0% found this document useful (0 votes)

514 views8 pagesExample Manual Handling Risk Assessment - Moving Equipment

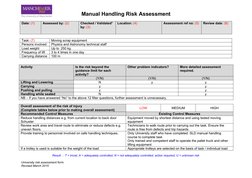

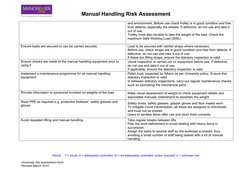

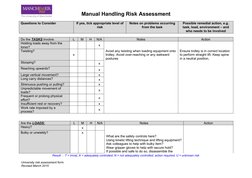

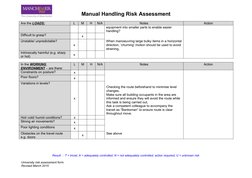

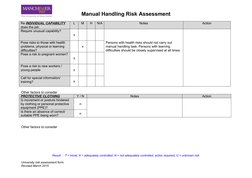

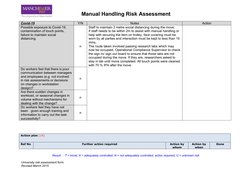

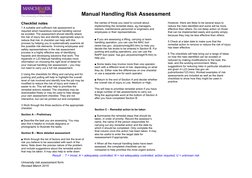

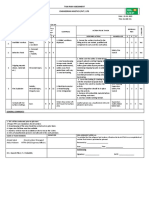

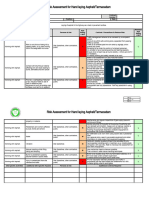

The document summarizes a manual handling risk assessment for moving scrap equipment weighing up to 250kg by technical staff. It identifies risks like carrying heavy loads over long distances. Controls include using tested moving equipment, training on safe techniques, inspecting equipment, and taking regular breaks. However, risks like carrying heavy loads long distances require further assessment and additional controls.

Uploaded by

fanehhh 10Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

514 views8 pagesExample Manual Handling Risk Assessment - Moving Equipment

The document summarizes a manual handling risk assessment for moving scrap equipment weighing up to 250kg by technical staff. It identifies risks like carrying heavy loads over long distances. Controls include using tested moving equipment, training on safe techniques, inspecting equipment, and taking regular breaks. However, risks like carrying heavy loads long distances require further assessment and additional controls.

Uploaded by

fanehhh 10Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd