Professional Documents

Culture Documents

Chassis

Uploaded by

Nimish PandeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chassis

Uploaded by

Nimish PandeCopyright:

Available Formats

Anshul SinghalEngine and Chassis

FSAE

Chassis

1. Introduction

Although it is simple to design a single part or system, it is more difficult to incorporate all of the parts and systems into a single package, such as a racecar. The design team for each system or part must keep in mind how its design will affect the overall package. For example, the suspension design team must leave enough room for the drivers legs between the left and right control arm pivot points. The purpose of the frame is to rigidly connect the frontand rear suspension while providing attachment points for the different systems of the car. Relative motion between thefront and rear suspension attachment points can cause inconsistent handling. The frame must also provideattachment points, which will not yield within the carsperformance envelope.There are many different styles of racecar frames - space frame,monocoque, and ladder, etc. The most popular style for FSAE is the tubular space frame. Space frames are a series of tubes, which are joined together to forma structure that connects all of the necessary componentstogether. However, most of the concepts and theories can beapplied to other chassis designs.

A Sample Frame Design

2. Stiffness of the frame.

The suspension is designed with the goal of keeping allfour tires flat on the ground throughout the performancerange of the vehicle. Generally, suspension systems aredesigned under the assumption that the frame is a rigid body.For example, undesirable changes in camber and toe canoccur if the frame lacks stiffness. In most cases, a chassis that is stiff enough for competition will not yield. However, some care should be taken to ensure that the attachment points of the frame do not yield when subjected to design loads. For example, the engine mounts should be made stiff enough to reduce the possibility of failure. 2.1 Torsional Stiffness.

Anshul SinghalEngine and Chassis

FSAE

Torsional stiffness is the resistance of the frame to torsional loads. Some extra structure can be added to the frame to increase its safety. A chassis can be madeextremely stiff by adding significant amounts of material tothe frame. However, this additional material might degradethe performance of the car because of the added mass.Obviously, torsional rigidity is not the onlymeasurement for analyzing the stiffness of a chassis.Bending stiffness can also be used to analyze the efficiency ofa frame design. However, bending stiffness is not as important as torsional stiffness because deflection due tobending will not affect wheel loads.

2.2 Triangulation. Triangulation can be used to increasethe torsional stiffness of a frame, since a triangle is the simplest form, which is always a structure and not amechanism. Obviously, a frame, which is a structure, will betorsionally stiffer than a mechanism. Therefore, an effortshould be made to triangulate the chassis as much as possible.Visualizing the frame as a collection of rods which areconnected by pin joints can help frame designers locate themechanisms in a design. Designers can also evaluatetheir frame by checking to see if each pin-jointed nodecontains at least three rods, which complement the load path. Use of thin wall steel tubing for theframe design requires significant triangulation of the frame, since thin wall tubing performs very well intension and compression but poorly in bending. Thecomponents, which produce significant amounts of force, forexample the engine and suspension should be attached to the frame at triangulated points.

Frame Triangulation (Frame, Side View)

2.3 Area Moment of Inertia. The area moment of inertia has a large influence on the stiffness of a structure. Therefore, the farther material is from the axis of twist the stiffer the frame will be in bending and torsion. This concept is implemented by adding structural side pods to the basic frame.

Anshul SinghalEngine and Chassis Structural Sidepods (Frame Top View)

FSAE

The above figure shows the triangulated side pods, which can be used to increase the torsional rigidity of the frame. This material can also increase the side impact protection. The sidepods add structure as far from the centerline of the chassis as possible that increases the area moment of inertia between the front and rear suspensions. Most of the successful FSAE cars have structural side pods for safety and increased torsional stiffness. In addition to using the sidepods to increase the stiffness of the chassis, roll hoop and down tubes can also be used to increase the rigidity of the frame. The frame stiffness can be substantially increased by properly placing the roll hoop tubes.

2.4 Load Path. During the design process, it is important to consider how loads are passed into the frame. A load path describes the path through which forces are dissipated into the frame. For example, the figure below shows how the vertical load generated by the weight on the wheel will travel through the upright, push rod, rocker, and coil-over shock and into the structure of the frame. Of course, to properly investigate the forces involved, a free body diagram for each component must be drawn.Nevertheless, this concept can be used by the designers to visualize how the frame should be constructed.

