Professional Documents

Culture Documents

2022 Deep Foundation GI in SF

Uploaded by

JUanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2022 Deep Foundation GI in SF

Uploaded by

JUanCopyright:

Available Formats

FEATURE ARTICLE

2011 Transit Center construction,

near Millennium Tower (left rear)

Soil Mixing Evolution in San Francisco

“San Francisco is 49 square miles Seiko. This pioneering company was methods. Typically, groundwater is

surrounded by reality.” So said Paul based in the East Bay and some of its within 15 to 20 ft (5 to 6 m) of grade,

Kantner of the local ’60s icons, Jefferson early employees still work at the eight requiring cutoff walls for deep excava-

Airplane, and his words have still held soil mixing contractors now operating in tions. The Old Bay Clay unit, present at

true. The rate, scale and complexity of the area. approximately 100 ft (30 m) below the

recent construction in this city has Second, subsurface conditions here downtown Transbay district, is an

been remarkable, even compared to the are well suited to soil mixing methods. effective groundwater control layer, and

Gold Rush or reconstruction after the The stratigraphy at city sites typically cutoff walls are frequently keyed into

1906 earthquake. This article will comprises urban fill, dune sand, young this strata, or at least constructed with a

address developments in soil mixing in marine or marsh soils, Colma sand, and deep toe within the Colma unit.

San Francisco since 2011, and how the Old Bay Clay. The fill and dune sand are Third, the active seismicity of this

marked settlement of a downtown high predominantly granular, forming well- region generates geotechnical chal-

rise has influenced this booming blended soil cement. Although the lenges such as static settlement and

construction market. young marine and marsh soils are liquefaction. Soil mixing offers efficient

mainly cohesive, their low strength and cost-effective solutions for these

Local Soil Mixing allows for effective mixing, creating a situations. Finally, market demand has

Deep soil mixing has gained prominence reasonably consistent product. The enabled contractors and consultants to

in San Francisco for four reasons. First is stronger Colma formation, while rapidly evolve their expertise, as each

the regional concentration of expertise. predominantly dense well-graded sand, successful project sets a new bar for

Japanese deep mixing technology was contains some silt and clay, which is complex support of excavation in tight,

introduced to the U.S. in 1987 by S.M.W. mixable using shaft and end mixing constrained urban sites. Although in

AUTHOR Rob Jameson, Malcolm Drilling Company

DEEP FOUNDATIONS • JAN/FEB 2022 • 71

2012, 50 ft (15 m) was considered deep,

San Francisco’s Mission Bay, downtown in 2006

by 2020, multiple excavations had

extended over 70 ft (20 m), while being

directly adjacent to existing buildings.

Approaches in Early 2000s

Back in 2011, the local soil mixing

market predominantly involved multi-

axis deep soil mixing (DSM) rigs

operated by U.S. subsidiaries of

Japanese companies, or single-axis

mixing rigs operated by Malcolm

Drilling Company and Condon-Johnson

& Associates. San Francisco had seen

limited new building since the 1980s.

Construction projects were mainly

infrastructure, structural retrofits, or

relatively shallow excavations con-

structed with conventional pile and

lagging or underpinning methods. Jet

mixing had gained ground as being very

fast and efficient; however, equipment Constructed Mission Bay district in 2019, and Transbay District towers near downtown

constraints had limited this approach

to about 70 ft (20 m) of total drilling

depth. One unique project was the

Sunset Reservoir, where multiple tiered

soil mix cells provided slope stabiliza-

tion and liquefaction mitigation. This

project was constructed by Raito using

a multi-axis rig. Cutter soil mixing

(CSM) had not yet been used in San

Francisco.

