Professional Documents

Culture Documents

VFDB-4110-4160-4185 I en 20101011

VFDB-4110-4160-4185 I en 20101011

Uploaded by

Hung VanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VFDB-4110-4160-4185 I en 20101011

VFDB-4110-4160-4185 I en 20101011

Uploaded by

Hung VanCopyright:

Available Formats

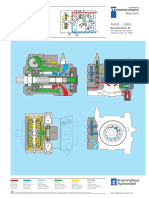

\ Basic Wiring Diagram

Input voltage setting for VFD B 4110/4160/4185

CHARGE ACT OC OH

Operation Explanation:

1. For safety consideration, install an overload relay between the braking unit and the braking resistor. In conjunction with the Power lamp Brake lamp Over-current Overheat lamp

magnetic contactor (MC) prior to the drive, it can perform complete protection against abnormality. lamp

2. The purpose of installing the thermal overload relay is to protect the braking resistor from damage due to frequent braking,

or due to braking unit keeping operating resulted from unusual high input voltage. Under such circumstance, just turn off

the power to prevent damaging the braking resistor. 480V

Input Voltage Setting 460V

3. Please refer to the specification of the thermal overload relay. Factory setting:440V 440V

4. The alarm output terminals (RA, RC) of the braking unit will be activated when the temperature of the heat sink exceeds 415V

o o

VFDB Series Braking Modules Instruction Sheet

80 C. It means that the temperature of the installation environment may exceed 50 C, or the braking %ED may exceed 400V

10%ED. With this kind of alarm, please install a fan to force air-cooling or reduce the environment temperature. If the 380V

condition isn’t due to the temperature, the control circuit or the temperature sensor may have been damaged. At this time,

please send the braking unit back to the manufacturer or agency for repair.

NFB MC Motor 5. The AC Motor Drive and braking unit 2. MASTER/SLAVE setting: The MASTER/SLAVE jumper is set “MASTER” as factory setting. The “SLAVE” setting is applied to

X Preface R/L1

S/L2

T/L3

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

IM

Thermal

will be electrified at the same time while

turning on the NFB (No-fuse breaker). For

the operation/stop method of the motor,

two or more braking units in parallel, making these braking units be enabled/disabled synchronously. Then the power

dissipation of each unit will be equivalent so that they can perform the braking function completely.

Thank you for choosing DELTA’s braking module. VFDB braking units are applied to absorb the motor regeneration energy Overload The SLAVE braking application of three braking

when the three-phase induction motor stops by deceleration. With VFDB braking unit, the regeneration energy will be O.L. VFD Series Relay please refer to the user manual of the AC The position of the jumper

MC +(P) DC+ B1 Motor Drives VFD Series. The braking unit units is shown as the above diagram. After wiring, MASTER/SLAVE

dissipated in dedicated braking resistors. To prevent mechanical or human injury, please refer to this instruction sheet before DC- VFDB

O.L.

the jumper of first unit shall be set as “MASTER”

wiring. VFDB braking units are suitable for DELTA AC Motor Drives VFD Series 460V. VFDB braking units need to be used in SA -(N)

BR will detect the inner DC voltage of the AC SETTING JUMPER 480V

Surge Absorber E.F RA Brake

motor drive when it stops the motor by and that of others must be set as “SLAVE” to 460V

conjunction with BR series braking resistors to provide the optimum braking characteristics. The content of this instruction Unit Brake M 440V Input Voltage Se tting

DCM RC B2 Resistor deceleration. The extra regeneration will complete the system installation.

sheet may be revised without prior notice. Please consult our distributors or download the most updated version at Therm al Overload 415V

http://www.delta.com.tw/industrialautomation. Relay or Tem perature switch be dissipated away rapidly by the braking S 400V

Temperature switch 380V

resistor in the form of heat. It can ensure

the stable deceleration characteristic. +( P) -(N) DC+ DC - DC+ DC - DC+ DC - M1: SLAVE output signal+

M2: SLAVE output signal-

M1 S1 M1 S1

S1: SLAVE input signal+

Y Specifications 6. Besides using thermal overload relay to be the protection system and braking resistor, temperature switch can be installed on

VFD

Series M

M2 S2 M2

S

S2

S

M1 M2 S1 S2 RA RC

S2: SLAVE input signal-

NOTE: Please use shielded

wires while wiring.

braking resistor side as the protection. The temperature switch must comply with the braking resistor specification or contact your SLAVE output/input terminal

dealer. B1 B2 B1 B2 B1 B2

VFDB Braking Units Braking Resistors

BR BR BR

Specification

Model VFDB□□□□ 4110

460V Series

4160 4185

Model no.

