Professional Documents

Culture Documents

Sinclair 1826

Uploaded by

rtorrescoralOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sinclair 1826

Uploaded by

rtorrescoralCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/328149624

Usage of Battery Energy Storage Systems to Defer Substation Upgrades

Conference Paper · October 2018

DOI: 10.1109/OI.2018.8535635

CITATIONS READS

5 1,938

3 authors:

Sinclair Pienaar Kanzumba Kusakana

Eskom Central University of Technology

5 PUBLICATIONS 6 CITATIONS 222 PUBLICATIONS 2,423 CITATIONS

SEE PROFILE SEE PROFILE

Patrick Manditereza

Central University of Technology

22 PUBLICATIONS 188 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Practical Implemetation of hybrid energy systems for small loads in rural South Africa View project

Optimal management of a small grid connected PV with groundwater-pump hydro energy storage for farming in arid areas View project

All content following this page was uploaded by Kanzumba Kusakana on 08 October 2018.

The user has requested enhancement of the downloaded file.

Usage of Battery Energy Storage Systems to Defer

Substation Upgrades

S.B. Pienaar, K. Kusakana and P.T. Manditereza

Department of Electrical, Electronic and Computer Engineering

Central University of Technology, Free State

20 Pres Brand, Bloemfontein 9300, South Africa

PienaaSB@eskom.co.za , kkusakana@cut.ac.za, pmandite@cut.ac.za

Abstract - Electricity is generated and distributed upwards, by increasing capacity or load shedding should be

instantaneously. In electricity utilities, this is occasionally an implemented [5].

enormous amount of wasted capacity. Illegal connections may No battery energy storage systems are currently installed in

contribute to overloads and trips, as the network is carrying substations in South Africa. Battery energy storage systems

more users than what it was designed for. Before substation

are still expensive; this is the reason why the demand is not

upgrades may take place, new and existing consumers who need

additional electricity are rejected, due to capacity constraints in high. Due to the depletion in the supply of fossil fuels and

existing substations. The installation of large scale battery energy concerns over environmental pollution, the use of renewable

storage systems may support the long-term carbon mitigation energy continues to grow [6].

strategy of South Africa, to transition to a low carbon economy. Battery energy storage systems may be installed and

The aim of this paper is to propose a Battery Energy Storage maintained by contractors under a business contract.

System (BESS) design that may lead to costly network upgrade Contractors should provide training and transfer skills to

deferral and reduced demand charges. electricity utility employees. Energy storage may be supported

or funded by the government, due to the expensive technology

Keywords - Battery, Substation, Upgrade, Demand charge

cost. This could be an alternative solution to achieve the

utilisation of renewable energy [7].

I. INTRODUCTION To determine the battery lifetime, two major aging effects

Battery energy storage has been widely used in China, are considered. The cyclation based state of health and the

Germany and the United States as one of the preferred calendrical aging. The cyclation based power loss is derived

alternatives for energy storage [1]. Battery energy storage from counting the amount of transferred coulombs. The

systems provide frequency regulation, voltage support, energy calendrical aging is the loss of power that occurs when the

time-shift, demand reduction, power reliability, power quality battery is not in service. The calendrical aging is due to three

and islanding operations. Distributed battery energy storage is main factors: temperature, state of charge and the non-

used to improve network capacity, quality of supply and to operating duration of the energy storage system [8].

defer costly substation upgrades [2]. The Northern Cape Operating Unit in South Africa is

The utilisation of storage devices, may lead to the safe experiencing load-growth, due to residential developments,

utilisation of substation equipment, by assisting on-load tap high electrification growth, agriculture and mining. The

changers with voltage control [2, 3]. Battery energy storage methods currently used to do substation upgrades are costly

systems are used to store energy, to be utilised during system and time consuming. Network upgrades require interrupting

peaks, allowing more consumers to be connected to the grid. continuity of supply to customers and this has a negative

