Professional Documents

Culture Documents

ALAS - Queenie Marie - Module 7 Review

Uploaded by

Buffle qwee0 ratings0% found this document useful (0 votes)

5 views3 pagesOriginal Title

ALAS_Queenie Marie_Module 7 Review

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views3 pagesALAS - Queenie Marie - Module 7 Review

Uploaded by

Buffle qweeCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Identification and modeling of process barriers

Implementing lean manufacturing in small and medium-size enterprises

Critique Paper

Major Ideas

This research will shed light on the factors contributing to process

barriers that inhibit small and medium-sized firms from implementing lean

manufacturing. Small and medium-sized businesses are essential in bringing

wealth and prosperity to society. Many big firms increasingly outsource to

small and medium-sized enterprises (SMEs). Such initiatives compel SMEs to

adopt the same competitive strategy as large businesses. Total quality

management, Six Sigma, and lean manufacturing are commonly used

competitive approaches in large organizations. As a result, the study indicated

that it is critical to develop competitive tactics that SMEs may adopt. This

article identifies significant process bottlenecks such as high rejection rates,

frequent breakdowns, and employee absenteeism for lean manufacturing

deployment in SMEs.

Findings

According to the study's findings, intense competition and evolving

technology have resulted in a shortened product life cycle during the preceding

decade. Because of this phenomenon, every new product introduced to the

market is brimming with great features. This is supported by introducing new

mobile phone models with high-tech features such as video conferencing and

online browsing. This implies that prior incarnations of a product become

obsolete extremely quickly. This change means that large firms can no longer

afford to swiftly construct facilities to develop a new product and earn a profit.

Large organizations are now looking to SMEs for assistance with their

workloads.

Relevance/Contribution

The barriers to implementing lean manufacturing have been extensively

researched during the preceding decade. However, there needs to be more

precise data to support the assertion that this variable impedes the seamless

adoption of lean manufacturing in SMEs. As a result, more study into the

process barriers to implementing lean manufacturing in SMEs is needed.

Considering the SEM output and deleting the unnecessary route from the

present model can lead to a better model fit. Choosing a model change based

on the modification indices necessitates considerable caution. In order to select

the optimal model, caution was utilized in this investigation. Furthermore, the

high rejection rate, employee absenteeism, and frequent breakdowns

discovered by this study are three major issues that are significant process

barriers for lean adoption inside SMEs.

Strengths/Weaknesses

Implementing global manufacturing techniques such as lean requires

more than simply the correct equipment and processes. Top management may

significantly impact how a plan to overcome these obstacles is developed,

implemented, and successfully dispersed throughout companies. Practitioners

will benefit from being familiar with the material offered in this article,

including identifying process bottlenecks and their contributing variables for

lean to be effectively applied in SMEs. Based on these process barriers and the

discussion of their relevant aspects, a preliminary road map is provided to

assist SMEs in proposing a plan to overcome these obstacles to adopt lean in

SMEs effectively.

Opinions

Small and medium-sized firms (SMEs) contribute significantly to

economic growth yet frequently struggle to survive. A factory, for example,

would frequently experiment with new technologies and procedures to ensure

the long-term viability of its production system. Adopting lean manufacturing

principles is one such initiative, which assists small and medium-sized firms

(SMEs) in creating things with added value while decreasing costs and

optimizing profits. Adopting lean in small and medium-sized organizations

(SMEs) is challenging. Small firms were long ignored, and specialist studies on

the issue were rarely done. When we consider the statistics and information we

have on the economic relevance of small firms, we see that they are numerous

and account for a large share of the total value generated in the non-financial

company economy.

Potential Future Research Ideas

Managers in the field should examine their lean implementation plans

and how well they are integrated into their broader strategies. They will also be

able to prioritize the few resources required for future lean efforts. This

exploratory research should shed light on small enterprises' latent potential

and give a variety of viable productivity-boosting tactics. Some of the

conclusions presented were unexpected, while others were consistent with

earlier studies and shed light on the subject in innovative ways. More work

could be done to bring these models into practice; however, the research that

arises will aid in the testing and validating process barrier models.

References:

Matt, Dominik & Rauch, Erwin. (2012). Implementation of Lean Production in

Small Sized Enterprises. Procedia CIRP. 12.

10.1016/j.procir.2013.09.072.

Qureshi, K. Mewada, B. Alghamdi, S. Almakayeel, N. Qureshi, M. Mansour, M.

(2022). Accomplishing Sustainability in Manufacturing System for Small

and Medium-Sized Enterprises (SMEs) through Lean Implementation.

https://www.mdpi.com/2071-1050/14/15/9732/pdf

Ramadas T. Satish K.P. (2017). Identification and modeling of process barriers

Implementing lean manufacturing in small and medium-size enterprises.

https://www.emerald.com/insight/2040-4166.htm

You might also like

- GarnicaDocument5 pagesGarnicaBuffle qweeNo ratings yet

- Research 2Document6 pagesResearch 2Buffle qweeNo ratings yet

- GaminoDocument9 pagesGaminoBuffle qweeNo ratings yet

- BarcenasDocument5 pagesBarcenasBuffle qweeNo ratings yet

- BES Q3 Week 1Document36 pagesBES Q3 Week 1Buffle qweeNo ratings yet

- Dropping FormDocument1 pageDropping FormBuffle qweeNo ratings yet

- Jacquiline ODocument1 pageJacquiline OBuffle qweeNo ratings yet

- NameDocument1 pageNameBuffle qweeNo ratings yet

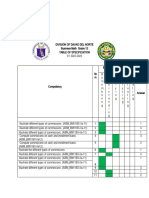

- NEW Brigada Eskwela CommitteeDocument11 pagesNEW Brigada Eskwela CommitteeBuffle qweeNo ratings yet

