Professional Documents

Culture Documents

Risk Assessment: Act/Hse/Ra 001: Confined Space Working

Uploaded by

brandedwahid0 ratings0% found this document useful (0 votes)

31 views1 pageRa

Original Title

21confinedspaceworkingriskassessmenttemplates-200616094507

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views1 pageRisk Assessment: Act/Hse/Ra 001: Confined Space Working

Uploaded by

brandedwahidRa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

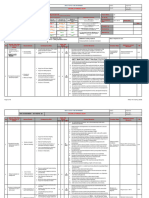

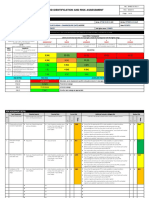

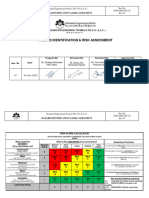

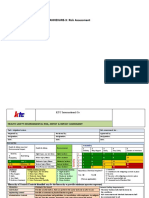

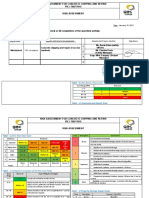

HEALTH SAFETY AND ENVIRONMENT Author: Approved:

Issued: Rev. Date:

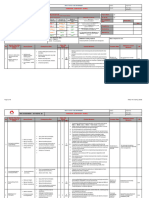

RISK ASSESSMENT: ACT/HSE/RA 001 CONFINED SPACE WORKING

Revision: 0

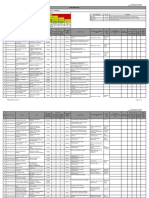

RISK SCORE CALCULATOR Project Name: xxx

Use the Risk Score Calculator to Determine the Level of Risk of each Hazard

What is the LIKELIHOOD of an occurrence? Hierarchy of Controls RA Ref No.: xxx

What w ould be the

CONSEQUENCE Frequent/Almost certain (5) Rarely (1) Can the hazard be Elim inated or removed

Continuous or will happen

Often (4) Likely (3) Possible (2) Less than once every 5 RA compilation

of an occurrence be? 6 to 12 times a year 1 to 5 times a year Once every 5 years from the w ork place? Review date:

frequently years Date:

Catastrophic (5) Can the product or process be substituted for Date:

High 25 High 20 High 15 Medium 10 Medium 5

Multiple Fatalities a less hazardous alternative?

Serious (4) Can the hazard be engineered aw ay w ith

High 20 High 16 High 12 Medium 8 Low 4 Compiled by:

Class 1 single fatality guards or barriers?

Moderate (3)

Can Adm inistration Controls be adopted

Class2 (AWI or LTI) or Class 1 High 15 High 12 Medium 9 Medium 6 Low 3 Reviewed by:

Permanently disabling effects

I.e. procedures, job rotation etc.

Minor (2)

Medical attention needed, no work Medium 10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipm ent & Approved by:

restrictions. MTI Clothing be w orn to safe guard against

Insignificant (1) hazards?

FAI

Medium 10 Medium 4 Low 3 Low 2 Low 1

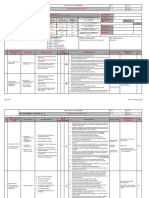

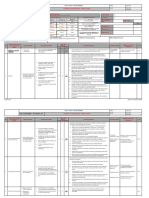

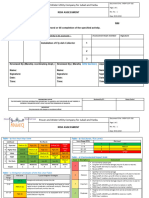

Overall Task Details Relevant Applicable MAS:

Additional Training required: NOC’s Required for task:

Working in area designated as a confined space 00246 – Excavations;

00233 – Lift Shafts

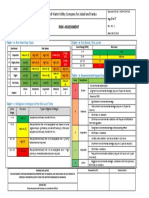

Specific Task Step Initial Risk

Additional Control

No (In sequence of Hazard Details Consequence/Risk Rating Control Measures Residual Risks RR

Measures

works) P S RR

i. All existing utility service drawings reviewed for known service details and

Risk of asphyxia;

Planned confined position;