Load Path for Front Inboard Suspension 2.5 Crash Worthiness. In the interest of safety, the Formula SAE Rules Committee has written very specific rules to

Anshul SinghalEngine and Chassis

FSAE

protect the driver from frontal, side, and rollover crash situations. While designing the 1996 entry, the UMRolla team found that if the FSAE rules were followed and the frame was optimized for stiffness, it was obvious that the car would be adequate for most possible crash situations. Due to the possibility of a head on collision, more structure should be placed in the nose of the frame. The probability of the vehicle running into a solid object, such as a curb or loading dock was high. Therefore, considerable thought should be given to the safety of the drivers feet during a frontal impact. Each of the systems of a FSAE car must be packaged within the frame. The placement of these components limits the available paths for tubes, which is usually detrimental to the chassis stiffness. For example, the driver occupies a section of the frame, which could be used to significantly increase the stiffness of the frame.

2.6 Suspension. Packaging of the suspension to the frame is generally not an interference problem since most of thecomponents are exterior to the frame. However, it isespecially important to attach the suspension components tostiff portions of the chassis to correctly distribute the loadsthat will be passed through these components. Designing the frame so the control arms are attached toa stiff portion of the chassis can sometimes be very difficult. Changing the distance between thecontrol arm pivot points can help to optimize the load pathfor the control arms. This distance can be changed because itwill not affect the suspension geometry, since the rotationalaxis of the control arm is not affected. However, decreasingthe span of the control arms will reduce the arms ability to react to the forces, which are generated by accelerating or braking. The suspension should be designed concurrently with the frame. This allows the designer to concentrate on the load paths from the push rods and rockers so that the frame can efficiently react to the loads.

2.7 Drivetrain. Correctly attaching the components of the drivetrain to the frame is very important for extended frame life. The relative stiffness between the engine, differential,and frame is not as critical as when attaching the suspension.This is due to the fact that most FSAE chassis layouts haveshort distances between the drivetrain components. The maindesign point is to ensure that the frame does not break duringan incorrect downshift or a violent release of the clutch. When designing the frame around the motor anddifferential on chain driven designs, sufficient clearance mustexist so that several front and rear sprockets can be used.This clearance allows a wide selection of final drive ratios. The lack of clearance proves to be adrawback when trying to drive the racecar in the confinedspace of the FSAE competition and the more open spaces ofautocrosses. Ease of maintenance is also an important designconsideration when designing the frame around thedrivetrain. Providing clearance fordirect removal of the engine will reduce the amount

Anshul SinghalEngine and Chassis

FSAE

ofmechanics stress involved with engine changes. It has alsobeen found advantageous to provide simple access to allcovers on the motor such as the clutch, alternator, and valvecover.

2.8 Ergonomics. Properly incorporating the driver into a FSAE frame design can be very difficult because of wide variations in driver sizes. Each driver interface has to be designed so that it is comfortable for a wide variety of drivers.

2.9 Controls. Designing the frame around the controls, such as the steering wheel and pedals, is a matter of ensuring that the structure of the frame does not interfere with the drivers task. Also, the frame must adequately support the controls so that the attachment points do not yield while the car is being driven. The frame should not interfere with the drivers as they move through the full range of motion, which is required to drive the car. The drivers arms are a particular problem in this area. The frame designers should look beyond the structuralconsiderations of the frame when designing it so majoroversights are reduced. For example, a teamencountered a packaging issue for their chassis when theyplaced the steering wheel directly over the rack and pinion.This was a design error because the universal joint betweenthe steering wheel and the rack and pinion was not able tobend 900.

2.10 Safety harness. Most importantly, the attachment points of the harness must be strong enough to ensure that they will not fail during a crash. They also must be positioned so that the buckles will not bind when the harness is tightened.

2.11 Egress. Rapid egress is very important since the rules mandate that the driver must exit the vehicle within five seconds. Sometimes for the drivers feet and legs to fit through, the designers have to compromise ergonomics for chassisstiffness.

3. A Possible design sequence.

This section explains the basic design sequence that is not only the avenue for the design of a vehicle but is a logical sequence for the design of FSAE cars.

