Professional Documents

Culture Documents

Attachment 13 - Packing and Preservation Procedure

Uploaded by

Yadir SánchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Attachment 13 - Packing and Preservation Procedure

Uploaded by

Yadir SánchezCopyright:

Available Formats

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 1 of 10 Project ID:

Packing and Preservation Procedure

End Customer:

End Customer Reference Number:

Document File Name: Packing and Preservation Procedure

Document Status: For Information

Authorizations

Name Function Signature

Developed By: Vishal Gaikwad Quality Engineer VG

Reviewed By: Kishorekumar .G Assistant Quality Manager KG

Distribution

Name Company Name Company

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 2 of 10 Project ID:

Revision History

Rev Status Description Date Developed By Reviewed By

0 IFI For Information 15.07.2021 VG KG

Reference Documents

The documents listed in below table form an integral part of this specification. The vendor shall

notify Emerson of a recommended resolution for cases where, conflicting requirements are found in

these documents.

Document Number Document Title Document Revision

© Emerson Automation Solutions. All rights reserved. Unauthorized duplication, in whole or in part, is

prohibited. Trademarks identified in this document are owned by one of the Emerson Automation Solutions

group of companies. Unless otherwise agreed to in writing by the parties, any information provided in this

document is confidential or proprietary and may not be used or disclosed without the expressed written

permission of Emerson Automation Solutions.

Emerson Automation Solutions

Measurement Solutions - Systems & Lifecycle Services

6001 Rogerdale Road

Houston, TX 77072 USA

www.Emerson.com

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 3 of 10 Project ID:

Contents

1 PURPOSE _________________________________________________________ 4

2 SCOPE ____________________________________________________________ 4

3 RESPONSIBLITY ____________________________________________________ 4

4 GENERAL _________________________________________________________ 4

5 PRESERVATION ____________________________________________________ 5

6 CONSOLIDATING AND PACKING ______________________________________ 5

7 SKID PREPARATION ________________________________________________ 6

8 MATERIAL AND WORKMANSHIP ______________________________________ 6

9 SKID CONSTRUCTION _______________________________________________ 7

10 MARKING __________________________________________________________ 7

11 PRESERVATION MAINTENANCE CHECK LIST __________________________ 10

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 4 of 10 Project ID:

1 PURPOSE

This specification outlines the requirements for preservation and storage of skid

mounted metering systems and associated loose shipped components for a time

period up to one year from shipment.

2 SCOPE

This specification defines the requirements for preservation, packing and crating in

preparation for shipment of metering systems, provers, and miscellaneous parts to

Daniel Systems’ customers. Where the customer’s specification is more stringent, the

customer’s requirements shall be followed

3 RESPONSIBLITY

Daniel Systems’ Subcontractor shall be responsible for providing materials, labor,

equipment and consumables necessary for completing the work outlined in Daniel

Systems’ Purchase Order and this specification.

The complete metering systems/ venturi/ flow nozzle shall be painted with the type

and colour of paints indicated in the paint colour schedule, included in this

specification. The following surfaces shall not be painted, unless otherwise specified.

Machined surfaces

Manufacturer’s name and data plate

Exposed stainless steel, Galvanized Surface, copper, brass, aluminium,

Valve stems, glands and control valve positioners Aluminium sheathing over

insulation

Items, which for various reasons may have special finish, applied by the

manufacturer.

4 GENERAL

If additional protection over and above the measures noted, and/or over and above

standard practices are required, Daniel Systems shall advise the Subcontractor of

the special requirements.

Shipping containers of whatever variety shall be constructed and sealed in a manner

that will provide maximum protection from pilferage.

Whenever practical, skids and equipment shall be shipped as complete and fully

assembled items.

Parts of equipment and machinery that are removed for reasons of either shipment

or for more adequate protection against damage shall be separately protected,

identified and included in the same container of the item to which they belong, if

possible.

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 5 of 10 Project ID:

5 PRESERVATION

All machined, bright finished, close clearance surfaces or bare metal surfaces shall

be protected with suitable anti-corrosive material which can be removed by standard

cleaning methods or solvents. All skids with carbon steel piping which is bare inside

shall be completely drained of water left from hydro test or flow test and blown dry

with shop air before shipment. Plugs on valve bodies shall be opened to drain water,

blown dry and plugs replaced. A corrosion inhibitor such as Houghton Rust Veto 377

shall be fog sprayed into the interior of carbon steel piping to prevent corrosion.

All painted surfaces are bubble -wrapped .