The Last Decade

After the Great Recession of 2008 and

2009, the city began a rapid growth

trajectory fueled by the technology

sector. Strong demand for state-of-

practice soil mixing further con-

centrated local expertise among

designers and contractors. Millennium

Tower, completed and opened in 2009,

b e c a m e i n f a m o u s fo r i t s p o s t-

construction settlement, resetting the complex excavations in an increasingly Millennium Tower Impact

risk perspective of many in the deep risk-focused environment led to Millennium Tower is a 58-story luxury

foundation industry. widespread adoption of CSM as a condominium whose opening in 2009

Soil mixing has followed three tracks preferred construction method. Within provided the first new downtown tower

of development since 2011. An increased this heated, but maturing market, in almost 20 years. Its concrete frame

application of DSM grid systems has construction demands have also construction is founded on up to 90 ft

occurred for combined bearing support encouraged refinement and optimiza- (27 m) long concrete piles driven into

and liquefaction mitigation; secondly, tion of more conventional methods, such the Colma formation. The site is directly

the demand for larger, deeper, more as single- and multi-axis and jet mixing. adjacent to the Transbay Transit Center,

72 • DEEP FOUNDATIONS • JAN/FEB 2022

whose construction from 2011 through order of $300 million (€260 million). compressible soils or on any other sites

2018 included a secant pile buttress Heightened sensitivity to potential as directed by DBI. Specific considera-

designed to limit deformation of construction impacts on nearby struc- tions the peer reviewer addresses

Millennium Tower during excavation tures has also occurred nationally, include ground improvement, effects of

of the adjacent 60 ft (18 m) deep station. further emphasized by the recent dewatering on site and nearby, and

The buttress was keyed into the 250 ft Champlain Towers collapse in South effects of construction-related activities

(75 m) deep Franciscan bedrock, with Florida. One outcome is an increased on neighboring foundations.

installation costs exceeding $50 million focus on contractual risk management In essence, Millennium has in-

(€44 million). for all parties, notably the design creased the focus on liability and risk

In 2016, it was publicly disclosed professionals and specialist subcon- transfer between parties engaged in

that Millennium Tower had settled 16 in tractors, as has certainly occurred in geotechnical construction and created a

(40 cm) in 7 years, compared to the San Francisco construction “Post- new requirement for third-party peer

predicted 20-year settlement of only Millennium.” review of support of excavation (SOE)

5.5 in (14 cm). The Transit Authority Another related impact of the and bearing support for critical projects.

reported that 10 in (25 cm) of that Millennium has been an increase in This means that design-build projects

settlement had occurred in the two regulation of geotechnical aspects of require earlier contractor engagement to

years before their adjacent work started; construction by San Francisco’s Depart- determine the optimal construction

by 2018, Millennium’s total settlement ment of Building Inspection (DBI). In approach and steer projects through

was 18 in (45 cm). The residents, city, 2017, Interim Guidelines for Structural, permit approvals. Often, the peer review

developer, Transit Authority and others Geotechnical and Seismic Hazard requires enhanced analysis, including

initiated legal claims and counterclaims. Design Review for Tall Buildings were finite element modelling of the geotech-

Settlements were reached without i s s u e d , a n d t h e n fo r m a l i z e d i n nical construction process, supple-

allocation or admission of fault. The November 2018. mental to the soil structure interaction

Millennium Tower fallout has still Although permitting previously studies that are conventionally run for

impacted most contractors and con- relied solely on geotechnical engineer of completed structures under seismic

sultants in San Francisco. In particular, record recommendations, the new loading. In consequence, complex

the project highlighted the potential guidelines require geotechnical peer projects now often have lead times of 6

scale of liabilities surrounding deep review of projects over 240 ft (75 m) to 18 months to break ground after a geo-

foundation and excavation support high. This requirement also applies to technical construction team is selected.

work. Some repair schemes that were buildings constructed in seismic zones These changes have afforded

considered had estimated costs on the with soft soils, on sites overlying soft or specialty contractors with an increased

role in project development and

participation in evaluating applicable

solutions for risks. Another upside is

that contractors are more frequently

selected based on expertise, rather than

solely on a low bid and potential

willingness to accept challenging

contract terms.

Post-Recession Challenges

Construction of 350 Mission Tower

kicked off the new, post-recession era in

San Francisco. Its 50 ft (15 m) deep

basement excavation was supported

with internally braced CSM walls that

extended through the Colma sands into

the Old Bay Clay. Since this project’s

successful completion, increasingly

deep, complex excavations have

occurred in direct proximity to

established structures. Several sites

A cutter soil mix tool

DEEP FOUNDATIONS • JAN/FEB 2022 • 73

have been excavated to over 70 ft (20 m) the SOE wall can further stiffen shoring Malcolm constructed a 140 ft (43 m)

in the Transbay District, with shoring systems to manage deformation and deep, 3.3 ft (1 m) thick, continuous peri-

walls extending deeper than 100 ft effects on adjacent properties. meter wall. To minimize deformation

