0% found this document useful (0 votes)

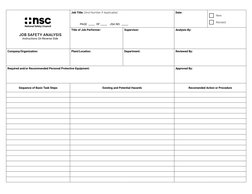

1K views2 pagesJsa Form Template

Uploaded by

jagsdCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views2 pagesJsa Form Template

Uploaded by

jagsdCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd