Professional Documents

Culture Documents

Catalogo Asca Valvula Retencao

Uploaded by

Maurício Duarte de AndradeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalogo Asca Valvula Retencao

Uploaded by

Maurício Duarte de AndradeCopyright:

Available Formats

Rg

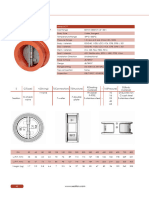

Flanged check valves

with disk counterseat

DIN PN 10 - 40 DN 250 to 400 mm RG 11, 21, 31

ANSI 125 - 300 10" to 16"

Check

Application

The RG check valves, with conical disk counterseat

form are used to avoid the return of liquids, gases

and steam in pipings. They are also indicated to be

applied as feet valve in pumping lines, ventilation or

vacuum arresterelements and as safety devices in

rotation lines.

Main characteristics

- Short body, it saves space;

- Lighter weight, easy handling;

- Reduced stroke, it softens the closing blow;

- Soon closing time, it minimizes the reflux;

- Useful long life;

- Minimum maintenance;

- They can be installed in any position.

Presentation

They are basically composed of flanged body, seat,

disk, guide and spring. RG 11, 21, 31

Technical competence, materials and connections

Model RG 11 RG 21 RG 31

Nominal diameter (mm) 250 300 350 400

(pol) 10" 12" 14" 16"

Max. service pressure bar (PSI) 10(140) 8(115) 7(100) 25(355) 20(285) 13(185) 40(570) 32(455) 21(300)

Max. correspondent temp. °C (°F) 120(248) 200(392) 250(482) 120(248) 250(482) 400(752) 120(248) 250(482) 400(752)

Cast iron Cast steel

1 Body

ASTM A 126 GR. B ASTM A 216 WCB

Materials

2 Seat

Cast bronze Cast stainless steel

3 Disk with stem

ASTM B 62 ASTM A 351 CF 8 (AISI 304)

4 Complete guide

5 Spring Stainless steel ASTM A 313 (type 302)

Flanged connections PN 10 - ANSI 125 PN 25 - ANSI 150 PN 40 - ANSI 300

Measures and weights

Model RG 11, 21, 31

Nominal diameter (mm) 250 300 350 400

(pol) 10" 12" 14" 16"

Measures (mm)

L 275 355 395 444

D 390 468 536 615

Approximated weight (kg) 90 135 165 260

(lb) 198 297 363 572

Edition: 10/08 PR-02.30.10-I

Installation

Load loss chart

They can be installed in any position, noticing just

the flow indicatiing arrow, on the body. 10000

8000

When installed downstream of pumps or 6000

compressors drove by a piston, is necessary to 4000

install a compensation chamber. 16

"

2000

D N 4"

1

Optionals* D N 1 2"

DN "

Check

1000

800 10

-Rubber (perbunam) or Teflon sealing; 600

DN

Flow in m³/h

-Basket type filter for the RG's applicated as feet 400

valve.

200

*The optional items are supplied by means

of price increase. 100

80

60

Operation 40

The input flow pressure displaces the disk (3) of 20

the valve against the spring force (5) (see Opening

Pressure chart) in direction of opening, giving 10

0,01 0,02 0,04 0,07 0,1 0,2 0,4 0,7 1 2 4 7 10

passage to the fluid. Interrupting the input flow,

the backpressure downstream displaces the disk Load loss ∆ p in m water column

(3) in direction to the seat (2), closing the valve.

The reduced stroke and the actions of the spring

shorten the closing time softening the closing blow The values indicated on the chart are Standard specification

and minimizing the reflux before complete based in valves provides of spring and

obstruction of the seat by disk. mounted in horizontal position. If the Flanged check valves with disk

flow is vertical, insignificant variations counterseat model RG ............. from ASCA

Opening pressure (in mbar) according to prospect PR-02.30.10-I

will occur only within partial opening

Flanged connections................................

Without With spring limits. Pressure class.........................................

DN spring

Per norm...................................................