BR1K5W005

Specification

1500W 5.0Ω

] Wiring Notice O.L. O.L. O.L.

Max. Motor Capacity (KW)

Max. Discharge Current

110

126

160

190

185

225

BR1K2W6P8

BR1K2W008

1200W 6.8Ω

1200W 8.0Ω

Do not proceed with wiring while power is applied to the circuit.

The wiring gauge and distance must comply with the electrical code.

` Braking Resistors & Braking Units Use in the AC Drives

(A) 10%ED

The +(P), -(N) terminals of the AC motor drive (VFD Series), connected to the braking unit (VFDB), must be

Output

Rating

Continuous Discharge Applicable

45 50 100 BR1K5W012 1500W 12Ω confirmed for correct polarity lest the drive and the braking unit be damaged when power on. 125% Braking Torque/ 10%ED

Current (A) Motor

Voltage

Braking Start-up Voltage When the braking unit performs braking, the wires connected to DC+, DC-, B1 and B2 would generate a

618/642/667/690/725/750±6V BR1K2W015 1200W 15Ω powerful electromagnetic field for a moment due to high current passing through. These wires should be wired Braking Resistor Value Braking Unit Max.

(DC) Braking Resistors Min. Equivalent

separately from other low voltage control circuits lest they make interference or mis-operation. HP KW Torque Spec. for Each Part No. and Discharge

Part No. and Quantity Resistor Value

Rating

(kg-M) AC Motor Drive Quantity Current (A)

Input

DC Voltage 400-750VDC BR1K5W040 1500W 40Ω To prevent personal injury, do not connect/disconnect wires or Inflammable solids, gases or liquids must be avoided at

regulate the setting of the braking unit while power on. Do not the location where the braking resistor is installed. The 150 110 74.5 12000W 6Ω 4110 1 BR1K2W015 10 126 6Ω

Min. Equivalent Resistor for touch the terminals of related wiring and any component on braking resistor had better be installed in individual 175 132 89.4 18000W 4Ω 4160 1 BR1K5W012 12 190 4Ω

6Ω 4Ω 3.4Ω BR1K0W050 1000W 50Ω

Each Braking Unit PCB lest users be damaged by extreme dangerous DC high metallic box with forced air-cooling. 215 160 108.3 18000W 4Ω 4160 1 BR1K5W012 12 190 4Ω

Connect the ground terminal to the Earth Ground. The

460V

Over-current level (A) 190 290 340 BR1K0W075 1000W 75Ω voltage. 250 185 125.3 21000W 3.4Ω 4185 1 BR1K5W012 14 225 3.4Ω

Protection

Do not connect DC reactor between the braking unit and the ground lead must be at least the same gauge wire as 300 220 148.9 24000W 3Ω 4110 2 BR1K2W015 20 252 3Ω

Z Dimensions

Blackout until bus(DC+~DC-)voltage is below 375 280 189.6 36000W 2Ω 4160 2 BR1K5W012 24 380 2Ω

Power Charge Display DC-bus capacitor of the AC motor driver. leads +(P), -(N).

100VDC 425 315 213.3 36000W 2Ω 4160 2 BR1K5W012 24 380 2Ω

Wiring distance Please install the braking resistor with forced air-cooling

Overheat Alarm Output Relay contact 3A 250Vac/28Vdc(RA.RC) or the equivalent when frequent deceleration braking is 475 355 240.3 42000W 1.7Ω 4185 2 BR1K5W012 28 450 1.7Ω

-Braking Resistors

Installation Location Indoor(no corrosive gases, metallic dust) performed (over 10%ED).

-10℃~+50℃ (14oF to 122oF) The ring terminals are suggested to be used for main

Environment

Operating Temperature

a Wiring Examples of Braking Resistors

circuit wiring. Make sure the terminals are fastened

Storage Temperature -20℃~+60℃ (-4oF to 140oF) before power on.

