Professional Documents

Culture Documents

DHV - Dual Plate Wafer Check Valve

Uploaded by

Andry HermawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DHV - Dual Plate Wafer Check Valve

Uploaded by

Andry HermawanCopyright:

Available Formats

Seeking a Great Name in Valve Technology

Please visit our DHV website: www.dhvindustries.com or www.dhvvalve.com for a copy of our API 6D

monogram certificate. Customer and Project referrals are available upon request. For certified data

and current specifications, please contact us or your local DHV agent. Information provided in this

catalog is for general purposes only.

DHV reserves the right to discontinue the manufacture or change and modify our design and construc-

tion of any DHV product, in due course of our manufacturing procedure without incurring any obligation

to accept for credit, to replace or furnish or install such changes or modifications on products previously

or subsequently sold.

DHV Industries, Inc.

3451 Pegasus Drive Bakersfield. CA 93308 U.S.A.

Call Toll Free: (877) DHV-USA1

Phone: (661) 392-8948 Fax: (661) 392-8947

E-mail: sales@dhvindustries.com

Website: www.dhvindustries.com

DHV Valve Company Inc.

10810 W. Little York, Suite 120 Houston, TX. 77041 U.S.A.

Phone: (713) 983-6046 Fax: (713) 983-9076

E-mail: sales@dhvvalve.com

Website: www.dhvvalve.com

Your local DHV agent

Cast Steel Valves

Gate / Globe / Check / Plug

Catalogue No: A1-04

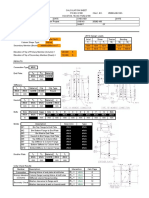

Butt-Welding Ends DHV Figure Numbers

ANSI B16.25 Cast Steel Valves

Pressure Class

1 = Class 150 End Connections

Dimensions of Butt-Welding Ends

Nominal Schedule Outside Diameter Nominal Machined Nominal 2 = Class 300 F = Raised Face Flanged End

Pipe Number (Cast Steel Valves) lnside Diameter lnside Diameter Wall Thickness Ty p e C 3 = Class 600 R = Ring Type Joint Flanged End

Size or A B C t P = Plain Flate Face Flanged End

1= OS & Y Gate 4 = Class 900

Wall inches mm inches mm inches mm inches mm

2 = Globe 5 = Class 1500 B = Butt-welding End

3 xxs 3 19/32 91.28 2.300 58.42 2.409 61.19 0.600 15.24

4 xxs 4 5/8 117.48 3.152 80.06 3.279 83.29 0.674 17.12 3 = Swing Check 6 = Class 2500 T = Threaded End

160 4.313 109.55 4.428 112.47 0.625 15.88 4 = NRS GATE S = Socket-welding End

5

xxs

5 11/16 144.46

4.063 103.20 4.209 106.91 0.750 19.05

Body and Bonnet Material

5 = Pressure Seal Bonnet Gate W= Wafer-Type

120 5.501 139.73 5.600 142.24 0.562 14.27

6 = Pressure Seal Bonnet Globe 0 = ASTM A216 WCB

6 160 6 25/32 172.34 5.189 131.80 5.327 135.31 0.719 18.26 L = Lug-Tpye or Full Flange

7 = Pressure Seal Bonnet Check 1 = ASTM A216 WCC

xxs 4.897 124.38 5.072 128.83 0.864 21.95 D = Double Flange-Type

100 7.439 188.93 7.546 191.67 0.594 15.09 8 = Y Pattern 2 = ASTM A352 LCB

120 7.189 182.60 7.327 186.11 0.719 18.26

X = Other Type End Connection

9 = Angle 3 = ASTM A352 LCC

8 140 8 25/32 223.04 7.001 177.83 7.163 181.94 0.812 20.62

A = Conduit Gate 4 = ASTM A351 CF8M

xxs 6.875 174.63 7.053 179.15 0.875 22.23

160 6.813 173.05 6.998 177.75 0.960 23.01

B = Plug Valve 5 = ASTM A351 CF8 Conduit Gate &

C = Strainer

80 9.564 242.93 9.671 245.64 0.594 15.09

6 = ASTM A351 CF3M Plug Valve Seat Type

100 9.314 236.58 9.452 240.08 0.719 18.26 D = Soft Seat Block & Bleed Gate

10 120 10 15/16 277.81 9.064 230.23 9.234 234.54 0.844 21.44 7 = ASTM A351 CF3 None = Other Valves