Anshul SinghalEngine and Chassis

FSAE

3.1 Layout. First determine the track width and wheel base dimensions of the vehicle. Once this is completed, the driver and engine placement should be sketched into the design for an estimation of weight distribution. Some thought should be given to the placement of other important or hard-to-package systems. For example, the fuel system may have to be packaged near the center of gravity to reduce the effects of its varying mass during the race.

3.2 Suspension Geometry. After the track width and wheelbase had been determined, the team should make a preliminary decision on tire and wheel size. The design team should then settle on some basic suspension parameters: camber gain, caster, KPI, scrub radius, and roll center height. These are needed so that the design team could model the suspension geometry. A suspension-modeling program can be used to analyze camber change and roll center movement. The suspension can be modeled with 00 of static camber, because static camber could be optimized during testing. During the modeling of the suspension, the team should look at vertical and lateral roll center movement and camber change. It is necessary to perform several iterations before a satisfactory geometry can be obtained. After the suspension design had been determined, the steering system should be designed based on the probable location of the frame rails and steering arms. The suspension-modeling program should also be used to reduce bump steer.

3.3 Solid Modeling. Once the preliminary suspension design is complete, the next step is to enter the suspension points into a 3-D computer model. Then the preliminary mechanical designs of the suspension components should be drawn. The suspension should then be moved through its range of motion in a solid modeling package to check for interference between the control arms, tie rods, uprights, and wheels. After the suspension system had been checked for interference problems, the next step is to start designing the frame. A CAE package like Solid Works or Catiacan be used to model the framestructure. The major components, such as engine anddifferential, should be drawn into the model. To simplify thisprocess only mounting points or rough sketches can be entered.Also, sufficient room must be designed into the frame for thesystems that had not been completed. For instance, ampleroom can be left for the controls needed for various driver sizes.

Anshul SinghalEngine and Chassis

FSAE

After the major components had been modeled, the first roll hoop design can be placed into the model. This is needed because it represents a major component of the frame, which is defined by the FSAE rules. Figure below represents this frame model.

Major Frame Components. At this point, the inboard suspension system had not been designed. However, some preliminary designs for the inboard suspension can allow a load path analysis to drive the design of the structure. 3.4 Connecting the points. Once the main points of the frame are defined in the model, the connect the dots phase could begin. By using the concepts of triangulation and area moment of inertia, the defined points should be connected with tubes. Connecting the dots simply consists of attaching the front suspension to the rear suspension while providing attachment points for the systems of the car. Refer to Figure below for the frame design.

Connecting the Dots.

3.5 Analysis.

Anshul SinghalEngine and Chassis

FSAE

Once all of the points have been connected, the frame is ready for finite element analysis. This analysis can be performed on a commercially available CAD/FEA software package like Solid Works or Catia. Beam elements can be used for the major frame structure while rod elements can be used for the suspension as illustrated in Figure below. A more representative load could be applied by using a model with the suspension attached. Since accurately modeling a welded joint is beyond the undergraduate level, this model is strictly for determining if the frame is a satisfactory structure.

FEA Model After the model is solved, the results could be viewed as an animation to expose any weak links. This approach allows for quick what ifs. For example, if an area appeared to be over-stressed, a different geometry for that joint could be substituted and modeled. Also one of the designers found that tubes with long versus short spans between joints should have a larger area moment of inertia to increase the stiffness. To reduce the cost of the racecar, only a small selection of tube sizes can be used, which makes the modeling simpler since wall thickness optimization is limited. The following tubing sizes can be used to construct the structure of the chassis: y y y y 1 x 0.065 (Roll Hoop Material) 1 x 0.035 3/4 x 0.035 5/8 x 0.035

To simplify the complexity of the frame construction, the number of tubes, which had bends in more than one plane, can be reduced to only two.