- New Action Plan BrigadaDocument2 pagesNew Action Plan BrigadaBuffle qweeNo ratings yet

- ALAS - Queenie Marie - Module-3 - ReviewDocument4 pagesALAS - Queenie Marie - Module-3 - ReviewBuffle qweeNo ratings yet

- TOS sECOND qUARTERDocument3 pagesTOS sECOND qUARTERBuffle qweeNo ratings yet

- BE Area 25 Alas Accomp ReportDocument5 pagesBE Area 25 Alas Accomp ReportBuffle qweeNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- International Trade Law in Nigeria by IsochukwuDocument12 pagesInternational Trade Law in Nigeria by IsochukwuVite Researchers100% (1)

- TNC Grab Deals MerchantDocument2 pagesTNC Grab Deals MerchantRuchita JainNo ratings yet

- JIT & Backflush CostingDocument5 pagesJIT & Backflush CostingMaureen LobinNo ratings yet

- Module 1 International MarketingDocument6 pagesModule 1 International Marketingmark david sabella100% (2)

- Indian Construction CostsDocument33 pagesIndian Construction CostsSarthak ShuklaNo ratings yet

- Fisa de Lucru 1 Ka-ChingDocument5 pagesFisa de Lucru 1 Ka-ChingMihaela EneNo ratings yet

- Factor Tilts and Asset Allocation: Javier EstradaDocument14 pagesFactor Tilts and Asset Allocation: Javier EstradaLoulou DePanamNo ratings yet

- Obstacles in Doing Business GloballyDocument14 pagesObstacles in Doing Business GloballySTAR CHINEMANo ratings yet

- Deliverable 14 - Statutory Financial Statements Redachem Industries Maghreb V08042022Document3 pagesDeliverable 14 - Statutory Financial Statements Redachem Industries Maghreb V08042022Loubna MikouNo ratings yet

- Foreign Person's U.S. Source Income Subject To Withholding: Copy BDocument2 pagesForeign Person's U.S. Source Income Subject To Withholding: Copy BshamlaNo ratings yet

- Ch07 Mini Case DisneyDocument9 pagesCh07 Mini Case DisneyRahil VermaNo ratings yet

- 10Document24 pages10Abhishek GuptaNo ratings yet

- Corporate Governance in India: Case Study of Satyam Manpreet KaurDocument3 pagesCorporate Governance in India: Case Study of Satyam Manpreet KaurJill RoseNo ratings yet

- Fabm1 2ND ST PDFDocument2 pagesFabm1 2ND ST PDFRoda ReyesNo ratings yet

- Internet Dec22Document1 pageInternet Dec22Hari HaranNo ratings yet

- 7bddec72-70b0-402c-9ffd-c7f1165fb590Document338 pages7bddec72-70b0-402c-9ffd-c7f1165fb590More's KaushikNo ratings yet

- Pages From Marx - Capital - Vol - 3Document2 pagesPages From Marx - Capital - Vol - 3Abelard BonaventuraNo ratings yet

- Positioning A Long Island BankDocument8 pagesPositioning A Long Island BankChirag MakhijaNo ratings yet

- Case Study - Ten Thousand VillagesDocument7 pagesCase Study - Ten Thousand VillagesDana XiaNo ratings yet

- 形式发票PROFORMA INVOICEDocument2 pages形式发票PROFORMA INVOICEBau2NineNo ratings yet

- Practice Paper Pre-Board Xii Acc 2023-24Document13 pagesPractice Paper Pre-Board Xii Acc 2023-24Pratiksha Suryavanshi100% (1)

- AccountStatement 3Document19 pagesAccountStatement 3MD Mahbubur Rahman T0% (1)

- Loan 5,000,000 Interest 5.0% First EMI Month Jun 2011 Tenure 120 EMI 53,033 Planned EMI 66,075Document6 pagesLoan 5,000,000 Interest 5.0% First EMI Month Jun 2011 Tenure 120 EMI 53,033 Planned EMI 66,075mbastudy2010No ratings yet

- Corporate Finance - Berk - 4CE - SolutionsDocument4 pagesCorporate Finance - Berk - 4CE - SolutionsZhichang ZhangNo ratings yet

- 81601CP575Notice 1692149599160Document3 pages81601CP575Notice 1692149599160FGHJJ FDJFHDNo ratings yet

- IntermediateAccounting (PPE)Document5 pagesIntermediateAccounting (PPE)belle crisNo ratings yet

- Case Study Tax102Document6 pagesCase Study Tax102Edrymae TobiasNo ratings yet

- XyzzzzzzzzzDocument13 pagesXyzzzzzzzzzAmish GangarNo ratings yet

- Group 11 - Section A - BRM Project Proposal - Premium HotelDocument9 pagesGroup 11 - Section A - BRM Project Proposal - Premium Hotelpeacock yadavNo ratings yet

- Ugc Net Set Commerce Paper - 2 & 3Document282 pagesUgc Net Set Commerce Paper - 2 & 3UJJWALNo ratings yet