Professional Documents

Culture Documents

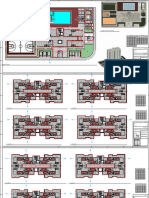

Planta Tratamiento A.residuales

Uploaded by

Aqeel SaleemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planta Tratamiento A.residuales

Uploaded by

Aqeel SaleemCopyright:

Available Formats

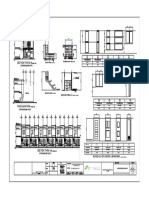

0.

30

0.30

0.60 4.80 0.15 View Detail No.4

LANDFILLS

0.41

2.85 45°

0.20

0.15

0.45 0.25 Metal

the gascable

pipe to give stability to

CERCHA

View Detail No.1

PROTECTIVE

View Detail No.2

TILES

CUT 1-1 4.80

3.00

2.35 0.65

1.80

2.35 0.50

REACTOR UASB

45°

SCALE: 1:25

L=0.10 L= 2.64

17

10#5

18 c/0.3 L=6

L=5.6 L= 0.20

0.60 L=2.33

10#5

19 c/0.3 L=2.53 L= 0.20 1.48

0.50

LANDFILLS

View Detail No.4

L= #4

32

28 2.76

1.88

c/0.15 L=1.98 L= 0.8 24# 5 c/ 0.15 24#5.00

L=

10#

20 4 c/0.3

c/ 0.15

L=6 L= 0.20 38 L=2.64

22

39

22#5

#5c/0.3

3.38 c/0.3L=5.6

L=6.0 L=0.60

L= 0.20 L=2.33

22#5

40

1.30 c/0.3 L=2.53 L= 0.20 68

67

66

65

0.54

0.58

0.53

0.1

0.48 52-53

51

59

58

57

56

55

54

0.63

0.85

0.76

0.75

61

60

64

63

62

0.44

0.54

0.53

0.45

0.46

0.35

0.1

0.36

0.58

0.47 38

50

49

48

47

46

45

44

43

42

41

40

39

0.82

0.79

0.78

0.83

0.74

0.73

0.56

0.65

0.58

0.64

0.57

0.72

0.84

0.1

0.48 34

33

32

31

30

29

28

27

26

25

1.50

1.51

37

36

35

0.68

0.45

0.78

1.25

0.61

2.43

0.66

2.37

0.2

0.94

0.1

3.78

0.25

0.4 11

12

0.2

1.07

18

17

1.45

1.32

1.44

16

15

14-

13

24

23

22

21

20

19

0.55

3.55

0.4

4.02

2.15

2.34

1.96

2.46

0.3

3.57

0.1

1.52

0.75

3.26

FIGURE

No

1

Ref.

5

4

3

2

0.50

0.68

6

2.84

9

8

7

1.46

2.24

0.2

1.07

-10

APPROVED: L= 0.8 L= 2.66

10#

21 4 c/0.3 L=3.66 L= 0.20 L=0.10

L=2.76

L=2.76 L=0.10 # 5 c/ 0.15

# 4 c/ 0.15

41

L=0.30 0.68

0

1

0.58

0.74

1.69

0.1

20

3/8"

.68

TOTAL STEEL 24

0.83

1.05

12

0.96

1.91

0.64

1.6

0.74

0.56

1.51

1.63

2

0.66

1.61

0.1

1

0.58

3/8"

.69 6.68

3

1.98

3/8"

0.99

1.94

1.03

0.94

1.72

0.85

0.58

0

1

0.72

2.28

12

0.1

/8"

.89

.80

.77 1.47

1.60

3

3/8"

1.82

0

1.01

2

0.85

2.63

0.47

1.33

5

1.34

3.88

0.2

.61

.85

.2

.03 5.01

2.07

20

1.47

1.65

0.1

1.32

10

4.08

4.1

4.42

3/8"

2.25

2.44

2

4

0.2

1.62

3 .06

.56

.07 Quantity

Longitude

ISLAND

(m)

(ONE)

4.28

3/8"

0.94

3

1.13

4.65

4

1.86

1

3.01

0.2

0

5

3.55

0.11

10

1.47

.86

.24

.2

IRON TABLE

L= 2.74

20#5

29

7.10 c/0.15 L=2.74 32# 4 c/ 0.15 L=4.68

52

SCALE:

CUTTING

CUT 1:25

1-1 # 4 c/ 0.15

L=0.80

L=0.10 L=2.7c/0.3 L=3.8

22#4

44 L=4.52

L=

22#4

43 0.20

c/0.3 L=6 L= 0.29

L=0.30

L=0.20

22#4

42 c/0.3 L=1 L=0.10

L=0.48

L=0.50

22#4 c/0.3 L=0.8 L=0.10 PVC

P

2 = 5%

12" PVC

P = 5%

12" 0.556

0.41

0.94

7.56

0.38

297.56

3 KG L=0.20

0.556

0.91

0.733

1.79

0.62

1.68

0.355

0.89

0.82

1.88

0.53

1.06

11.07

7.00 L=0.20

L=1.46

4#

6

0.556

15.21

4.54

0.43

0.96

0.47

1.00

0.52

1.05

0.55

1.08

0.57

1.10

3.44

3 c/ 0.25 L=1.86 L= 0.94

L=0.20

0.556

3.72

10.78

2.36

7.31

3.69

6.86

5.64

2.80

0.95

2.02

2.68

2.67 0.556

2.7

6.68

6.78

4.27

3.75

4.07

3.44

6.84

7.37

16.34

9.17

22.68

5.75

1.50

0.10

2 Bar

(Medical

WEIGHT

(Kg-m)

0.556

8.17

9.87

8.367

7.21

12.93

4.14

7.20

11.89

PVC

P

Comesweight

collector

= 5%

0.10 12" history)

from final

47#4 c/0.3 L=4.88

CUT

0.10

0.10

SCALE: 2-2

L=0.21

L=0.18

1:25

Comes from Bypass Chamber

Comes from Bypass Chamber

REACTOR

OF

OBJECT: 5.80

32

27 #4 c/0.15 L=6 L= 0.8 L=0.30

L=0.69

L=0.20

L=0.2

L=1.05

L=0.1

5#4

30

5#

31 c/0.1

c/0.1L=1.46

L=3.21

REACTOR UASB

L=0.10

L=0.80 L=2.7c/0.3 L=3.8

22#4

45 L=4.52

L=

22#4

46 0.20

c/0.3 L=6.0 L= 0.29

L=0.30

L=0.20

22#4

47 c/0.3 L=1 L=0.48

L=0.10

L=0.51

48

UASB

# 5 c/ 0.15

# 5 c/ 0.15

# 4 c/ 0.15

L=0.50

L=0.82

L=0.81

3#

25

24

1 3 c/ 0.25 L=1.60

L=1.62 L=0.18

L=0.2

L=0.10

27

26

1 170°

4 0.80

0.20

0.15

170°

4 L= 0.48

L=0.20 5# 3 c/ 0.25 L=1.86 5# 3

4#

L=

1

2 2.84

c/ 0.25 L=3.24

L=4.28 Going

PVC

P

1 = 5%

12"

to Screening 10%

0.50

0.90

1

STUDIES,

TREATMENT

22#4 c/0.3 L=0.8

L=0.50

3#

L= 3

0.82

0.81

5

24# 5 c/ 0.15

0%

THE ABOVE

L=1.6

c/ 0.25 L=1.61

GENERAL

PLANT

SANITARY

5# 3 c/ 0.25 L=3.24 FLOOR

FOR AND/OR

WASTEWATER

DESIGNS,

SEWER OXIDATION

DOMESTIC L= 0.8 L= 2.66

10#

22 4 c/0.3 L=3.66 L= 0.20

10#

23 4 c/0.3 L=6 L=1.04

L=0.78

L=0.10

L=0.80

L=1.06

L=0.2

32

5#4

33 c/0.1 L=1.00

L=1.46 L=0.20

L=0.2

L=0.10 L=0.10

L= 0.68

0.65 L=2.64 L= 2.32 L= 0.30 L=0.17 L=0.58

L=0.30

5# 3 c/ 0.25

L= 3

5# 0.50

0.55

c/ 0.25

0.02 hole

L= 0.17

0.4

Metal

See detail

Grid

0.02

Grid

12"

rod

in

Length

0.70

0.60welded

concrete

anchors

= to

25the

cm

to grid

concrete

and recessed 5##3

L=

4 2.84

3c/c/0.25

0.25L=4.65

L=3.24 L= 3

5# 0.50

c/ 0.25 L=4.28 ends %

100.50

2.90

TREATMENT

PLUVIAL,

5# 3 c/ 0.25 L=4.65

L=1.86

0.60

Angled link mesh 1" at the

LAGOON OR COMBINATION

L= 0.10

L=2.76 24#0.20

L= 5 c/ 0.15 24# 4 c/ 0.15

L=5.00

L=0.20

35

36 24# 4 c/ 0.15 22#5 c/0.3 L=4.17

51 L=2.64

22#5

50 c/0.3 L=4.57 L=0.60

L= 0.20 22#4 c/0.3 L=2.53

49 L=0.20 L=3.26

3#

23 3 c/ 0.25 L=4.01 PLANT 5# 3 c/ 0.25 2

1

L=

3#

16 3

3.55

Horizontal

anchorage

"w

Length

concrete.