Dual purpose energy storage systems are to justify the use of impact on the performance of the network (System Average

battery energy storage systems, for peak shaving during the Interruption Duration Index and System Average Interruption

winter and increased battery power charging during the Frequency Index).

summer. Charging the batteries during load off-peak times, Furthermore, the South African energy utility Eskom,

when the price of electricity is low, and discharging the stored upgrades their substations, due to equipment that has reached

energy during load peak evening time, is an alternative method their functional lifespan. Outdated control plant schemes, used

of saving on electricity expenses [4]. in existing substations are less reliable with no fault recording

Battery energy storage systems may perform both FCR-N capability. The cost to maintain outdated equipment that

(frequency containment reserve for normal operation) and interrupts security and continuity of supply to customers is

FCR-D (Frequency containment reserve for disturbances). high.

FCR-N should be able to increase and decrease power to This paper provides details of the proposed integration

maintain the system frequency in the normal area, among 49.9 design for Battery Energy Storage Systems (BESS). Further, it

and 50.1 Hz. FCR-D is initiated in the low frequency range presents the benefits of battery energy storage systems.

between 49.5-49.9 Hz. FCR-D should control the frequency Finally, modern substation upgrade designs and costs for

future high voltage network upgrades are compared to the

battery energy storage system costs.

978-1-5090-1629-7/16/$31.00 ©2018 IEEE

II. BATTERY TECHNOLOGIES predicted in advance [12]. The life cycle of lead-acid cells is

determined by positive grid corrosion, positive plate material

A. Vanadium Redox Flow Battery deterioration, loss of water and electrolyte stratification [13].

Vanadium Redox Flow Battery (VRFB) technologies are

the preferred energy storage systems, due to the long lifespan, C. NiFe Battery Cells

flexible design, fast response time, deep-discharge capability To improve the highly efficient NiFe battery cells, iron

and low pollution [9]. Leak sensors are installed inside the electrodes, based on Fe/FeS/CuSO4, were investigated.

battery container to monitor any leaking of electrolyte Condition based maintenance will prolong the life of battery

remotely and cause the battery management system to isolate cells and will ensure their capability of supplying peak power

the affected component. Vanadium Redox Flow Batteries may requirements. Battery capacity acceptance tests should be done

be used for load levelling. This approach may increase the at the factory or upon initial installation [6].

function of renewables, during periods of low demand [10]. The capacity test should meet a specific discharge rate and

Batteries should be replaced if the capacity test indicates duration, relating to the manufacturers specification. Test

that the battery capacity is below 80% of the manufacturer's results proved that copper sulphate increases the performance

specification. The ion membrane condition of Redox Flow of iron-based electrodes with approximately 6%. The addition

Batteries is often a determinant for complete battery or of iron sulphide in the electrode, improves the performance of

individual cell replacement. Vanadium redox flow batteries are NiFe cells, rather than using copper alone [6].

exclusive electrochemical energy storage systems. VRFB’s

may repeatedly convert and store multi-megawatt-hours III. BATTERY ENERGY STORAGE SYSTEM OPERATION

(MWhs) of electrical energy to chemical energy and convert

the chemical energy back to electrical energy as needed [11].

Figure 2: Structure diagram of the Battery Energy Storage System [14].

Structure diagram of the Battery Energy Storage System

Figure 1: Structure of a Vanadium Redox Flow battery [11] (BESS), as shown in Figure 2, consists of three main systems:

the power conversion system (PCS), energy storage system

Vanadium flow battery’s electrolyte is completely non- and the battery management system (BMS). The power

flammable, effectively minimizing the fire hazard of the whole conversion system consists of a three-phase, full bridge

system. Electrical fires that may occur in Vanadium redox converter, which couples the battery system to the electricity

flow batteries, due to an internal fault, are mitigated by a utility’s network [14].