All small, loose components are shipped in sealed containers

Open ends of pipes and fittings are covered by Heavy plastic Flange covers, caps or

plugs sealed and fixed as dictated by the pipe configuration

Flanged openings and weld ends on piping, vessels and equipment items shall be

protected with dust and waterproof covers of suitable design and material. Flanged

openings may be covered with minimum 6mm thick water resistant plywood Plate

with a minimum of four galvanised bolts (4) securing Plate. Gasket seal surfaces

shall be greased prior to installing covers. Heat shrink plastic covering of 8mil (0.2

mm) thickness shall be applied over the flange and cover and heat shrunk to the pipe

and flange.

Gas meter tubes or other piping shipped loose or separate from skids shall be

provided with wooden skids, with the pipe secured to the skid by means of steel

bands as outlined in section 8.4 below. Painted piping shall be protected by use of

cardboard strips or plastic foam sheet between the bands and the pipe. Orifice plates

shall be packed carefully to be sure that damage does not occur during

transportation. Orifice plates shall remain in their original factory packaging. Staples

or nails are not allowed to be used on these packages. The crating Subcontractor

shall provide additional material such as bubble wrap to separate and protect each

orifice plate package.

Threaded openings in piping and equipment shall be either plugged with NPT plugs

or plastic thread protectors.

Equipment packages separately, such as computers, instruments, motors, power

supplies, and electrical equipment or related parts and circuit boards shall be

protected by a moisture proof vapor barrier or 12.9mil (0.33 mm) scrim foil plastic bag

with silica gel or a similar desiccant to absorb moisture within the package or

enclosure.

6 CONSOLIDATING AND PACKING

It should not be prepared to pack or pack any material until you have passed the

internal inspection, and by the client or customer confirmation that not performed.

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 6 of 10 Project ID:

Should exercise caution in the preparation of the materials to be packed to ensure

they do not suffer any damage or aesthetic or functional.

All equipment must be thoroughly clean and dry before preparing to pack them, thus

avoiding possible degradation during transport and storage customer premises.

Articles shall be nested or packed to reduce volume as much as possible. They

should also be packed to prevent crushing or damage to each other by blocking off of

the use of a partition. All fragile items, such as gauges, glass, or other breakable

material shall be protected and cushioned within the container to prevent damage

from shock, vibration and rough handling. Hazardous material must be packed

separately, marked accordingly and accompanied by Material Safety Data Sheets.

All Equipment shall be carefully protected and packed to ensure adequate protection

during transit.

Under no Circumstances may go loose parts inside a package.

Packing is sufficient to withstand handling during loading/ Unloading, Sea or inland

transport and storage at sites

Packing is done in a such a manner to enable cargo Handling by fork lift or pellet

jack. Packages needs mechanical handling by pallet jack, Over head crane and

Forklift can be skidded to allow two way pallet entry and for lift entry

7 SKID PREPARATION

All meter and / or prover systems shall be prepared for shipment to prevent the

possibility of damage due to vibration resulting from transportation to site.

Small bore vent and cross over headers shall be removed from the system and

packed separately. Vertical branch connections with valves and piping in excess of 3

feet in height (1 meter) as measured from branch flange connection shall be removed

and securely packed.

Horizontal branches greater than or equal to 1-1/2” NPS with heavy, unsupported

valves or instrumentation shall be removed and packed separately.

All other piping, valves or fittings shall be properly supported and braced for

transportation to site. Any piping branches, fittings or connections identified as at risk

to experiencing vibration damage during transportation shall be evaluated by the

shipping, quality and engineering teams to determine the appropriate action.

All piping U-bolts, tubing clamps and other structural / piping fasteners shall be

checked to ensure that they are tightened to the required torque prior to

transportation.

8 MATERIAL AND WORKMANSHIP

All lumber shall be sound and well-seasoned. All wood for export packing shall be

certified to meet the requirements for fumigation. Knots are permitted provided they

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 7 of 10 Project ID:

are sound and tight and do not exceed one-third (1/3) of the board width. Flooring

skids and structural members shall be of good structural grade and species. Green or

wet lumber shall not be used where the contents of the container are adjacent to the

lumber. All nails shall be of the etched or cement coated type except that smooth

nails may be used when they pass through the sheeting and framing and are

clinched.

When specified by the Purchase Order, wood shall be treated for insects as required

by the applicable export / import regulations.

For spans of 2 feet of less, minimum 1/4” thick plywood, typically 24/o C-D (sheathing

grade) INT-APA with exterior glue may be used. For greater spans up to 4 feet, or

when crate load exceeds 10,000 lbs. use 3/8” or thicker plywood, typically 32/16 C-D

(sheathing grade) INT-APA with exterior glue.