E = API 6D Swing Check

140 8.750 222.25 8.959 227.56 1.000 25.40

F = Twin Seal Plug Valve 8 = ASTM A890 4A S = Soft Seal

160 8.500 215.90 8.740 222.00 1.125 28.58

X = Special X = Special M = Metal Seal

60 11.626 295.30 11.725 297.82 0.562 14.27

80 11.376 288.95 11.507 292.28 0.688 17.48

100 12 31/32 329.41 11.064 281.03 11.234 285.34 0.844 21.44 Ty p e WC

12 8˝ OS &Y Gate valve, class 300,

120 10.750 273.05 10.959 278.36 1.000 25.40

1 = Single-Plate Wafer Check

140 10.500 266.70 10.740 272.80 1.125 28.58 A216 WCB body & bonnet, raised

160 10.126 257.20 10.413 264.49 1.312 33.32 2 = Dual-Plate Wafer Check face, flanged end, with HF / HF

60 12.814 325.48 12.921 328.19 0.594 15.09 3 = Lift Wafer Check Trim, Gear Operated

80 12.500 317.50 12.646 321.21 0.750 19.05

100 14 1/4 361.95 12.126 308.00 12.319 312.90 0.938 23.83

X = Special

14

120 11.814 300.08 12.046 305.97 1.094 27.79

140 11.500 292.10 11.771 298.98 1.250 31.75

160

60

80

11.188

14.688

14.314

284.18

373.08

363.58

11.498

14.811

14.484

292.05

376.20

367.89

1.406

0.656

0.844

35.71

16.66

21.44

Example:8˝-C120F2-XX-X-GO

100 16 1/4 412.75 13.938 354.03 14.155 359.54 1.031 26.19

16

120 13.564 344.53 13.827 351.21 1.219 30.96

140 13.124 333.35 13.442 341.43 1.438 36.53

160 12.814 325.48 13.171 334.54 1.594 40.49

40 16.876 428.65 16.975 431.17 0.562 14.27 Trim Material

60 16.500 419.10 16.646 422.81 0.750 19.05

80 16.126 409.60 16.319 414.50 0.938 23.83 Seat Seal Disc Seal Stem Operator

18 100 18 9/32 464.34 15.688 398.48 15.936 404.77 1.156 29.36 Face Face Material None = Lever or Handwheel Operator

120 15.250 387.35 15.553 395.05 1.375 34.93

1= 13CR 13CR F6 CO = Chain Wheel Operator

140 14.876 377.85 15.225 386.72 1.562 39.67

160 14.438 366.73 14.842 376.99 1.781 45.24 Code 2= HF HF F6 GO = Gear Operator

40 18.814 477.88 18.921 480.59 0.594 15.09 C = Cast Steel Valves 3= HF 13CR F6 BS = Bare Stem

60 18.376 466.75 18.538 470.87 0.812 20.62

F = Forged Steel Valves 4= Monel Monel Monel EM = Electric Motor Operator

80 17.938 455.63 18.155 461.14 1.031 26.19

20 100 20 5/16 515.94 17.438 442.93 17.717 450.01 1.281 32.54 I = Cast Iron Valves 5 = 316 SS 316 SS F316 PA = Pneumatic Actuator

120 17.000 431.80 17.334 440.28 1.500 38.10 HA = Hydraulic Actuator

B = Ball Valves 6= HF 316 SS F316

140 16.500 419.10 16.896 429.16 1.750 44.45

160 16.064 408.03 16.515 419.48 1.969 50.01 WB = Wafer Butterfly 7 = 304 SS 304 SS F304 PH = Pneumatic-Hydraulic Actuator

30 22.876 581.05 22.975 583.57 0.562 14.27 WC = Wafer Check Valve 8= HF 304 SS F304

40 22.626 574.70 22.757 578.03 0.688 17.48

60 22.064 560.43 22.265 565.53 0.969 24.61

W = Wellhead Valves 9 = Inconel Inconel Inconel

80 21.564 547.73 21.827 554.41 1.219 30.96 A= HF HF F316 Conduit Gate Type

24

100 24 3/8 619.13 20.938 531.83 21.280 540.51 1.531 38.89 None = Other Valves

B = Duplex S.S.