elded

3.50 0.25

c/ 25 L=4.42

to anchored

cm

to

anchorage

the concrete

and

of recessed

the

with rodin

2.20

Collectionremoved

material

0.10

0.76 chamber solid L= 0.93

L=0.20 L=0.20 4 # 3 c/ 0.25 L=1.86

L=1.46 L=0.20

3 PVC

P

2 = 5%

0.20 10" Go to the river

0.10

SCALE: 1:20

10#5 c/0.3 L=6

25 L= 2.64

10#5

26 c/0.3 L=5.6 L= 0.60

24

L=0.3

0.20 4# 5

L=

10#5

L=0.75

L=0.20

L=0.1

L=0.84

25#4

34

13#5

2.32

0.82

0.74

0.2

c/c/0.15

c/0.3

0.15L=2.53

L=1.35

L=1.14

L=1.96 4# 4 c/ 0.15 # 4 c/ 0.15 # 5 c/ 0.15 # 5 c/ 0.15 OBJECT: L=3.57

L=0.20

3#

22 3 c/ 0.25 L=4.07 5#

Comes

Screening

2 3 c/ from

0.25 System L=

3#

17 3

3.55

Anjeo

maximum

Concrete

0.15 0.25

c/metallic

channel

10L=4.1

mmwith

15holes

cm thick

of Concrete

0.60channel 15 cm thick

0.15

0.65

0.82

5.13 L = 0.1

13 L = 0.2

10#3

15

14

0.201.07

c/0.25 L= 1.47 L=

=0.55

=0.2

0.2

0.20 5#3 c/0.25 L=1.47

L = 1.07 L =0.2

5#3

11

10=1.12

=

0.200.2

0.1

c/0.25 L=2.07 1.20 SCALE: 1:20

DOMESTIC

L= 0.2

TREATMENT

anjeo

Platform

Thickness

cleaning

SCREENING SYSTEM

BYPASS CHAMBER

STUDIES, SANITARY

in=particular

10 cm for

10#3 c/0.25 L= 1.65

CUT 1 - 1

5# 3 c/ 0.25 L=3.24

PLANT AND/OR

5.10 Comes from Fat Trap # 5 c/ 0.15

REACTOR UASB

PROFILE -STEELS OUTER FACE

SCALE: 1:25

OF THE ABOVE FOR WASTEWATER TREATMENT

SEWER OXIDATION

DESIGNS, PLUVIAL,

L=0.13

L=0.14

L=0.35

L=

L=0.47

L=0.20

L=0.26

L=0.31

3#

21

20 3

0.29

Goes c/

to0.25 L=2.25

L=2.56

Canaleta Parshall

L=

the

Metal

height

L= 3

3#

5#

18

19 0.2

0.27

0.47

0.43

0.35

0.34

c/ 0.25 L=3.24

L=2.06

L=2.44 L=

Goes

0.15

0.46

0.31

0.30

0.3to Canaleta Parshall

0.15 10° height

11°

0.08

0.26

0.16

the

Screening

Comes from

of System

the water L=

=1.45

0.1 L=

=1.12

0.2

1.20

1.50 L = 0.2

0.20 5#3 c/0.25 L=1.47

L = 1.07 L = 2.81

5#3

7

9

2.500.2

c/0.25 L=3.01 CUT 2 - 2

L=0.14

0.13

ruleroffor

0.15

Concrete

Metal ruler

water

themeasuring

LAGOON OR COMBINATION

Parshall gutter in fiberglass

channel

for measuring

15 cm thick

5# 3 c/ 0.25 L=3.24

0.30 4.80 PVC

P = 5%

10" # 5 c/ 0.15 # 5 c/ 0.15 # 4 c/ 0.15 L=0.31

L=0.10

L=0.1

L=0.39

L=0.47 L= 0.32

L=0.11

L=0.1

L=0.45

L=0.41

L=0.06

0.31 0.31

0.10

0.40

0.50 0.18

of

Goes

GREASE

Fatsto the TrapTRAP

0.15 L=

10#3

12=1.44

0.2

c/0.25 L=4.08 L = 2.24

5#3

8 c/0.25 L=3.55 L = 0.1

0.201.11

0.2 5# 3 c/ 0.25 L=1.86

BOARD OF

5# 3 c/ 0.25 L=3.24

CONSTRUCTION

DATE: 1.65 4" PVC pipe Gas pipe

trusses

14"

platinum

and

anchorage

the bell. to

3" the

x 1#30.57

L=0.48

L=0.10

L=

1#3L=0.77

48

47 0.56

L=1.72 1#30.65

L=0.48

L=0.10

L=

1#3L=0.94

1#3L=0.85

46

45

44

43 0.73

0.64

0.10

0.74

L=1.89

L=1.80 L=0.48 1#30.79

L=0.48

L=0.10

1#3L=

L=

1#3L=0.99

42

41

40 0.78

0.83

L=1.94

1.03 L=

L=0.10

L=0.48

CUT

1#3

39

PVC

P L=1.98

4-4

=0.82

5%

12" Comes from Bypass Chamber

3 L =1.12

L=

37 0.20

SOLE L=0.45

L=0.94

L=0.20

L=0.48

2#3

29

28 L=0.85 SOLE

PVC

P = 5%

12" Comes from Bypass Chamber

0.20

IN 4" PIPE

1.15

170°

0.15

5#3

L=0.94

REINFORCEMENT

c/0.225 L=1.34

2#3 L=1.82

SCALE: INDICATED

0.92 0.38

0.67 Ø= 3"

Pipeline

1" for gas collection

1.15

Elbow of 90 in 10"

PVC # 4 c/ 0.15 # 5 c/ 0.15 # 4 c/ 0.15 L=0.48

L=

1#30.1

L=0.68 L= 0.10

L=0.10 L=0.48

L=0.10

L=

1#30.10

0.1

L=0.68 L=0.68

L=0.48

1#3 L=0.48

L=0.10

L=

1#30.10

0.1

L=0.68 L=0.10

L=0.48

of

L=

1#3

49

4 CUT

0.10

0.1

L=0.68

4-4 170°

4 L=0.1 L= 0.20 L=0.61

L=0.58

L=0.20

5#3

31

30 c/0.25 L=1.01 %

10

0.15

0.40

0.10

0.45

0.03

0.05

79° 1.00

0.15

0.80

0.85

SIDE

0.10

DATE:

5#

L=1.25

0.10

A

The

must

slot

between

grid

CONTAINS:

1-1 plan

View Detail No.1

3 c/ 0.25 L=2.03

5#3 c/0.25 L=2.03

cover

the

should

with

grid

is simplyand

made

be sealant

the

for

supportedthe

toconcrete

STRUCTURAL

SCALES: INDICATED

on

prevent

grid, this

thewater

concrete.

