Professional Documents

Culture Documents

Gujarat Technological University

Uploaded by

yicef376890 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

3173617

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesGujarat Technological University

Uploaded by

yicef37689Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

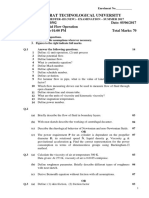

Seat No.: ________ Enrolment No.

___________

GUJARAT TECHNOLOGICAL UNIVERSITY

BE - SEMESTER–VII (NEW) EXAMINATION – WINTER 2021

Subject Code:3173617 Date:13/12/2021

Subject Name:Principles of Process Equipment Design

Time:10:30 AM TO 01:00 PM Total Marks: 70

Instructions:

1. Attempt all questions.

2. Make suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

4. Simple and non-programmable scientific calculators are allowed.

MARKS

Q.1 (a) Define: (a) Tray Efficiency (b) Tie Rods (c) Equivalent length of Pipe 03

(Le)

(b) Explain the pressure drop in fittings and valves. 04

(c) Write a brief note on selection of heating media and cooling media in 07

heat exchanger.

Q.2 (a) Write down the advantage and disadvantage of PFR over MFR. 03

(b) How reflux ratio affects distillation column design. 04

(c) State the various types of shell and tube heat exchanger. Discuss the 07

advantages and disadvantages of different types of shell and tube heat

exchanger with each other.

OR

(c) Explain in detail about various steps for shell and tube Heat exchanger 07

design.

Q.3 (a) Explain degree of completion of reaction. 03

(b) Discuss the effect of various parameters in design of equipment: 1. Baffle 04

spacing in heat exchanger 2. Tray spacing in tray tower 3. Weir length in

tray column

(c) Benzene at 40 0C is pumped through the system at a rate of 10 m3 /h with 07

the help of a centrifugal pump. The reservoir is at atmospheric pressure.

Pressure at the end of discharge line is 350 kPa g. The discharge head is

3.05 m and the pump suction head is 1.1 m above the level of liquid

reservoir. The friction loss in suction line 3.45 kPa and that in discharge

line is 39 kPa. The mechanical efficiency of the pump is 0.65. The

density of benzene is 870 kg/m3 and its vapour pressure at 40 0C is 29

kPa. Calculate (a) (NPSH)A and (b) power required by centrifugal pump.

OR

Q.3 (a) Discuss the process design of kettle type reboiler. 03

(b) List important industrial application of reactors. 04

(c) Design a bubble column reactor with suitable rate equation. 07

Q.4 (a) Discuss in brief jet flooding and downcomer flooding 03

(b) How to select key components for multicomponent distillation. 04

(c) Explain McCabe-Thiele method for binary distillation. 07

OR

Q.4 (a) Mention the selection criteria for heat exchanger. 03

(b) Discuss Tinker’s flow model with neat figure. 04

(c) In vertical thermosyphon reboiler recirculation ratio is fixed by trial and 07

error method. Discuss how to find or fix the recirculation ratio in the

following conditions: (i) ΔPav ≈ ΔPt (ii) ΔPav > ΔPt (iii)ΔPav < ΔPt

1

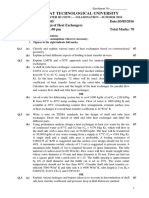

Q.5 (a) Define (a) Weeping (b) Jet flooding (c) Down comer flooding 03

(b) Mention the different types of weirs & down comers of tray tower. 04

(c) 1-2 shell and tube heat exchanger is used to cool methanol condensate 07

from 95 °C to 40°C. Flow rate of methanol is 100000 kg/h. Brackish

water is used as coolant with temperature rise from 25 °C to 40 °C.

Choose 20mm OD, 16 mm id, 4.88 m long cupro-nickle tubes with

triangular pitch Pt = 1.25 dO. Based on overall heat transfer coefficient

600 W/m2 C Calculate (1) Number of tubes (2) Shell Diameter K1 and

n1 for tube bundle diameter: (For triangular pitch Pt= 1.25dO)

No. of tube

1 2 4 6 8

side passes

K1 0.319 0.249 0.175 0.0743 0.0365

n1 2.142 2.207 2.285 2.499 2.675

Property Methanol Brackish Water

Heat Capacity, kJ/kg

2.84 4.2

°C

Density, kg/m3 750 995

Viscosity, mN.s/m 0.34 0.8

Thermal conductivity,

0.19 0.59

W/m °C

OR

Q.5 (a) Explain in brief about liquid entrainment. 03

(b) Discuss the advantages and disadvantages of Vacuum distillation. 04

(c) Explain concept of NPSH in pumping system. Distinguish between 07

(NPSH)A and (NPSH)R. If (NPSH)A is less than (NPSH)R, then suggest

corrective action to make (NPSH)A greater than (NPSH)R.