Important Nominal diameter......................................

Optionals..................................................

mm pol We must remember that in the most

250 10" 2 48 29 12 industrial installations, the ∆p of the

300 12" 2,3 55 33 12 check valve does not cause any ef-

350 14" 2,5 59 35 12 fect in the general performance of the

400 16" 2,6 65 38 14 system and, therefore, does not cause

any influence in the choice of the

Load loss chart valve.

The curves of the chart prevail for water at 20 °C Data for sizing

/ 68 °F. To determine the load loss of other fluids,

ASCA will make pleasure the sizing

the equivalent water flow is calculated, applying

For this purpose must be supplied:

the following formula:

- Service temperature and pressure;

- Circulating fluid;

- Nominal diameter;

ρ - Pressure norm and class of the

Vw = . V where flanges between that the valve will be

1000

mounted.

Vw = Equivalent water flow in m³/h.

ρ = Fluid density (service condition) in kg/m3.

V = Fluid flow (service condition) in m³/h.

ASCA EQUIPAMENTOS INDUTRIAIS LTDA..

202, Fernandes da Cunha Street- Vigário Geral - Rio de Janeiro - RJ - COD 21241-300 We reserv the right of introducing fast

Tel.: (21) 2472-6900 - Fax (21) 3014-7622 - e-mail: office@asca.com.br modifications of technical order.

homepage: http://www.asca.com.br COPYRIGHT 2000 BY ASCA INDUSTRIAL EQUIPMENTS LTDA.

You might also like

- Pneumatic Actuators Act-1750Document4 pagesPneumatic Actuators Act-1750cvfNo ratings yet

- Pneumatic Actuator Parts and MaterialsDocument4 pagesPneumatic Actuator Parts and MaterialscvfNo ratings yet

- 2.25.e.rp45 Pressure Reducing Valve DN15-100-EnDocument5 pages2.25.e.rp45 Pressure Reducing Valve DN15-100-EnMa KiepNo ratings yet

- Pneumatic Actuators Parts & MaterialsDocument4 pagesPneumatic Actuators Parts & MaterialscvfNo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Flame ArrestorDocument2 pagesFlame ArrestorArunkumar SelvamNo ratings yet

- Vent-Line / In-Line Crimped Metal Flame Arrester: ObjectiveDocument2 pagesVent-Line / In-Line Crimped Metal Flame Arrester: ObjectiveHector Flores MarcosNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- SY Y StranerDocument2 pagesSY Y StranerPhú Song LongNo ratings yet

- Valvula de Retencion A Clapeta Oscilante Din pn16 dn50 300Document2 pagesValvula de Retencion A Clapeta Oscilante Din pn16 dn50 300JOHNNY CALERONo ratings yet

- Actreg Act 200Document4 pagesActreg Act 200Rafael LovatoNo ratings yet

- Re 91401Document20 pagesRe 91401JozefNo ratings yet

- Pneumatic Actuators Act-0130Document4 pagesPneumatic Actuators Act-0130Leandro AlbuquerqueNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- Air Trap RL1090 - RL1290Document2 pagesAir Trap RL1090 - RL1290satphoenixNo ratings yet

- FIREKING Valves & Accessories (Jun 2022) V1.4Document2 pagesFIREKING Valves & Accessories (Jun 2022) V1.4Ahlan kpNo ratings yet

- Pneumatic Actuators Act-0040Document4 pagesPneumatic Actuators Act-0040cvfNo ratings yet

- 4000 A Gate Valve - DN 80-200Document2 pages4000 A Gate Valve - DN 80-200AkmalNo ratings yet

- Dfu Ti D148 01 BRDocument2 pagesDfu Ti D148 01 BRNoo SokiNo ratings yet

- EBARA Horizontal Split Case Pump ManualDocument6 pagesEBARA Horizontal Split Case Pump ManualRido MardanNo ratings yet

- Fabric bellows, valves, chains and related equipment for AFBC and WHRB plantsDocument9 pagesFabric bellows, valves, chains and related equipment for AFBC and WHRB plantsgowriNo ratings yet