smoke detector in each battery. RFB (Redox flow battery) The BMS (Battery Management System) is used to

cells comprise of two electrodes and two circulating monitor and measure the power system’s performance

electrolyte solutions. The electrodes are separated by an ion- parameters, such as voltages, currents, and temperatures. A

exchange membrane, as illustrated in Figure 1 [11]. battery energy storage system with an incorrect state of charge

may be overcharged or over-discharged. This may damage the

B. Lead-acid battery storage system, shorten the life time, or even cause fire or an

Lead-acid batteries have an electrolyte which contains explosion. The BMS will communicate with the PCS (Power

dilute sulphuric acid, which may cause severe chemical burns. Conversion System), the state of charge (SOC) and the state of

High battery temperatures increase conductor resistances, health (SOH) [14].

accelerate electrochemical processes and diffusion processes When the state of charge (SOC) is 1, the energy storage

in lead-acid cells [12]. system is fully charged. The energy storage system should

During the charging process, lead-acid batteries may develop pause charging the storage system, to avoid damaging the

hydrogen gas and oxygen. This may result in an explosive batteries. When the SOC is 0, the storage system is discharged

mixture. The voltages of all the cells are monitored, so that fully. The energy storage system should stop discharging the

individual cell state of charge and state of health may be batteries as the battery system is empty [8, 14].

discharging process. The 4 quadrant power conversion

IV. PROPOSED DESIGN FOR BESS systems, further releases capacity back to the utility system, to

provide active and reactive power control [16, 17].

Figure 3: Proposed Battery Energy Storage System design.

The proposed Battery Energy Storage System (BESS)

design, in Figure 3 may be applied in substations with two or

more constrained medium voltage feeders. The BESS should

be protected from direct lightning strikes, by means of 21 Figure 4: Schematic diagram of a Battery Energy Storage System (BESS)

meter lightning masts. Kiosk circuit-breakers are three-pole [16].

operated circuit-breakers with integrated protection and

current measurement transformers. The proposed Kiosk

breaker is used for control, measuring, indicating, maintenance

and protection purposes.

The 22 kV Isolators should be used to isolate the battery

energy storage system before equipment may be refurbished.

Linking the Direct Current (DC) batteries to a step up 400

V/22 kV Transformer should be done through DC to AC

inverters [15]. The 400 V/22 kV Transformer should be used

as a source of AC power for the battery energy storage

systems. A yard distribution box with a chop-over module

should be installed, to provide auxiliary supply for two or

more Energy Storage Systems (ESS).

The battery energy storage system should be strung with a bull

conductor and connected to the 22 kV bypass Isolators, as

designed in Figure 3. The bypass of bays refers to the

complete switching out of the battery energy storage bay,

including the protection and control panel. The bypassed

battery energy storage bay should be rerouted to a fully

Figure 5: MICOM P145 relay

equipped alternative bay, which has its own protection scheme

and revenue metering.

The 4RF1100 protection scheme is preferred, for the

The bolted/bolted type clamps should be used on non-current

interconnection of medium voltage feeder protection. The

carrying equipment and the bolted/compression type clamps

4RF1100 scheme is also used for Embedded Generators to

should be used on current carrying equipment. All the

Eskom’s electrical medium voltage networks. The 4RF1100

stringing should be done in accordance with the proposed

scheme may further be used to protect the medium voltage

sections and general arrangement designs.

network and the consumers from possible adverse effects of

Foundations for the battery energy storage bay equipment

the battery energy storage systems. The 4RF1100 protection

should be bonded to the main earth mat, via the bolts installed

scheme utilizes a main Intelligent Electronic Device (IED), the

within the foundations. The holding down bolts should be

MiCOM P145 feeder management relay, as indicated in Figure

bonded to the 10mm main earth grid, via 50 x 3 mm flat

5. The scheme provides over current, earth fault, sensitive

copper, for earth-fault conditions.

earth fault protection, breaker fail and auto reclose control.