*************

You might also like

- GENERATOR DATA - CaterpillarDocument8 pagesGENERATOR DATA - Caterpillarschraz4575100% (2)

- General Education September 2016Document195 pagesGeneral Education September 2016Ronalyn AndaganNo ratings yet

- Hospital Management System Synopsis and Project ReportDocument152 pagesHospital Management System Synopsis and Project ReportKapil Vermani100% (1)

- Ligot v. MathayDocument1 pageLigot v. MathayJoyce BaylonNo ratings yet

- Zodiac Working Boat MK6HDDocument4 pagesZodiac Working Boat MK6HDdan antonNo ratings yet

- Manual Flowpet 5GDocument56 pagesManual Flowpet 5GRahkmat DanizarNo ratings yet

- Filling Out Forms Detailed Lesson Plan in English VDocument9 pagesFilling Out Forms Detailed Lesson Plan in English VAIAN CALIBAYAN0% (1)

- 2020 Ifs InsuranceDocument262 pages2020 Ifs InsuranceSensi CTPrima100% (1)

- Ppe PDFDocument2 pagesPpe PDFNihal ShahiNo ratings yet

- Gujarat Technological University: Subject Code: 2171910 Date: Subject Name: Power Plant Engineering Time: Total Marks: 70Document2 pagesGujarat Technological University: Subject Code: 2171910 Date: Subject Name: Power Plant Engineering Time: Total Marks: 70Chavda jayesh laljibhaiNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShruti BiradarNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- GTU BE Semester VI Process Equipment Design ExamDocument2 pagesGTU BE Semester VI Process Equipment Design ExamRîkèñ PâtélNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityvifaket581No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityRîkèñ PâtélNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShivam PanchalNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityfeyayel988No ratings yet

- Winter 16Document2 pagesWinter 16Bala DuttNo ratings yet

- Gtu Mechanical 2171910 Summer 2021Document2 pagesGtu Mechanical 2171910 Summer 2021rajushamla9927No ratings yet

- Summer 18Document2 pagesSummer 18Bala DuttNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021starboyNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHitesh PariharNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityRîkèñ PâtélNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJainam JoshiNo ratings yet

- GTU Exam Guide: Design of Heat ExchangersDocument2 pagesGTU Exam Guide: Design of Heat ExchangersBala DuttNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityRîkèñ PâtélNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityprince.patelNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityfeyayel988No ratings yet

- S2022 AthDocument2 pagesS2022 AthKALPESH MALINo ratings yet

- GTU BE Semester 1&2 Exam Winter 2018 Basic Mechanical EngineeringDocument2 pagesGTU BE Semester 1&2 Exam Winter 2018 Basic Mechanical EngineeringRavi ModiNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityRîkèñ PâtélNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityArpit vaishnavNo ratings yet

- BmeDocument2 pagesBmeCarry MinatiNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShivam PanchalNo ratings yet

- CRE2 (7th) Dec2017Document2 pagesCRE2 (7th) Dec2017Mayank PandyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityUrmit ParmarNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021Deep SasaniNo ratings yet

- Be Winter 2022Document1 pageBe Winter 2022Chirag RanaNo ratings yet

- GTU BE Semester VII Chemical Reaction Engineering II Exam Summer 2019Document2 pagesGTU BE Semester VII Chemical Reaction Engineering II Exam Summer 2019Hitesh VariyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitydevang majithiyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- GTU BE Semester VII Theory of Heat Transfer exam questionsDocument2 pagesGTU BE Semester VII Theory of Heat Transfer exam questionshiral gohilNo ratings yet

- GTU BE Semester V Mechanical Operations Exam QuestionsDocument2 pagesGTU BE Semester V Mechanical Operations Exam QuestionsOmer LalaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJaineshNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityAkashNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityaxayzala778No ratings yet

- Paper BMEDocument3 pagesPaper BMEJaishree ChauhanNo ratings yet

- Be Winter 2019Document2 pagesBe Winter 2019Rahul BulchandaniNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityChavda jayesh laljibhaiNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityvifaket581No ratings yet

- Gujarat Technological UniversityDocument5 pagesGujarat Technological Universitysaiyed moinsaniNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Q. P. Code: 37785: Page 1 of 2Document2 pagesQ. P. Code: 37785: Page 1 of 2Joyce VicenteNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- Sfo PDFDocument2 pagesSfo PDFKashyap TailorNo ratings yet