Humidity Less than 90%RH Non-condensing

Vibration

2

20~50Hz

2

9.8m/s (1G)under 20Hz、2m/s (0.2G)at

^ Definition for Braking Usage ED% NOTE: Before wiring, please notice equivalent resistors value shown in the column “Equivalent resistors specification for each

braking unit” in the above table to prevent damage.

460V 150HP 460V 175HP/215HP

Mechanical Configuration Wall-mounted enclosed type IP10

100%

Z Dimensions [ Individual Parts and Braking Time

T1 ED% = T1/T0x100(%)

- VFDB Braking Units Function Explanation Cycle Time

T0

Explanation: The definition of the barking usage ED(%) is for assurance of enough time for the braking unit and braking resistor

to dissipate away heat generated by braking. When the braking resistor heats up, the resistance would increase with

temperature, and braking torque would decrease accordingly. 460V 250HP 460V 300HP

VFDB

CHARGE ACT OC OH

_ The Voltage Settings

1. Regulation of power voltage: the power source of the braking unit is DC voltage from +(P), -(N) terminals of the AC motor

drive. It is very important to set the power voltage of the braking unit based on the input power of the AC motor drive before

operation. The setting has a great influence on the potential of the operation voltage for the braking unit. Please refer to the

table below.

460V 375HP/425HP

NOTE

Before regulating the power voltage, make sure the power has been turned off. Please set power voltage as the possible

highest voltage for unstable power system. Take 380VAC power system for example. If the voltage may be up to 410Vac,

415VAC should be regulated.

For DELTA’s AC motor drive VFD Series, please set parameter (Over Voltage Stall Prevention) as “close” to disable

over-voltage stall prevention, to ensure stable deceleration characteristic.

The Selection of Power Voltage and Operation Potential of PN DC Voltage

Terminal Wire Gauge Braking Start-up voltage

460V Model AC Power Voltage

DC Bus (DC+,DC-) Voltage

2

Circuit Terminal Mark Wire Gauge AWG (mm ) Screw Torque 380Vac 618Vdc

Power Input 400Vac 642Vdc

DC+,DC- 4~6AWG (21.2~13.3mm2) M8 30 kgf-cm (26 in-lbf) 415Vac 667Vdc 460V 475HP

Circuit

Braking 440Vac 690Vdc

B1,B2 4~6AWG (21.2~13.3mm2) M8 30 kgf-cm (26 in-lbf) 460Vac 725Vdc

Resistor

480Vac 750Vdc

Output M1,M2 18~20AWG (0.8~0.5mm )

2

SLAVE Circuit M2 4 kgf-cm (3 in-lbf) NOTE: Input Power With Tolerance ±10%

(with shielded wires)

Input S1,S2

Fault Circuit RA,RC 18~20AWG (0.8~0.5mm2) M2 4 kgf-cm (3 in-lbf)

You might also like

- VOL 5 - Electromagnetic Testing PDFDocument529 pagesVOL 5 - Electromagnetic Testing PDFSubramanian100% (4)

- LG 55UN7300PUC UAX3E Schematic Diagram and Service ManualDocument72 pagesLG 55UN7300PUC UAX3E Schematic Diagram and Service Manualaze1959100% (1)

- 3.3KW InstructionDocument4 pages3.3KW Instructionnu duangtanooNo ratings yet

- 166-31590 Manual BaylorDocument54 pages166-31590 Manual BaylorJairo Peña100% (5)

- BL2 & BL4 DriverDocument68 pagesBL2 & BL4 DriverVasuPatelNo ratings yet

- 3A Switching Charger, 2.4A Boost and Fuel Gauge in One ESOP8 With Single InductorDocument5 pages3A Switching Charger, 2.4A Boost and Fuel Gauge in One ESOP8 With Single InductorLeeNo ratings yet

- ALTAIR05T-800: Off-Line All-Primary-Sensing Switching RegulatorDocument28 pagesALTAIR05T-800: Off-Line All-Primary-Sensing Switching RegulatorJosé M. Do PradoNo ratings yet

- D - Fuente de Alimentacion AuxiliarDocument2 pagesD - Fuente de Alimentacion AuxiliarJohn HuamaniNo ratings yet