The Power Conversion System (PCS) in Figure 4 may be

An alternative design, that may be used for the energy storage

used as a rectifier in the charging process and as a DC (Direct

system is to utilize two kiosk breakers on both sides of the 400

Current) to AC (Alternating Current) inverter in the

V/22 kV step up transformer, as designed in Figure 6. The

current transformers of the kiosk breaker should be used for The battery management system should ensure that the

over-current, earth fault, differential protection and restricted storage system output is matched to the grid. The battery

earth fault protection. management system should further prevent any stray currents

or electrical problems from impacting the grid [18, 19]. A

GPRS modem should be installed, for remote downloading of

revenue metering data. The ION8800A meter may be used for

quality measurements.

V. POSITIONING OF BESS

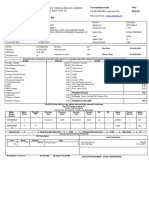

As presented in Table 1. Battery energy storage systems

may be deployed on the power system, at a substation, on a

high voltage feeder, medium voltage feeder or as a residential

community focused system. Calculating the size and

placement of battery energy storage systems on the

distribution network, is dependent on the battery technology

and the purpose of the battery energy storage system [3].

Table 1: Positioning of BESS

Category Placement Application

A Battery energy storage For voltage

systems may be support, solar

connected as close as smoothing or

Figure 6: Alternate proposed BESS design possible to consumers frequency

(230 V-400 V). stabilization.

The SEL487E two terminal differential protection relay in B Battery energy storage For peak shifting,

Figure 7, may be used when two kiosk breakers are utilized. systems may be substation

The on-load tap change of the step-up transformer may be connected to the upgrades deferral

protected and controlled by the 4TC-5200 tap change medium voltage busbars. or for additional

protection scheme. The circulating current scheme uses the BESS may further be capacity.

REG-DA voltage regulating relay for on-load tap changing connected to the

applications. medium voltage feeders

(3.3 kV-33 kV).

C Battery energy storage For reliability of

systems may be supply,

connected to the high substations

voltage busbars. upgrades deferral

Furthermore, BESS may or back - up

also be connected to the supply.

high voltage feeders (44

kV - 132 kV).

VI. RADIAL DISTRIBUTION FEEDERS

On a radial distribution feeder, the end of the feeder lacks

consistent back-up supply connection from other feeders. This

increases the interruption time and reliability methods may be

difficult to achieve. With a single source of supply, as

illustrated in Figure 8. Battery energy storage offers one

possibility to decrease the outage times experienced by

consumers [15]. Historic data, combined with network

Figure 7: SEL-487E relay planning, allows an estimation of where interruptions are

likely to occur. Energy storage systems may further be used

for reliability improvement, as an alternative to more costly

distribution line capacity upgrades [16].

substations, is approximately R1 800 000 per

kilometre.

Table 2: BESS technology and performance cost [21].

Technology Power Energy Round-trip Cycles

Subsystem Storage Efficiency

Cost Subsystem (%)

($/kW) Cost ($/kWh)

Advanced 400 330 80 2000

Lead-acid

Batteries

Figure 8: Basic topology for connecting the Battery Energy Storage to the grid Sodium/Sulfur 350 350 75 3000

[12] Batteries

Lead-acid 400 330 75 20000

When loss of supply occurs due to a fault, the BESS Batteries with

responds to the frequency changes, by discharging the battery Carbon-

energy. The customer loads are further supplied, using battery enhanced

Electrodes

energy storage systems located close to loads, until the local

Zinc/ 400 400 70 3000

utility power is restored. This is because it is impossible to

bromine

predict where future interruptions will happen [15, 16, 18, 20]. Batteries

Vanadium 400 600 65 5000

VII. DESIGN COMPARISON Redox

Batteries

PowerOffice 14 was utilized for the new 132/22 kV modern Lithium-ion 400 600 85 4000

substation design costing and for the 132 kV single circuit Batteries

Tern feeder with Optic Ground Wire (OPGW) expenses. (large)

PowerOffice 14 software makes use of design modules and

cells for the costing of final design packages of substations Table 3: 40 MVA substation cost breakdown.

and feeders.