(30 m); this depth allowed for structural effects, heavy W30 and W33 steel

embedment and sealing into the clay Project Example sections were placed at 4 ft (1.2 m)

unit for groundwater control. Some- Malcolm Drilling constructed SOE and centers around the site perimeter.

times, walls have exceeded 130 ft (40 m) deep foundations for Oceanwide Center, Structural beam lengths and other

to seal off and depressurize confined an L-shaped site that has a 61-level factors meant “over-the-hole” mech-

aquifers for blowout mitigation, and for tower and a 53-level tower, over anical splices were employed during

basal heave control in the underlying multilevel basements. The complex site wet set placement of the reinforcement.

clay layers. Bedrock is too deep to footprint wraps around six adjacent Two of the six structures adjacent to

contribute strength or stability. structures, and required an SOE scheme Oceanwide were high-rise towers

Although traditional SOE schemes that could allow tower excavation to founded on piles driven into the Colma

in San Francisco used the dense Colma progress without schedule constraints. formation. The planned excavation

sand to provide toe stability for shoring Overall, the mass excavation depth extended below pile tip of those

walls, the current, deeper excavations extended to 72 ft (22 m) depth, structures. To further stiffen the SOE

effectively remove this competent soil, penetrating into the top of the Old Bay wall at these critical locations, soil

and walls embed into the weaker, Clay. This uncharacteristic depth was cement buttresses were installed

underlying clay. This increases the further complicated by a thick sand lens perpendicular to the perimeter align-

potential for basal heave effects that within the underlying clay soils that ment. The buttresses were constructed

escalate the already significant ground required cut-off and depressurization. from original site grade by overlapping

movements predicted for these deep Due to the large depth and extensive nominally reinforced soil cement

excavations. The CSM method has removal of the Colma, the excavation panels end to end. They were removed

provided an effective solution to stiffen had a relatively low factor of safety in lifts as excavation progressed and

SOE systems by allowing thicker walls against basal heave. bracing levels were installed, with the

to accommodate larger, heavier steel The selected SOE approach was an remaining length below final subgrade

sections than in traditional multi-axis internally braced, combined shoring acting as a shear-key to resist lateral

soil mixing layouts. Also, buttress and cutoff wall. Using a steerable, movement and basal heave. Finite

elements constructed perpendicular to instrumented CSM mixing tool, element modelling of the shoring

The 72 ft (22 m) deep Oceanwide Center basement excavation

74 • DEEP FOUNDATIONS • JAN/FEB 2022

the Colma or on soil cement grids that

transfer load down to this soil unit. The

12-story mixed use building at 1066

Market has three basement levels and

imposes a peak load demand of 7 ksf

(335 kPa). The site abuts double-

stacked transit tunnels and multiple

existing buildings. Its stratigraphy is

comprised of undocumented fill

materials and compressible marsh

deposits overlying the Colma. Analysis

p r e d i c t e d u p to 3 i n ( 8 c m ) o f

liquefaction-induced settlement and

up to 5.5 in (14 cm) of seismic densifi-

cation of the fill.

Malcolm Drilling developed its

bearing support design using 3 and 7 ft

(0.9 and 2.1 m) diameter overlapped soil

cement columns to create a combined

bearing support and liquefaction

Soil mix buttress elements exposed during excavation

mitigation grid extending through the

system provided deformation and Deep Mixing meeting paper in 2012 fill and marsh soils, and 5 ft (1.5 m) into

e s t i m a t e s , a n d t h e p ro j e c t w a s by Filz and colleagues, and a 2013 the underlying dense Colma formation.

completed with actual movements FHWA deep mixing design manual. Also For the peak bearing pressure noted

within the predicted 0.1% to 0.2% of the Boulanger and Shao keynote from above, a 100% area replacement ratio

excavation depth. DFI’s 2021 Deep Mixing Conference (ARR) was used, with reduced coverage

presents a comprehensive review of of 45-55% ARR elsewhere. Soil mix

Liquefaction and Bearing recent developments in this field. walls constructed around the site

Capacity perimeter and to accommodate site

DSM use for liquefaction mitigation in Market Street Example grade changes were incorporated into

the U.S. dates back to Jackson Lake Dam Three blocks of San Francisco’s arterial the liquefaction grid pattern.

