Professional Documents

Culture Documents

Rivets Multi Grip Countersunk

Uploaded by

Israel OluwagbemiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rivets Multi Grip Countersunk

Uploaded by

Israel OluwagbemiCopyright:

Available Formats

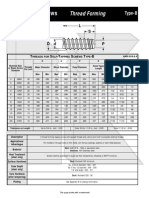

Aluminum Blind Rivet/

Steel Mandrel

Multi-Grip Countersunk Head Rivets

B

o

120 E

C A

D

COUNTERSUNK MULTI-GRIP ALUMINUM BODY /STEEL MANDREL BLIND RIVETS Avdel*

A B C D E Shear Tensile

Part Recom-

Length Head Diameter Head Height mended Strength Strength

Number Rivet Grip

Diameter Range Hole Size

Max Min Max Min Max Min Pounds Pounds

C-0412 1/8 .470 .410 .217 .198 .034 .026 .093-.250 .136 165 230

C-0414 1/8 .530 .480 .217 .198 .034 .026 .155-.312 .136 165 230

C-0416 1/8 .600 .530 .217 .198 .034 .026 .217-.375 .136 165 230

C-0514 5/32 .550 .490 .257 .238 .036 .028 .109-.312 .166 255 375

C-0615 3/16 .610 .520 .351 .343 .055 .047 .125-.312 .199 350 530

C-0621 3/16 .800 .710 .351 .343 .055 .047 .250-.500 .199 350 530

*Avdel Cherry Textron is the original writer of the multi-grip dimensions.

An aluminum blind fastener with a self-contained steel mandrel. The multi-grip rivet design differs from a standard blind rivet two

Description ways: (1) a section of the body shank has a slightly reduced outside diameter, and (2) the stem of the mandrel is pinched at a point

above the mandrel head. The rivet's head is countersunk at an angle of 120°.

Multi-grip rivets provide maximum clamping action over a full range of material thicknesses while using the same rivet length. This

Applications/ allows flexibility in design, cuts production costs and reduces inventories. The countersunk head style provides a smooth offside

Advantages surface and sufficient clearance for moving parts which pass over the rivet head. They should be used when fastening materials with

mechanical and physical properties similar to aluminum.

Rivet: Aluminum Alloy 5251 or equivalent alloy.

Material Mandrel: Low carbon steel with a choice of coating: black phosphate or zinc with yellow chromate.

Rivets shall have ultimate shear loads not less than the minimum ultimate shear loads specified for the applicable size given in the

Shear Strength above table.

Rivets shall have ultimate tensile loads not less than the minimum ultimate tensile loads specified for the applicable size given in the

Tensile Strength above table.

PART NUMBER COMPARISON - COUNTERSUNK MULTI-GRIP RIVETS

Kanebridge- Avdel Avex® - Kanebridge- Avdel Avex® - Pop® -

Zinc yellow mandrel Zinc yellow mandrel Black phos mandrel Black phos mandrel Plain steel mandrel

C-0412Y 1682-0412 C-0412B 1604-0412 AK41-44BS

C-0414Y 1682-0414 C-0414B 1604-0414 -

C-0416Y 1682-0416 - 1604-0416 -

C-0514Y 1682-0514 - 1604-0514 -

C-0615Y 1682-0615 C-0615B 1604-0615 -

C-0621Y 1682-0621 C-0621B 1604-0621 -

®Pop is a registered trademark of Pop Fastening Systems, Emhart Fastening Teknologies, a Black & Decker Company.

®Avex is a registered trademark of the Avdel Cherry Textron Corporation. Kanebridge’s rivets are not manufactured by or connected with the producers of Avex® or Pop® rivets.

