratings yet

- HWHL Router Table PlansDocument9 pagesHWHL Router Table PlansIlberto FortunaNo ratings yet

- Planos para Gabinete Esquinero de MaderaDocument16 pagesPlanos para Gabinete Esquinero de MaderaIsmael Perez100% (2)

- DIY Miter Saw Station PDFDocument6 pagesDIY Miter Saw Station PDFNana Obiri Yeboa DarkoNo ratings yet

- AdheDocument225 pagesAdheMâñî MíghtyNo ratings yet

- Advanced Electronic ComponentsDocument17 pagesAdvanced Electronic Componentsprem_chandranNo ratings yet

- CatalogueBuilding2015 AdnotatDocument708 pagesCatalogueBuilding2015 AdnotatOctavian GrigoreNo ratings yet

- Thesis 1 - 4 - TedDocument21 pagesThesis 1 - 4 - TedMa Gelanie Bardillon Crisostomo100% (21)

- Hitachi Hiacs Multi3000Document10 pagesHitachi Hiacs Multi3000a_596No ratings yet

- Method Statement For Miscellaneous Metal WorksDocument19 pagesMethod Statement For Miscellaneous Metal Worksmohsin.meizaNo ratings yet

- Question Bank Power Plant Performance: Decreasing EfficiencyDocument6 pagesQuestion Bank Power Plant Performance: Decreasing EfficiencyMY NAME IS NEERAJ..:):)No ratings yet

- RT8205LZQWDocument28 pagesRT8205LZQWcNo ratings yet

- k11 2Document6 pagesk11 2jeshupunkNo ratings yet

- Hiwin Linear Guideway Catalog - G99TE13-0809Document0 pagesHiwin Linear Guideway Catalog - G99TE13-0809frahedlerNo ratings yet

- Nitto - MOS Pressure TestDocument6 pagesNitto - MOS Pressure TestNajwa AmirahNo ratings yet

- Vehicle Body Engineering and Safety: Unit 5Document17 pagesVehicle Body Engineering and Safety: Unit 5MOHAMMED SAQLAINNo ratings yet

- Solid Short Notes PDFDocument32 pagesSolid Short Notes PDFsanjeet singh kainturaNo ratings yet

- Multi Core ProcessorsDocument7 pagesMulti Core ProcessorsBhavin Joshi100% (5)

- Analisis de La Susmpension Con AdamsDocument18 pagesAnalisis de La Susmpension Con AdamscorsasportNo ratings yet

- 2014 07 22 Ronnie Flaugh Tips 3DQuickPressDocument37 pages2014 07 22 Ronnie Flaugh Tips 3DQuickPressHarisAvdagićNo ratings yet

- Senior DesignI Fall 2014 IntroductionDocument31 pagesSenior DesignI Fall 2014 IntroductionSarah WilliamsNo ratings yet

- Liugong 375A PDFDocument2 pagesLiugong 375A PDFArle SalasNo ratings yet

- ProTech2Ch4 PDFDocument39 pagesProTech2Ch4 PDFweldsvNo ratings yet

- SJVMDocument3 pagesSJVMMukesh NegiNo ratings yet

- IM10 DatasheetDocument2 pagesIM10 DatasheetLê TườngNo ratings yet

- Lgrplgso PDF 1615650993Document9 pagesLgrplgso PDF 1615650993Emerald GrNo ratings yet

- 01) Machine Design I PDFDocument24 pages01) Machine Design I PDFDebasis soorNo ratings yet

- BOP IndoreDocument52 pagesBOP IndoreUma KoduriNo ratings yet

- Alignment Report (Kolar-Chikkaballapura)Document38 pagesAlignment Report (Kolar-Chikkaballapura)Kiran R Gowda100% (2)

- 150 Sample-Chapter PDFDocument25 pages150 Sample-Chapter PDFMochammad Waris SNo ratings yet

- SA Model Paper Solutions - III SemesterDocument23 pagesSA Model Paper Solutions - III Semesterkotireddy.vaishnaviNo ratings yet

- Robot GeometryDocument50 pagesRobot Geometrymk_chandruNo ratings yet

- D3 Tips and Tricks PDFDocument482 pagesD3 Tips and Tricks PDFaitheljarNo ratings yet