- Spirax BSA TDocument4 pagesSpirax BSA TNang DapiNo ratings yet

- cp1210 SpecsDocument2 pagescp1210 Specsyoucef alimNo ratings yet

- KITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFDocument16 pagesKITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFYulita Ika PawestriNo ratings yet

- Van Cổng OS & Y GATE VALVE KVS-4150Document1 pageVan Cổng OS & Y GATE VALVE KVS-4150Nguyễn Kỳ TúNo ratings yet

- SC77Document1 pageSC77bhaaskarNo ratings yet

- Hawle Ventili20-200Document2 pagesHawle Ventili20-200Kenan HotiNo ratings yet

- Valve and SupportsDocument3 pagesValve and SupportsMohamed ArafaNo ratings yet

- Drawing 80AQ15-60 Non CodedDocument2 pagesDrawing 80AQ15-60 Non Codeddaus nasNo ratings yet

- OS&Y VikingDocument42 pagesOS&Y VikingayaNo ratings yet

- OS&Y Viking Copy 4Document42 pagesOS&Y Viking Copy 4ayaNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- Valve-Gestra NRV VPENC000050Document2 pagesValve-Gestra NRV VPENC000050bokachoda786No ratings yet

- Swing Check Valve Rubber DiscDocument2 pagesSwing Check Valve Rubber DiscsathishNo ratings yet

- R/F - 150Lb Rating Cast Y'-Type Strainer: SDD/YFL/R15/STLDocument1 pageR/F - 150Lb Rating Cast Y'-Type Strainer: SDD/YFL/R15/STLNagLakshmananNo ratings yet

- Fireking Y StrainerDocument1 pageFireking Y Strainermirdraco68No ratings yet

- OSFDocument2 pagesOSFUyab100% (1)

- Spirax Sarco Piston Valve RP31Document2 pagesSpirax Sarco Piston Valve RP31PaulNo ratings yet

- Data Sheet 1.60 Issue C: OS&Y Flanged Gate Valve F4 Series Fig. 116FFDocument2 pagesData Sheet 1.60 Issue C: OS&Y Flanged Gate Valve F4 Series Fig. 116FFMohammed sabatinNo ratings yet

- Fsa - Ebara End Suction Volute PumpDocument6 pagesFsa - Ebara End Suction Volute PumpkhristprasatyaNo ratings yet

- Resilient Seated Gate Valve Product Data SheetDocument2 pagesResilient Seated Gate Valve Product Data SheetEm Es WeNo ratings yet

- Avk Y-Strainer, PN 16 910/21: N50-300, A2 Plug and Fasteners 001Document3 pagesAvk Y-Strainer, PN 16 910/21: N50-300, A2 Plug and Fasteners 001AgieYogaswaraNo ratings yet

- Re 91401Document16 pagesRe 91401Jamin SmtpngNo ratings yet

- Specification - 9110 - 201510 at Globe (Rev.03)Document10 pagesSpecification - 9110 - 201510 at Globe (Rev.03)Công PhạmNo ratings yet

- 1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmDocument1 page1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmNon Etabas GadnatamNo ratings yet

- Strainer Y-Type Production StandardsDocument3 pagesStrainer Y-Type Production StandardsMohamed RaafatNo ratings yet

- 84-93-001 Avk002ax Eni 432477Document3 pages84-93-001 Avk002ax Eni 432477Gotica ManagementNo ratings yet

- Butterfly Valve GRWDocument8 pagesButterfly Valve GRWilkinNo ratings yet

- Ficha Tecnica Valvula Check 10 MilDocument1 pageFicha Tecnica Valvula Check 10 MilTrujillo TrujilloNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- 3521 Gala Gate Valve CatalogDocument1 page3521 Gala Gate Valve CatalogChhomNo ratings yet

- SpecDocument2 pagesSpecMSNo ratings yet

- CTR 004 Yardr 0008 enDocument3 pagesCTR 004 Yardr 0008 enAndy GarciaNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