120 20.376 517.55 20.788 528.02 1.812 46.02

140 19.876 504.85 20.350 516.89 2.062 52.37 X = Special EG = Expanding Gate

160 19.314 490.58 19.859 504.42 2.344 59.54 SG = Slab Gate

49 DHV Industries, Inc. DHV Industries, Inc. 2

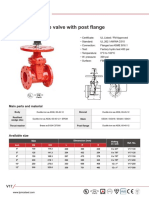

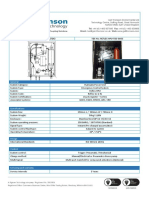

Dual-Plate Wafer Check Valves Class 150 Globe Valve

Class 150 / 300 / 600 ( 2˝-24˝ )

Standards Compliance: Fig. WC210W7

• Class 150 300 600 WC225D7 Features Fig. C210F3

• NPS 2˝-24˝

• Basic Design: API 594 WC234W5

• OS & Y, Rising Stem C210B3

• Plug Disc

• Face to Face Dimensions: API 594

• End Flange Dimensions: ANSI B16.5 • Bolted Bonnet

• Inspection and Testing: API 598 • Renewable seat Rings Welded or Threaded

• Type: Wafer, Wafer-Lug, and Double Flange

• Flanged Ends or Buttwelding Ends

Specifications

Basic Design: BS1873 ANSI B16.34

Face to Face: ANSI B16.10

E End to End: ANSI B16.10

End Flange: ANSI B16.5

B.W End: ANSI B16.25

Test and Inspection: API-598

Manufacturing to NACE MR0175 on request

Type Lug Full Flange

Type Lug or Full Flange Type Wafer

Dimensions and Weights

CLASS 150 CLASS 300 CLASS 600

NPS

L E D W(kg) L E D W(kg) L E D W(kg)

2˝ 2.38 4.75 3.62 1.2 2.38 5.00 3.62 2.0 2.38 5.00 3.62 2.5

21/2˝ 2.62 5.50 4.13 2.3 2.62 5.88 4.13 2.9 2.62 5.88 4.13 3.4 Bevel Gear Bearing Yoke

3˝ 2.88 6.00 5.00 3.0 2.88 6.63 5.00 5.5 2.88 6.63 5.00 6.3 ≥ 12˝ ≥ 12˝

4˝ 2.88 7.50 6.18 7.0 2.88 7.88 6.18 9.2 3.12 8.50 6.18 10.2

6˝ 3.88 9.50 8.50 15 3.88 10.63 8.50 20 5.38 11.50 8.50 22

8˝ 5.00 11.75 10.63 23 5.00 13.00 10.63 25 6.50 13.75 10.63 35 Dimensions and Weights

10˝ 5.75 14.25 12.76 30 5.75 15.25 12.76 32 8.38 17.00 12.76 41

Valve Size

12˝ 7.12 17.00 15.00 37 7.12 17.75 15.00 39 9.00 19.25 15.00 57 Description

14˝ 7.25 18.75 16.26 49 8.75 20.25 16.26 52 10.75 20.75 16.26 72 2˝ 2 1/2˝ 3˝ 4˝ 6˝ 8˝ 10˝ 12˝ 14˝ 16˝ 18˝ 20˝

16˝ 7.50 21.25 18.50 62 9.12 22.50 18.50 67 12.00 23.75 18.50 83

in 8.00 8.50 9.50 11.50 16.00 19.50 24.50 27.50 31.00 36.00 38.50 38.50

18˝ 8.00 22.75 20.98 78 10.38 24.75 20.98 82 14.25 25.75 20.98 100 RF/BW L / L1

20˝ 8.62 25.00 22.99 97 11.50 27.00 22.99 102 14.50 28.50 22.99 140 mm 203 216 241 292 406 495 622 698 787 914 978 978