Workmanship shall be in accordance with best industry standards. Imperfections or

omissions which would tend to impair the protection otherwise afforded by the box or

crate will not be accepted.

9 SKID CONSTRUCTION

Packing Process – Certified Wooden Base, HDPE sheet for base, stretch film and

Lashing belts for internal equipment’s.

Internal equipment and spool nozzles to be bubble wrapped topped with stretch film

thoroughly than after Vacuum Packing, placed Desiccants, Rewrapping to hole

equipment and covering HDPE Cover with strapping etc.

Skid base members shall be arranged so that the package may be conveniently lifted

by means of either forklift or lifting slings beneath the package.

All instrumentation, electrical panels, gauges and valve controls shall be protected by

bubble wrap material secured with duct tape and then boxed or crated. Shafts and

other protrusions must be supported and protected. In addition, all procedures listed

in these specifications will apply.

All machined, bright finished, close clearance surfaces or bare metal surfaces shall

be protected with suitable anti-corrosive material which can be removed by standard

cleaning methods or solvents.

Sliding door openings shall be provided on the sides and tops of skid hood boxes for

access and use of lifting lugs and slings for loading and unloading of skids for

transportation.

10 MARKING

Each package shall be marked in accordance with the customer’s marking

instructions.

To identify the each box at any point of time with required detail like batch number

and lifting instructions.

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 8 of 10 Project ID:

Main shipping mark – If the box does not have main shipping mark or it cannot be

stencilled then printed labels of shipping mark as per customer order is firmly fixed to

the package. The marks is printed in black colour & is clearly legible.

Graphic symbols are clearly stencilled which includes sling, right position, centre of

Gravity and handle with care.

Package numbering- All the packages are marked with package number

Two copies of packing list are affixed on outside of each package.

The packing list show manufacturers name & country of origin, actual good packed

in box, size and quantity , gross weight and net weight.

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 9 of 10 Project ID:

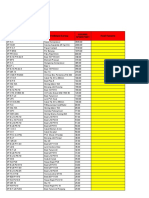

PRESERVATION RECORD:

Emerson Logo Project Name:

Preservation Record

Project No:

PO Number: Area: Package No:

Manufacturer: System: Tag Number:

Description: Subsystem:

Inspection Item Supplier Fabricator HOOKUP Remarks

1 Supplier Initial

Preservation Instruction

Issued

2 Preservation Performed

3 Preservation Labels

fixed

4 Corrosion Inhibitor

installed

5 Storage and Transport

Protection implemented

6 Ship loose items

marked and preserved

7 Equipment Enclosure

sealed off

8 Inlet /Outlet sealed off

9 Periodical Preservation

carried out

Verified Supplier Fabricator HOOK UP

Name

sign

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

Packing and Preservation Procedure

Document Number: MSS-PE-PROC-10 Project Name:

Revision 00 –15-Jul-21 Page 10 of 10 Project ID:

11 PRESERVATION MAINTENANCE CHECK LIST

1. Inspection and Punch list any damage to the equipment.

2. Check storage and preservation condition on all mechanical Shipped loosed

equipment.

3. Check that dust blinds are fitted on nozzles in and out from skids on singles

items of equipment and on free pipe ends

4. Check that painted and machined surface which shall be coated with rust

preventive wax or oil are maintained.

5. Check that the protective cover maintained.

6. Check for physical damage and damage of preservation protection.

7. Check that all sensitive Instrumentation exposed to damage are protected .

8. Check external surfaces and painting are not damaged.

9. Check for corrosion, cleanliness and moisture and add preservative as required

and ensure sealing protection

Emerson Automation Solutions – Confidential and Proprietary

Template No. MSS-PE-PROC-10, Packing and Preservation Procedure, Revision: 00, Date: 15-Jul-21

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Air Control1 Kody I Usterki enDocument2 pagesAir Control1 Kody I Usterki ensebastian92% (12)

- Hydraulic Grab Carrier: Bauer GB 46Document8 pagesHydraulic Grab Carrier: Bauer GB 46RizkiNo ratings yet

- EMERSON Standard COATING SPECIFICATIONDocument9 pagesEMERSON Standard COATING SPECIFICATIONYadir SánchezNo ratings yet

- G21LAHL1377 - A - ICA Fluor Ethenol GADocument2 pagesG21LAHL1377 - A - ICA Fluor Ethenol GAYadir SánchezNo ratings yet

- TechnipFMC - Pipeline StrainersDocument6 pagesTechnipFMC - Pipeline StrainersYadir SánchezNo ratings yet

- Safety King - Air Conditioner WCSK-SeriesDocument7 pagesSafety King - Air Conditioner WCSK-SeriesYadir SánchezNo ratings yet

- Marley ICG36081 CalentadorDocument2 pagesMarley ICG36081 CalentadorYadir SánchezNo ratings yet

- Welker Crude Oil Sample System - LSY3332 Rev.BDocument6 pagesWelker Crude Oil Sample System - LSY3332 Rev.BYadir SánchezNo ratings yet

- Isms-C Doc 16.1.5 PDFDocument2 pagesIsms-C Doc 16.1.5 PDFdhir.ankurNo ratings yet

- Per Spek TivaDocument17 pagesPer Spek TivaIvana MiloševićNo ratings yet

- Unit 1 Lesson 2Document5 pagesUnit 1 Lesson 2JessaNo ratings yet

- Blue StarDocument8 pagesBlue StarPrabhakar JhaNo ratings yet

- Ship Stability FormuleDocument12 pagesShip Stability FormuleHaziq Ismail100% (1)

- Getting Started With Sharepoint Learning KitDocument24 pagesGetting Started With Sharepoint Learning KitLee CallahanNo ratings yet

- SECTION III SCOPE OF WORK - 12.11.2018 - Without WIW 215Document273 pagesSECTION III SCOPE OF WORK - 12.11.2018 - Without WIW 215Kamila WehbeNo ratings yet

- Design of Free Standing WallsDocument12 pagesDesign of Free Standing Wallssaif.mulla0% (1)

- Pedestrian Comfort Guidance Technical Guide PDFDocument41 pagesPedestrian Comfort Guidance Technical Guide PDFРоман КваснійNo ratings yet

- Catálogo Compresores Baja Presion-AersenDocument32 pagesCatálogo Compresores Baja Presion-AersenJuan Camilo RestrepoNo ratings yet

- 3 Phase Short-Circuit PDFDocument227 pages3 Phase Short-Circuit PDFPuppy Ayu Jatmiko50% (2)

- SCL (NATM) TunnellingDocument74 pagesSCL (NATM) Tunnellingthauwui86100% (1)

- Delete BATSEL - 3S#: For IT8752 PowerDocument1 pageDelete BATSEL - 3S#: For IT8752 PowerAlan_88No ratings yet

- Préfixe Gamme CATDocument356 pagesPréfixe Gamme CATChristopheNo ratings yet

- Automatic Cell Image Segmentation Using Genetic AlgorithmsDocument5 pagesAutomatic Cell Image Segmentation Using Genetic AlgorithmsAintMustache AvedearenaNo ratings yet

- Bda 14303Document8 pagesBda 14303Mahfuzah MustaphaNo ratings yet

- Kerendan ESIADocument0 pagesKerendan ESIARobert WataniaNo ratings yet

- Levation: Rigid Core SPC Flooring / Revêtement de Sol Structure SPCDocument13 pagesLevation: Rigid Core SPC Flooring / Revêtement de Sol Structure SPCABDULQURESHINo ratings yet

- Antonov, An-2 PDFDocument2 pagesAntonov, An-2 PDFDdweng100% (1)

- Punching Shear Reinforcement: Technical ApprovalDocument12 pagesPunching Shear Reinforcement: Technical Approvalandrewzay_670173166No ratings yet

- Vandv: 48 The Maxwell-Boltzmann DistributionDocument2 pagesVandv: 48 The Maxwell-Boltzmann DistributionNandNNo ratings yet

- Optical Transport Network (OTN) : Future Ready. TodayDocument4 pagesOptical Transport Network (OTN) : Future Ready. Todaypriyanka joshiNo ratings yet

- HPLC ColumnsDocument26 pagesHPLC ColumnsitzamaraNo ratings yet

- Radiation Heat Transfer Between Parallel PlatesDocument4 pagesRadiation Heat Transfer Between Parallel Platestiny085057No ratings yet

- Basics of Control ComponentsDocument131 pagesBasics of Control ComponentskarinaNo ratings yet

- CDMA 800 TestDocument10 pagesCDMA 800 TestermellowNo ratings yet

- Kuantitas Barang Per Daftar Gudang: PT. Mahajaya Plastindo IndonesiaDocument10 pagesKuantitas Barang Per Daftar Gudang: PT. Mahajaya Plastindo IndonesiaDesain OMINo ratings yet

- Profile of VHTP CompaniesDocument33 pagesProfile of VHTP CompaniesSerge BatovNo ratings yet