This page prints with a watermark 193

You might also like

- Alloy Steel Socket Shoulder ScrewsDocument2 pagesAlloy Steel Socket Shoulder ScrewsShreenidhiNo ratings yet

- Armstrong Isolation ValveDocument4 pagesArmstrong Isolation ValveAnggaNo ratings yet

- Two-Valve Block & Bleed Manifolds: DescriptionDocument8 pagesTwo-Valve Block & Bleed Manifolds: Descriptiondibujante3No ratings yet

- Class 150Lb Rating R/F Cast Cartridge Filter: SDD/CCF/R15/STLDocument1 pageClass 150Lb Rating R/F Cast Cartridge Filter: SDD/CCF/R15/STLrob.careyNo ratings yet

- Gate ValvesDocument2 pagesGate ValvesArnold Ochochoque ArcosNo ratings yet

- Steel Bush Knuckle Chain Renold JeffreyDocument7 pagesSteel Bush Knuckle Chain Renold JeffreyJesus SansjNo ratings yet

- Maverick Valves CatalogueDocument84 pagesMaverick Valves Cataloguer4mms3sNo ratings yet

- 400a-Non-Rising Stem Resilient SeatedDocument2 pages400a-Non-Rising Stem Resilient SeatedNguyễn Chu ThànhNo ratings yet

- Grapa Tipo Pistola - MACLEAN AR-A0930Document1 pageGrapa Tipo Pistola - MACLEAN AR-A0930RogerNo ratings yet

- #3 Domed Head Plow Bolt: Earnest Technical BulletinDocument3 pages#3 Domed Head Plow Bolt: Earnest Technical BulletinNarvaxisNo ratings yet

- V4-CWD-A200: Double Door Check ValveDocument1 pageV4-CWD-A200: Double Door Check ValveArthur DeiparineNo ratings yet

- Cherry 1900 Bulbing Blind Rivet: SPS Fastener Division, ADocument4 pagesCherry 1900 Bulbing Blind Rivet: SPS Fastener Division, AДенис СергеевичNo ratings yet

- StdrillserratedDocument2 pagesStdrillserratedSaul AguilarNo ratings yet

- Thermocouple With Flange Thermowell Tapered & Adjustable Compensation FittingDocument1 pageThermocouple With Flange Thermowell Tapered & Adjustable Compensation Fittingmohan babuNo ratings yet

- Globe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"Document4 pagesGlobe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"dmitosNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- FLO DS 0006 Wafer Butterfly ValvesDocument4 pagesFLO DS 0006 Wafer Butterfly ValvesShubhajit ChakrabortyNo ratings yet

- FT Valvula Acero 300 LBS Crane 33xu.fDocument1 pageFT Valvula Acero 300 LBS Crane 33xu.fFernando CarreñoNo ratings yet

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- An800 6Document3 pagesAn800 6jcNo ratings yet

- Manual Valves Datasheet. Rev 1Document7 pagesManual Valves Datasheet. Rev 1eke23No ratings yet

- Power Team C-Series CylindersDocument2 pagesPower Team C-Series CylindersTitanplyNo ratings yet

- R/F - 150Lb Rating Cast Y'-Type Strainer: SDD/YFL/R15/STLDocument1 pageR/F - 150Lb Rating Cast Y'-Type Strainer: SDD/YFL/R15/STLNagLakshmananNo ratings yet

- Basket Strainer 2Document2 pagesBasket Strainer 2RAJASEKAR KingNo ratings yet

- DMP PDFDocument39 pagesDMP PDFberkahharianNo ratings yet

- Ms Blind Bolts: Alloy Steel and A-286 StainlessDocument19 pagesMs Blind Bolts: Alloy Steel and A-286 StainlessJuan Fernando Quintero BalcazarNo ratings yet

- Valv. Comp. Ansi 150 Crane Fig. 47xuDocument2 pagesValv. Comp. Ansi 150 Crane Fig. 47xujulio sanchez camonesNo ratings yet

- Ez Arc Brochure-14Document2 pagesEz Arc Brochure-14Shalom AvadovNo ratings yet

- Compact Wire Rope Isolators CR SeriesDocument16 pagesCompact Wire Rope Isolators CR SeriesKarimZianiNo ratings yet

- Lista de MaterialesDocument39 pagesLista de MaterialesCristian Ookami CcenchoNo ratings yet