4. Conclusion.

8

Anshul SinghalEngine and Chassis

FSAE

It is obvious that frame design is a compromise between stiffness, weight, and packaging. The stiffness of the frame is important because it affects the overall performance of the vehicle. If too much material is added to the frame in the quest for stiffness, the performance of the vehicle will be degraded because of the added mass. Not only must the frame be stiff and light, it must also package all of the vehicle systems. Therefore, the design of the frame will require much iteration to achieve a balance. The timeline of the competition will limit the number of iterations possible so that the car can be built and tested. If the basic design concepts have been applied to the frame and some thought has been given to the integration of each sub-system, the end result will be a sound foundation for a FSAE car. Unlike the school environment, there are no right or wrong answers in the FSAE competition. Constructing FSAE carsimparts to college students the knowledge of how to functionin real world design groups while also introducing them tothe entire design process involved in a productsdevelopment. During the design process, the team must achieve acompromise between cost, manufacturing, performance, anddesign time so that their car will be competitive in all aspectsof the FSAE competition. The timeline of the competition,combined with the rigorous schedule of college, limits thenumber of iterations for each design. However, the teamshould understand that it would take several iterations toconverge on a satisfactory design. The amount of time usedfor the design process subtracts from the time available formanufacturing and testing. Although this paper hasconcentrated on design, it is very important to test the car sothat any design oversights will be highlighted beforecompetition. A poorly engineered vehicle may not perform well at thecompetition. Conversely, a highly engineered car may notperform well unless there is time to manufacture and test.For the inexperienced FSAE team, concentrating on complexengineering techniques can be too time consuming for theamount of performance gained. Therefore, FSAE teamsshould use basic engineering concepts to design their car.This will simplify the design process and allow the team tofinish the car as early as possible to allow for testing andredesign. Teams, which finish their car and compete, will gainthe most knowledge and experience from Formula SAE.

You might also like

- Race Car Frame Design and DevelopmentDocument16 pagesRace Car Frame Design and DevelopmentMahmood KhallidNo ratings yet

- Automobile Chasis: Project OnDocument41 pagesAutomobile Chasis: Project OnSai CoolNo ratings yet

- Vehicle Chassis Designs (Various Types of Vehicle Structures)Document5 pagesVehicle Chassis Designs (Various Types of Vehicle Structures)Muhammad AsifNo ratings yet

- Research Paper SuspensionDocument7 pagesResearch Paper SuspensionAnirudh GuptaNo ratings yet

- Vehicle Dynamics of A Solar Racing CarDocument20 pagesVehicle Dynamics of A Solar Racing CarVikas KumarNo ratings yet

- NIT Raipur SAE Club problem statements for design domainsDocument2 pagesNIT Raipur SAE Club problem statements for design domainsShubham GuptaNo ratings yet

- Planning Your Engineering DrawingDocument14 pagesPlanning Your Engineering Drawingapi-3707012100% (1)

- Chassis Stiffness and ComplianceDocument6 pagesChassis Stiffness and ComplianceMohamed GhareebNo ratings yet

- 2d Design Case Study.Document7 pages2d Design Case Study.o_dimitrovNo ratings yet

- ChassisDocument70 pagesChassisamitav_chak9523No ratings yet

- Fallsem2020-21 Mee3006 Ela VL2020210102308 Reference Material Automobile Engineering Lab PDFDocument31 pagesFallsem2020-21 Mee3006 Ela VL2020210102308 Reference Material Automobile Engineering Lab PDFSanjit RameshNo ratings yet

- Understanding Between Chassis and Handling: How Strut Bars and Anti-Roll Bars Improve PerformanceDocument13 pagesUnderstanding Between Chassis and Handling: How Strut Bars and Anti-Roll Bars Improve PerformanceAmr SkylineNo ratings yet

- Tech-03 Springs-Roll Stiffness-4 PDFDocument9 pagesTech-03 Springs-Roll Stiffness-4 PDFMibsão EsdrasNo ratings yet

- Chassis Frame and Body ComponentsDocument23 pagesChassis Frame and Body ComponentsPalak NaikNo ratings yet

- Baja SAE Auburn Design Report Cleveland State University 16Document10 pagesBaja SAE Auburn Design Report Cleveland State University 16Noel Mahung Melendez100% (1)

- Senior Project ReportDocument6 pagesSenior Project ReportRoss Bunnell100% (1)

- Project Report FINALDocument24 pagesProject Report FINALViraj MhatreNo ratings yet

- Continental Racing Tires Flyer 2017Document7 pagesContinental Racing Tires Flyer 2017Keith VonHertellNo ratings yet

- MEE 3006 Automobile Engineering: Dr. Ponnusamy PDocument55 pagesMEE 3006 Automobile Engineering: Dr. Ponnusamy PShivam KencheNo ratings yet

- 13th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics AerodynamicsDocument6 pages13th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics AerodynamicsLeo LonardelliNo ratings yet

- Vehicle FrameDocument17 pagesVehicle FrameashokkdesignNo ratings yet

- Suspension Design by Ravi DeshmukhDocument11 pagesSuspension Design by Ravi DeshmukhsonirocksNo ratings yet

- 3d Printing For Manufacture A Basic Design Guide Download OriginalDocument26 pages3d Printing For Manufacture A Basic Design Guide Download OriginalritamendesNo ratings yet

- Designing Efficient Commuter Vehicle Using Finite Element Analysis and Computational Fluid DynamicsDocument6 pagesDesigning Efficient Commuter Vehicle Using Finite Element Analysis and Computational Fluid DynamicsSyed Anas SohailNo ratings yet

- Go Kart Design ReportDocument17 pagesGo Kart Design ReportabhayNo ratings yet

- The Summary of Race Car Chassis DesignDocument2 pagesThe Summary of Race Car Chassis Designmohamed elbakryNo ratings yet

- Composite Effects On Tire MechanicsDocument22 pagesComposite Effects On Tire MechanicsTomislavMatanićNo ratings yet

- Space Frame DesignDocument5 pagesSpace Frame DesignAmeer ShNo ratings yet

- The Re-Design and Analysis of The Suspension System On The Formula Student Race CarDocument53 pagesThe Re-Design and Analysis of The Suspension System On The Formula Student Race CarPabloNo ratings yet

- 2019 BajaSAE Roll Cage Documentation PackageDocument6 pages2019 BajaSAE Roll Cage Documentation PackageAndrés LimaNo ratings yet

- Vehicle Systems ConstructionDocument25 pagesVehicle Systems ConstructionWinaponNo ratings yet

- 272 Concept Class Mansoura University DR Rev 2Document8 pages272 Concept Class Mansoura University DR Rev 2Gazzara WorldNo ratings yet

- 3d Bike CarbomqDocument30 pages3d Bike CarbomqRafael Rossini RprNo ratings yet

- BasearDocument115 pagesBasearRicardo StancoNo ratings yet

- Preliminary Design Report for Single-Seat Racing VehicleDocument8 pagesPreliminary Design Report for Single-Seat Racing VehicleAman MaanNo ratings yet

- Banshee Scythe InfoDocument1 pageBanshee Scythe InfobuilttorideNo ratings yet

- A Review On Fabricating Procedures in Ra-59942624Document18 pagesA Review On Fabricating Procedures in Ra-59942624manoj smNo ratings yet

- Concise Title for 14 User Manual SectionsDocument51 pagesConcise Title for 14 User Manual SectionsJuan Unaf VargasNo ratings yet

- Manufacturing and Testing of Composite Hybrid Leaf SpringsDocument94 pagesManufacturing and Testing of Composite Hybrid Leaf SpringsSatish KulkarniNo ratings yet

- Car Chassis BasicsDocument84 pagesCar Chassis BasicsDhruv TalwarNo ratings yet

- 1.design and Fabrication of A Go KartDocument8 pages1.design and Fabrication of A Go KartRicardo Wan AgueroNo ratings yet

- 2016 FSAE Electric Vehicle Pedal Assembly Design PDFDocument40 pages2016 FSAE Electric Vehicle Pedal Assembly Design PDFCarlos LLivisacaNo ratings yet

- Autoclassnotes 140411043241 Phpapp01Document76 pagesAutoclassnotes 140411043241 Phpapp01Mr ShrekNo ratings yet

- CFD of Clubman Roll CagesDocument18 pagesCFD of Clubman Roll CagesJoel ForbesNo ratings yet

- SAE Project Workbook 2010Document198 pagesSAE Project Workbook 2010jay100% (1)

- Chassis Design ExampleDocument9 pagesChassis Design ExampleWisdom Patrick EnangNo ratings yet

- PRAVEEN SolidworksDocument19 pagesPRAVEEN SolidworksgauravNo ratings yet

- FSAEDocument81 pagesFSAE69x4No ratings yet

- AUTOMOBILE (4) 3 - Wheel AlignmentDocument15 pagesAUTOMOBILE (4) 3 - Wheel AlignmentArun V NairNo ratings yet

- IndyCar Chassis Dimensions GuideDocument4 pagesIndyCar Chassis Dimensions GuideKarthikeyan NavaneethakrishnanNo ratings yet

- Design Optimization of Brushless Permanent Magnet Hub Motor Drive Using FEADocument5 pagesDesign Optimization of Brushless Permanent Magnet Hub Motor Drive Using FEASuman SahaNo ratings yet

- SAE 2002-01-3105 (Screen)Document14 pagesSAE 2002-01-3105 (Screen)rajdrklNo ratings yet

- Porsche Chassis DevelopmentDocument18 pagesPorsche Chassis DevelopmentArif OthmanNo ratings yet

- Modeling and Validation of Off-Road Vehicle Ride DynamicsDocument17 pagesModeling and Validation of Off-Road Vehicle Ride DynamicsAnderson MoribeNo ratings yet

- GenZe 2.0 Owner ManualDocument36 pagesGenZe 2.0 Owner ManualBobby kNo ratings yet

- Designing Shell Eco Marathon Car Bodies With SolidDocument8 pagesDesigning Shell Eco Marathon Car Bodies With Solidالامير حسنNo ratings yet

- Design and Analysis of an Automobile ChassisDocument5 pagesDesign and Analysis of an Automobile ChassisAdrián Fernández AraújoNo ratings yet

- An Introduction To Automotive Suspension SystemsDocument19 pagesAn Introduction To Automotive Suspension SystemsSahil ChouhanNo ratings yet

- MET2013 Hinojosa RicardoDocument27 pagesMET2013 Hinojosa RicardoAmal GeorgeNo ratings yet

- Suspension AnalysisDocument11 pagesSuspension Analysisanmol6237No ratings yet

- 2011 Baron GRE19th Ed New PDFDocument264 pages2011 Baron GRE19th Ed New PDFDida KhalingNo ratings yet

- Introduction To Combustion in Diesel EnginesDocument30 pagesIntroduction To Combustion in Diesel EnginesAghajaniNo ratings yet

- Film Izle, HD Film Izle, HD Film Sitesi, Tek Parça Izle, Filmi Full Izle, 720p Film Izle, Yeni Çıkan Filmler, 2014 Filmleri, Türkçe Dublaj Izle, Tek Part Izle, Full HD Izle, Ücretsiz IzleDocument8 pagesFilm Izle, HD Film Izle, HD Film Sitesi, Tek Parça Izle, Filmi Full Izle, 720p Film Izle, Yeni Çıkan Filmler, 2014 Filmleri, Türkçe Dublaj Izle, Tek Part Izle, Full HD Izle, Ücretsiz IzlesinevadiNo ratings yet

- Braking NumericalsDocument7 pagesBraking NumericalsNimish PandeNo ratings yet

- Final ReportDocument42 pagesFinal ReportNimish PandeNo ratings yet

- Terminology SpurDocument3 pagesTerminology SpurNimish Pande100% (1)

- ClutchesDocument16 pagesClutchesNimish PandeNo ratings yet

- GearDocument4 pagesGearNimish PandeNo ratings yet

- Economy KnowledgeDocument26 pagesEconomy KnowledgecarloscanaisNo ratings yet

- Qtools 2Document38 pagesQtools 2Nimish PandeNo ratings yet

- Qtools 1Document49 pagesQtools 1Nimish PandeNo ratings yet

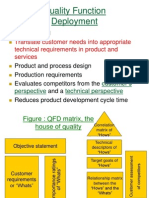

- QFDDocument22 pagesQFDNimish PandeNo ratings yet

- BITS, PILANI – DUBAI Quality Control Test 1Document7 pagesBITS, PILANI – DUBAI Quality Control Test 1Nimish PandeNo ratings yet

- 2Document21 pages2Nimish PandeNo ratings yet

- Dayal Bagh: Spircon 2013: Book of AbstractsDocument202 pagesDayal Bagh: Spircon 2013: Book of AbstractsSant Mat100% (2)