groove

circulate

is they

AND ELEVATION

UASB

No. 3-hydraulic

0.97

7.10

COURT 0.70

0.42 3" the

in sanitary

chamber

PVC=nipple,

20 cm length CERCHA

1.15 # 4 c/ 0.15

REACTOR UASB

PROFILE -STEELS INNER FACE

SCALE: 1:25 L= 0.44

L=0.10

58

59

1#3 L=1.6

L=0.64 L=0.48 1#3L=0.96

L=0.48

L=0.10

L=

56

55

57

2#30.75

0.76

0.53

0.54

0.10

L=1.69

L=0.74 12#3c/0.25

L=0.84

L=0.10

L=

1#3

L=0.48

CUT

54

50 0.10

L=1.91

5-5

Other

andL=2.28 L=

L=0.62

CUT

0.020.10

5 5-5

hole 50.02 36

SOLE 6#3 according to plane L=1.03

L=0.83

L=0.10

38 L=0.20

3.50 2

1

SOLE

"0.02

rod

recessed

Collection

material

welded

0.20

0.05

0.10

0.30

0.23

0.70 holein

to

removed

chamber

concrete

the grid and

solid Grid anchorage to concrete

UASB

IN 4" PIPE

5#3

L=3.78

0.53

0.76

CALCULATION

VIEW

AND

REINFORCEMENT

SCALE: 1:25

CONTAINS:

PLANT c/0.25 L=3.88

5#

L=0.20

3 c/ 0.25 L=3.88

OFDETAILS

1.70 4" PVC pipe Anchoring

View

CERCHA

Detailthe

No.1

bell to Trusses.

REACTOR UASB

Conduction

Material

gas

1.15 : Copper

pipe 3" # 5 c/ 0.15 # 5 c/ 0.15 # 4 c/ 0.15 L= 0.48

L=0.10

65

64

1#30.47

L=1.63

L=0.68 L=0.48 L=0.48

L=0.10

L=

63

62

61

68

67

2#3

1#30.35

0.36

0.45

0.46

0.10

0.53

0.54

0.1

L=1.61

L=1.69

L=0.56

L=0.66

L=0.74

0.15

12#3c/0.25

L=0.85

L=0.10

2#3

of

L=

L=0.48

20#3

51

60

66 CUT

0.10

0.15

0.60L=1.51

L=0.68

Other

4-4 and

L=1.05

3# 3 c/ 0.25

5# 3 c/

CUT 5-50.25 Collectionremoved

material chamber solid SCALE: 1:20 L=0.66

L=0.27

L=0.20

5#3

33

% c/0.25 L=1.33

10 L=

5#3

32 2.17

5.13 c/0.25 L=2.47

horizontal

CUT 2 - 2

0.8

maximum

Channel

of

with cmin

% 15rod

10

45° thick

10

particular

mm CUT 3 - 3 SCALE: 1:20

REACTORS

2

1

Length

welded

Vertical30

Anjeo metallic

SCALE: 1:20

the

toanchorage

Total

withto

cm.anchoring

ofholes

theand

anchors:

concrete

anchor

CANALETA PARSHALL

of recessed

fourtovertical

theand

theinconcrete

SCREENING STRUCTURE, GUTTER PARSHALL

four

concrete.

rod of

DREW:

PROJECT: 2 3.38

4.80 SUPPORT

GAS,

CONCRETE

1.05

2 EMBEDDED

FOR TUBAERÍA

IN THE 52

51

50

49

48

47

2.84

4.68

0.1

3.24

1.33

2.33

0.5

0.3

0.2 46

45

44

43

42

41

40

39

38

37

36

35

34

0.82

0.84

0.75

0.35

3.51

0.1

0.5

0.3

2.33

0.2

3.04

2.84

2.76

2.7

4.52

0.9 33

32

31

30

29

28

27

26

25

24

23

22

21

2.84

2.32

5

2.66

2.76

3.24

0.8

1.06

3.21

2.74

1.88

0.1

5.8

0.2 12

8

20

19

18

17

15

13

11

9

0.61

1.38

0.96

16

0.56

0.68

14

0.73

0.43

1.39

1.4

1.09

3.51

0.25

10

2.61

2.86

5.0

2.84

5

2.33

0.2

2.76

3.24 FIGURE

No

5

4

3

2

1.87

Ref.

7

6

0.2

3.51

2.62

5.00

1.88

1

5.75 L= 0.10

L=0.48

L=0.10 L= 0.10 L= 0.10

L=0.63

52

12#3

53

60.15L=0.83 0.60

0.15

6Screening Canaleta Parshall L= 0.31

L=0.20

L=0.10

L=0.45

0.31

0.30 2

1

Canaleta

Platform

anjeo

"Thickness

0.42

welded

cleaning

Parshall

in

to=particular

the

10 anjeo

cm for

FILTER

PROTECTIVE

View Detail No.2

No.3

0.3

TOTAL

0.3

STRUCTURAL CALCULATION

0.15

TILES

Comes from System

0.46

measure

Metal ruler

thefor

STEEL X 2UASB =

height of the water

PLAN No: BOARD

CONSTRUCTION

OF 4.00 It will 0.55

0.20

0.24 1.08

0.10

1.33

1.28

0.88 0.1

4.88

47

4.17

4.57

2.53

5/8"

0.8

0.2

1

1/2"

22 0.94

1.96

1.14

13

0.35

1.35

25

5

2

3/8"

3.71

0.1

0.8

2.53

5/8"

1

6

0.2

3.8

1/2"

22

0.58

.6

/2" 5.6

2.53

0.8

10

3.66

6

1

0.1

1.46

0.2

3.21

2.74

20

1/2"

32

1.98

5

5/8"

/8"

/2" 2.01

2.34

0.7

1.94

0.65

4

1.81

0.53

1.92

0.45

3

3/8"

2.94

0.25

4.01

32

5.47

1.0

5

0.8

1/2"

6

5/8"

2.53

102

.6

/8"

Bar weight

Quantity

Longitude

ISLAND

5/8"

2.12

(m)

(ONE)

2.86

3

2.13

0.2

4.01

5.48

6

32

0.25

1/2"

2

IRON TABLE PROJECT:

DREW:

8

70.15

8

11°

0.08

0.26

0.16

710° L=0.45

L=0.2

5#3

34

5# 3c/0.25

c/ 0.25L=2.63

L=2.63 L=0.17 L=0.99

L=0.31

0.10

0.31

0.15

0.50 0.44

0.38

6°

21°

fiberglass

SOLE

Comes

PVC

Parshall

P = 5%

0.05

0.10

0.40 12"

from

Gutter

Canaleta

in

sedimentador

PLAN No:

4.20 1.55

1

229.36

142.19

155.83

86.27

17.6

22

4624.36

9248.72 KG 0.556

1.55

1

83.6

132

22

17.6

86.3

204.6

190.96

4.12

39.49

22.97

33.75 1.55

1

5

7.3

16.05

54.8

63.36

192

93

86.8

39.215

60

36.6 0.556

1

1.55

60

39.215

93.0

86.8

4.47

5.20

4.31

4.02

3.20

4.90

128.32

271.31

297.6 TOTAL WEIGHT

(Medical

1.55

(Kg-m)

1

192

68.16

128.32

271.80

297.6

192.0

67.84 history) 0.18

GREASE

0.15

3 TRAP L=

2#3

35 0.20

L=0.85

GREASE TRAP 0.40 GREASE TRAP

1.09

1.00 2.11

support

Boquilleras

L= 0.2 27 #3

18

L= 3.76

c/0.3 L= 4.16 L= 0.2

PVCenmodules

alumnio de 3" x

1.05

0.20

2

1

Boquilleras

support

BOARD enmodules

CONSTRUCTION

PVCOF alumnio de 3" x 0.35

0.25

IN

2.05

DIFFUSER

0.10

0.20 2

1

" for 0.50 13#3

16

L= 1.88

0.2

c/0.3 L= 2.28 L= 0.2 L=1.36

5#3

6 c/0.25

Concrete channel

L=1.7615 cm thick L= 0.2 Comes from Canaleta

Parshall

0.18

0.15 Concrete channel 15 cm thick

LIME SHEET 18

CIINDRO

1.06

0.49

4.10

4.50 " for

1.00

1.20 1.85 1.00

PROFILE 1.00

0.80

1.20 4.50

4.10

3.50

3.30 1.05

0.50

PLANT SCALE: 1:1 17

L=5.80 L= 0.2

L=0.20

L=0.87 L= 0.2 PVC

P = 5%

0.55

0.50 12" Tee de PVC

12"