- SRNE - Datasheet - HF4850S80-H Series Solar Charge Inverter - E1 1Document1 pageSRNE - Datasheet - HF4850S80-H Series Solar Charge Inverter - E1 1arfilsyongcoNo ratings yet

- ACT4060ADocument11 pagesACT4060ASanjeev GuptaNo ratings yet

- 09 PH1800 ProDocument1 page09 PH1800 ProAung Kyaw MinNo ratings yet

- Mur440 E3Document4 pagesMur440 E3Oussama MessaoudiNo ratings yet

- IgnitioncoilDocument6 pagesIgnitioncoilFabian Henao CalleNo ratings yet

- PV1500Document1 pagePV1500Diego SousaNo ratings yet

- Eaton 265912 NZMN4 4 AE1000 en - GBDocument5 pagesEaton 265912 NZMN4 4 AE1000 en - GBnelson1235No ratings yet

- Vs-Vskt320Pbf Series: Vishay SemiconductorsDocument7 pagesVs-Vskt320Pbf Series: Vishay SemiconductorsRyu DanNo ratings yet

- Flexible Step-Down Switching Regulators With Built-In Power MOSFETDocument26 pagesFlexible Step-Down Switching Regulators With Built-In Power MOSFETNgân Hàng Ngô Mạnh TiếnNo ratings yet

- LA47516 AMPpdfDocument7 pagesLA47516 AMPpdfMy TVBoxNo ratings yet

- Sol-Ark 8K-P Spec Sheet: Battery Output Power 8000WDocument2 pagesSol-Ark 8K-P Spec Sheet: Battery Output Power 8000Wluis violaNo ratings yet

- TokaiDocument9 pagesTokaiDavid LimNo ratings yet

- Stearns Electronic Brake Release Indicator (Proving Switch) ArmatureActuated Brake Series Product SheetDocument2 pagesStearns Electronic Brake Release Indicator (Proving Switch) ArmatureActuated Brake Series Product Sheetashar khanNo ratings yet

- SRNE - Datasheet - HF4850S80-145 - Solar Charger Inverter 1 1Document1 pageSRNE - Datasheet - HF4850S80-145 - Solar Charger Inverter 1 1arfilsyongcoNo ratings yet

- Smart Grid Inverter Mis-1400 Manual: PV Monitoring System Operating InstructionsDocument6 pagesSmart Grid Inverter Mis-1400 Manual: PV Monitoring System Operating InstructionsSantos Huete ArgotaNo ratings yet

- Sofar 3k 6ktlm-g3 Certificate Iec 61727Document3 pagesSofar 3k 6ktlm-g3 Certificate Iec 61727jadiles da silvaNo ratings yet

- ERPF 400 SpecDocument4 pagesERPF 400 SpecAnonymous XoW23y58ONo ratings yet

- Data Battery ChargerDocument2 pagesData Battery ChargerUma A. UcheNo ratings yet

- HF2430S80 H DatasheetDocument1 pageHF2430S80 H DatasheetWaruna NarmalNo ratings yet

- SR502 - SR506: High Current Schottky Barrier RectifierDocument2 pagesSR502 - SR506: High Current Schottky Barrier RectifierAndres Raul Diaz PeñaNo ratings yet

- Ower Mplifiers: Rem-S Series-Power AmplifiersDocument4 pagesOwer Mplifiers: Rem-S Series-Power AmplifiersМаксым КовальськыйNo ratings yet

- Eaton 066168 Emt6 DBK en GBDocument4 pagesEaton 066168 Emt6 DBK en GBAriel TorresNo ratings yet

- Quick Start Guide - ATV212: Check The Delivery of The DriveDocument4 pagesQuick Start Guide - ATV212: Check The Delivery of The DriveDella Ayu OktaNo ratings yet

- F - 7 - Onduleur Hybride Must ProDocument1 pageF - 7 - Onduleur Hybride Must Provebajan654No ratings yet

- Supertex Inc.: SR086 Adjustable Off-Line Inductorless Switching RegulatorDocument8 pagesSupertex Inc.: SR086 Adjustable Off-Line Inductorless Switching RegulatorSerg SergNo ratings yet

