Professional Documents

Culture Documents

Premade Pouch 10 Questions

Uploaded by

adeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Premade Pouch 10 Questions

Uploaded by

adeCopyright:

Available Formats

Machine Guide

10 Premade Pouch

Machine Questions

What to ask when purchasing Premade

Pouch Packaging Machinery

10 Premade Pouch Machine Questions 1

Contents

1 Introduction

2 Question 1 What materials are used to construct the machine?

4 Question 2 How is the machine designed?

6 Question 3 How complex is the machine?

8 Question 4 What is the machine bag/size changeover process?

9 Question 5 Can multiple SKUs be packaged on one machine?

11 Question 6 Can the machine be used in dusty/wet environments?

12 Question 7 How durable are the machine components?

13 Question 8 What is involved in the package sealing process?

14 Question 9 Where is the (HMI) Human Machine Interface located ?

15 Question 10 Where is the machine’s control platform?

16 About Viking Masek

2 10 Premade Pouch Machine Questions

Introduction

Premade pouch fill and seal packaging, as its name

suggests, is a packaging method in which machines fill

preformed pouches with product and seal them closed.

This process is repeated, up to 200 bags per minute on

some high-end multi-lane models.

Consumer demand for premade have developed this guide to provide

pouches is increasing in many food and information for manufacturers and

non-food industries. Because of contract packagers interested in

their modern look, convenience, and streamlining their production operations

portability, many top manufacturers by incorporating premade pouch

and contract packagers are introducing packaging systems into their facilities.

premade pouch packaging machinery to

their production floor lineup. You can expect to learn the key design

aspects of premade pouch machines

With the beneficial help of continuous as well as the advantages they offer

technological advancements in the in optimizing production and ease of

packaging industry, manufacturers and use. When the time comes to make

contract packagers can now increase a purchasing decision, you will be

their efficiency and decrease occupied better prepared.

floor space by utilizing packaging lines

with modular rotary packaging systems

achieving a sleek, professional design

without incurring excessive costs. We

10 Premade Pouch Machine Questions 1

Question 1

What materials are used to

construct the machine?

2 10 Premade Pouch Machine Questions

The best premade pouch packaging machines

feature welded stainless steel frames and contact

parts. Stainless steel construction provides many

advantages. It has a high strength-to-weight

advantage, making it uniquely resistant to

corrosion, chemicals, and high heat at a reduced

thickness as compared to other materials.

Stainless steel packaging machines Another way to evaluate the quality of

are suitable for nearly any industry and a packaging machine’s construction

facility. Other construction materials is to look at the IP rating assigned to

such as iron or specialty alloys simply the machine’s enclosures. IP ratings, or

cannot match the corrosion resistance Ingress Protection Ratings, specify

of stainless steel. Iron, for example, will the environmental protection the

rust in reaction to oxygen and water, enclosure provides.

making it more brittle over time.

The higher the IP rating number, the

Stainless steel’s resilient properties more protection an enclosure provides

allow it to endure almost any conditions, against dust, liquids, and mechanical

from dusty shop environments to impacts. An IP55 rating is standard, but

highly sensitive applications that you may want an option to upgrade to

demand frequent cleanings with harsh IP65 for dairy specifications.

chemicals. This high-quality material

makes it the best long-term investment

for your facility.

10 Premade Pouch Machine Questions 3

Question 2

How is the machine designed?

Modular, open concept, and rotary machine

designs contain all the right elements for

efficient premade pouch packaging.

Modular Open Concept

allows easy service, maintenance allows for safe and easy machine

and ease of training for operators and cleaning and maintenance without

technicians. A modular machine is maneuvering around machine parts

also more aesthetically pleasing and or enclosures.

calming to the eye, which may sound

inconsequential, but many studies Rotary

have shown the impact of work designed in an ergonomic style and

environment design on an employee’s allow for a much cleaner, efficient

general emotional and mental health packaging process, while taking up

is substantial. minimal floor space.