0.40

SCALE: 1:20

SCALE: 1:20

CUTTING OF SUBFLOOR PLATE

13#3 c/0.3 L=6.0

5# 3 c/ 0.25 L=1.76

0.21 CIRCULAR

ROUND

0.20

0.25 0.2x0.25

BEAM PVC Modules

Polystylene

0.53 caliber 40 Perimeter exit landfills

1.55

2.05

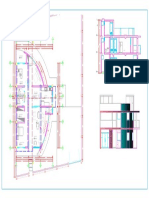

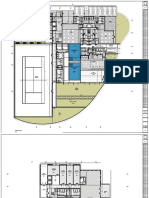

SEDIMENTADOR

0.20

SEDIMENTADOR

0.50 L= 0.2

0.20

0.75

1.60 Cumnetas in particular 0.15

0.245

0.40

0.50

L= 0.2

L=3.34

5#3

5

4 c/0.25 L=4.92 5# 3 c/ 0.25 L=3.76

L=3.24 L=3.36

L=

5#3

2 0.45

Concrete

thick L=3.76

c/0.25 plate of 15 cm PVC

% the

10

at

See detail

8"edgesNo. 2 0.70

L=3.36

5#3 c/0.25 L=3.76

0.60

3.20

3.00

3.40

Perimeter capture channel

Mesh linked with 1" angles

1.05

0.20 BOARD

CONSTRUCTION

0.75 OF

0.82

0.20 3

1.63

3 13#3

11

L= 5.80

c/0.3 L=6.0

7.56

L=0.20

L=0.31

2 5# 3c/

5#3

2 c/0.25

0.25L=4.81

L=3.24 L= 0.2

L=3.34

5#3

1

0.60

1

2 c/0.25 L=4.81 %

10

2 %

10

1

APPROVED:

sedimented

Effluent Chamber

OPERATION BOOTH

1.50

1.70

1.30

1.50

8"

BOARD

CONSTRUCTION

PVC pipeOF

0.20

0.20

1.50

0.20

L= 0.2 Cumnetas in particular 0.15 Cumnetas in particular 0.15

SCALE:

PLANT1:10 L= 0.2

1 3 L =1.02 1 Goes 10"

UASB

PVC

1.00

1.40

0.50 to REACTOR 0.20

0.10

AND

BOOTH

LABORATORY

OPERATOR

OBJECT:

23

L=1.97

L=0.30

56#3 c/0.25 L=4.79

18

L=2.07

L=0.20 L=0.20

L=2.14 9 #3 c/0.25 L= 3.8

4

9# 3 c/ 0.25

9 #3 c/0.25 L= 3.6

8

L=0.3

1.90 9 #3

1

L= 3.5

c/0.25 L= 3.8 13#3

11

L= 1.88

0.2

c/0.3 L= 2.28

OBJECT: 0.50

0.25

2.50

0.20

1.25 Channel 90 L= 0.2 L=1.36

5

3

L

6

11= 1.67

#30.2

c/0.25 L=3.75

L=1.76 L= 0.2 3 Parshall

OF

STUDIES,

DOMESTIC

TREATMENT

THE ABOVE

OF

STUDIES,

DOMESTIC

TREATMENT

PLANT

SANITARY

THE ABOVE

FOR AND/OR

PLANT

SANITARY

Comes from Canaleta

SCALE: 1:20

WASTEWATER

FOR AND/OR

DESIGNS,

SEWER OXIDATION

WASTEWATER

TREATMENT

PLUVIAL,

L=0.55

L=0.50

2# 4 L=1.25

L=1.95

56#3 c/0.25 L=2.65 3# 4L=1.45

L=1.01

3#4

21

L=0.15

L=0.10

L=0.20

L=0.94

22 L=1.45-Sound 12 #4 19 0.54

56#3

20

L=

L=0.30

L=0.15

L=0.26

L=0.14

c/0.25 L=1.25

L=2.64 9# 3c/0.25

2#3

12 c/ 0.25L= 3.0 2# 3 c/ 0.25 9#

2

9 #33c/0.25

c/ 0.25L= 3.0

DESIGNS,

SEWER OXIDATION

2#4

L=0.15

38#3L=1.29

L=0.20 L =1.68

L=0.1

=0.2 L #3

6

10= 1.65

c/0.25 L=2.05 L = 0.2 PVC

P

Tee

12"

= 5%

de12"

PVC SOLE

0.40

0.50

0.05 PVC

P

Tee

12"

= 5%

0.10

0.40de12"

PVC

and/0.1

TREATMENT

PLUVIAL,

GREASE TRAP

-Sound

L=0.758 #4

LAGOON OR COMBINATION

LAGOON OR COMBINATION

L=0.54 2# 4 L=1.25

L=0.49 2#4 L=1.45

22

L=0.20

L=0.96

L=0.15

3#4

21

L=1.01

L=0.10

L=1.29 -Sound 12

8 #4

#4 L= 0.54

L=0.15

L=0.26

20

L=0.14 9 #3 c/0.25 L= 3.6

7 2# 3 c/ 0.25

9# 2# 5 L=3.0 2# 5

3 L=3.9

c/ 0.25

SEDIMENTADOR

SCALE: 1:20

4.50

PROFILE PLANT 9 #3 c/0.25 L= 3.6

5

SCALE: 1:20 L =1.71

=0.2 1.70

0.20 %

10

BOARD

CONSTRUCTION

1.53 OF 0.86

0.70

1.50

0.80

56#3 c/0.25 L=1.25

SEDIMENTADOR

0.80

L=1.97

L=1.95

56#3

23 c/0.25 L=2.65 3# 4 L=1.45

L=0.30

L=0.20 56#3 c/0.25 L=2.64

19

L=0.30

L=2.14 L=0.20 9# 3c/0.25

2#3

11 c/ 0.25L= 3.0 2# 3 c/ 0.25 9# 3c/0.25

2#3

10 c/ 0.25L= 3.0 11

8

10

14

13

12

18

17

16

15

9 No

1

Ref.

5

4

3

2

7

6

6#3

L =1.71

9 PVC 8" 3.00 PVC 8"

0.30

1.86 Mesh

at

Seethe

0.80

1.56 detail

edges

linked

No.with

2 1" angles CUT 3 - 3

c/0.25 L=3.62

CONSTRUCTION

L=0.20

L=0.25

L=0.52

L=0.1 6# 3c/0.25

22#3

24

L=1.43

L=0.20

L=1.44

6#3

27 c/c/0.25

0.25L=2.35

L=1.89

25

56#3 c/0.25 L=4.79

L=2.07

L=0.20

26

L=0.30

18

L=0.25

L=0.20 L=0.3

Effluent Chamber

sedimented 9 #3 c/0.25 L= 3.8

3

L=2.00

L=0.3

15 L=0.3 6# 3 c/ 0.25 6##3

9

6 3 c/0.25

c/ 0.25L= 3.6 9 #3 c/0.25 L= 3.8

2 1.64

5.86

1.32

2.07

3.75

2.05

1.65

3.62

1.7

1.66

3.76

4.16

6

5.8

2.08

2.28

1.35

0.1

3/8"

1.55

2.42

2.02

1.68

1.67

1.71

0.2

TOTAL STEEL GREASE TRAP ISLAND

FIGURE

4.81

0.45

1.02

(m)

3/8"

1.46

3.36

1.07

3.34

0.51

1.36

0.2

2.04

3.76

4.92

1.76

Longitude TABLE

IRON L =0.2

L=0.1 0.25 0.20 %

10

BOARD

0.25 OF 0.80

0.10

6#3 c/0.25 L= 2.5

DATE:

L =1.70

Goes

PVC 10"

to REACTOR

0.20

Goes

PVC 10"

to REACTOR

DATE: 6#3 c/0.25 L=2.04

29

L=1.26

L=1.84

SCALE: INDICATED 6# 3 c/ 0.25

CUT 3-3 L=1.82

6#4

L=1.84

L=0.1

8#4 c/0.25 L=3.75

L=2.24 22#3 c/0.25 L=1.89

24

L=1.44

L=0.20

L=1.43 L=2.04

6#3

17

L=0.20

c/0.25 L= 3.06 L=0.20 L=2.02

L=2.00

13

L=0.20

6#3

14 c/0.25 L= 2.5

3.58 6# 3 c/ 0.25 SCALE: 1 : 20 339.79 KG 27

13

0.556

16

6

62.45

43.36

16.47

13.78

21.52

52.13

12.51

6.83

12.07

12.54

6.8 Bar

Quantity

(Medical

WEIGHT

0

(ONE)