Bill of quantities and the ACNAC program may be used for Description New Substation

the battery energy storage system detail design costing. For Engineering ( E ) R 3 316 603

new energy storage technology quotations of external

Material ( M ) R 22 063 659

consultants, external contracts on the detail costing sheet may

be used. Further, the bill of quantities and the ACNAC Internal Contracts R 97 252

program was also used for the decommissioning costs. External Contracts R 13 478 602

Below, the design comparisons are given: Commissioning ( T ) R 693 493

• Labour expenses: labour costs for a modern Overheads (7.5%) R 2 973 721

substation design may be more cost effective, IDC R0

compared to the battery energy storage system design Land and Rights R 31 170

expenses. The decommissioning cost of the existing

Total Project DRA Costs R 42 654 500

66 kV network is approximately R 600 000 per

kilometre. Further, the decommissioning costs of the

existing 66/22 kV substations is approximately VIII. CONCLUSION

R9 000 000 per substation.

Sufficient capacity may be created on the medium voltage

• Land development expenses: battery energy storage network for future growth, by installing battery energy storage

systems require more servitude for the same capacity systems. However, the cost to upgrade high voltage networks

as newly designed substations.

and substations is more cost effective. Batteries experience

• Equipment costs: The battery energy storage systems capacity degradation with usage over time; energy storage

in Table 2 are noticeably more expensive. This is companies should incorporate new methods from prognostics

compared to the designing, procurement of and health management (PHM), in order to extend battery life.

equipment and the construction of a new 40 MVA As the actual mechanisms leading to cell ageing are complex

modern substation in Table 3. The cost to upgrade the to understand, we need to develop new methods that may

existing 66 kV network in South Africa, to a single monitor the battery storage system health and predict failure.

circuit 132 kV Tern line using monopoles, with Optic This is to increase the reliability and life cycle of the overall

Ground Wire (OPGW) for communication between system. By using battery storage systems, distribution assets,

such as overhead conductors, remain under their thermal limits [11] L. Li, S. Kim, W. Wang, M. Vijayakumar, Z. Nie, B. Chen, J. Zhang, G.

Xia, J. Hu, G. Graff, J. Liu and Z. Yang: “A Stable Vanadium Redox-

and their useful lifetime is improved [22]. Battery energy Flow Battery with High Energy Density for Large-Scale Energy

storage systems may further assist on-load tap changers, Storage”, Advanced Energy Materials, pp. 394–400, 2011.

capacitor banks and step voltage regulators, to achieve a [12] B.B. McKeon, J. Furukawa and S. Fenstermacher: “Advanced Lead–

flexible, real-power control in distribution systems [23, 24]. Acid Batteries and the Development of Grid-Scale Energy Storage

Further, energy storage systems may be used to avoid the cost Systems”, Proceedings of the IEEE, Vol. 102, No. 6, June 2014.

of coal and carbon emissions by coal generating stations. [13] D.A.J. Rand, P.T. Moseley, J. Garche and C.D.P. Eds: “Valve-Regulated

Lead-Acid Batteries”, Netherlands: Elsevier, Amsterdam, pp. 3–7, 2004.

[14] S. PENG, C. CHEN, H. SHI, Z. YAO: “State of Charge Estimation of

Battery Energy Storage Systems Based on Adaptive Unscented Kalman

REFERENCES Filter With a Noise Statistics Estimator”, IEEE Access, 31 July 2017.