4 10 Premade Pouch Machine Questions

The noise the machine makes while offer a truly unencumbered and safe

in operation is also an important operator experience.

factor to consider. Be sure to watch

the machine do its work. Initially, Lastly, premade pouch machines can

sturdiness can be evaluated simply by either be designed with mechanical

listening to and watching the machine or servo drives. While mechanical

in operation. A loud machine with lots of drives get the job done, they also have

vibrations will cause excess wear and their limitations.

tear on machine parts, which will equal

more maintenance and downtime Viking has developed proprietary

over the life of the equipment. As an premade pouch machine technologies

added benefit, a quieter machine that feature servo drives. Via position

provides a safer and less stressful feedback, servo driven machines

work environment for employees. feature smoother operation, better

accuracy, and a faster packaging

The best premade pouch machines process by as much as 50%.

also are designed with electrical and

pneumatic wiring hidden from view

in an unobtrusive fashion. Machines

with the wiring contained in its frame

10 Premade Pouch Machine Questions 5

Question 3

How complex is the machine?

When it comes to packaging machinery, less

is more and simpler is better. Unnecessary

complexity adds barriers to efficient production.

High-quality premade pouch item requirements for the production

packaging machines are designed parameter memory.

for ease-of-use, featuring an

accessible open design concept The machine’s production parameter

and a rotary configuration. memory should include:

• gripper size

A digital control system, preferably

• machine speed

with a touch screen human machine

• sealing temperature

interface (HMI), can store multiple

product formulas. This makes it easier • filling volume

for operators to enter packaging

configurations and parameters into the HMI control designs that appear in

system all at once. devices such as pin code payment

pads, self-checkout counters, and

The HMI can facilitate quick and easy airport ticket issuers also add value to

changeovers by including a few minimum plant safety, production, and operation.

6 10 Premade Pouch Machine Questions

Depending on system complexity, Premade pouch machinery requires

HMI features can include: less technical expertise to operate,

meaning training for your employees,

• streamlining communications with

(both existing and new) will be a much

sophisticated, smart messaging

easier task than with other packaging

equipment formats.

• displaying graphical content for a

more intuitive user experience

With an intuitive interface and

simple, modular design, operation

• customizing programs to reduce

and maintenance are much less

maintenance and training

technically complex.

• setting safety alarms for

equipment malfunctions

• lowering operation costs by

consolidating control panels

– all while minimizing the

need for space and labor.

10 Premade Pouch Machine Questions 7

Question 4

What is the machine bag/size

changeover process?

Premade pouch packaging machines have the

ability to change over to different bag styles or

sizes seamlessly, without any tools required.

The resulting decrease in changeover The changeover process for a well-

time and subsequent cost savings made machine can be accomplished in

helps companies optimize productivity, two simple steps.

production, and profitability for their

unique business. Changeover Process

1. push a button on the HMI

It also facilitates a shorter learning 2. load new bags into the feeding area

curve for new packaging line and

maintenance employees.

8 10 Premade Pouch Machine Questions

Question 5

Can multiple SKUs be packaged

on one machine?

10 Premade Pouch Machine Questions 9

A versatile premade pouch machine can

effectively replace the need for multiple

packaging lines.

With easy tool-free changeover, the Premade pouch machine design

same machine can quickly and easily versatility and simplicity allows

switch among different bag styles and manufacturers and contract packagers

sizes to package a variety of products to effectively and efficiently handle a

with unique features (like zippers) and proliferation of SKUs on one machine

custom bag shapes in a relatively short in lieu of many, thereby providing a

period of time. cost effective alternative to operating

multiple machines in-house.

10 10 Premade Pouch Machine Questions

Question 6

Can the machine be used in

dusty/wet environments?

There are several design elements that can

protect premade pouch machines from dusty,

wet, or otherwise harsh environments.

A robust stainless steel frame allows airborne particulates when packaging

the machinery to operate in almost any that can cause major maintenance

facility, while upgrades to electrical issues if allowed to penetrate into vital

and pneumatic enclosures with a moving machine parts.

higher IP Rating protect vital machine

components from potentially harmful While dust and moisture may not be

dust and moisture in the environment. a concern for some manufacturers

and contract packagers at the current

This is especially important for industries moment, recognizing the implications of

that package powder or liquid products differing packaging environments is key

like drink mixes, ground coffee, or to creating a custom packaging solution

sauces. Even some solid products like best suited to your operations, both now

pasta and dry pet food can release and in the future.

10 Premade Pouch Machine Questions 11

Question 7

How durable are the

machine components?

In a quality rotary premade pouch packaging

process the machine needs to grip the pouch and

lift it into the packaging area of the machine.

These gripper arms will be tasked with If vital machine parts are constructed

holding the pouch as it completes every with plastic or other non-durable

step of the packaging process, including materials, these parts can require

product filling. frequent maintenance and must be

replaced at shorter intervals.