24˝ 8.75 29.50 27.24 125 12.50 32.00 27.24 135 17.25 33.00 27.24 350

in 13.93 15.16 16.61 18.38 23.62 25.63 33.58 38.53 57.00 64.76 69.75 82.12

Height to Open H

STANDARD MATERIAL SPECIFICATIONS mm 354 385 422 467 600 651 853 928 1450 1645 1772 2086

Cartion Steel Alloy Steel Stainless Steel

No Part Name in 7.87 7.87 9.84 11.81 15.75 17.72 17.72 19.69 23.62 23.62 30.00 39.38

WCB LCB WC6 WC9 C5 CF8 CF8M A890 4A(F51) Inconel 625 Handwheel Dia W

1 Body A216 WCB A352 LCB A217 WC6 A217 WC9 A217 C5 A351 CF8 A351 CF8M A890 4A Inconel 625 mm 200 200 250 300 400 450 450 500 600 600 762 1000

2 Sealing face overlay BUNA-N (NBR) / PTFE / 13Cr / 18Cr-8Ni / HF (Co-CrA) / DSS / Inconel 625

Turns to Open 5.3 5.9 8.3 11.4 7.9 13.0 17.0 18.0 19.0 19.0 20.0 22.0

3 Disc A216 WCB A352 LCB A217 WC6 A217 WC9 A217 C5 A351 CF8 A351 CF8M A890 4A Inconel 625

4 Spring AISI 6150 17-7PH Stainless Steel(inconel for NACE standard)Ni-CrAlloy RF lb 51 70 88 132 231 396 639 771 1100 1500 1850 2600

5 Pin A182 F6 A182 F6 A182 F304 A182 F304 A182 F304 A182 F304 A182 F316 A182 F51 Inconel 625 Weight

BW lb 43 51 65 110 202 351 520 687 950 1300 1630 2340

The materials according to ASTM standard.

31 DHV Industries, Inc. DHV Industries, Inc. 20

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- DHV - Swing Check ValvesDocument5 pagesDHV - Swing Check ValvesAndry HermawanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 4TB & 8TB Moment ConnectionDocument13 pages4TB & 8TB Moment ConnectionShamik Ghosh0% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Scupper DrainDocument216 pagesScupper DrainMunzuara AktherNo ratings yet

- Data Sheet Flushing Ring - Anillo PurgaDocument2 pagesData Sheet Flushing Ring - Anillo PurgaMarcelo PellizzaNo ratings yet

- Roof StrainerDocument220 pagesRoof Strainerpria prcNo ratings yet

- SVC1300 SVC1835Document2 pagesSVC1300 SVC1835Gustavo Hernández PérezNo ratings yet

- VAV TerminalsDocument18 pagesVAV TerminalsFaquruddinNo ratings yet

- Watts PDFDocument220 pagesWatts PDFZain ShariffNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiNo ratings yet

- Canadian Catalogue & Price List: Specification Drainage ProductsDocument252 pagesCanadian Catalogue & Price List: Specification Drainage ProductshrithikvNo ratings yet

- Valvula Check CraneDocument1 pageValvula Check CraneMIGUEL ANGELNo ratings yet

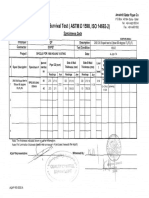

- 1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataDocument24 pages1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataNADEEM AHMEDNo ratings yet

- DS Ac9105 GB 871 PDFDocument2 pagesDS Ac9105 GB 871 PDFAbbasNo ratings yet

- Catalog PDFDocument72 pagesCatalog PDFVIVEK UPADHYAYNo ratings yet

- Fig 907 Resilient Seated Gate Valve FlangedDocument1 pageFig 907 Resilient Seated Gate Valve FlangedSebastian Andres Quilodran BaquedanoNo ratings yet

