Professional Documents

Culture Documents

Afex - Caterpillar 798ac

Afex - Caterpillar 798ac

Uploaded by

Cesar Torres RojasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Afex - Caterpillar 798ac

Afex - Caterpillar 798ac

Uploaded by

Cesar Torres RojasCopyright:

Available Formats

6031 Oak Forest Drive

Raleigh, NC 27616

(919) 781-6610

info@afexsystems.com

SYSTEM SPECIFICATION Weight:

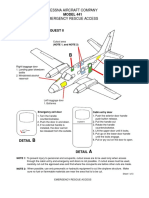

VEHICLE OVERVIEW

1375000 lb (623689 kg

Capacity: 410 yd3 / 313 m3

CATERPILLAR CAT C175-16

Engine(s): 1

3500 HP / 2609 kW

798 AC Diesel: 1300 gal (4920 L)

Mining Truck Hydraulic: 385 gal (1457 L)

RECOMMENDED AFEX SYSTEM CONFIGURATION

ENGINE TIER IV TIER II / TIER III ADDITIONAL HARDWARE RECOMMENDATIONS

Fire sleeve for hoses in protected area

Dry Chemical 3x60 lb. 3x60 lb.

1 Remote actuator(s)

2 Portable extinguisher(s)

+ Liquid Agent 2x5 gal. 2x5 gal.

CAT Product Link integration

SYSTEM NOTE: Dual agent systems combine the fast knockdown properties of A:B:C dry chemical powder with the suppression and cooling properties of the AFEX liquid

agent for greater effectiveness and to reduce the chance of fire reflash.

For electric drive trucks, a standalone manually actuated liquid agent system can be used for protection of the resistor grid box.

SYSTEM FEATURES

Satisfies NFPA 17, Chapter 5.7.2.1: Supervision of electrically or pneumatically operated automatic systems shall be provided unless

Control Unit specifically waived by the authority having jurisdiction.

Satisfies NFPA 17, Chapter 9.9.7: At least one easily accessible manual actuator or operating device shall be provided for use by the

Firing Mechanism equipment operator.

Satisfies NFPA 17, Chapter 9.9.8: An additional manual actuator or operating device shall be located so that it is in the path of egress and

Remote Actuator operable from ground level.

Satisfies NFPA 17, Chapter 5.5.2: Where systems protect hazards that have flowing flammable or combustible fluids or gases, the systems

Engine Shutdown shall be provided with automatic means to ensure shutoff of power and fuel valves upon operation of the extinguishing systems.

INSTALLATION CONSIDERATIONS

The guidelines below are minimum recommendations. The system may include additional nozzles or sensors that should be used to address additional fire risks that are

identified in the fire risk assessment. Linear wire may also be used for detection. Special attention should be paid to certain hazard areas such as, but not limited to,

turbochargers, exhausts, hydraulic connections to pumps, valves and tanks, transmissions, starters, alternators, and additional fuel and heat sources.

TOTAL DRY NOZZLES: 33

18 engine compartment 3 rear axle

Dry Distribution

6 alternator

6 rear hydraulics

TOTAL LIQUID NOZZLES: 4

Liquid Distribution 4 turbochargers and exhaust

(if recommended above)

TOTAL SENSORS: 9

5 engine compartment

Detection 2 transmission

(choose one method)

2 rear hydraulics

TOTAL LINEAR WIRE: 120 ft.

INSTALLATION NOTE: For maximum effectiveness, dry chemical nozzles should be placed above the spray path of the liquid agent nozzles.

This information is only a guideline and does not provide definitive rules or specifications. Due to variations in vehicle models and accessories, the actual installation may vary from that listed above. All installations should

include a detailed fire risk analysis as described by NFPA 122 and the AFEX service manual. The purpose of a fire suppression system is to mitigate fire damage to the equipment. The system cannot be designed or

expected to extinguish all fires. As with all mechanical equipment, AFEX Fire Suppression Systems require regular maintenance to assure they will operate safely and effectively. In accordance with the manufacturers or

designers’ recommended inspection and maintenance procedures and schedules, all fire suppression systems, including alarms, shutdowns, and other associated equipment, shall be thoroughly examined and checked for

proper operation by competent personnel. (NFPA 122)