When a premade pouch is filled, the

extra package weight places stress Time spent maintaining the machine,

upon these grippers, so they must be while necessary, should be kept to

able withstand heavier package fills an absolute minimum to maximize

without sagging. throughput and plant efficiency. Inferior

construction has a deleterious effect on

The best premade pouch equipment production line efficiency.

features a grip strength of at least 10 kg

or 22 pounds. This grip strength must

stand the test of time, which necessitates

a durable, robust build.

12 10 Premade Pouch Machine Questions

Question 8

What is involved in the package

sealing process?

Creating a strong package seal is one of the most

important parts of any packaging process.

One small leak from an improperly That’s why the best premade pouch

sealed package can spell disaster for machines feature a two-step sealing

your product. process.

A poor seal can result in: Two-Step Sealing:

• degradation 1. A strong package seal is

• spoilage created with heat seal jaws.

• oxidation

2. A cooling seal jaw rapidly

• contamination

decreases the temperature

of the seal area, solidifying a

clean, strong package seal.

10 Premade Pouch Machine Questions 13

Question 9

Where is the (HMI) Human

Machine Interface located ?

The HMI is an integral part of the premade

pouch machine operation and has the ability

to move as needed to satisfy different needs.

When cleaning or changing over the When attached to the machine but

machine, the ability to move the HMI placed at the end of a swivel arm, the

out of the way makes the process HMI offers much more flexibility than

unencumbered and more efficient. one that is fixed in place or rests on the

floor separately from the machine.

14 10 Premade Pouch Machine Questions

Question 10

Where is the machine’s

control platform?

A programmable logic controller (PLC) is a

digital computer that can be programmed to

control packaging machinery.

A human can interact with the PLC to Modern premade pouch machinery can

program the machine through the HMI come standard with a certain controls

(human machine interface). platform like Siemens, but should also

offer upgrades to a different platform if

Basically, the PLC reads inputs from the customer prefers.

various sensors, executes a user-

defined program for machine operation, Allen Bradley is the most widely used

and writes digital and analog outputs to in the United States and Europe,

machine elements for optimal operation. and thus has become a preferred

controls platform for premade pouch

Many companies produce quality PLCs packaging machinery.

for packaging machinery.

Internationally competitive packaging

The primary PLC suppliers for OEMs: OEMs like Viking offer their reliable

premade pouch machinery with Allen

• United States

Bradley controls.

Allen Bradley, Siemens, & Schneider

• Europe

Allen Bradley & Siemens

10 Premade Pouch Machine Questions 15

About Viking Masek

Viking Packaging Technologies manufactures, sells, and services

flexible packaging machinery for food and non-food markets

worldwide. With over two decades of industry experience, we offer

a broad range of Simplex, Duplex, and Quadplex Premade Pouch

packaging machines – each with completely customizable features –

to ensure every customer receives a solution that matches their unique

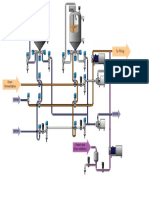

needs. Our baggers integrate seamlessly with weighers and fillers, infeed

and outfeed equipment, metal detectors and X-ray systems, cartoners

and casepackers, and other automated packaging equipment. Viking

Masek has flexible packaging covered from Tote to Pallet™.

Viking Masek Packaging

40 Woodland Court, Oostburg, WI 53070

P 920-564-5051

http://www.vikingmasek.com

You might also like

- Beckwood Guide To Press AutomationDocument16 pagesBeckwood Guide To Press AutomationOARIASCONo ratings yet

- 2018 Applications Industry4Document123 pages2018 Applications Industry4Ridwan MerduNo ratings yet

- MEM 5 Plant visit explores automation advantages and integration tipsDocument20 pagesMEM 5 Plant visit explores automation advantages and integration tipsSalah Eldin AbdallaNo ratings yet

- Process Selection and Facility Layout: Teaching NotesDocument25 pagesProcess Selection and Facility Layout: Teaching Notesyasin arafatNo ratings yet

- Iti Bangalore Report AbstractDocument9 pagesIti Bangalore Report AbstractSagar NagarajNo ratings yet

- Design and Construction of An Automated Adjustable-Can Foil Sealing MachineDocument9 pagesDesign and Construction of An Automated Adjustable-Can Foil Sealing Machinepharmafactoryegstore 2021No ratings yet

- MASE lABDocument3 pagesMASE lABAli Aslam100% (1)