- 2-01201-N-T-019 R05 Diseño de TuberiasDocument55 pages2-01201-N-T-019 R05 Diseño de TuberiasnarufredNo ratings yet

- CTLG Ca Ata 08Document2 pagesCTLG Ca Ata 08Yrene De Jesus Alvarez VasquezNo ratings yet

- Fig 147XU Check CraneFS DS 1702 P100 1Document1 pageFig 147XU Check CraneFS DS 1702 P100 1Juan Carlos FernandezNo ratings yet

- Perar WCWB Trunnion Welded BodyDocument19 pagesPerar WCWB Trunnion Welded BodyAlexandra HarperNo ratings yet

- Uniflange - Serie 900Document1 pageUniflange - Serie 900JohanAndrésVillarrealNo ratings yet

- 830 2449 KRV Edition3 En0607Document2 pages830 2449 KRV Edition3 En0607AhmedRamadanNo ratings yet

- Xyzljsdöaklsd Ask 1En/Ld, Kdks 1En/Ld and Kdks 1Pe/LdDocument1 pageXyzljsdöaklsd Ask 1En/Ld, Kdks 1En/Ld and Kdks 1Pe/LdJuan Esteban Benjumea BenjumeaNo ratings yet

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- Rivets Multi Grip CountersunkDocument1 pageRivets Multi Grip CountersunkIsrael OluwagbemiNo ratings yet

- Del West: Ready-to-Ship ComponentsDocument12 pagesDel West: Ready-to-Ship ComponentsADNo ratings yet

- Fig. 810/910 Cast Iron Y-Type: Material Specification Features and BenefitsDocument1 pageFig. 810/910 Cast Iron Y-Type: Material Specification Features and BenefitsMuhamad SuryaNo ratings yet

- Flush Bottom Valve 9100Document4 pagesFlush Bottom Valve 9100BASKARNo ratings yet

- HTRI-COMPRESS Kettle CalculationsDocument227 pagesHTRI-COMPRESS Kettle Calculationsb363nk100% (2)

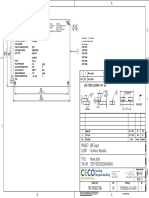

- 1 1 Name Plate Plate 1, 160 X 100 A240 TP316 (L) Qty Description Dimensions Material CommentsDocument1 page1 1 Name Plate Plate 1, 160 X 100 A240 TP316 (L) Qty Description Dimensions Material CommentsHiệp Phạm VănNo ratings yet

- (S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Document3 pages(S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Bernard Bonnin CervantesNo ratings yet

- Al/Alx: SeriesDocument76 pagesAl/Alx: SeriesQuynh Bui DucNo ratings yet

- ASME B16.5 - Pipe Flanges and Flanged Fittings 2009Document2 pagesASME B16.5 - Pipe Flanges and Flanged Fittings 2009Nguyễn Đại DươngNo ratings yet

- Technical SummaryDocument2 pagesTechnical SummaryRidhuan RaisNo ratings yet

- Elite Flange-Api B16.47-150#-Grandes DiametrosDocument7 pagesElite Flange-Api B16.47-150#-Grandes DiametrosSergio BragaNo ratings yet

- .204 DIA Hole Thru .375 Roll Inside Edges: UmpcoDocument1 page.204 DIA Hole Thru .375 Roll Inside Edges: UmpcoFredNo ratings yet

- Transicion C900 - Brida Tyler UnionDocument3 pagesTransicion C900 - Brida Tyler UnionJohanAndrésVillarrealNo ratings yet

- D 0100Document20 pagesD 0100Bang OchimNo ratings yet

- Manual Valves Datasheet. Rev 1Document7 pagesManual Valves Datasheet. Rev 1eke23No ratings yet

- Forged Steel Swing Check Threaded SW Socket Welded 853 803 1553 1503 A105N F316 1Document3 pagesForged Steel Swing Check Threaded SW Socket Welded 853 803 1553 1503 A105N F316 1Ana Gabriela Gómez PeraltaNo ratings yet