[1] Kusakana, K., and H. J. Vermaak. "Hybrid Diesel Generator-battery [15] O. Vilppo, J. Markkula, P. Järventausta, S. Repo and T. Hakala: “Cost–

systems for offgrid rural applications." In Industrial Technology (ICIT), benefit analysis for using the Li-ion batteries in low-voltage network for

2013 IEEE International Conference on, pp. 839-844. IEEE, 2013. decreasing the outage time experienced by customers”, 24th

[2] Kusakana, K. "Minimum cost solution of isolated battery-integrated International Conference & Exhibition on Electricity Distribution

diesel generator hybrid systems." In South African University Power and (CIRED), pp. 2201-2204, 12-15 June 2017.

Energy conference (SAUPEC 2015), pp. 141-147. 2015. [16] X. Xu, M. Bishop, D.G. Oikarinen and C. Hao: “Application and

[3] M.Z. Degefa, H. Saele, J.A. Foosnaes and E. Thorshaug: “Seasonally Modeling of Battery Energy Storage in Power Systems”, CSEE

variant deployment of electric battery storage systems in active JOURNAL OF POWER AND ENERGY SYSTEMS, VOL. 2, NO. 3,

distribution networks”, 24th International Conference & Exhibition on SEPTEMBER 2016.

Electricity Distribution, pp. 1975–1979, 12-15 June 2017. [17] T.H. Mehr, M.A. Masoum and N. Jabalameli: “Grid-connected Lithium-

[4] H. Karami, M.J. Sanjari, S.H. Hosseinian and ET AL: “An optimal ion battery energy storage system for load leveling and peak shaving”,

dispatch algorithm for managing residential distributed energy Power Engineering Conference (AUPEC), 2013.

resources”, IEEE Transactions Smart Grid, pp. 2360–2367, 2014. [18] N.L. Filipe, A. Leiria, R. André, J. Damásio, M. Gerlich and S.

[5] H. Hellman, A. Pihkala, M. Hyvärinen, P. Heine, J. Karppinen, K. Siilin, Rodriguez: “Protection system analysis in low-voltage grid, with high

P. Lahtinen, M. Laasonen and J. Matilainen: “Benefits of battery energy distributed resource penetration, in parallel and islanding operation”,

storage system for system, market, and distribution network – case 24th International Conference & Exhibition on Electricity Distribution

Helsinki”, 24th International Conference & Exhibition on Electricity (CIRED), pp. 1388–1392, 12-15 June 2017.

Distribution (CIRED), pp. 1588-1592, 12-15 June 2017. [19] P.R. Langley and R. Clarke: “Key Learnings from The Establishment of

[6] A.H. Abdalla, C.I. Oseghale, J.O. Gil Posada and P.J. Hall: a Battery Energy Storage Testing Facility”, Smart Grid Conference,

“Rechargeable nickel–iron batteries for largescale energy storage”, IET Johannesburg, 19-21 September 2017.

Renewable Power Generation, pp. 1529-1534, 2016. [20] A. Nourai, V.I. Kogan and C.M. Schafer: “Load leveling reduces T & D

[7] Z. Qiao and J. Yang: “Comparison of centralised and distributed battery line losses”, IEEE Transactions Power Delivery, pp. 2168–2173, 2008.

energy storage systems in LV distribution networks on operational [21] S. Schoenung: “Energy Storage Cost Update”, SAND2011-2730,

optimisation and financial benefits”, The 6th International Conference California, pp. 1-28, April 2011.

on Renewable Power Generation (RPG), pp. 1671-1675, 19–20 October

2017. [22] M. Andoni, W. Tang, V. Robu and D. Flynn: “Data analysis of battery

storage systems”, 24th International Conference & Exhibition on

[8] H. Hellman, A. Pihkala, M. Hyvärinen, P. Heine, J. Karppinen, K. Siilin, Electricity Distribution (CIRED), pp. 96-99, 12-15 June 2017.

P. Lahtinen, M. Laasonen and J. Matilainen: “Benefits of battery energy

storage system for system, market, and distribution network – case [23] H. Ravindra, M.O. Faruque, K. Schoder, M. Steurer, P. Mclaren and R.