in 1987, with multiple projects since Market Street (5th to 8th) have seen 10 In a 2013 ASCE Journal of Geotechnical

then relying on its ability to construct soil mixing projects this past decade. and Geoenvironmental Engineering article,

below-grade shear structures to These mid-rise structures have used Nguyen and colleagues shared the basis

enhance slope stability and mitigate soil-mixed SOE walls for basement of the grid design, with predicted

lateral spreading. These civil structures excavation, and are either founded on performance based on ARR, strength of

include dams, wharfs and reservoirs. soil cement, depth of

However, the last decade has seen the mixed columns,

rapid adoption of these methods for cyclic stress ratio and

building projects, combining soil cyclic resistance ratio.

mixing grids for seismic mitigation and The grid configuration

permanent bearing capacity support. reduces the shear

Since soil mixing is often used for the strain imposed on

perimeter SOE of these projects too, enclosed soil and

efficient combined systems have provides a barrier to

offered commercial advantages that excess pore pressure

have accelerated DSM grid adoption in migrating from sur-

San Francisco. The development of rounding unimproved

industry-wide design standards has soils. The overlapped

also assisted nationally in applying this soil cement grid

approach. Key references include a 2011 elements are con-

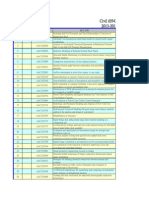

USACE design guide for levees and Market St. soil mix grid layout and applied loads of approximately 1 ksf figured to remain in

floodwall stability, an ASCE Grouting (50 kPa, in blue) to over 7 ksf (335 kPa, in red) compression, in

DEEP FOUNDATIONS • JAN/FEB 2022 • 75

contrast to the bending and cracking

induced in individual elements subject

to the same loading. The selected grid

layout was integrated with the

perimeter soil cement SOE walls for the

Market Street project to provide

completed enclosed cell elements.

Conclusion

Since 2011, San Francisco has experi-

enced a massive surge in commercial

Excavated Market Street site

and residential development. Millen-

nium Tower issues and legal fallout

triggered changes to business practices, mixing systems, CSM’s combination of for soil mixing with conventional tools

local code and the review of geotech- direct down-hole monitoring, operator (multi- and single- axis and jet mixing)

nical requirements. control and variable wall thickness has continued to thrive.

As developers continued to pursue provides significant technical advan-

larger, deeper and more complex tages for most challenging SOE projects.

Rob Jameson has 30 years of geotechnical

excavations in an increasingly dense, The use of soil mix grid systems for

experience. Based in San Francisco, he oversees

constrained environment, CSM has combined bearing support and lique- engineering and technical risk management

become the preferred system to faction mitigation has become more throughout the U.S. for Malcolm Drilling

successfully execute these works. widespread, as new industry standard Company, which celebrates its 60th anniversary

Although typically costlier than references provide an accepted design this year.

conventional vertical multi-axis soil basis. In addition, the existing market

76 • DEEP FOUNDATIONS • JAN/FEB 2022

You might also like

- Earthquake Aspects of Roller Compacted Concrete and Concrete-Face Rockfill DamsDocument12 pagesEarthquake Aspects of Roller Compacted Concrete and Concrete-Face Rockfill DamsHaryadi StNo ratings yet

- ARTICULO Vibro-Replacement For Challenging Soil Conditions in Port StructuresDocument8 pagesARTICULO Vibro-Replacement For Challenging Soil Conditions in Port StructuresYimi Huisa CalapujaNo ratings yet

- Piled Raft Foundation in Calcareous Cemented Sand in Kuwait CityDocument10 pagesPiled Raft Foundation in Calcareous Cemented Sand in Kuwait CitysonNo ratings yet

- Contexto Minero en Chile y El MundoDocument13 pagesContexto Minero en Chile y El MundonarayaniIoNo ratings yet

- Full Paper 302 Agua Dulce Project-2Document9 pagesFull Paper 302 Agua Dulce Project-2rftorresrNo ratings yet

- RollerDocument4 pagesRollerkapola100% (1)

- Review of Some Drained Reclamation Works - Hongkong PDFDocument54 pagesReview of Some Drained Reclamation Works - Hongkong PDFJamie MooreNo ratings yet