REVISED: 11/2/21

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Engel Service Manual - Machine: Serial No.: 167521 VC 750/150 TECHDocument164 pagesEngel Service Manual - Machine: Serial No.: 167521 VC 750/150 TECHЖеня Драчук100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hitachi Zaxis 270 Class Excavator Operator's Manual SN 010310 and Up PDFDocument14 pagesHitachi Zaxis 270 Class Excavator Operator's Manual SN 010310 and Up PDFsekfsekmddde100% (1)

- 7mock Test 3Document9 pages7mock Test 3Bryan FadrequilanNo ratings yet

- 9th CLFO Barangay Category MechanicsDocument11 pages9th CLFO Barangay Category MechanicsAllan Resma100% (1)

- Mitsubishi Electric MXZ-F Service Manual EngDocument206 pagesMitsubishi Electric MXZ-F Service Manual EngMarina CoskovicNo ratings yet

- Workplace and Safety PracticesDocument6 pagesWorkplace and Safety PracticesAngela Christine CagaoanNo ratings yet

- 2019 Styrene Handling GuideDocument45 pages2019 Styrene Handling Guideomidketabi100% (1)

- Ansul - Cartridge Red LineDocument6 pagesAnsul - Cartridge Red LineamardonesNo ratings yet

- Is 15493 2004Document32 pagesIs 15493 2004Siddharth GupteNo ratings yet

- F01 Guide 1Document11 pagesF01 Guide 1vrNo ratings yet

- FM Approval 5970 AFEX Systems - Dry - Wet ChemicalDocument1 pageFM Approval 5970 AFEX Systems - Dry - Wet ChemicalFrancisco Leonel Dueñas MontesNo ratings yet

- MLS305 Hema Lec PrelimsDocument16 pagesMLS305 Hema Lec PrelimsEvanka BaguistanNo ratings yet

- Emergency Rescue AccessDocument3 pagesEmergency Rescue AccessGustavo Silva AeEngNo ratings yet

- USAF Fire Station Design GuideDocument66 pagesUSAF Fire Station Design GuideCAP History LibraryNo ratings yet

- Safety Visit Questionare Power PlantDocument11 pagesSafety Visit Questionare Power PlantparthaNo ratings yet

- FK CO2 Fire Ex Portable (2,5) KGDocument1 pageFK CO2 Fire Ex Portable (2,5) KGmohammadNo ratings yet

- Complete Fire Protection Systems From A Single Source: Safe For CertainDocument36 pagesComplete Fire Protection Systems From A Single Source: Safe For Certainioan cristian cotorobaiNo ratings yet

- Rule 1940Document40 pagesRule 1940Easy Write33% (3)

- 03 Suggested Guidelines For Museum SecurityDocument52 pages03 Suggested Guidelines For Museum SecurityEdmundo CrisostomoNo ratings yet

- Peek 2012Document4 pagesPeek 2012AnkuNo ratings yet

- Arson Module in MidtermDocument18 pagesArson Module in MidtermJasper EstevesNo ratings yet

- As-NZS 1841.8.2007 Potable Fire Extinguishers, Pt8 Spec ReqDocument6 pagesAs-NZS 1841.8.2007 Potable Fire Extinguishers, Pt8 Spec ReqEdward NonakaNo ratings yet

- OmsDocument53 pagesOmsocean marine servicesNo ratings yet

- CMM 26 25 12 Rev 8 Dated Jan 2019Document32 pagesCMM 26 25 12 Rev 8 Dated Jan 2019TESTNo ratings yet

- 5th Research PaperDocument6 pages5th Research PaperPranshu SharmaNo ratings yet

- Ficha Tecnica Narrow Vein DrillDocument4 pagesFicha Tecnica Narrow Vein DrillJuan David Rondinel BulejeNo ratings yet

- Abandonship DrillDocument3 pagesAbandonship Drilljade abarillaNo ratings yet

- 59a f2015 Lng-Aaa SD SrreportDocument24 pages59a f2015 Lng-Aaa SD SrreportAsifNo ratings yet

- W18ke00-Workshop Manual PDFDocument549 pagesW18ke00-Workshop Manual PDFRavinder SinghNo ratings yet

- Safety Plan ProgramDocument68 pagesSafety Plan ProgramdanielcabasaNo ratings yet