(Kg-m)

0.556

6

5

13.67

4.89

10.45

13.37

.556

weight

history) L

6

7

8 =0.2

=

#3

UASB1.66

0.2

1.64

c/0.25 L=3.76

L=2.04

P

PVC

= 5%

12"

L = 0.2 UASB

1.76

2.11

CONTAINS:

L=0.1

37

36

38

1.1

2

3.5

CONTAINS: 6#3 c/0.25 L=2.89

L=1.43

L=0.20

31

30

29

28

27

26

25

24

23

35

34

33

32

1.95

1.82

0.3

1.44

3.1

1.84

0.1

1.26

1.43

0.2

3.85

3.25

3.95

4.65

5.36 22

21

20

19

18

17

15

13

11

12

16

2.02

1.26

14

10

3

2.0

1.84

1.97

2.07

2.04

0.3

0.10

1.01

0.14

0.15

0.54

0.26

2.14

0.94

0.2 FIGURE

No

1

Ref.

8

7

6

5

4

2

9

3

3.6

3.8

.8 L=0.52 L=1.26

L=1.84

6#3

16

L=0.20

c/0.25 L=2.24 8#3 L= 3.1

30

L=0.3

4#3 L= 3.25

4 #3 L=4.65

32

L=0.3

L=4.35 8 #3 L= 3.1

30

L=2.9 L =1.32

16

12 #3 c/0.25 L=5.86 L =2.07 L =0.20 Tee de PVC

12"

GREASE

HIGH-RATE

STRUCTURAL

TOTAL STEEL X 2 SETTLERS =

OPERATION

STRUCTURAL

TRAP

SETTLERS

BOOTH

CALCULATION

0.556

3/8"

1

2

3.5

.1

1.0

0.556

1/2"

3/8"

0.5

56

2.65

3.75

1.63

2.24

0.25

22

1.89

3

8

0.1

2.04

0.2

6

2.89

0.72

2

3.85

3.25

3.95

4.65

4

5.36

.35

.1

1.00

0.556

0.556

3.0

3.58

2

2.5

3

2.24

0.55

0.72

6

12

1.45

0.2

1.25

0.3

0.30

2.64

56

4.79

1/2"

3/8"

0.15

8

1.29

.0

/8"

.06

0

Bar

0.556

.556

(Kg-m)

weight

Quantity

Longitude

ISLAND

(m)

(ONE)

2

3.0

9

3.6

3.8

3/8"

IRON TABLE 4#3

31

4

33

L=0.3

#3L=

L=5.36

3.95 34 L=2

36

38

2#3

37

L=2.95

L=3.20

L=0.1

L=1.0

L=1.8

L=0.3

L= 1.1

3.5 4 #3L=

31

4#3

33

2#3

35

L=5.06

L=3.65

L=3.55

L=0.3L=4.85

3.95

5.36 L=0.3

- DETAILS

CALCULATION

L =0.10 L =2.07

2.11 L =0.20

PVC 8"

Fat

5%

0.24

1.00

0.20 HOOK

1.00

0.20

0.10 1.20

P

PVC

= 5%

R0.05 12"

SCALE: 1:20

CUTTrap

1-1

0.02 HOLE AND

PROJECT: 1.223

2.224

3.89

731.69

1463.4

DREW: KG 4.28

7.23

8.78

10.34

11.92

13.788

6.80

9.64

7.84

18.9

13.44

23.12

82.51 10.32

17.4

38.92

82.20

149.14

10.21

7.47

8.34

11.94

3.336 TOTAL WEIGHT

(Medical

3.336

18.01

19.01 history)

8#3 L= 3.1

30 32#3 L= 3.25

4

34

L=4.35

L=2.95 4.65 8 #3 L= 3.1

30

SEDIMENTADOR

DREW:

PROJECT: L =0.10

16#3

15=1.35

c/0.25 L=1.55

CUTTrap

Fat

1.40 1-1 0.25 1.81

0.20

3 1.50

0.20

PLAN No: PLAN No: L = 0.2 L =2.02

16

13

14 #3 c/0.25 L=2.42 L =0.20 PVC 10"

Goes

UASB to REACTOR

L=0.2

L=0.2 10#3 c/0.20 L=5.59

35

L=2.44

L=2.46

2.5X2.5

L=0.2

L=0.2 0.15 1.50 3.00

2 0.15

THE

EXTENSION OF

STRUCTURE

3.00

3.60

L=1.9

2.46

40 10#3 c/0.20 L=2.86

37

1.50

1.90

0.20 c/0.2 L=2.86

L=0.3

L=2.46

L=1.25

10#3

38 1.90

0.75

4.50

2.00 %

10 2"

every

10leachate

5% 10 cmdrainage

and 10%pipe

slope

with perforations 6" elbow

1.15 6" elbow 0.75 0.65

12

0.60 0.15 1 0.15

0.60 2.10 0.60

0.75

0.20

1.05

10#3 c/0.2 L=2.86

DISTRIBUTION

PIPES OF 4" EACH

Trampa

Comes from

of Fat

SYSTEM CAUDAL

L=0.3

L=0.2

L=0.51 L=2.44

L=2.46

10#3

39 c/0.2 L=2.86 0.20 c/0.2 L=4.72

0.95

L=0.2

10#3

L=1.17

36 8" GATE

VALVE

0.75

3

0.50

0.15 1.00

0.15 6" feed pipe 1.83

0.20 PVC

P = 5%

10" 1.15

Tee 10 x 10 en PVC

L=0.3

L=1.88

L=0.1 L=1.93

41

L=1.94

22#3

42

1.80 c/0.20 L=3.44

L=4.01 0.20

0.95

1.05

4L=0.2

VALVE

8" GATE

1.05

2.10

2.50

43 6" GATE

VALVE

1.80 SCALE:

STEEL -

2.00 PLANT %

10 %

10 1.00 6" gate

Tee of 6valve

x6 EFFLUENT

5% SLOPE CHANNEL WITH "

10

0.51 EFFLUENT

5% SLOPE CHANNEL WITH

1.85 2 EFFLUENT

SLOPE OF 5%

CHANNEL WITH "

10

1.85 EFFLUENT

SLOPE OF 5%

CHANNEL WITH 1.15

2

VALVE 10" GATE

VALVE 10" GATE

22#3 c/0.20 L=2.86

L=2.66

45 L=0.3 1.50

0.20

CUT 3-3

4 -4 0.75

1.70 8.75

0.15 Sludge

Sediemntadores

Tee of 6from

x 6 the

DRYING BEDS 7.10 Ø 3"

0.20 Trusses in metal structure 1.35 1.35 Ø 3" 1.15 SCALE:

7.10 1:20

DETAIL OF EFFLUENT JUNCTION CHAMBER SEDIMENTED

1.30

SLUDGE PURGE PIPE

UASB-SON 2 REACTOR

L=0.51

L=0.3

L=0.1 L=0.2c/0.20 L=2.94

L=1.93

L=1.94

43

22#3

44 L=3.44 L=0.2 0.15

2.00

1 %

10 %

10 6" elbow

0.70 1 3.58 Ø 6" Ø 6" 0.45 0.65

2.35 0.45 1.15

VALVE 6" GATE

TEE

VALVE

Ø 6" de 6"

6 xGATE

6 en PVC

VALVE 6" GATE

OBJECT: 45

2.66 34

33

32

44

37

36

39

38

41

40

43

42

35

1.25

1.9

1.05

1.93

0.3

1.94

2.13

1.88

2.86

0.2

1.47

2.44

0.81

0.1 31

30

29

28

27

26

25

24

23

22

21

20

19

3.47

1.25

3.77

2.0

2.25

2.22

6.00

1.05

0.10

1.61

1.62

1.1

0.9

0.3

0.2 80

7

18

17

15

13

11

1

9

16

14

3.06

1.2

2.12

1.72

6.00

3.26

1.63

0.1

0.9

0.2

0.3

2

ISLAND

IRON

FIGURE

No

1

Ref.