- Spojki Za Doktorot Vo SolidworksDocument24 pagesSpojki Za Doktorot Vo SolidworksStamen KatardzievNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01cmpuckNo ratings yet

- 32 Koenig 2013Document1 page32 Koenig 2013shashibagewadiNo ratings yet

- Imi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"Document2 pagesImi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"SAM AZNo ratings yet

- Cobalt Catalog Forged-Chains-SprocketsDocument12 pagesCobalt Catalog Forged-Chains-SprocketsporometalNo ratings yet

- On-Off Valves Ball Side-Entry TopsideDocument2 pagesOn-Off Valves Ball Side-Entry TopsideshamekhalmaamariNo ratings yet

- Cast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscDocument3 pagesCast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscMina MagdyNo ratings yet

- 1 110 Gauge Shutoff ValveDocument2 pages1 110 Gauge Shutoff ValveAinayya alfatimahNo ratings yet

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- VB516SP2CDocument2 pagesVB516SP2CadelNo ratings yet

- ATLAS FM Full Metric Inserts CatalogDocument12 pagesATLAS FM Full Metric Inserts CatalogRajnish KumarNo ratings yet

- CS Ball Valve TM-590Document1 pageCS Ball Valve TM-590Hector Dario Tobon BenjumeaNo ratings yet

- RivetsDocument16 pagesRivetszayyin rizkiNo ratings yet

- Bollard Catalogue PDFDocument16 pagesBollard Catalogue PDFHaris PrasetiyoNo ratings yet

- Visual Inspection of WeldDocument102 pagesVisual Inspection of Weldyodie s sidabutarNo ratings yet

- KF Ball FloatingThreadedGroovedDocument20 pagesKF Ball FloatingThreadedGroovedBhupatiNo ratings yet

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLDocument1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLNagLakshmananNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- Del West: Ready-to-Ship ComponentsDocument12 pagesDel West: Ready-to-Ship ComponentsADNo ratings yet

- Butterfly ValvesDocument28 pagesButterfly ValvesLAWRENCENo ratings yet

- Gala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BDocument7 pagesGala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BChhomNo ratings yet

- CRANE-Ficha Tecnica-Valvula CompuertaDocument1 pageCRANE-Ficha Tecnica-Valvula CompuertaWillyam JiménezNo ratings yet

- TornilleriaDocument26 pagesTornilleriacorpSIG corpSIGNo ratings yet

- OSY Flanged X Grooved Ends 3299 300 FXGLFDocument1 pageOSY Flanged X Grooved Ends 3299 300 FXGLFmelashry2023No ratings yet

- Self Tapping ScrewsDocument1 pageSelf Tapping ScrewsGulfstream Data, IncNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Corvalis Vs Cirrus SR22Document4 pagesCorvalis Vs Cirrus SR22Israel OluwagbemiNo ratings yet

- Computational Challenges in High Angle of Attack Ow: August 2011Document9 pagesComputational Challenges in High Angle of Attack Ow: August 2011Israel OluwagbemiNo ratings yet

- XFlow2013 UserGuide v90Document203 pagesXFlow2013 UserGuide v90Israel OluwagbemiNo ratings yet

- A Study of Flap Management An Analysis of The Consequences of FLDocument17 pagesA Study of Flap Management An Analysis of The Consequences of FLAŞKIN FIRATNo ratings yet

- Prices: Incredible Four-Seat Comfort, Speed and CapacityDocument4 pagesPrices: Incredible Four-Seat Comfort, Speed and CapacityAndreasNo ratings yet

- XFlow2019x Refresh2 UserGuideDocument325 pagesXFlow2019x Refresh2 UserGuideIsrael OluwagbemiNo ratings yet

- Vans RV14FLY-e-02012019Document4 pagesVans RV14FLY-e-02012019Israel OluwagbemiNo ratings yet

- XFlow2019x Refresh2 TheoryGuideDocument32 pagesXFlow2019x Refresh2 TheoryGuideIsrael OluwagbemiNo ratings yet