Presence of live

space work in areas Risk of explosion due to gas ignition; ii. NOC and Utility provider and HLG permits to be completed, unique

underground services;

where live services number added and recorded in log;

may be present Services not in area Risk of flooding of confined space;

20 iii. All services clearly communicated to all workers at briefings and TBT’s,

1 including: specified on drawings; 4 4 LOW

Risk of hazardous waste entering HIGH signed off and recorded;

Water;

Presence of confined space due to live sewerage; iv. Permit/NOC/JSEA/Approved design Drawings copies to be with task

Sewerage;

unmarked services; supervisor in work area for review;

Gas; Risk of vehicles / Plant entering

confined space; v. Suitable training undertaken for operatives;

PRIOR TO ENTRY

i. Permit to be issued & gas monitoring undertaken if required before works

commence;

ii. No works above, as in lift shafts etc.;

Confined space iii. Adequate air circulation & lighting to be maintained in work areas;

Excess or lack of oxygen;

working – iv. Equipment which may release excess oxygen or carbon monoxide gases

Supervision to constantly

Deep excavations; Presence of Toxic gases; shall not be used in confined space areas without adequate extraction;

Workers not monitor workers;

Tanks; Ingress of water or other substances; v. Local weather forecast should be noted to watch for heavy rains which

Vessels; adhering to

may cause flooding; Regular TBT’s & Trainings to

Manholes; Workers required to Explosion due to build-up of gases; vi. Special consideration to be given to any hot works or work using toxic

requirements;

20 be given on working Confined

2 NDRC pits; work in confined Sudden water ingress into excavation; 4 5 substances inside a confined space; space; Low

High

Bridge decks; space; vii. Materials to be stored well away from confined space area; Gas detector not

Pipework; Collapse of worker; calibrated Gas detector to be calibrated

viii. Top man to be appointed at the entry of the confined space area as to standards and

Sewerage; Restricted emergency evacuation; required, regular contact with workers in confined space;

resulting in

manufacturers

Lift shafts; incorrect reading

Musculoskeletal disorders; ix. Workers connected to lifeline, leading to outside confined space; recommendations.

Ducting;

x. Rescue drills to be undertaken as required to ensure rescue procedure is

Etc.

communicated and understood;

xi. Workers should be physically fit and competent to enter and undertake

the work in confined spaces.

xii. Rotation of workers if area cramped / difficult to move;

Page 1 of 1 HSEQ -Rev-01(Aug-2018)

You might also like

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- Risk AssessmentDocument13 pagesRisk AssessmentDisha Shah100% (3)

- Compliance Risk Assessment TemplateDocument13 pagesCompliance Risk Assessment Templateczar castillo100% (1)

- SCC5-4000F Single ShaftDocument15 pagesSCC5-4000F Single ShaftudelmarkNo ratings yet

- Best of The Photo DetectiveDocument55 pagesBest of The Photo DetectiveSazeed Hossain100% (3)

- Differential Calculus ExamDocument6 pagesDifferential Calculus ExamCaro Kan LopezNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument6 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPearl TeresaNo ratings yet

- JB Pumping Pty LTDDocument2 pagesJB Pumping Pty LTDJB PumpingNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPRASAD6219No ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Saravana0% (1)

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardAffin RoyNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardSaravanaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- 13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558Document6 pages13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558test fypNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneKhalid KhalidNo ratings yet

- Rev-01-Mariner WorkDocument40 pagesRev-01-Mariner Workrohit kumarNo ratings yet

- 31.0.9 ALR - Loading & Off-Loading TruckDocument5 pages31.0.9 ALR - Loading & Off-Loading TruckGerrit100% (1)

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- Risk Assessment Guidance: Hazard Severity (A) Likelihood of Occurrence (B)Document3 pagesRisk Assessment Guidance: Hazard Severity (A) Likelihood of Occurrence (B)Ahmad Syauqi SuhairiNo ratings yet

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerritNo ratings yet

- 31.0.12 ALR - Traffic Control by FlagmanDocument3 pages31.0.12 ALR - Traffic Control by FlagmanGerrit100% (1)

- Risk Assessment For Structural Concretes Works at Birkat Al Awamer Logistic ParkDocument22 pagesRisk Assessment For Structural Concretes Works at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Jsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.Document67 pagesJsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.jafar mohdNo ratings yet

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- Context - General Risk AssessmentDocument14 pagesContext - General Risk AssessmentAngeloNo ratings yet

- Risk Assessment Guidance: Hazard Severity Likelihood of OccurrenceDocument10 pagesRisk Assessment Guidance: Hazard Severity Likelihood of OccurrenceSaleem AkhtarNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- Site Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkDocument26 pagesSite Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Risk Assessment Fitout SalonDocument19 pagesRisk Assessment Fitout SalonVision ConceptNo ratings yet

- Sample of JHA - Roofing Top Installation Rev 2Document5 pagesSample of JHA - Roofing Top Installation Rev 2vajiravel407No ratings yet

- SF 011 Hazard Risk AseessmentDocument3 pagesSF 011 Hazard Risk AseessmentShahid RazaNo ratings yet

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazNo ratings yet

- HIRARC TemplateDocument2 pagesHIRARC TemplateIzham ZainalNo ratings yet

- Bubas RA 2013Document4 pagesBubas RA 2013vilashni prasadNo ratings yet

- Blank Risk Assessment TemplateDocument4 pagesBlank Risk Assessment TemplateMNo ratings yet

- SFSDFDocument6 pagesSFSDFali shahNo ratings yet

- Baseline Risk Assessment1 PDFDocument25 pagesBaseline Risk Assessment1 PDFRico100% (2)

- RA Excessive Noise .Vibration.Document11 pagesRA Excessive Noise .Vibration.Ndifor Dinho0% (1)

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- International Building Systems Factory Co. LTDDocument6 pagesInternational Building Systems Factory Co. LTDMohammad Imtiaz AliNo ratings yet

- Hazard Identification and Risk Assessment FormDocument4 pagesHazard Identification and Risk Assessment FormAli Al-GhamghamNo ratings yet

- Risk Assessment Concrete Cutting - 01Document1 pageRisk Assessment Concrete Cutting - 01kapsarcNo ratings yet

- Risk Assessment 004 NGSCHDocument2 pagesRisk Assessment 004 NGSCHsheraaz87100% (1)

- Instructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Document4 pagesInstructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Abdelrahman N. AliNo ratings yet

- Risk Assement UpdatedDocument10 pagesRisk Assement Updatedashwin0% (1)

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- Risk Assesment Generic Tender Despatch Electrical DepotDocument10 pagesRisk Assesment Generic Tender Despatch Electrical DepotanishavanloggerenbergNo ratings yet

- Risk Assessment ContDocument4 pagesRisk Assessment Contdevnraj 09No ratings yet

- 5 Why Root Cause Corrective ActionsDocument13 pages5 Why Root Cause Corrective Actionsalex1123No ratings yet

- Welcome To TÜV Rheinland Vietnam: Risk AssessmentDocument50 pagesWelcome To TÜV Rheinland Vietnam: Risk AssessmentTruong Quang HuyNo ratings yet

- Risk Analysis - Bangalore 190404Document7 pagesRisk Analysis - Bangalore 190404Rakesh SNo ratings yet

- HIRA - Construction of Ball Handling Pit Rev-00 - TILL EXCAVATIONDocument28 pagesHIRA - Construction of Ball Handling Pit Rev-00 - TILL EXCAVATIONBhagat DeepakNo ratings yet

- Installation of CollectorsDocument20 pagesInstallation of CollectorsShah MuzzamilNo ratings yet

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- Chemical Risk Assessment FormDocument7 pagesChemical Risk Assessment FormCamilo piconNo ratings yet

- Cafe Risk Assessment XDocument6 pagesCafe Risk Assessment Xpaul bladesNo ratings yet

- Compliance Risk Assessment TemplateDocument13 pagesCompliance Risk Assessment TemplateMariano HernánNo ratings yet

- Ra Concrete Chipping 7514Document5 pagesRa Concrete Chipping 7514Charles DoriaNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- Micronet TMRDocument316 pagesMicronet TMRHaithem BrebishNo ratings yet

- Eureka Math Grade 2 Module 3 Parent Tip Sheet 1Document2 pagesEureka Math Grade 2 Module 3 Parent Tip Sheet 1api-324573119No ratings yet

- Journal Articles: Types of JournalsDocument4 pagesJournal Articles: Types of JournalsOtieno SteveNo ratings yet

- Asme b16.3 (1998) Malleable Iron Threaded FittingsDocument30 pagesAsme b16.3 (1998) Malleable Iron Threaded FittingsMarcos RosenbergNo ratings yet

- Material Safety Data Sheet: - AdsealDocument12 pagesMaterial Safety Data Sheet: - Adsealwuhan lalalaNo ratings yet

- Amine Processing Unit DEADocument9 pagesAmine Processing Unit DEAFlorin Daniel AnghelNo ratings yet

- Practical Applications of Electrical ConductorsDocument12 pagesPractical Applications of Electrical ConductorsHans De Keulenaer100% (5)

- PDFDocument3 pagesPDFvaliNo ratings yet

- TV Antenna Tower CollapseDocument4 pagesTV Antenna Tower CollapseImdaad ChuubbNo ratings yet

- Useful Methods in CatiaDocument30 pagesUseful Methods in CatiaNastase Corina100% (2)

- Wind Turbines - I. Al-BahadlyDocument664 pagesWind Turbines - I. Al-Bahadlykevin_leigh_1No ratings yet

- Elerick Ron Cynthia 1983 SouthAfricaDocument4 pagesElerick Ron Cynthia 1983 SouthAfricathe missions networkNo ratings yet

- Beer Lambert'S Law: Dr. Swastika Das Professor of ChemistryDocument19 pagesBeer Lambert'S Law: Dr. Swastika Das Professor of ChemistryShabanaNo ratings yet

- Bai Tap Av 12 Thi Diem Unit TwoDocument7 pagesBai Tap Av 12 Thi Diem Unit TwonguyenngocquynhchiNo ratings yet

- Things You Can Do at Burnham ParkDocument2 pagesThings You Can Do at Burnham ParkBcpo TeuNo ratings yet

- Crown BeverageDocument13 pagesCrown BeverageMoniruzzaman JurorNo ratings yet

- The Art of Street PhotographyDocument13 pagesThe Art of Street PhotographyDP ZarpaNo ratings yet

- A Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixDocument12 pagesA Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixPraveen KumarNo ratings yet

- 120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnDocument9 pages120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnAlex TranNo ratings yet

- Letter Writing: An Informative Powerpoint About LetterDocument11 pagesLetter Writing: An Informative Powerpoint About LetterMalik KamranNo ratings yet

- Mang-May-Tinh - 03a.-Dns1 - (Cuuduongthancong - Com)Document52 pagesMang-May-Tinh - 03a.-Dns1 - (Cuuduongthancong - Com)Anh Quân TrầnNo ratings yet

- S O S Services Alert Level Help Sheet - REFERENCIALESDocument20 pagesS O S Services Alert Level Help Sheet - REFERENCIALESDavid Poma100% (1)

- Adigrat University: College of Engineering and Technology Department of Chemical EnginneringDocument39 pagesAdigrat University: College of Engineering and Technology Department of Chemical EnginneringSeid Aragaw100% (1)

- Kamapehmilya: Fitness Through Traditional DancesDocument21 pagesKamapehmilya: Fitness Through Traditional DancesValerieNo ratings yet

- Laporan Keuangan TRIN Per Juni 2023-FinalDocument123 pagesLaporan Keuangan TRIN Per Juni 2023-FinalAdit RamdhaniNo ratings yet

- Acc 106 Account ReceivablesDocument40 pagesAcc 106 Account ReceivablesAmirah NordinNo ratings yet

- Modular ResumeDocument1 pageModular ResumeedisontNo ratings yet