- Oem Ap114a en PDocument2 pagesOem Ap114a en PCARLOSWAR101No ratings yet

- SSPL Catalog Regular - Resize PDFDocument25 pagesSSPL Catalog Regular - Resize PDFusman379No ratings yet

- 4 Axis Pick and Place RobotDocument6 pages4 Axis Pick and Place Robotsjcit.bracNo ratings yet

- Sustainable Packaging Machine Thanks To The Digital Twin - AutomationDocument3 pagesSustainable Packaging Machine Thanks To The Digital Twin - AutomationMartinNo ratings yet

- Empaques 4Document131 pagesEmpaques 4MARIA ALEJANDRA LOPEZ REVELONo ratings yet

- Project Report on Industrial Automation SystemsDocument15 pagesProject Report on Industrial Automation SystemsAtul KirtiNo ratings yet

- Oem Ap149 - en PDocument4 pagesOem Ap149 - en PdangkhuyenmaiNo ratings yet

- Office Machines and Equipment ComparisonDocument5 pagesOffice Machines and Equipment ComparisonXtian AmahanNo ratings yet

- IRJET - Automatic Weighing and PackagingDocument10 pagesIRJET - Automatic Weighing and PackagingDaniel EmekaNo ratings yet

- Sanitary Design Guidelines - Email #3EDocument2 pagesSanitary Design Guidelines - Email #3EBaja Consulting Group BCGNo ratings yet

- Erect, Seal & Palletize System for BottlesDocument2 pagesErect, Seal & Palletize System for BottlesMarco PoloNo ratings yet

- Process StructuresDocument38 pagesProcess StructuresPayalmba19No ratings yet

- Od Intervention at Oswal Electricals Pvt. LTD: Submitted By: Manu M Nair AM - BU.P2MBA18029Document7 pagesOd Intervention at Oswal Electricals Pvt. LTD: Submitted By: Manu M Nair AM - BU.P2MBA18029Manish NairNo ratings yet

- Mapping To Industrial Dynamics Oct15 - 202Document3 pagesMapping To Industrial Dynamics Oct15 - 202th.idthichaiNo ratings yet

- Automatoc Stamping MachineDocument5 pagesAutomatoc Stamping Machinesamadhan khaireNo ratings yet

- EtmDocument16 pagesEtmchavhansachin029No ratings yet

- IT Extra 13 April 2020Document20 pagesIT Extra 13 April 2020neilradcliffeNo ratings yet

- Design and Fabrication of Portable Material Packing MachineDocument12 pagesDesign and Fabrication of Portable Material Packing MachineTJPRC PublicationsNo ratings yet

- Hubs EngineeringDocument8 pagesHubs EngineeringHubs EngineeringNo ratings yet

- Bus 2C 12 Operations Management: Dr.A.Abirami / OmDocument17 pagesBus 2C 12 Operations Management: Dr.A.Abirami / OmBalujagadishNo ratings yet

- Advanced Robotics in Fucture PDFDocument15 pagesAdvanced Robotics in Fucture PDFNPMYS23No ratings yet

- Vision Guided Robotics SolutionsDocument12 pagesVision Guided Robotics SolutionsNg Wei LihNo ratings yet

- YouQuanTex BD - ENDocument12 pagesYouQuanTex BD - ENAndy YouQuanTexNo ratings yet

- speechDocument9 pagesspeechJovie LopinaNo ratings yet

- MFG Chapter 11Document19 pagesMFG Chapter 11Thanakrit RUNGRUANGSATENo ratings yet

- DL Texturing OBA DTY enDocument28 pagesDL Texturing OBA DTY enJuan Francisco Rubio JovelNo ratings yet

- Automation in Automobile Industry: Presented byDocument17 pagesAutomation in Automobile Industry: Presented bySnehal PawarNo ratings yet

- Jose Antonio Moreno - Danobat ScoopDocument6 pagesJose Antonio Moreno - Danobat ScoopÂrbaoui MedNo ratings yet

- Product Storage Automation SystemDocument14 pagesProduct Storage Automation SystemDurgesh KollaNo ratings yet

- INNOVATIVE MANUFACTURING IDEASDocument5 pagesINNOVATIVE MANUFACTURING IDEASSwagatika Mohanty100% (1)

- Advancingindustry 40 Inplasticswithhydraulicfluids 1540892358026Document14 pagesAdvancingindustry 40 Inplasticswithhydraulicfluids 1540892358026Sly LumbaNo ratings yet