- Artigo David SmithDocument10 pagesArtigo David SmithandreaseveriNo ratings yet

- Iicep 1979 2267Document22 pagesIicep 1979 2267EngwarwickNo ratings yet

- Tailings Dam Design and Structural FactorsDocument22 pagesTailings Dam Design and Structural FactorsVíshñu Offishàl100% (1)

- Optimization of Deep Mixing Design For Seismic Liquefaction Mitigation of Caisson WallsDocument28 pagesOptimization of Deep Mixing Design For Seismic Liquefaction Mitigation of Caisson WallsFabrizio MansuetoNo ratings yet

- Paper 06Document14 pagesPaper 06Samoon IbrahimNo ratings yet

- Kansai Airport 2005Document23 pagesKansai Airport 2005divugoelNo ratings yet

- Improving Soil with Stone ColumnsDocument6 pagesImproving Soil with Stone ColumnsmooolkaNo ratings yet

- Part 4 2 RMCdamDocument38 pagesPart 4 2 RMCdamKremen Mitov100% (1)

- Roller-Compacted Concrete For Ports PDFDocument2 pagesRoller-Compacted Concrete For Ports PDFHugo LeiteNo ratings yet

- Remedial Measures Incorporating Jet Grouting and Micropiles For The Construction of A New Back Ow PreventerDocument10 pagesRemedial Measures Incorporating Jet Grouting and Micropiles For The Construction of A New Back Ow Preventerrigaz6366No ratings yet

- Challenges in Slope Engineering in Hong KongDocument15 pagesChallenges in Slope Engineering in Hong KongFatin AmilinNo ratings yet

- DFI JanFeb2014 - BrooklinDocument7 pagesDFI JanFeb2014 - BrooklinMapeixNo ratings yet

- A Case Study On Rectification of Damaged Structures On ExpansiveDocument8 pagesA Case Study On Rectification of Damaged Structures On ExpansiveArnold TunduliNo ratings yet

- General Description of Recent Projects Involving Rockfill DamsDocument38 pagesGeneral Description of Recent Projects Involving Rockfill DamsSamoon IbrahimNo ratings yet

- Stones DevelopmentDocument52 pagesStones Developmenttajman90No ratings yet

- Soil Improvement Technique by IIT Chennai Professor Dr. S.R.GandhiDocument214 pagesSoil Improvement Technique by IIT Chennai Professor Dr. S.R.Gandhiarpit67% (3)

- Git PDFDocument214 pagesGit PDFPrateepNo ratings yet

- Recent Experience On Design, Construction and Performance of CFRDDocument10 pagesRecent Experience On Design, Construction and Performance of CFRDSamoon IbrahimNo ratings yet

- Design Concepts For Quay WallsDocument12 pagesDesign Concepts For Quay WallsAdrian Frantescu100% (3)

- Pressure Grouting A Multipurpose Solution For Dam RehabilitationDocument14 pagesPressure Grouting A Multipurpose Solution For Dam RehabilitationSlan ClanNo ratings yet

- Implementing An On-Site Concrete Batch Plant On A Large ConstructDocument6 pagesImplementing An On-Site Concrete Batch Plant On A Large Constructsagi prathimaNo ratings yet

- 210040117-Roller Compacted ConcreteDocument5 pages210040117-Roller Compacted Concretesahilbarbade.ee101No ratings yet

- Recent Experience On Design Construction and Performance of CFRDDocument10 pagesRecent Experience On Design Construction and Performance of CFRD박래건No ratings yet

- Eqs 070 MDocument20 pagesEqs 070 MMohamed SobhyNo ratings yet

- Stabilized Mobile Paste Backfill North Longo April2015Document2 pagesStabilized Mobile Paste Backfill North Longo April2015Anil SinghNo ratings yet

- Post Tensioned Concrete Case Study PDFDocument6 pagesPost Tensioned Concrete Case Study PDFShaurya Chauhan0% (1)

- Erra Otes: A Ground Improvement Update From TerrasystemsDocument3 pagesErra Otes: A Ground Improvement Update From TerrasystemsAnonymous koR9VtfNo ratings yet

- Bahrain - Shaikh Khalifa Bin Salman CausewayDocument2 pagesBahrain - Shaikh Khalifa Bin Salman CausewayMonirul IslamNo ratings yet