- GTU Semester III Exam: Heat Exchanger Design, Types, AnalysisDocument2 pagesGTU Semester III Exam: Heat Exchanger Design, Types, AnalysisBala DuttNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversitykrunalNo ratings yet

- 23.end Sem Question Paper - BMEL-405 2016-17Document2 pages23.end Sem Question Paper - BMEL-405 2016-17Manish SharmaNo ratings yet

- GTU BE Semester III Exam Fluid Flow BasicsDocument2 pagesGTU BE Semester III Exam Fluid Flow Basicsfeyayel988No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityTNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityprince.patelNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityprince.patelNo ratings yet

- Fluid Flow Operation BE Semester ExamDocument2 pagesFluid Flow Operation BE Semester ExamRohit SharmaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- Be Winter 2022Document2 pagesBe Winter 2022samip shahNo ratings yet

- GTU BE Thermodynamics Exam QuestionsDocument2 pagesGTU BE Thermodynamics Exam QuestionsRenieNo ratings yet

- Be Summer 2022Document2 pagesBe Summer 2022samip shahNo ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- GTU AI Machine Learning Exam QuestionsDocument1 pageGTU AI Machine Learning Exam Questionsyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- GTU BE Semester VII Exam Questions on Silicone Rubber TechnologyDocument2 pagesGTU BE Semester VII Exam Questions on Silicone Rubber Technologyyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- WCDocument2 pagesWCkn patelNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- WCDocument2 pagesWCkn patelNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- WCDocument2 pagesWCkn patelNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- Discharging A ClientDocument6 pagesDischarging A ClientNorman Batalla Juruena, DHCM, PhD, RNNo ratings yet

- Was Bali 2005Document786 pagesWas Bali 2005RoyOrtegaNo ratings yet

- What Is A Human Resources Strategy?Document8 pagesWhat Is A Human Resources Strategy?abdallah abdNo ratings yet

- Problem Solving 5Document4 pagesProblem Solving 5Raphael Pizarro ArceoNo ratings yet

- NY B17 ATF FDR - 7-24-03 ATF Email and 10-25-01 ATF After Action Report 092Document20 pagesNY B17 ATF FDR - 7-24-03 ATF Email and 10-25-01 ATF After Action Report 0929/11 Document Archive100% (2)

- Engine Tune-UpDocument43 pagesEngine Tune-UpЮра ПетренкоNo ratings yet

- Patient-Centred CareDocument15 pagesPatient-Centred CareMwanja MosesNo ratings yet

- SRX835 Spec Sheet - 11 - 11 - 19Document4 pagesSRX835 Spec Sheet - 11 - 11 - 19Eric PageNo ratings yet

- Nitro - Quiz 3 Ged102-A13Document3 pagesNitro - Quiz 3 Ged102-A13Eliezer NitroNo ratings yet

- Presentation On Tutorial Question On Promissory EstoppelDocument13 pagesPresentation On Tutorial Question On Promissory EstoppelNaqeeb NexerNo ratings yet

- Inductive sensor technical specifications in 40 charactersDocument3 pagesInductive sensor technical specifications in 40 charactersBasarNo ratings yet

- FIAMM FLB Battery Range Delivers Highest PerformanceDocument4 pagesFIAMM FLB Battery Range Delivers Highest PerformanceDrgnNo ratings yet

- Much NeedeDocument11 pagesMuch NeedeRijul KarkiNo ratings yet

- j00m HD FLV SQL Injection - PyDocument4 pagesj00m HD FLV SQL Injection - PyZeljko PanovicNo ratings yet

- ) (Significant Digits Are Bounded To 1 Due To 500m. However I Will Use 2SD To Make More Sense of The Answers)Document4 pages) (Significant Digits Are Bounded To 1 Due To 500m. However I Will Use 2SD To Make More Sense of The Answers)JeevikaGoyalNo ratings yet

- George Washington's Presidency NotesDocument5 pagesGeorge Washington's Presidency Notesf kNo ratings yet

- Static GK For Iift Snap and XatDocument19 pagesStatic GK For Iift Snap and XatnavinkumargNo ratings yet

- SatconDocument18 pagesSatconBADRI VENKATESHNo ratings yet

- Tle 6 Ict Q4 M9Document16 pagesTle 6 Ict Q4 M9Christ Khayzee R. BacalsoNo ratings yet

- Tipster Job AdvertDocument3 pagesTipster Job AdvertDatateq ConsultancyNo ratings yet

- CPQMDocument2 pagesCPQMOlayinkaAweNo ratings yet

- Theory of Planned Behaviour (TPB)Document18 pagesTheory of Planned Behaviour (TPB)Afiq Wahyu AjiNo ratings yet