- Braking Unit For Frequency Inverter Serie 3CV 380 - 480V 18,5 Bis 55kWDocument14 pagesBraking Unit For Frequency Inverter Serie 3CV 380 - 480V 18,5 Bis 55kWany3000No ratings yet

- 12KSpecSheet - 9 24 2021Document2 pages12KSpecSheet - 9 24 2021Afzal ImamNo ratings yet

- VEM3665T InfoPacket 5HP 1750RPMDocument11 pagesVEM3665T InfoPacket 5HP 1750RPMrrobles011No ratings yet

- MUST PH1800 MPK Plus Series PH18-4K MPK Plus PDFDocument1 pageMUST PH1800 MPK Plus Series PH18-4K MPK Plus PDFAyman0% (1)

- SMC-ESHM Series Programmable Logic Controller MPUDocument1 pageSMC-ESHM Series Programmable Logic Controller MPUwaleed alqatabNo ratings yet

- MPPT InverterDocument1 pageMPPT InverterIshant JagotraNo ratings yet

- FS7M0680, FS7M0880: Fairchild Power Switch (FPS)Document18 pagesFS7M0680, FS7M0880: Fairchild Power Switch (FPS)Candelaria CortesNo ratings yet

- DSSLTC 4020Document42 pagesDSSLTC 4020cueNo ratings yet

- Schneider Electric Altivar 21 Quick StartDocument4 pagesSchneider Electric Altivar 21 Quick StartMahdi HadadzadehNo ratings yet

- Control Circuit For Switch Mode Power Supplies Using Mos TransistorsDocument7 pagesControl Circuit For Switch Mode Power Supplies Using Mos TransistorsokeinfoNo ratings yet

- Calculating Sheet and Setting List For Protection of #01/#02 Startup/Standby TransformerDocument46 pagesCalculating Sheet and Setting List For Protection of #01/#02 Startup/Standby TransformerAmaresh NayakNo ratings yet

- Gen Paid For Test Report 111214 - 0P1910Document1 pageGen Paid For Test Report 111214 - 0P1910ale gamingNo ratings yet

- Ups Cyber Power PDFDocument64 pagesUps Cyber Power PDFgiangpd vtNo ratings yet

- Features Description: LT8316 560V Micropower No-Opto Isolated Flyback ControllerDocument26 pagesFeatures Description: LT8316 560V Micropower No-Opto Isolated Flyback ControllerKamil Gökberk ErginNo ratings yet

- Control and Disconnection: Compact Ns630Bna To 1600na Switch-DisconnectorsDocument2 pagesControl and Disconnection: Compact Ns630Bna To 1600na Switch-DisconnectorsKao SophearakNo ratings yet

- 05-PV1800 ProDocument1 page05-PV1800 ProEla Suyapa Valladares AlvarengaNo ratings yet

- 120V-PV3600 TLVDocument1 page120V-PV3600 TLVrobertralexNo ratings yet

- Magvfc: Installation and Owner'S ManualDocument24 pagesMagvfc: Installation and Owner'S ManualyudiNo ratings yet

- HV320Document9 pagesHV320Jean DiazNo ratings yet

- Sharp 540 BIFACIALDocument2 pagesSharp 540 BIFACIALchris dascalopoulosNo ratings yet

- BC4A - DATAKOM Auto Select Battery ChargerDocument1 pageBC4A - DATAKOM Auto Select Battery ChargerRehab WahshNo ratings yet

- Cr3-A 2 035 P: CR-series SCR Operation ManualDocument4 pagesCr3-A 2 035 P: CR-series SCR Operation ManualBENJAMIN COLELLNo ratings yet

- OB2301W On BrightElectronicsDocument11 pagesOB2301W On BrightElectronicsIlago BenignoNo ratings yet

- VEM3546T InfoPacket 4Document10 pagesVEM3546T InfoPacket 4Gerardo ReyesNo ratings yet

- Nano Very Fast Acting Fuse 456 SeriesDocument3 pagesNano Very Fast Acting Fuse 456 Seriesm3y54mNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Hydraulic SymbolsDocument1 pageHydraulic SymbolsHung VanNo ratings yet

- Brake Unit 400V Class Type Bu-H: Transistorized Inverter Instruction ManualDocument15 pagesBrake Unit 400V Class Type Bu-H: Transistorized Inverter Instruction ManualHung VanNo ratings yet