- Case StudyDocument15 pagesCase StudyPankaj KapseNo ratings yet

- Production Management: Weightage: 1 Short Question + 1 Essay Question 18 MarksDocument19 pagesProduction Management: Weightage: 1 Short Question + 1 Essay Question 18 MarkssatyaNo ratings yet

- Mechanical Transmission System Saves TimeDocument2 pagesMechanical Transmission System Saves TimePablo Zven MtzNo ratings yet

- Alegro - Engl 1Document16 pagesAlegro - Engl 1COVAI BALAJINo ratings yet

- Operation Management - I (MFT4CCOQ01) Individual Assignment - IDocument9 pagesOperation Management - I (MFT4CCOQ01) Individual Assignment - IComplete AramNo ratings yet

- Oracle Work in Process Interview QuestionsDocument3 pagesOracle Work in Process Interview QuestionsPritesh Mogane100% (3)

- Lecture 6 Overview of Material Handling and Management (Part II)Document10 pagesLecture 6 Overview of Material Handling and Management (Part II)sharifah atiqahNo ratings yet

- Industrial Automation: Conveyors, Machines Increase Quality, FlexibilityDocument3 pagesIndustrial Automation: Conveyors, Machines Increase Quality, FlexibilityRudresh RakeshNo ratings yet

- 2021 01 Elobau-Product-Overview E-SinglepageDocument16 pages2021 01 Elobau-Product-Overview E-SinglepagePurnama AbhieNo ratings yet

- Operations PlanningDocument3 pagesOperations PlanningWesley KisiNo ratings yet

- Differences Between Product and Process LayoutsDocument4 pagesDifferences Between Product and Process LayoutsConstance ChoiNo ratings yet

- Collaborative Vs Industrial RobotDocument5 pagesCollaborative Vs Industrial RobotHartadi KurniaNo ratings yet

- Lower Costs Workforce Productivity & Retention Healthier Inventory Sustainable "Green" PracticesDocument4 pagesLower Costs Workforce Productivity & Retention Healthier Inventory Sustainable "Green" PracticesShaifali RawatNo ratings yet

- Calalog Automatiz 2014Document282 pagesCalalog Automatiz 2014Paun AlNo ratings yet

- Chapter 7 - Conversion Cycle P4Document26 pagesChapter 7 - Conversion Cycle P4Joana TrinidadNo ratings yet

- Additive Manufacturing and Future of Automated FactoryDocument30 pagesAdditive Manufacturing and Future of Automated FactoryBhramith KNo ratings yet

- Om2 TPSDocument21 pagesOm2 TPSharischarmNo ratings yet

- Efficient Separation with Pusher CentrifugesDocument12 pagesEfficient Separation with Pusher CentrifugesdanielmercadoiqNo ratings yet

- IJERTV6IS120029Document9 pagesIJERTV6IS120029RagavgloryfireNo ratings yet

- CIM Handbook: The Opportunities for Rationalisation Opened up by the Acquisition and Integration of Computer AutomationFrom EverandCIM Handbook: The Opportunities for Rationalisation Opened up by the Acquisition and Integration of Computer AutomationM. MesinaNo ratings yet

- AL Dairy Cleaning in PlaceDocument1 pageAL Dairy Cleaning in PlaceadeNo ratings yet

- AL Dairy Buffer StorageDocument1 pageAL Dairy Buffer StorageadeNo ratings yet

- Effect Storage To Viscosity SCMDocument10 pagesEffect Storage To Viscosity SCMadeNo ratings yet

- Application LN2 PouchDocument1 pageApplication LN2 PouchadeNo ratings yet

- MicroTrack Manual v-0Document91 pagesMicroTrack Manual v-0Marlon Arguedas GuzmànNo ratings yet

- Audiovisual TouringBrochure SLAMLexDocument44 pagesAudiovisual TouringBrochure SLAMLexantonioNo ratings yet

- Switch BoxDocument15 pagesSwitch BoxKscf KhereijiNo ratings yet

- POWERCELL PDX BrochureDocument8 pagesPOWERCELL PDX BrochureFredie LabradorNo ratings yet

- Terminal Block Diaphragm Switch: D1T, D2T SeriesDocument2 pagesTerminal Block Diaphragm Switch: D1T, D2T Serieschris a gutierrexNo ratings yet

- Ma-Wa58-1X 5 GHZ Broadband Subscriber Antenna: SpecificationsDocument1 pageMa-Wa58-1X 5 GHZ Broadband Subscriber Antenna: SpecificationsAnnBlissNo ratings yet