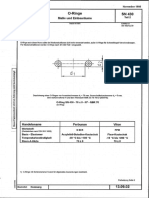

- Round Washers SN 808: July 2000Document1 pageRound Washers SN 808: July 2000Maurício Duarte de AndradeNo ratings yet

- E BSEN10131Document11 pagesE BSEN10131Maurício Duarte de AndradeNo ratings yet

- eSN901 3Document1 pageeSN901 3Maurício Duarte de AndradeNo ratings yet

- En 10305-1 PDFDocument28 pagesEn 10305-1 PDFVlad100% (3)

- eSN470 1Document4 pageseSN470 1Maurício Duarte de AndradeNo ratings yet

- En 10305-1 PDFDocument28 pagesEn 10305-1 PDFVlad100% (3)

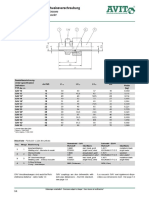

- União GAV AVITDocument1 pageUnião GAV AVITMaurício Duarte de AndradeNo ratings yet

- eSN901 7Document1 pageeSN901 7Maurício Duarte de AndradeNo ratings yet

- TIMKEN - BearingsDocument476 pagesTIMKEN - Bearingsbube2No ratings yet

- SN430 2Document2 pagesSN430 2Maurício Duarte de AndradeNo ratings yet

- A020a020m PDFDocument31 pagesA020a020m PDFDaniel LodiNo ratings yet

- DINEN10163-1 Delivery Requirements For Surface Condition of Hot-Rolled Steel Plates, Wide Flats and Sections - Part 1: General RequirementsDocument8 pagesDINEN10163-1 Delivery Requirements For Surface Condition of Hot-Rolled Steel Plates, Wide Flats and Sections - Part 1: General RequirementsMaurício Duarte de AndradeNo ratings yet

- Dinen10056 2Document4 pagesDinen10056 2Maurício Duarte de AndradeNo ratings yet

- A906A906Document6 pagesA906A906Maurício Duarte de AndradeNo ratings yet

- Dinen10056 1Document9 pagesDinen10056 1Maurício Duarte de AndradeNo ratings yet

- Din 50150Document52 pagesDin 50150Maurício Duarte de Andrade100% (2)

- MSS Standard Practice SP-95: SectionDocument3 pagesMSS Standard Practice SP-95: SectionMaurício Duarte de AndradeNo ratings yet

- DIN Handbook 402A PDFDocument813 pagesDIN Handbook 402A PDFMaurício Duarte de Andrade100% (4)

- Thread-Swage-Nipple MSS SP 95Document3 pagesThread-Swage-Nipple MSS SP 95MaurícioAndradeNo ratings yet

- DIN Handbook 404Document834 pagesDIN Handbook 404Maurício Duarte de Andrade100% (5)

- Workshop Manual. VW Polo Estate 1998 4-Cyl. Injection Engine (4 Valve), Mechanics (APE, AUA) - Edition 11.1999, 00056407620Document162 pagesWorkshop Manual. VW Polo Estate 1998 4-Cyl. Injection Engine (4 Valve), Mechanics (APE, AUA) - Edition 11.1999, 00056407620Аргос GNo ratings yet

- Unit 8: Title: Cylinder Block and Cylinder Head General ObjectiveDocument15 pagesUnit 8: Title: Cylinder Block and Cylinder Head General ObjectiveAdid PunyaNo ratings yet

- MAVJ Catalogue (En - 0898)Document8 pagesMAVJ Catalogue (En - 0898)renjithas2005No ratings yet

- 05diffsep07 PDFDocument38 pages05diffsep07 PDFNaomi Lizzy FluegelNo ratings yet

- IIT Bombay Chemical Engineering Mini Project Analysis of Piping Network and Natural Gas ReformerDocument3 pagesIIT Bombay Chemical Engineering Mini Project Analysis of Piping Network and Natural Gas ReformerFake Account 1No ratings yet

