Professional Documents

Culture Documents

Tasks

Uploaded by

Martin.c.figueroa0 ratings0% found this document useful (0 votes)

7 views3 pagesTraining basics

Original Title

tasks

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTraining basics

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesTasks

Uploaded by

Martin.c.figueroaTraining basics

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

TRAINING TO

„LEAN BASICS” MODULE

PART I

1. Run „Waste Walk” in the area of your choice and identify

as much loss as possible.

2. Find 3 ways that will eliminate or reduce the identified

loss

3. Ask 10 GEMBA questions to 5 operators (in the area of

your choice) then review the responses. Are the

responses „normal”?

PART II

1. Run analysis of usefulness of all tools and objects in the area of your choice. Remove unused items

from the workplace. Then, for the items left, find a place and mark it. Take pictures before and after.

2. Measure processing times performed by operators divided into activities on a production line of your

choice. What are the differences in work load? Which operator is the most overloaded and which one

the least? You can use „Time analysis DEMO” tool available in materials for download.

3. Count Work in Progress (WiP) between the workstations of a selected production line. Answer the

question – is there a one piece flow? If not - what actions should be taken to reduce the amount by

half?

4. Identify the root cause of a loss on the production line using the „5 x Why” analysis.

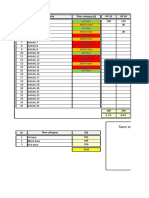

5. Using the Kanban Board schedule tasks for a Sprint (weeks 1-4) and write them down on post-it notes

in the ‘to do” column. When a task changes status, move a post-it note to the relevant column then

summarize how many tasks you managed to complete any why.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- GEHO Positive Displacement Pumps MCU Introduction Training CourseDocument12 pagesGEHO Positive Displacement Pumps MCU Introduction Training CourseMartin.c.figueroaNo ratings yet

- ML in Mineral ProcessingDocument24 pagesML in Mineral ProcessingMartin.c.figueroaNo ratings yet

- Drop Ball Testing: Background and Standard ProcedureDocument6 pagesDrop Ball Testing: Background and Standard ProcedureMartin.c.figueroaNo ratings yet

- Time AnalysisDocument5 pagesTime AnalysisMartin.c.figueroaNo ratings yet

- Chapter 5Document20 pagesChapter 5Martin.c.figueroaNo ratings yet

- 2016 ML For Mineral ProcessingDocument37 pages2016 ML For Mineral ProcessingMartin.c.figueroaNo ratings yet

- A Simple Definition of MLDocument4 pagesA Simple Definition of MLMartin.c.figueroaNo ratings yet

- MS2019 - Progress Report For LCT and Cleaner Flotation Test ResultsDocument9 pagesMS2019 - Progress Report For LCT and Cleaner Flotation Test ResultsMartin.c.figueroaNo ratings yet

- Label CuoxDocument781 pagesLabel CuoxMartin.c.figueroaNo ratings yet

- Sampling-27 1Document5 pagesSampling-27 1Martin.c.figueroaNo ratings yet

- Minerals: Semi-Autogenous Wet Grinding Modeling With CFD-DEMDocument17 pagesMinerals: Semi-Autogenous Wet Grinding Modeling With CFD-DEMMartin.c.figueroaNo ratings yet

- Processes: Research On Non-Uniform Wear of Liner in SAG MillDocument11 pagesProcesses: Research On Non-Uniform Wear of Liner in SAG MillMartin.c.figueroaNo ratings yet

- Theory of SamplingDocument4 pagesTheory of SamplingMartin.c.figueroaNo ratings yet

- Optimization of The Design of AG Mill Shell Liners at The Gol-E-Gohar Concentration PlantDocument11 pagesOptimization of The Design of AG Mill Shell Liners at The Gol-E-Gohar Concentration PlantMartin.c.figueroaNo ratings yet

- Reporting JK Drop Weight and SMC Test ResultsDocument5 pagesReporting JK Drop Weight and SMC Test ResultsMartin.c.figueroaNo ratings yet

- Slurry Pooling and Transport Issues in SAG Mills PDFDocument10 pagesSlurry Pooling and Transport Issues in SAG Mills PDFMartin.c.figueroaNo ratings yet

- Hydrocyclone BrochureDocument8 pagesHydrocyclone BrochureMartin.c.figueroaNo ratings yet