- Hydraulic SymbolsDocument1 pageHydraulic SymbolsHung VanNo ratings yet

- Ingersoll Yh45Document3 pagesIngersoll Yh45Hung VanNo ratings yet

- A4VG ... DAD: Baureihe/series 32Document1 pageA4VG ... DAD: Baureihe/series 32Hung VanNo ratings yet

- Bee Lab - 17-18Document30 pagesBee Lab - 17-18upender raoNo ratings yet

- 6es7321 1CH00 0aa0Document3 pages6es7321 1CH00 0aa0Fabio CavalheiroNo ratings yet

- DC MotorDocument21 pagesDC MotorAshvani ShuklaNo ratings yet

- Medium Voltage CableDocument7 pagesMedium Voltage Cableakheel201No ratings yet

- Vector Group of Transformer - Electrical Notes & Articles Vector Grop ChangeDocument26 pagesVector Group of Transformer - Electrical Notes & Articles Vector Grop Changehizbi750% (4)

- UV Sensor UVS 10: Technical Information GBDocument10 pagesUV Sensor UVS 10: Technical Information GBrafaeluriza6No ratings yet

- Takex GS-5SN Data SheetDocument6 pagesTakex GS-5SN Data SheetJMAC SupplyNo ratings yet

- Digital Flow Transmitter For Continuous Flow MeasurementDocument7 pagesDigital Flow Transmitter For Continuous Flow MeasurementChemikal EngineerNo ratings yet

- Bdj005-90a-005 (k02) - Dual Relay SpecificationDocument4 pagesBdj005-90a-005 (k02) - Dual Relay SpecificationAung100% (2)

- Automatic Transfer Switch Changeover Type - SocomecDocument40 pagesAutomatic Transfer Switch Changeover Type - Socomecallanbatiancila100% (1)

- AB Engg.: ArevaDocument15 pagesAB Engg.: ArevaVishal SalveNo ratings yet

- Psa Lab ManualDocument31 pagesPsa Lab ManualRida ZainabNo ratings yet

- Foot Step Power Generation System For Rural Energy Application To Run AC and DC LoadsDocument35 pagesFoot Step Power Generation System For Rural Energy Application To Run AC and DC Loadsraghunandanr199350% (2)

- Name: - Class: - DateDocument7 pagesName: - Class: - DateNorell EkimNo ratings yet

- Electronic Expansion ValveDocument5 pagesElectronic Expansion Valveemongclooney11No ratings yet

- ICASolar PV On Grid BookDocument7 pagesICASolar PV On Grid BooktemonsoejadiNo ratings yet

- Modeling and Digital Simulation of DPFC System Using Matlab SimulinkDocument5 pagesModeling and Digital Simulation of DPFC System Using Matlab SimulinkUmashankar VermaNo ratings yet

- DC Power For Test Rig and Lab: Laboratory Power Supplies Electronic LoadsDocument16 pagesDC Power For Test Rig and Lab: Laboratory Power Supplies Electronic Loadsjose0enar0munozNo ratings yet

- 5 Amp Current TransformerDocument1 page5 Amp Current TransformerDarvin VargheseNo ratings yet

- R-390A SSB ModDocument6 pagesR-390A SSB ModYiannis GiannarakisNo ratings yet

- Economical Dual Display Type, PID ControlDocument13 pagesEconomical Dual Display Type, PID ControlMasoudNo ratings yet

- Electrical Quantities 2 MSDocument4 pagesElectrical Quantities 2 MSAref DahabrahNo ratings yet

- Micrel MIC5801BNDocument6 pagesMicrel MIC5801BNVolkan YılmazNo ratings yet

- OKI FACTORY TEST REPORT E135780-A105-CB-1-Amendment-1Document19 pagesOKI FACTORY TEST REPORT E135780-A105-CB-1-Amendment-1Tayfun SezişNo ratings yet

- Clap Switch CircuitDocument5 pagesClap Switch CircuitSabid Uddin100% (2)

- Modulo SetPoint FESTODocument4 pagesModulo SetPoint FESTOIOZEF1No ratings yet

- MDQ Series: M D Q 30A 1600VDocument5 pagesMDQ Series: M D Q 30A 1600VAl-FarabiNo ratings yet