Professional Documents

Culture Documents

BB 2

Uploaded by

SaidFerdjallah0 ratings0% found this document useful (0 votes)

8 views1 pageOriginal Title

bb2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageBB 2

Uploaded by

SaidFerdjallahCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

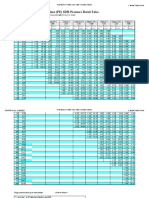

Aspen Exchanger Design and Rating Shell & Tube V12.

2

File: Printed: 10/08/2022 at 21:43:59

Overall Summary

1 Size 600 X 3600 mm Type BEM Hor Connected in 1 parallel 1 series

2 Surf/Unit (gross/eff/finned) 92,2 / 87,1 / m² Shells/unit 1

3 Surf/Shell (gross/eff/finned) 92,2 / 87,1 / m²

4 Simulation PERFORMANCE OF ONE UNIT

5 Shell Side Tube Side Heat Transfer Parameters

6 Process Data In Out In Out Total heat load kW 4504,2

7 Total flow kg/h 86557 337871 Eff. MTD/ 1 pass MTD °C 27,76 / 27,81

8 Vapor kg/h 19018 53770 337871 337431 Actual/Reqd area ratio - fouled/clean 1 / 1

9 Liquid kg/h 67540 32787 0 440

10 Noncondensable kg/h 0 0 Coef./Resist. W/(m²-K) m²-K/W %

11 Cond./Evap. kg/h 34752 440 Overall fouled 1862,5 0,00054

12 Temperature °C 13,18 43,31 65 50 Overall clean 1862,5 0,00054

13 Bubble Point °C -30,1 -31,05 -14,49 -14,99 Tube side film 3418,3 0,00029 54,49

14 Dew Point °C 69,16 68,72 64,99 64,94 Tube side fouling 0 0

15 Vapor mass fraction 0,2197 0,6212 1 0,9987 Tube wall 21535,7 5E-05 8,65

16 Pressure (abs) kPa 2535,025 2499,321 9661,327 9627,13 Outside fouling 0 0

17 DeltaP allow/cal kPa 40 35,705 60 34,199 Outside film 5052,5 0,0002 36,86

18 Velocity m/s 1,88 3,95 11,35 10,14

19 Liquid Properties Shell Side Pressure Drop kPa %

20 Density kg/m³ 492,78 482,81 991,47 Inlet nozzle 0,458 1,3

21 Viscosity cp 0,1014 0,0927 0,5444 InletspaceXflow 2,036 5,78

22 Specific heat kJ/(kg-K) 2,777 2,927 4,306 Baffle Xflow 21,126 59,94

23 Therm. cond. W/(m-K) 0,0903 0,0801 0,6432 Baffle window 5,233 14,85

24 Surface tension dynes/cm 6,8 5,7 67,7 OutletspaceXflow 3,92 11,12

25 Molecular weight 41,82 47 18,02 Outlet nozzle 2,474 7,02

26 Vapor Properties Intermediate nozzles

27 Density kg/m³ 36,09 40,54 111,83 125,03 Tube Side Pressure Drop kPa %

28 Viscosity cp 0,0109 0,0113 0,0169 0,0172 Inlet nozzle 2,037 5,7

29 Specific heat kJ/(kg-K) 2,173 2,229 2,938 3,153 Entering tubes 3,546 9,92

30 Therm. cond. W/(m-K) 0,0264 0,0269 0,0444 0,0444 Inside tubes 23,96 67,01

31 Molecular weight 27,3 33,31 24,21 24,22 Exiting tubes 4,931 13,79

32 Two-Phase Properties Outlet nozzle 1,281 3,58

33 Latent heat kJ/kg 280,8 263,1 2218,1 2223,8 Intermediate nozzles

34 Heat Transfer Parameters Velocity / Rho*V2 m/s kg/(m-s²)

35 Reynolds No. vapor 94418,18 256278,2 1110899 1091975 Shell nozzle inlet 2,07 560

36 Reynolds No. liquid 35980,71 19119,84 45,03 Shell bundle Xflow 1,88 3,95

37 Prandtl No. vapor 0,89 0,94 1,12 1,22 Shell baffle window 1,9 3,98

38 Prandtl No. liquid 3,12 3,39 3,64 Shell nozzle outlet 7,61 3598

39 Heat Load kW kW Shell nozzle interm

40 Vapor only 0 -2,2 m/s kg/(m-s²)

41 2-Phase vapor 639,1 -4228,7 Tube nozzle inlet 6,37 4539

42 Latent heat 2622,2 -268,9 Tubes 11,35 10,14

43 2-Phase liquid 1242,8 -4,3 Tube nozzle outlet 5,69 4055

44 Liquid only 0 0 Tube nozzle interm

45 Tubes Baffles Nozzles: (No./OD)

46 Type Plain Type Single segmental Shell Side Tube Side

47 ID/OD mm 14,83 / 19,05 Number 11 Inlet mm 1 / 355,6 1 / 457,2

48 Length act/eff m 3,6 / 3,4009 Cut(%d) 39,69 Outlet 1 / 273,05 1 / 457,2

49 Tube passes 1 Cut orientation V Intermediate / /