6

5

4

3

2

4.95

1.05

4.00

3.5

2.5

3.75

2.00

1.53

0.95

1.36 0.79 OBJECT: 1.70 1.05

OF

STUDIES,

DOMESTIC

TREATMENT

THE ABOVE

6" gate valve

OF

STUDIES,

PLANT

SANITARY

2.00 TABLE

TREATMENT

0.46

0.46

0.20

THE ABOVE

FOR AND/OR

TOTAL STEEL DRYING BEDS =

PLANT

SANITARY

WASTEWATER

FOR AND/OR

DESIGNS,

SEWER OXIDATION

WASTEWATER

TREATMENT

PLUVIAL,

0.556 5.59

0.556

1.55

13

2.94

3.44

4.01

22

2.86

4.72

10

3/8" 1.55

4.72

3.77

3.25

2.32

6.0

3/8"

1.15

13

5.43

0.556

34 3/8"

6

3

4

3.46

34

0.556

1.4

.84

.32

.0

.66

0.15

Bar

Quantity

Longitude

(m)

(ONE)

(Kg-m)

3/8"

0

6

3

5

4

0.556

.556

.75

.53

.37weight %

10 10

5% 0.40

1.19 Sludge

Reactors

6" elbow

from UASB

DESIGNS,

SEWER OXIDATION

TREATMENT

DOMESTIC SLOPE OF 5% CAMERA OF

COLLECTION

EFFLUENT

0.46 CHANNEL

OF WITH Tiles

protection

EFFLUENT

SLOPE

FEED

=

SEDIMENTATOR

8" ofPIPE

OF 5%

OF

CHANNEL WITH See flat cut No. 4 1 SLOPE OFOF

CAMERA

COLLECTION

EFFLUENT

0.46

0.15

0.50 5%

CHANNEL

OF WITH Tiles

protection

SLOPE

FEED

=

SEDIMENTATOR

8" ofPIPE

0.15 OF 5%

OF EFFLUENT CHANNEL WITH

0.45

0.20

0.40

(Medical history)

TOTAL WEIGHT

PLUVIAL,

1.40

0.80

0.15

0.50

1.40

0.15

1.40

0.80

1.40

LAGOON OR COMBINATION

LAGOON OR COMBINATION

0.05

BOARD

It comes OF

Sedimenter

34.98

948.62 from

KGreactor

LechosUASB

de L=1.05

35.96

42.07

49.05

15.90

26.24

31.08

11.20 21 0.1

L=

L=0.2

11.20

34.116

27.25

23.49

16.78

43.36

8.31

102.64

26.46 L= 1.23

65.407

26.46

8.139

7.38

8.54

13.34

11.94 L= 3.06

4#3

6

7.85

8.34

13.344

2.00

0.3

c/0.25 L=5.37 Leachate

see

CONCRETE

0.6 xdetail

0.1 moutput

no. 1PLATE 0.6 x 0.60

2 24# 5 c/ 0.15 24# 4 c/ 0.15

9

L=0.25 L=2.46

L= 0.25 L =0.40

L=

32

10 #4

3.51

c/0.15 L= 4.01 L==1.00

L 0.25

CONSTRUCTION

13# 3 c/ 0.25

13#3

L=0.75

13# 3c/0.25

c/ 0.25L=1.15

1.50

every 10

Longutid

Slope

SOLE

0.15 = 10

cm

= 8.9

% m

%

6"

Elbow

10feedinpipe

0.40

0.18

0.50 6" PVC L=2.0c/0.25 L=1.55

24

13#3

L=0.3

L=1.05

27 L=3.25 4#30.3

5

L=

L=0.2

c/0.25 L=3.53 L= 0.65

2.0

0.3 L= 0.3

1.06 4# 3 c/ 0.25 4# 3 c/ 0.25 4.80 L=1.96

32 #5 c/0.15 L= 5.47 5# 3 c/ 0.25 L=1.76 5# 3 c/ 0.25 L=1.76 L=0.1 L==1.87

L

1 0.25

13# 3 c/ 0.25

34# 3 c/ 0.25

34# 3 c/ 0.25

32#4 c/0.15 L=2.12

2" leachate drain pipe with perforations

3.30 Splash

placed

plate

material:

0.15 dimensions

under

plate,

steeleach

for

or erotion

coldroll

0.5

pipe

x 0.5

of

control

sheet

feeding.

x 0.1 of

m the sand. A plate is 13# 3c/0.25

29

13#3

L=0.3

L=1.05

28 c/ 0.25L=1.55 13# 3 c/ 0.25

L=0.2 L= 0.2

0.3 11 3.26

L=

4#3

12 c/0.25 L=3.66 4#30.2

1

L= 4.00

c/0.25 L=6.0 4# 3 c/ 0.25 4# 3 c/ 0.25 32# 4 c/ 0.15 L==0.65

L

7 5.10 5# 3 c/ 0.25 L=1.76 5#3 c/ 0.25 L=4.81 L2#5

3 =5.00

c/0.15 L= 6 L=0.65

DATE:

L=0.3

SCALE:

PROFILE

32 #4 c/0.15 L=61:20

SCALE: INDICATED

1.50

0.15

0.95

0.97

%

10

0.60

L=0.3

13# 3c/0.25

13#3

L=3.17

25 c/ 0.25L=3.77 L= 6.0

22 L= 0.2

4

4#3

10

L= 3.15

6.0

c/0.25 L=6.0

L=3.75 4#30.2

7

L= 0.3

6.00

c/0.25 L=6.0 34# 3 c/ 0.25 34# 3 c/ 0.25 SCALE: 1 : 20

DATE:

7.10 6.50

REACTOR UASB -STEELS OUTER FACE

4# 3 c/ 0.25

2#3 c/0.25 L=3.71

37a

L=3.51

STEEL

STEEL

STEEL

13#3 c/0.25 L=6.0

DRYING

SCALE:PROFILE

1:20BEDS

DRYING 1:20

SCALE:PLANT

1:20

SCALE:PLANT

-CUT 2-2

BEDS

L= 0.3

34#3

17 0.9c/0.25 L=1.4

CONTAINS: BOARD

CONSTRUCTION

COBBLESTONE

HOLES

20

THICKNESS

L=0.2

L= cm

CM

0.1 SAND

ENGRAVER

OF LAYER

CUT 1 - 1 WITH

COVER 13# 3c/0.25

L=0.3

31

13#3

L=1.05

30 c/ 0.25L=1.55

DRYING BEDS 13# 3 c/ 0.25

L=0.2

L= 0.3

L= 0.2 L= 3.26

13

4#3

14 c/0.25 L=3.66 L= 0.2 4# 3 c/ 0.25 4# 3 c/ 0.25 CONTAINS: 24# 5 c/ 0.15 5# 3 c/ 0.25 L=1.76 L=0.1

REACTOR UASB

L=

3

2 2#4

5.10

c/0.15 L= 6

DRYING

EFFLUENT

SEDIMENTED

BEDS AND

JUNCTION

STRUCTURAL CALCULATION

L= 1.62

34#3

20 0.9c/0.25 L=5.43 L= 1.63

34#3

18

L=0.2c/0.25 L=3.46 13# 3c/0.25

13#3

L=0.3

L=1.05

32 c/ 0.25L=1.55 L=0.2 L= 0.2 L= 3.26

4#3

15 c/0.25 L=3.66 2 0.2

L= 4.65 34# 3 c/ 0.25 4# 3 c/ 0.25 34# 3 c/ 0.25

STRUCTURAL CALCULATION

UASB 24# 5 c/ 0.15 24# 4 c/ 0.15

3

L=1.88

L2=#5

L=

3

8

6 0.65

5.00

c/0.15 L= 6.00 5#3 c/ 0.25 L=4.81 L=0.65

CHAMBER

4#3 c/0.25 L=6.0

2 #4 c/0.15 L= 2.13

PROJECT:

L= 1.61

DREW:

0.15 L= 1.63

0.97

1.12 13# 3c/0.25

L=3.47

26

13#3

L=0.3

L=1.05

33 c/ 0.25L=1.55

L=4.72

23

3 0.3

13#

L=

L=0.2

3 c/ 0.25

4

4#3

9 0.2

L= 3.50

1.82

0.3 L= 3.26

4#3

16 c/0.25 L=3.66

L=

8 0.2

L= 0.3 4# 3 c/ 0.25 34#33c/c/0.25

4# 0.25 DREW:

PROJECT: 4# 5 c/ 0.15 24#44c/c/0.15

4# 0.15 L=0.25

L=6.0

#3 c/0.25 L=3.32

4#31.42

c/0.25 L=3.84

L=0.96

L=0.25 5#3 c/ 0.25 L=4.81 5#3 c/ 0.25 L=4.81

12

L= 0.30 L=1.97

4

32 #5 c/0.15 L= 5.48

PLANO No: 34#3

19

L= 0.3c/0.25 L=1.4

0.9 L= 0.9

L=0.2

0.1 13# 3c/0.25

13#3

L=0.3

L=1.05

34 c/ 0.25L=1.55 13#3

L=

L=0.2

L=0.1

1.92

c/0.25 L=2.32 L= 2.20

L=0.9 L=0.3

L= 0.3

2.12 L= 1.05 34# 3 c/ 0.25 4# 3 c/ 0.25 PLAN No: L=1.00

L=0.51

L=0.10

16 4#3 c/0.25 L=2.34 L=0.50

L=0.56

L=0.48

L=0.20

L=1.38

4#3

14

15 c/0.25 L=1.94 L =0.43

L=0.20

L=0.45

13 L=0.40

L=0.45

L=0.25

L #3

L=1.40

L=1.39

L=0.53

11

3 =2.46

c/0.25 L=1.92

L= 2.94 L=0.79

4#3 c/0.25 L=2.01

4#3 c/0.25 L=1.81

L=1.40 L=0.25 L=3.51

L=0.73 32 #4 c/0.15 L= 4.01 5

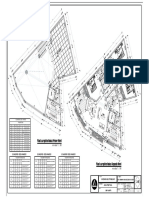

RA

IL

TR

CK A

RA

IL

TR

CK A

BD

119

1639.12

EA

RT

HE

N

TR

AC

K

15

'

NU

LL

AH EA

RTH

EN

TR

A CK

15

'

EA

RT

HE

N

TR

AC

K

15

'

NU

1271.8666

LL

AH

3277.8913

N1

212

1640.38

IL

213

1636.82

2046.0381

1345.1197

NU

LL

AH

EA

RT

HE

N

TR

AC

K

15

'

3297.4971

NU

LL

3297.50

AH

1785.1928

You might also like

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- Blow Up 1 Blow Up 2: Drawing WorkingDocument1 pageBlow Up 1 Blow Up 2: Drawing WorkingLilisNo ratings yet

- Area Construida: Vivienda - Tingo MariaDocument1 pageArea Construida: Vivienda - Tingo MariaMarco EstradaNo ratings yet

- Legend:: A. P. Garcia & AssociatesDocument1 pageLegend:: A. P. Garcia & AssociatesDominic Robiso DatuinNo ratings yet

- Asesoria Jueves - Estadio 1Document1 pageAsesoria Jueves - Estadio 1Carlos MejicanosNo ratings yet

- Plan 3 BuildingDocument1 pagePlan 3 BuildingcimpstazNo ratings yet

- La MZ 2 M0 PDocument1 pageLa MZ 2 M0 Pjose vargas avilaNo ratings yet

- Product analysis reportDocument1 pageProduct analysis reportKevin Padilla LopezNo ratings yet

- Distancia Entre Correas de Madera: Modulo AdministrativoDocument1 pageDistancia Entre Correas de Madera: Modulo AdministrativoGabriel Condorcahua PalaciosNo ratings yet

- La 6Document1 pageLa 6YASMIN ENERONo ratings yet

- ELECTRICAS 4A Model (1)Document2 pagesELECTRICAS 4A Model (1)zenaidaNo ratings yet

- PROJETO EXECUTIVO (Iluminação) - Layout1Document1 pagePROJETO EXECUTIVO (Iluminação) - Layout1work.rafaelafddNo ratings yet

- PROJETO EXECUTIVO (Iluminação)Document1 pagePROJETO EXECUTIVO (Iluminação)work.rafaelafddNo ratings yet

- Proposed 4-Storey Apartment: Schedule of Doors & WindowDocument1 pageProposed 4-Storey Apartment: Schedule of Doors & WindowArch. John Bernard AbadNo ratings yet

- Planta General GrifoDocument1 pagePlanta General GrifoKaterine Brigitte Pascal EchevarriaNo ratings yet

- ARQ-02Document1 pageARQ-02MOISES AARONNo ratings yet

- L/4 L/4 Support Support Mid-Span: RC SlabDocument1 pageL/4 L/4 Support Support Mid-Span: RC SlabLarizza TesicoNo ratings yet

- Distribucion A 02Document1 pageDistribucion A 02Luis Hernan lupaca quispeNo ratings yet

- TQ Cisterna y TQ Elevado EstructurasDocument1 pageTQ Cisterna y TQ Elevado EstructurasjhonelNo ratings yet

- Estacionamientos (Terminal Terrestre) - LÁMINASDocument3 pagesEstacionamientos (Terminal Terrestre) - LÁMINASEDGAR PAUL IDROVO HEREDIANo ratings yet

- Deptos Axonometrica SinDocument1 pageDeptos Axonometrica SinCarlos AlfonzoNo ratings yet

- Urb - La Solucion I - Proyecto Final 19092022 Categorizado MODIFICADO - 1 - 8054 - 80fdb21a - P1-ModelDocument1 pageUrb - La Solucion I - Proyecto Final 19092022 Categorizado MODIFICADO - 1 - 8054 - 80fdb21a - P1-ModelJoaquin Galvis CabreraNo ratings yet

- AA-N° 14 L 8.40m: Municipalidad Provincial de ChotaDocument1 pageAA-N° 14 L 8.40m: Municipalidad Provincial de ChotaMalcolm Herrera CayatopaNo ratings yet

- Panel EntregaDocument1 pagePanel EntregaHortencia Gabriela Martinez BarrosoNo ratings yet

- Plantas Corte AmbientacionDocument1 pagePlantas Corte AmbientacionJhampool NeiraNo ratings yet

- Piso 2Document1 pagePiso 2Rosario BouzoNo ratings yet

- Station Design Blueprint DimensionsDocument3 pagesStation Design Blueprint DimensionsFethi Mouaki BenaniNo ratings yet

- SOLDERMASKDocument1 pageSOLDERMASKahmadmuksinNo ratings yet

- LepacAdutoraEEEMachadodeMeloTrecho1 20230925141400.875 XDocument1 pageLepacAdutoraEEEMachadodeMeloTrecho1 20230925141400.875 XEdie EdNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterEdwin Martinez GalvanNo ratings yet

- Luka Sucuraj - Hvar - Graficki Prikazi ElektroradovaDocument21 pagesLuka Sucuraj - Hvar - Graficki Prikazi Elektroradovak08ivanNo ratings yet

- DISEDocument1 pageDISEcarlos vistinNo ratings yet

- Truss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionDocument1 pageTruss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionChrysler DuasoNo ratings yet

- Chart 1 Load, Vacuum and Dry Bulb TemperatureDocument1 pageChart 1 Load, Vacuum and Dry Bulb TemperaturesoumitrabanNo ratings yet

- ARQUITECTURADocument1 pageARQUITECTURACarlos Moran GarciaNo ratings yet

- Baños Central-Arq A1Document1 pageBaños Central-Arq A1Mascco Castro JainorNo ratings yet

- Projeto CompletoDocument12 pagesProjeto Completoeng.williamgabrielNo ratings yet

- Psychrometric Chart Psychrometric Chart: Normal Temperature I-P Units Sea Level Normal Temperature I-P Units Sea LevelDocument1 pagePsychrometric Chart Psychrometric Chart: Normal Temperature I-P Units Sea Level Normal Temperature I-P Units Sea LeveldanielaNo ratings yet