- Front Screen For Flange and FittingsDocument12 pagesFront Screen For Flange and FittingsNITINNo ratings yet

- V4-CWD-A200: Double Door Check ValveDocument1 pageV4-CWD-A200: Double Door Check ValveArthur DeiparineNo ratings yet

- KSB Sicca HP Cast Gate Valve PDFDocument4 pagesKSB Sicca HP Cast Gate Valve PDFJamalNo ratings yet

- New Paint Book FormattDocument2 pagesNew Paint Book FormattRam JNo ratings yet

- Ms Blind Bolts: Alloy Steel and A-286 StainlessDocument19 pagesMs Blind Bolts: Alloy Steel and A-286 StainlessJuan Fernando Quintero BalcazarNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- UL FM NRS Gate Valve, AWWA C515 - ANSI 250-300 Flanged Ends - Water Works - Fire Protection - Model 2510Document1 pageUL FM NRS Gate Valve, AWWA C515 - ANSI 250-300 Flanged Ends - Water Works - Fire Protection - Model 2510alanNo ratings yet

- Flanged NRS Gate Valve With Post Flange: Main Parts and MaterialDocument1 pageFlanged NRS Gate Valve With Post Flange: Main Parts and Materialmourad laatatNo ratings yet

- Forging CatalogueDocument27 pagesForging CatalogueTháiSơnTrầnNo ratings yet

- Cast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscDocument3 pagesCast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscMina MagdyNo ratings yet

- Eliminador de AireDocument4 pagesEliminador de AiresusansueNo ratings yet

- 1100 MSDocument1 page1100 MSAhmed RamzyNo ratings yet

- Disc Springs To Din 2093: Outside Dia. D I II III IV OMDocument1 pageDisc Springs To Din 2093: Outside Dia. D I II III IV OMstrijelavremenaNo ratings yet

- DemblaDocument12 pagesDemblaISHAN VERMANo ratings yet

- Fv101x - Specsht2Document1 pageFv101x - Specsht2Claudio Rivadeneira CarrascoNo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWBenny 37No ratings yet

- Vikings-Halar Coated Deluge ValveDocument12 pagesVikings-Halar Coated Deluge ValveHenry WuNo ratings yet

- Stainless Steel - E11Document6 pagesStainless Steel - E11Matthias StrubNo ratings yet

- R-Stud-Tds - 0001Document1 pageR-Stud-Tds - 0001Andry HermawanNo ratings yet

- Reflex Hpu-Tds-0003Document1 pageReflex Hpu-Tds-0003Andry HermawanNo ratings yet

- Avalon-GT Release Systems and DevicesDocument8 pagesAvalon-GT Release Systems and DevicesAndry HermawanNo ratings yet

- Trilliumflow Brochure - Formerly Weir GlobalDocument7 pagesTrilliumflow Brochure - Formerly Weir GlobalAndry HermawanNo ratings yet

- Hipps - Paladon SystemsDocument2 pagesHipps - Paladon SystemsAndry HermawanNo ratings yet

- Poster Wouter Witzel EuroValve Type EVBSDocument1 pagePoster Wouter Witzel EuroValve Type EVBSAndry HermawanNo ratings yet

- ZM Low Pressure Leaflet EN Antwerp 2935 0624 11Document12 pagesZM Low Pressure Leaflet EN Antwerp 2935 0624 11Andry HermawanNo ratings yet

- Poster Wouter Witzel Econaxe W201Document1 pagePoster Wouter Witzel Econaxe W201Andry HermawanNo ratings yet

- MSM Marketing Bulletin - Gas BlowerDocument18 pagesMSM Marketing Bulletin - Gas BlowerAndry HermawanNo ratings yet

- Mini Project Report IRABDocument10 pagesMini Project Report IRABNaveenkondi100% (1)

- Ac Motor Research PaperDocument4 pagesAc Motor Research Paperfvgcaatd100% (1)

- D50 60 70S-5 (Sb1101e05)Document401 pagesD50 60 70S-5 (Sb1101e05)goxmad100% (1)