50 Tube No. 428 Spacing: c/c mm 255 Impingement protection None

51 Tube pattern 30 Spacing at inlet mm 432,8

52 Tube pitch mm 23,81 Spacing at outlet mm 418,14

53 Insert None

54 Vibration problem (HTFS / TEMA) Yes / RhoV2 violation No

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- TEG Transfer PumpDocument22 pagesTEG Transfer PumpSaidFerdjallahNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Expansion Loop FotDocument7 pagesExpansion Loop FotSaidFerdjallahNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Techetch ComDocument2 pagesTechetch ComSaidFerdjallahNo ratings yet

- WhatsnewPF V1403Document2 pagesWhatsnewPF V1403SaidFerdjallahNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Thin and Thick-Walled Stress Analysis of Pressure VesselDocument31 pagesThin and Thick-Walled Stress Analysis of Pressure VesselSaidFerdjallahNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Carotek Filtration Strainers Selection Guide 06042020Document3 pagesCarotek Filtration Strainers Selection Guide 06042020SaidFerdjallahNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Whatispiping ComDocument2 pagesWhatispiping ComSaidFerdjallahNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Turbo Expander CompressorDocument8 pagesTurbo Expander CompressorSaidFerdjallahNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- What Is Modal Analysis and Why Is It Necessary Caesar II Piping Modal Analysis Steps With PDFDocument8 pagesWhat Is Modal Analysis and Why Is It Necessary Caesar II Piping Modal Analysis Steps With PDFSaidFerdjallah100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 05 StimulatingDocument11 pages05 StimulatingSaidFerdjallahNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 15 Gate ValvesDocument2 pages15 Gate ValvesSaidFerdjallahNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- BB 1Document1 pageBB 1SaidFerdjallahNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Simulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsDocument14 pagesSimulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsSaidFerdjallahNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- JT Assembly English Letter ADocument2 pagesJT Assembly English Letter ASaidFerdjallahNo ratings yet

- Polyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsDocument24 pagesPolyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsSaidFerdjallahNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Improvement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventDocument7 pagesImprovement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventSaidFerdjallahNo ratings yet

- Asme CodesDocument14 pagesAsme CodesSaidFerdjallahNo ratings yet

- Samson: Improved Control Valve Sizing For Multiphase FL OwDocument8 pagesSamson: Improved Control Valve Sizing For Multiphase FL OwSaidFerdjallahNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- What Is Winterization? Requirements For The Basic Design of Winterization SystemsDocument7 pagesWhat Is Winterization? Requirements For The Basic Design of Winterization SystemsSaidFerdjallahNo ratings yet

- A Guide of Refinery ProcessDocument32 pagesA Guide of Refinery ProcessSaidFerdjallahNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- DOCUMENT TITLE: Instrument IndexDocument4 pagesDOCUMENT TITLE: Instrument IndexSaidFerdjallahNo ratings yet

- Dokumen - Tips Inspection Checklist Distillation ColumnDocument5 pagesDokumen - Tips Inspection Checklist Distillation ColumnSaidFerdjallah100% (1)