- GF For Rcc-ModelDocument1 pageGF For Rcc-Modelharshad bahikarNo ratings yet

- Arq - 2Document1 pageArq - 2Liliana Acuña GilNo ratings yet

- Plano Casa 5x8 2p 2dDocument1 pagePlano Casa 5x8 2p 2dJosé Antonio Alarcón LeónNo ratings yet

- Sección A - A: Tanque Desarenador No. 1Document1 pageSección A - A: Tanque Desarenador No. 1Tuart CotzojayNo ratings yet

- How to optimize your website for search enginesDocument1 pageHow to optimize your website for search enginescharland IbrahimNo ratings yet

- Cuadro de Carpintería - PuertasDocument1 pageCuadro de Carpintería - PuertasJORGE ALEJANDRO SUAREZ CAMPOSNo ratings yet

- Pachacamac Smart Luxury-V2Document12 pagesPachacamac Smart Luxury-V2prixma gamingNo ratings yet

- Monthly sales report by product categoryDocument1 pageMonthly sales report by product categoryCt MajoNo ratings yet

- Detalles de Zapatas: CimentaciónDocument1 pageDetalles de Zapatas: CimentaciónMiguel AngelNo ratings yet

- 3dratio Without PelatDocument1 page3dratio Without PelatCempaka AnjaniNo ratings yet

- Plantas IngenieriaDocument1 pagePlantas IngenieriaLisandroMartinezOveidNo ratings yet

- How to optimize your website for search enginesDocument1 pageHow to optimize your website for search enginescharland IbrahimNo ratings yet

- 02 Arquitectura - LayoutDocument1 page02 Arquitectura - LayoutErick AvalosNo ratings yet

- Manzana ÑDocument1 pageManzana Ñvaleriano juvenal quispe pumaNo ratings yet

- Topographic Survey Plan: Rehabilitation and Expansion of Puntales Feeder Port CW-02 31-59Document1 pageTopographic Survey Plan: Rehabilitation and Expansion of Puntales Feeder Port CW-02 31-59alezandro del rossiNo ratings yet

- Lamina: Universidad Andina Nestor Caceres Velasquez UancvDocument1 pageLamina: Universidad Andina Nestor Caceres Velasquez UancvEdgarRaulMamaniSuañaNo ratings yet

- Ah Villa Victoria Ah Bellavista: Sistema de Alcantarillado Sanitario Ah Bellavista: Av. AgrariaDocument1 pageAh Villa Victoria Ah Bellavista: Sistema de Alcantarillado Sanitario Ah Bellavista: Av. AgrariaMel RiszeNo ratings yet

- Pl-Herbert Yu-P-2 PDFDocument1 pagePl-Herbert Yu-P-2 PDFSoy DesignoNo ratings yet

- Tribuna: Plano de Corte B-B ESC.1/500Document1 pageTribuna: Plano de Corte B-B ESC.1/500Avimael SucasacaNo ratings yet

- LED lighting component specificationsDocument1 pageLED lighting component specificationsGrover ChambiNo ratings yet

- C'T PL AN: Borehole Location PlanDocument1 pageC'T PL AN: Borehole Location Planalezandro del rossiNo ratings yet

- 1Document1 page1Sanal SamsonNo ratings yet

- Field Visit Programme - 13 February 2014Document1 pageField Visit Programme - 13 February 2014Aqeel SaleemNo ratings yet

- Fist Draft-Success Story of HEIS ProjectDocument4 pagesFist Draft-Success Story of HEIS ProjectAqeel SaleemNo ratings yet

- Economic Analysis Report for HEIS Crop ProjectDocument4 pagesEconomic Analysis Report for HEIS Crop ProjectAqeel SaleemNo ratings yet

- 2739, Upthane BrochureDocument2 pages2739, Upthane BrochureAqeel SaleemNo ratings yet

- B-Protech John CraneDocument6 pagesB-Protech John CranePatricia J ÁngelesNo ratings yet

- Machine Design REE 302: Tutorial 3 (Ch.2: Materials II)Document19 pagesMachine Design REE 302: Tutorial 3 (Ch.2: Materials II)Dull PersonNo ratings yet

- Project Report On Continuous Contact EquipmentDocument16 pagesProject Report On Continuous Contact EquipmentSavan LadaniNo ratings yet

- CBN/Diamond Coated Carbide Insert GuideDocument10 pagesCBN/Diamond Coated Carbide Insert GuideChellamuthu MechNo ratings yet

- TA326Document3 pagesTA326halimitbNo ratings yet

- Sika Aktivator PRODocument2 pagesSika Aktivator PROVictor GladunNo ratings yet

- Ultrafiltration Explained: A Guide to Membrane Filtration Processes and Their ApplicationsDocument5 pagesUltrafiltration Explained: A Guide to Membrane Filtration Processes and Their Applicationsan_iboreg8720No ratings yet

- Effectively Control Column PressureDocument12 pagesEffectively Control Column PressurefedecvazquezNo ratings yet

- Waste Report Moldova Final 30 01Document22 pagesWaste Report Moldova Final 30 01EaP CSFNo ratings yet

- Investigation of Seismic Behavior of Steel Coupling Beams in Hybrid Coupled StructuresDocument9 pagesInvestigation of Seismic Behavior of Steel Coupling Beams in Hybrid Coupled StructuresSinem Kocabaş ŞirikçiNo ratings yet

- b676 Boysen Quick Drying Enamel OrangeDocument10 pagesb676 Boysen Quick Drying Enamel OrangeMike Advincula100% (1)

- Cement Manufacturing ProcessDocument2 pagesCement Manufacturing ProcessTeja Mandapati100% (2)

- June 2017 1C Que IGCSE Edexcel ChemistryDocument36 pagesJune 2017 1C Que IGCSE Edexcel ChemistryMichael EllisNo ratings yet

- Neo-Dyn Series 130PDocument2 pagesNeo-Dyn Series 130PDaniel ReyNo ratings yet

- Biermann's Handbook of Pulp and Paper - Cap 07Document18 pagesBiermann's Handbook of Pulp and Paper - Cap 07chau_riberNo ratings yet

- ASNT Level III Study Guide-Magnetic Particle Testing Method (MT) - Second EditionDocument122 pagesASNT Level III Study Guide-Magnetic Particle Testing Method (MT) - Second EditionMOHAMMAD RAMZANNo ratings yet

- Ibtm5660 2223-08Document84 pagesIbtm5660 2223-08Yuki ChanNo ratings yet

- Klasifikasi Tanah - USCS & AASHTODocument11 pagesKlasifikasi Tanah - USCS & AASHTOQyuQyu ConvectionNo ratings yet

- 1.direct Strength Method Approch For Cold Formed Steel Sections With and Without Perforation For Compression Member JRNLDocument5 pages1.direct Strength Method Approch For Cold Formed Steel Sections With and Without Perforation For Compression Member JRNLK RaghuNo ratings yet

- Taylor Southon NI&M-B 2007 PDFDocument6 pagesTaylor Southon NI&M-B 2007 PDFSean Pitman, MDNo ratings yet

- Owner's Manual: Powered byDocument20 pagesOwner's Manual: Powered byKeny Anchante100% (1)

- Biogas - Instructables Methane For BiogasDocument19 pagesBiogas - Instructables Methane For Biogaslouis adonis silvestreNo ratings yet

- Chem 121-1Document45 pagesChem 121-1Zechariah NggitaNo ratings yet

- Thermal analysis of inoculation effects on ductile iron solidificationDocument13 pagesThermal analysis of inoculation effects on ductile iron solidificationXantos YulianNo ratings yet

- Saudi Aramco Inspection Checklist: Plumb Drainage System Lay-Out SAIC-S-4040 30-Apr-13Document13 pagesSaudi Aramco Inspection Checklist: Plumb Drainage System Lay-Out SAIC-S-4040 30-Apr-13khurram ijazNo ratings yet

- Conbextra GP 1011Document4 pagesConbextra GP 1011Srinivasan ReddyNo ratings yet

- Astm A255Document26 pagesAstm A255Yherson Cerin Chavarria100% (1)

- Paints & CoatsDocument29 pagesPaints & CoatsMaitreyi YellapragadaNo ratings yet

- Butt 2000Document100 pagesButt 2000kasra7No ratings yet

- WCP, SPDocument2 pagesWCP, SPAnil Kumar Sabu100% (1)