Helsinki”, 24th International Conference & Exhibition on Electricity Meeker: “Dynamic interactions between distribution network voltage

Distribution (CIRED), pp. 1588-1592, 12-15 June 2017. regulators for large and distributed PV plants”, In Proc. Transm.

Distribution Conf. Exposition (T&D), pp. 1–8, May 2012.

[9] J. Xi, Z. Wu, X. Qiu and L. Chen: “Nafion/SiO2 hybrid membrane for

vanadium redox flow battery”, Journal of Power Sources 166 (2007) [24] X. Liu, A. Aichhorn, L. Liu and H. Li: “Coordinated control of

531–536, China, 24 January 2007. distributed energy storage system with tap changer transformers for

voltage rise mitigation under high photovoltaic penetration,” IEEE

[10] G. Kear, A.A. Shah and F.C. Walsh: “Development of the all vanadium Trans. Smart Grid, vol. 3, no. 2, pp. 897–906, June 2012.

redox flow battery for energy storage: a review of technological,

financial and policy aspects”, International journal of energy research,

Highfield, Southampton SO17 1BJ, 2011.

View publication stats

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Log Home Living 2012 01Document92 pagesLog Home Living 2012 01cazacenco_alexandruNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Resistive & Capacitive TransducerDocument52 pagesResistive & Capacitive TransducerAimenRaza89% (19)

- Calculate Size of Capacitor BankDocument5 pagesCalculate Size of Capacitor BankMedyouNo ratings yet

- Kaplan TurbinesDocument19 pagesKaplan TurbinesLuis0% (1)

- Service Bulletin A - 3.1: Technical Information To All The Owners of Sulzer A Type Diesel Engines 22.03.96Document8 pagesService Bulletin A - 3.1: Technical Information To All The Owners of Sulzer A Type Diesel Engines 22.03.96zbkt07No ratings yet

- Failure Analysis of TransformersDocument56 pagesFailure Analysis of TransformersSANJIV GUPTANo ratings yet

- Fire Safety in Power plants-NPTIDocument65 pagesFire Safety in Power plants-NPTIbijoyNo ratings yet

- 115 KV GIS Design Criteria Considering Service ContinuityDocument2 pages115 KV GIS Design Criteria Considering Service Continuityraghavendran raghuNo ratings yet

- Peak Shaving Through Battery Storage For Low-VoltaDocument17 pagesPeak Shaving Through Battery Storage For Low-VoltartorrescoralNo ratings yet

- 1 DESIGN AND COSTING OF 10KW Solar ModuleDocument7 pages1 DESIGN AND COSTING OF 10KW Solar ModuleYash PratapNo ratings yet

- Erection of TurbineDocument73 pagesErection of TurbineNipun PharliaNo ratings yet

- DMX PumpsDocument33 pagesDMX PumpsGROIIMNo ratings yet

- A Comprehensive Model For Lithium-Ion Batteries: From The Physical Principles To An Electrical ModelDocument38 pagesA Comprehensive Model For Lithium-Ion Batteries: From The Physical Principles To An Electrical ModelrtorrescoralNo ratings yet

- Energies 12 04603 v2Document31 pagesEnergies 12 04603 v2rtorrescoralNo ratings yet

- Optimal Power Flow in Microgrids With Energy Storage: Power Systems, IEEE Transactions On August 2013Document10 pagesOptimal Power Flow in Microgrids With Energy Storage: Power Systems, IEEE Transactions On August 2013rtorrescoralNo ratings yet

- Investigating Power System Primary and Secondary Reserve Interaction Under High Wind Power PenetrationDocument37 pagesInvestigating Power System Primary and Secondary Reserve Interaction Under High Wind Power PenetrationrtorrescoralNo ratings yet

- Electricity Market DesignDocument24 pagesElectricity Market DesignrtorrescoralNo ratings yet