- JCBMulcherDocument1 pageJCBMulcherayush bansalNo ratings yet

- 2008-2009 GM Magna Transfer Case Detailed Info, Bulletin # 1226Document10 pages2008-2009 GM Magna Transfer Case Detailed Info, Bulletin # 1226davidNo ratings yet

- Tonepad BigmuffDocument2 pagesTonepad BigmuffWasabiRockNo ratings yet

- Pistones SMCDocument72 pagesPistones SMCIsai AnguianoNo ratings yet

- Nad T743 GBDocument32 pagesNad T743 GBemehranNo ratings yet

- Ph27000Pri Engine (157F) : Valve Cover AssyDocument3 pagesPh27000Pri Engine (157F) : Valve Cover AssyAriel Rodrigo MuñozNo ratings yet

- Leviton VRS05-1L Installation ManualDocument2 pagesLeviton VRS05-1L Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Baker - 690981 PDFDocument24 pagesBaker - 690981 PDFAsep SuhermanNo ratings yet

- STC15F2K32S2 FeaturesDocument21 pagesSTC15F2K32S2 FeaturesJoserecon BonillaNo ratings yet

- fILE PERSIAPAN UKKDocument4 pagesfILE PERSIAPAN UKKLuqman Pramana SudibyaNo ratings yet

- Delta Technical Data Sheet PDFDocument4 pagesDelta Technical Data Sheet PDFNguyễn NgọcNo ratings yet

- CMOSIC For Current-Mode PWM Power Supply: Hiroshi MaruyamaDocument6 pagesCMOSIC For Current-Mode PWM Power Supply: Hiroshi MaruyamaMalfo10No ratings yet

- Hino 700 Exhaust Brake-Engine Retarder WireingDocument2 pagesHino 700 Exhaust Brake-Engine Retarder Wireingg.shien5150100% (1)

- 1VCP000138 1201Document91 pages1VCP000138 1201zhang1988No ratings yet

- x70 IdentifikasjonsplateDocument4 pagesx70 IdentifikasjonsplatepeterNo ratings yet

- And Power in Full Subtractor Circuit: Transistor Gating: Reduction of Leakage CurrentDocument11 pagesAnd Power in Full Subtractor Circuit: Transistor Gating: Reduction of Leakage CurrentBhupender KumawatNo ratings yet

- 3512 Diag - Engine - 1243-06 - SisDocument8 pages3512 Diag - Engine - 1243-06 - Sisshashank715No ratings yet

- Dem 20487 Syh-LyDocument14 pagesDem 20487 Syh-LyPreda AndreiNo ratings yet

- XRXS 566 CD XRVS 606 CD: Parts List For Portable CompressorsDocument162 pagesXRXS 566 CD XRVS 606 CD: Parts List For Portable CompressorsSales AydinkayaNo ratings yet

- 2.0 Fsi Engine 1Document16 pages2.0 Fsi Engine 1Mohd FairusNo ratings yet

- EX-150 Electronic Experiment Kit PDFDocument163 pagesEX-150 Electronic Experiment Kit PDFpkrajniNo ratings yet

- Byd DolphinDocument6 pagesByd DolphinGervásio OliveiraNo ratings yet

- Ferno 175 Fastener System User ManualDocument20 pagesFerno 175 Fastener System User ManualIvvete Bernal0% (1)

- Ford 4F27E & FNR5: FWD 4/5 SpeedDocument6 pagesFord 4F27E & FNR5: FWD 4/5 SpeedernestohjNo ratings yet

- Salisbury 40 Cal Arc Flash Protection Clothing Kit X-Large SALSK40RGXL - Salisbury Electrical SafetyDocument1 pageSalisbury 40 Cal Arc Flash Protection Clothing Kit X-Large SALSK40RGXL - Salisbury Electrical SafetyMohamed Shamnad محمد شمندNo ratings yet

- AC Drives Reliance ElectricDocument12 pagesAC Drives Reliance ElectricnmvikramNo ratings yet

- Yanmar - 3tna72lDocument194 pagesYanmar - 3tna72lTiago Campos100% (1)