- Manual Monitoring Relay SIRIUS Monitoring DevicesDocument392 pagesManual Monitoring Relay SIRIUS Monitoring DevicesDebye101No ratings yet

- Unit-Iii Electromagnetic Waves - NotesDocument13 pagesUnit-Iii Electromagnetic Waves - NotesAnusha KovuruNo ratings yet

- Invoice 1553736Document1 pageInvoice 1553736yashuNo ratings yet

- Physics Chapter 7 Kinetic Energy and Work QuestionsDocument57 pagesPhysics Chapter 7 Kinetic Energy and Work QuestionsJames AguilarNo ratings yet

- Advances in IPM For HybridDocument6 pagesAdvances in IPM For HybridArchana Diwakar RanjishNo ratings yet

- United States Court of Appeals, Fourth CircuitDocument17 pagesUnited States Court of Appeals, Fourth CircuitScribd Government DocsNo ratings yet

- Engine Harness P/N 0587299-00 Diagram Revision - A - : Component ListDocument1 pageEngine Harness P/N 0587299-00 Diagram Revision - A - : Component ListPabloAntonioCerdaSotoNo ratings yet

- Compressor Risk Assessment v2b PDFDocument4 pagesCompressor Risk Assessment v2b PDFmukeshkatarnavareNo ratings yet

- FSI-P-CHME Chemical Engineering ExamDocument6 pagesFSI-P-CHME Chemical Engineering ExamAaqib AshrafNo ratings yet

- Technotrans Brochure Beta.zDocument4 pagesTechnotrans Brochure Beta.zfranck LedouxNo ratings yet

- ProposalDocument22 pagesProposalKD CarlosNo ratings yet

- List Price: W.E.F. 22nd December, 2020Document11 pagesList Price: W.E.F. 22nd December, 2020Kundan DuttaNo ratings yet

- Exploring relationships between environmental management, debt financing and financial sustainability in energy industryDocument20 pagesExploring relationships between environmental management, debt financing and financial sustainability in energy industryRose PbNo ratings yet

- 921e Cargador Frontal CaterpillarDocument8 pages921e Cargador Frontal CaterpillarElvis Eberth Huanca MachacaNo ratings yet

- CIS-E Airflow Sensor Potentiometer Replacement GuideDocument2 pagesCIS-E Airflow Sensor Potentiometer Replacement Guideazizja1100% (2)

- Chemistry For Engineers ElectrochemistryDocument7 pagesChemistry For Engineers ElectrochemistryCHRIST IAN JAN PALGANNo ratings yet

- GFL-WDA - e Spesifikais AlatDocument19 pagesGFL-WDA - e Spesifikais Alatlabkimia unisbaNo ratings yet

- QualifyingExamProblemSolutionsUnivOfILLionisNotesStatisticalMechanics PDFDocument216 pagesQualifyingExamProblemSolutionsUnivOfILLionisNotesStatisticalMechanics PDFHarikrishnan GurusamyNo ratings yet

- MECH HovercraftDocument16 pagesMECH HovercraftAbhay KumarNo ratings yet

- Essential For Those Who Want To Use The Radio Transmitters From A Car To Use in Your Home Is You Need A Ham Radio Power Supply DCDocument4 pagesEssential For Those Who Want To Use The Radio Transmitters From A Car To Use in Your Home Is You Need A Ham Radio Power Supply DCdundonaldsNo ratings yet

- Manufacturing Facilities Design and Material HandelingDocument7 pagesManufacturing Facilities Design and Material Handelingabdelghani cherkaouiNo ratings yet

- Xylem TotalcareDocument8 pagesXylem TotalcareAndrey GyrychNo ratings yet

- Theotoglou Main PDFDocument8 pagesTheotoglou Main PDFHako KhechaiNo ratings yet

- Baffle Selection PDFDocument7 pagesBaffle Selection PDFmaruthigabbita100% (3)

- SEO PhysicsDocument8 pagesSEO PhysicsMuhammad AdreesNo ratings yet