- Conversion of A Volkswagen Engine For Aircraft Use PDFDocument4 pagesConversion of A Volkswagen Engine For Aircraft Use PDFIsrael OluwagbemiNo ratings yet

- Aluminum AlloyDocument1 pageAluminum AlloyMehmet SoysalNo ratings yet

- Ready. Set. IELTS. Idioms.Document45 pagesReady. Set. IELTS. Idioms.Renatochka BakirovaNo ratings yet

- Training SCLDocument60 pagesTraining SCLAlu menzikenNo ratings yet

- Snowflake Schema - JennyDocument2 pagesSnowflake Schema - JennyJennyNo ratings yet

- Gr4 Reading InterventionDocument2 pagesGr4 Reading InterventionEvelyn Del RosarioNo ratings yet

- Cross Cultural Management: Hana MaumetDocument32 pagesCross Cultural Management: Hana MaumetGiovanni Francesco PalmaNo ratings yet

- Angkasa Pura II - AR 2020 - 210813Document598 pagesAngkasa Pura II - AR 2020 - 210813Shreelalitha KarthikNo ratings yet

- NEBULIZATIONDocument2 pagesNEBULIZATIONMae ValenzuelaNo ratings yet

- Mad-Lib ExerciseDocument2 pagesMad-Lib Exercisejbk23100% (2)

- Phy Interface Pci Express Sata Usb31 Architectures Ver43 PDFDocument99 pagesPhy Interface Pci Express Sata Usb31 Architectures Ver43 PDFRaj Shekhar ReddyNo ratings yet

- Filcro - LabrevDocument19 pagesFilcro - LabrevKim ArniñoNo ratings yet

- Application Icx Sales ManagerDocument5 pagesApplication Icx Sales ManagerPersy LópezNo ratings yet

- Model Teaching CompetenciesDocument12 pagesModel Teaching CompetenciesTeachers Without BordersNo ratings yet

- ACCSA Module 1 - 8 Practice Dimensions & Skillsets of Addiction CounsellingDocument148 pagesACCSA Module 1 - 8 Practice Dimensions & Skillsets of Addiction Counsellingskye42817No ratings yet

- CostcoDocument12 pagesCostcoThảo Nguyên PhạmNo ratings yet

- Nutrition: DR Hiten KalraDocument81 pagesNutrition: DR Hiten KalraAmit SagarNo ratings yet

- Theory of Multiple Intelligences and WhyDocument7 pagesTheory of Multiple Intelligences and WhyEveNo ratings yet

- Social Change Theme in The Cherry Orchard - LitChartsDocument17 pagesSocial Change Theme in The Cherry Orchard - LitChartsShivashankar. DNo ratings yet

- FD72 Technical Manual 28.10.09Document74 pagesFD72 Technical Manual 28.10.09cavgsi16vNo ratings yet

- Sika Comfor PorefillerDocument5 pagesSika Comfor Porefillerrangarajan1989No ratings yet

- Vat Reg. CertificateDocument1 pageVat Reg. CertificateMaaz AzadNo ratings yet

- Leta 2022Document179 pagesLeta 2022Bigovic, MilosNo ratings yet

- DBMS NotesDocument6 pagesDBMS Notesᴠɪᴄɪᴏᴜs ᴄᴜʀsᴇNo ratings yet

- Business Tax ReviewerDocument22 pagesBusiness Tax ReviewereysiNo ratings yet

- Server Preparation Details LinuxDocument9 pagesServer Preparation Details Linuxbharatreddy9No ratings yet

- DX-790-960-65-17.5i-M: Electrical PropertiesDocument2 pagesDX-790-960-65-17.5i-M: Electrical PropertiesАлександрNo ratings yet

- Online Banking TCsDocument52 pagesOnline Banking TCsmaverick_1901No ratings yet

- Procreate GuideDocument283 pagesProcreate GuideDiego D'Andrea100% (2)

- Distress Manual PDFDocument51 pagesDistress Manual PDFEIRINI ZIGKIRIADOUNo ratings yet

- RCD PDFDocument6 pagesRCD PDFsanjay975No ratings yet