- Chen at Al. (2022) - Heaving Material DCMDocument10 pagesChen at Al. (2022) - Heaving Material DCMs w leeNo ratings yet

- Articol Nr. 0735 ECSMGE 2019 CR CN AO RCDocument6 pagesArticol Nr. 0735 ECSMGE 2019 CR CN AO RCNuskin EstelaNo ratings yet

- 28 Sme Mining Engineering HandbookDocument1 page28 Sme Mining Engineering HandbookYeimsNo ratings yet

- Ports2004Sieglen LangsdorffDocument12 pagesPorts2004Sieglen LangsdorffMONCINo ratings yet

- DHL Concrete SocietyDocument2 pagesDHL Concrete SocietyTaraknath PalNo ratings yet

- Dock & Harbour EngineeringDocument12 pagesDock & Harbour EngineeringHRCNo ratings yet

- FP01Document9 pagesFP01Harold TaylorNo ratings yet

- Sandilands-ANZ2019 Building On Soft Ground A Case Study in Tauranga, New Zealand Rev01Document6 pagesSandilands-ANZ2019 Building On Soft Ground A Case Study in Tauranga, New Zealand Rev01danNo ratings yet

- Diaphragm Wall Quays For Myanmar Mega-PortDocument3 pagesDiaphragm Wall Quays For Myanmar Mega-PortrakhbirNo ratings yet

- Grouting To Shut Off SeepageDocument25 pagesGrouting To Shut Off SeepageHồ ThắngNo ratings yet

- Level Ton ReportDocument72 pagesLevel Ton ReportVelina MilevaNo ratings yet

- Floating Concrete StructuresDocument10 pagesFloating Concrete StructuresCyril LongtonNo ratings yet

- Naval Air StationDocument2 pagesNaval Air StationkbenjikaNo ratings yet

- Output Rates: Future Trends in Mining 29Document1 pageOutput Rates: Future Trends in Mining 29YeimsNo ratings yet

- Deep Foundations For New International Airport Passenger TerminalDocument10 pagesDeep Foundations For New International Airport Passenger TerminalSethuramanNo ratings yet

- Advances in Grouting TechnologyDocument18 pagesAdvances in Grouting TechnologyletuananhbNo ratings yet

- HF Material 1Document39 pagesHF Material 1Ayoub EL-hamrouniNo ratings yet

- Foundation and Diaphragm Wall Design Case Study in Kowloon Hong KongDocument17 pagesFoundation and Diaphragm Wall Design Case Study in Kowloon Hong KongMark Chan100% (2)

- Post Tensioned Concrete Case StudyDocument6 pagesPost Tensioned Concrete Case Studymark rushworth50% (2)

- Design of Geofoam Embankment for I-15 Reconstruction ProjectDocument20 pagesDesign of Geofoam Embankment for I-15 Reconstruction ProjectVa Ni SkyNo ratings yet

- Installation of Drilled Case MicropilesDocument13 pagesInstallation of Drilled Case MicropilesAntonio MorenoNo ratings yet

- The Design of Foundation Treatment Measures For Dams On Karst FoundationsDocument14 pagesThe Design of Foundation Treatment Measures For Dams On Karst FoundationsItalo GutierrezNo ratings yet

- RMC RMC 2-MergedDocument36 pagesRMC RMC 2-MergedBharthi 2GO20CV004No ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- DRRR_Presentation 5Document33 pagesDRRR_Presentation 5GIAN CHRISTIAN MANEJANo ratings yet

- 1893-Part 1 PDFDocument41 pages1893-Part 1 PDFDinakar Praneeth100% (2)

- Engineering-Civil (0543)Document48 pagesEngineering-Civil (0543)myusuf_engineerNo ratings yet

- Soil Liquefaction A Critical State Approach 2nd EdDocument2 pagesSoil Liquefaction A Critical State Approach 2nd Edyin hoe ongNo ratings yet

- Phivocs Philippines Manila Earthquake Damage ScenarioDocument60 pagesPhivocs Philippines Manila Earthquake Damage Scenariococoy.dayao831100% (2)