- Preliminary Assessment of The Photovoltaic Electricity Production Project Geographical Coordinates Report Generated Generated by Map LinkDocument18 pagesPreliminary Assessment of The Photovoltaic Electricity Production Project Geographical Coordinates Report Generated Generated by Map LinkrtorrescoralNo ratings yet

- An Econometric Analysis of Electricity Demand in Turkey: Gelişme Dergisi Studies in Development January 2000Document13 pagesAn Econometric Analysis of Electricity Demand in Turkey: Gelişme Dergisi Studies in Development January 2000rtorrescoralNo ratings yet

- Agriculture: Economic Feasibility Evaluation of Small Wind Systems in MichiganDocument2 pagesAgriculture: Economic Feasibility Evaluation of Small Wind Systems in MichiganrtorrescoralNo ratings yet

- Canadian Solar EnglishDocument15 pagesCanadian Solar EnglishAthrav 8538No ratings yet

- Wind Farm Challenges Green Palm Marine ConsultancyDocument23 pagesWind Farm Challenges Green Palm Marine ConsultancyOffshore JackupNo ratings yet

- Tut. 05 - Cost Targeting FinalDocument4 pagesTut. 05 - Cost Targeting Finalpeterbookworm2014No ratings yet

- Accepted Manuscript International Journal of Structural Stability and DynamicsDocument28 pagesAccepted Manuscript International Journal of Structural Stability and DynamicsMarcus Girão de MoraisNo ratings yet

- Siemens Euroset 2005Document18 pagesSiemens Euroset 2005Chata KundiNo ratings yet

- Project Introduction: Central TowerDocument3 pagesProject Introduction: Central Towerمحمد ابن علیNo ratings yet

- Bharat Heavy Electricals Limited: Manufacturing of Stator Bar of 500 MW Turbo GeneratorDocument4 pagesBharat Heavy Electricals Limited: Manufacturing of Stator Bar of 500 MW Turbo GeneratoradityasmartiNo ratings yet

- محطة شبرا الخيمةDocument15 pagesمحطة شبرا الخيمةعبدالله عبدالمنعم100% (1)

- Bheltelephonediretory2015 PDFDocument132 pagesBheltelephonediretory2015 PDFTendernews EventsNo ratings yet

- 08 - Florida Heat Pumps WPDocument13 pages08 - Florida Heat Pumps WPpablofr_92No ratings yet

- Product Information Belviso C1 600 CDP LED3900nw ET 01 TOC: 6066140Document1 pageProduct Information Belviso C1 600 CDP LED3900nw ET 01 TOC: 6066140Dani Good VibeNo ratings yet

- Eskom Facility Performance GuaranteesDocument5 pagesEskom Facility Performance GuaranteesOribuyaku DamiNo ratings yet

- Candy Veš M.model Cj433tDocument19 pagesCandy Veš M.model Cj433tpedjavaljarevicNo ratings yet

- # Micro Pelton Turbines ! $Document93 pages# Micro Pelton Turbines ! $Nathaniel E. Barrios Fuentes100% (1)

- DC Circuit Breakers:: An Important Role in The Continuity and Quality of ServiceDocument3 pagesDC Circuit Breakers:: An Important Role in The Continuity and Quality of ServiceSagar GadhiaNo ratings yet

- Proceedings IndexDocument13 pagesProceedings Indexf2321125No ratings yet

- Allama Iqbal Open University: Semester Terminal Exam Autumn 2020Document8 pagesAllama Iqbal Open University: Semester Terminal Exam Autumn 2020AHA AssistanceNo ratings yet

- Sample Practice Sheet For Final TermDocument4 pagesSample Practice Sheet For Final TermMd MahfuzNo ratings yet

- For Assistance Dial 1912 5616195: For Bill SMS BILL Pay Your Bill OnDocument1 pageFor Assistance Dial 1912 5616195: For Bill SMS BILL Pay Your Bill OnKapil KumarNo ratings yet