- Referenc Es To "Confined Space" in Division 2/Q Welding, Cutting, and BrazingDocument4 pagesReferenc Es To "Confined Space" in Division 2/Q Welding, Cutting, and BrazingSaidFerdjallahNo ratings yet

- M389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisDocument52 pagesM389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisSaidFerdjallahNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Schx4007 Mass Transfer LabDocument60 pagesSchx4007 Mass Transfer LabAhmed AliNo ratings yet

- Tutorial-Lateral Earth PressureDocument4 pagesTutorial-Lateral Earth PressuremanarajNo ratings yet

- Stress Analysis of A Bicycle SpannerDocument3 pagesStress Analysis of A Bicycle SpannerkramanNo ratings yet

- 3 States of Matter and Changes of StateDocument21 pages3 States of Matter and Changes of StateAlyssa Mae Dapadap1996No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Chapter # 3Document64 pagesChapter # 3Pharo TotNo ratings yet

- Calculate Shelland Tube For PSV Fire CaseDocument5 pagesCalculate Shelland Tube For PSV Fire CaseJohanRodriguezNo ratings yet

- Geas Mod 17Document4 pagesGeas Mod 17Denaiya Watton LeehNo ratings yet

- Calculating The System Head PDFDocument9 pagesCalculating The System Head PDFIrfanshah2013No ratings yet

- Instruksi Kerja Holiday TestDocument10 pagesInstruksi Kerja Holiday Testzaenal arifinNo ratings yet

- Centrifugal PumpDocument4 pagesCentrifugal Pumpanil chejaraNo ratings yet

- Pagano Fontanella Sica Desideri2010SFDocument14 pagesPagano Fontanella Sica Desideri2010SFIsabela BalanNo ratings yet

- Cooling TowersDocument3 pagesCooling TowersThiruvilan Arakkonam MohanNo ratings yet

- Air Diffusion Performance Index (ADPI) of Diffusers For Heating ModeDocument21 pagesAir Diffusion Performance Index (ADPI) of Diffusers For Heating ModeAlbert Aromin EngrNo ratings yet

- Lecture 3 Shear Strength of Soil Part 1Document32 pagesLecture 3 Shear Strength of Soil Part 1F.a.AlfredThomNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Double Pipe Heat Exchanger - SsDocument72 pagesDouble Pipe Heat Exchanger - SsNathanian100% (2)

- EddBE2011 260-264 WahalathantriDocument6 pagesEddBE2011 260-264 WahalathantrikrishnanunniNo ratings yet

- Fluid Machinery (RME-601)Document13 pagesFluid Machinery (RME-601)gaurav pandey1212No ratings yet

- CHAPTER 6 Particle TheoryDocument7 pagesCHAPTER 6 Particle TheoryEunice Xiiao WennNo ratings yet

- ACC-performance-enhancement H ReuterDocument48 pagesACC-performance-enhancement H Reuterbaca88No ratings yet

- Study of Combustion in Industrial Ceramic Tile Manufacturing KilnsDocument4 pagesStudy of Combustion in Industrial Ceramic Tile Manufacturing KilnsMalith MadushanNo ratings yet

- Gas Turbine Performance by Rainer KurzDocument16 pagesGas Turbine Performance by Rainer KurzSulzerRuudNo ratings yet

- Knovel Steam TablesDocument27 pagesKnovel Steam TablesRafael Rodriguez MedinaNo ratings yet

- 5.deflections Using Energy Methods PDFDocument47 pages5.deflections Using Energy Methods PDFking burgosNo ratings yet

- Hydroballistics ModelingDocument373 pagesHydroballistics Modelinggaman leeNo ratings yet

- Hardy Cross TutorialDocument16 pagesHardy Cross TutorialNurul Shaheera50% (2)

- Les Photos de Matérieles de ForagesDocument18 pagesLes Photos de Matérieles de Foragesعبد العزيز مروى100% (1)

- Un Symmetrical Bending and Shear CentreDocument11 pagesUn Symmetrical Bending and Shear CentreanilNo ratings yet

- Series Pegasus: Air ConditionerDocument76 pagesSeries Pegasus: Air ConditionerMarouane OubaidiNo ratings yet

- Ems TutorialDocument43 pagesEms TutorialJohn Eric Balarao Ferranco33% (3)