- Embankment SlopeDocument16 pagesEmbankment SlopeFlorentina SuduNo ratings yet

- 3.8.1 SAES Q 14 Section 11Document1 page3.8.1 SAES Q 14 Section 11sergeproNo ratings yet

- Scour Under StructuresDocument24 pagesScour Under StructuresRamkumarNo ratings yet

- Git PDFDocument214 pagesGit PDFPrateepNo ratings yet

- WDC Version 4.0Document95 pagesWDC Version 4.0Ronnie oliveiraNo ratings yet

- Geo Final ExamDocument5 pagesGeo Final ExamIrish Pales CosidonNo ratings yet

- DX23-044 Final ReportDocument126 pagesDX23-044 Final ReportTAHANo ratings yet

- Updated LRFD Guidelines for Seismic Design of Highway BridgesDocument156 pagesUpdated LRFD Guidelines for Seismic Design of Highway BridgesSiamak Pejmanfar100% (1)

- Ground Improvement of Soils Prone To LiquefactionDocument62 pagesGround Improvement of Soils Prone To LiquefactionLennon Ferreira TomasiNo ratings yet

- 2slides-Anis EQ Lecture 5 EQ-Sizes and Measurements 1Document48 pages2slides-Anis EQ Lecture 5 EQ-Sizes and Measurements 1Mohammad AlhajNo ratings yet

- Important Questions Unit-1: Introduction: Soil DynamicsDocument2 pagesImportant Questions Unit-1: Introduction: Soil DynamicsPadmaja SharmaNo ratings yet

- Shear Stress Test Report SummaryDocument6 pagesShear Stress Test Report Summaryعبد الرحمن أبوخاطر, أبو رزقNo ratings yet

- 2004 Idriss & Boulanger - Semi-Empirical Method For Evaluating LiquefactionDocument26 pages2004 Idriss & Boulanger - Semi-Empirical Method For Evaluating LiquefactionJuan Pablo PradaNo ratings yet

- Evaluacion Del Potencial de LicuefaccionDocument55 pagesEvaluacion Del Potencial de LicuefaccionCristian Danilo Avila AbrilNo ratings yet

- Total Stress Analysis: Chapter FiveDocument4 pagesTotal Stress Analysis: Chapter FivelenanaNo ratings yet

- Study On Dynamic Behavior of Shallow Foundations o PDFDocument17 pagesStudy On Dynamic Behavior of Shallow Foundations o PDFSen HuNo ratings yet

- DRRR Unit 3 L1-L3Document4 pagesDRRR Unit 3 L1-L3Mary Rose TuburanNo ratings yet

- EarthquakeGeotechnicalEngineeringDesign 1 PDFDocument391 pagesEarthquakeGeotechnicalEngineeringDesign 1 PDFGülnur Kayış100% (4)

- Marine Safety Investigation: Coral Sea On 26 and 27 July 1999Document37 pagesMarine Safety Investigation: Coral Sea On 26 and 27 July 1999Anonymous UCveMQNo ratings yet

- Lindung Experimental Liquefaction Study of Southern Yogyakarta Using Shaking Table 11 18 Vol. 24 No. 1Document8 pagesLindung Experimental Liquefaction Study of Southern Yogyakarta Using Shaking Table 11 18 Vol. 24 No. 1KRIZHNo ratings yet

- Soil Investigation Report - BH Pile Test (P 877) (Rev.0) (NSCR ITD N03 ZWD RPT ST 000088)Document77 pagesSoil Investigation Report - BH Pile Test (P 877) (Rev.0) (NSCR ITD N03 ZWD RPT ST 000088)Charles Warren GoNo ratings yet

- The Loma Prieta EarthquakeDocument5 pagesThe Loma Prieta Earthquakeapi-3736392No ratings yet

- Strain Wedge Model Capability of Analyzing Behavior of Laterally Loaded Isolated Piles, Drilled Shafts, and Pile GroupsDocument10 pagesStrain Wedge Model Capability of Analyzing Behavior of Laterally Loaded Isolated Piles, Drilled Shafts, and Pile GroupsAhmed RamadanNo ratings yet

- UN DMTP - Disaster MitigationDocument66 pagesUN DMTP - Disaster MitigationBrian Griffin100% (1)

- 2019 CalARP Seismic Guidance DocumentDocument58 pages2019 CalARP Seismic Guidance DocumentaxiomataNo ratings yet