- NEOM-NDS-SPC-015 - 01.00 - Neutral Earthing Resistor (NER) SpecificationDocument15 pagesNEOM-NDS-SPC-015 - 01.00 - Neutral Earthing Resistor (NER) Specificationcawoc96196No ratings yet

- Comparison of Nema and Iec StandardsDocument1 pageComparison of Nema and Iec Standardsacortez3051No ratings yet

- EPC48300/2900 Series: Key FeaturesDocument2 pagesEPC48300/2900 Series: Key FeaturesGustavo de la Cruz100% (1)

- Manual Sps 4001b Single Probe Autocalibration Sequencer Rosemount en 1127750Document70 pagesManual Sps 4001b Single Probe Autocalibration Sequencer Rosemount en 1127750cocot 666No ratings yet

- EN (IEC) 61439 1 - 2 - en PDFDocument27 pagesEN (IEC) 61439 1 - 2 - en PDFasimjkhanNo ratings yet

- Safety Switch Brochure DET845B - Final PDFDocument36 pagesSafety Switch Brochure DET845B - Final PDFYousif MohammedNo ratings yet

- Series V Cooling Towers SpecificationsDocument6 pagesSeries V Cooling Towers SpecificationsGeelissonNo ratings yet

- MAX LimitSwitch45 DataSheet 2Document4 pagesMAX LimitSwitch45 DataSheet 2Luz ArazolaNo ratings yet

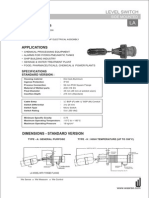

- Level Switch: ApplicationsDocument2 pagesLevel Switch: ApplicationsFranco M. CaverzanNo ratings yet

- Guide For Electric Service and Meter InstallationsDocument54 pagesGuide For Electric Service and Meter InstallationsRyan MallettNo ratings yet

- Brochure Plexpower Iec Fiber Panel Appleton en 5958274 PDFDocument5 pagesBrochure Plexpower Iec Fiber Panel Appleton en 5958274 PDFPuuje PurevjargalNo ratings yet

- WatLow - Immersion Heaters - 2018Document154 pagesWatLow - Immersion Heaters - 2018Victor PomboNo ratings yet

- S8600B, C, H, M S8610B, C, H, M S8670D, E, J, K Intermittent Pilot Gas Ignition ControlDocument16 pagesS8600B, C, H, M S8610B, C, H, M S8670D, E, J, K Intermittent Pilot Gas Ignition ControlmariopilarNo ratings yet

- MTL8000 1-1 Overview PDFDocument2 pagesMTL8000 1-1 Overview PDFapisituNo ratings yet

- Deep Sea 8721 ManualDocument72 pagesDeep Sea 8721 ManualJuan Carlos Guerra LugoNo ratings yet

- MicroLogix 1762-If4 Analog Input ModuleDocument28 pagesMicroLogix 1762-If4 Analog Input ModuleMárcio SantanaNo ratings yet

- Compliance Statement For SLCC (Aacm)Document11 pagesCompliance Statement For SLCC (Aacm)Prashant SharmaNo ratings yet

- Manual Millennium II Multi Channel Transmitters Rosemount en 71578Document70 pagesManual Millennium II Multi Channel Transmitters Rosemount en 71578davidNo ratings yet

- PGVAC4036MOBILE03Document2 pagesPGVAC4036MOBILE03aidin.ashtariNo ratings yet

- KLIPPON POK 161609 EX DatasheetDocument5 pagesKLIPPON POK 161609 EX DatasheetMarcos Vinicios Lima dos SantosNo ratings yet

- 06-427 Cheetah Xi and CyberCat 50 Enclosure InstallationDocument2 pages06-427 Cheetah Xi and CyberCat 50 Enclosure InstallationMarcos Vinicius Salvador TeixeiraNo ratings yet

- Camden CI-1KFS Data SheetDocument2 pagesCamden CI-1KFS Data SheetJMAC SupplyNo ratings yet

- GuardPLC 8-Digital Inputs and 8-Digital OutputsDocument20 pagesGuardPLC 8-Digital Inputs and 8-Digital OutputsTarun BharadwajNo ratings yet

- Allen-Bradley 30.5mm 3-Hole EnclosureDocument2 pagesAllen-Bradley 30.5mm 3-Hole EnclosureCARLOS COANo ratings yet