- BS (English) Dept of English University of SargodhaDocument36 pagesBS (English) Dept of English University of SargodhaFEROZ KHANNo ratings yet

- Risk Assissment 1Document12 pagesRisk Assissment 1Ibrahim BouzinaNo ratings yet

- An Introduction To Pascal Programming MOD 2010Document5 pagesAn Introduction To Pascal Programming MOD 2010Johnas DalusongNo ratings yet

- Chem 361 Separation Methods IntroDocument8 pagesChem 361 Separation Methods IntroTwum SomoahNo ratings yet

- Me8072 Renewable Sources of EnergyDocument13 pagesMe8072 Renewable Sources of EnergyNallappan Rajj ANo ratings yet

- List of SDAsDocument4 pagesList of SDAsAthouba SagolsemNo ratings yet

- Examining Language in Romeo and Juliet - The Prologue - Mastery TestDocument5 pagesExamining Language in Romeo and Juliet - The Prologue - Mastery TestPhạm MyNo ratings yet

- Anie Altamirano Learning For Life HandoutDocument4 pagesAnie Altamirano Learning For Life HandoutAnnapurna VNo ratings yet

- CitationCJ4-CB Checklists B v1.2Document4 pagesCitationCJ4-CB Checklists B v1.2Joao Vitor RojasNo ratings yet

- Keynote Proficient End-Of-Course Test BDocument7 pagesKeynote Proficient End-Of-Course Test Bana maria csalinasNo ratings yet

- Ethics in ResearchDocument21 pagesEthics in Researchmukku_raviNo ratings yet

- Renal Angina Index in Pediatric Septic Patients As A Predictor of Acute Kidney Injury in Remote AreaDocument9 pagesRenal Angina Index in Pediatric Septic Patients As A Predictor of Acute Kidney Injury in Remote AreaFarhanNo ratings yet

- An Introduction to Heisenberg Groups in Analysis and GeometryDocument7 pagesAn Introduction to Heisenberg Groups in Analysis and Geometrynitrosc16703No ratings yet

- Instruction Manual Series 854 XTG Level GaugeDocument60 pagesInstruction Manual Series 854 XTG Level GaugeJandri JacobNo ratings yet

- Query Operation 2021Document35 pagesQuery Operation 2021Abdo AbaborNo ratings yet

- ¿Cómo Hacerlo?: Dr. Jorge Ramírez Medina, Dr. Guillermo Granados Ruíz EGADE Business SchoolDocument17 pages¿Cómo Hacerlo?: Dr. Jorge Ramírez Medina, Dr. Guillermo Granados Ruíz EGADE Business Schoolgalter6No ratings yet

- Automation & Control Esst en 200804Document356 pagesAutomation & Control Esst en 200804Sveinn Rúnar JúlíussonNo ratings yet

- GulliverDocument8 pagesGulliverCris LuNo ratings yet

- ETEC 520 - Assignment 2 Group ProjectDocument19 pagesETEC 520 - Assignment 2 Group ProjectjennbosNo ratings yet

- CH - 1Document4 pagesCH - 1Phantom GamingNo ratings yet

- Đề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnDocument22 pagesĐề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnLily LeeNo ratings yet

- CA 1 - Đề thi AV5 - CLC - Made - efDocument5 pagesCA 1 - Đề thi AV5 - CLC - Made - efQuang NguyenNo ratings yet

- Motorship Oct 2023Document56 pagesMotorship Oct 2023Sahil PakhaliNo ratings yet

- Sist-En-6101-2016 .Document9 pagesSist-En-6101-2016 .lokelooksNo ratings yet

- Sri Dwi Mutiara-Jurnal CRSS OSNE 1Document11 pagesSri Dwi Mutiara-Jurnal CRSS OSNE 1sri dwi mutiaraNo ratings yet

- Fish HatcheryDocument14 pagesFish HatcheryYared Mesfin FikaduNo ratings yet

- Formulating and Solving LPs Using Excel SolverDocument8 pagesFormulating and Solving LPs Using Excel SolverAaron MartinNo ratings yet

- Halo Outdoor slmt1000 - slmt1000wDocument1 pageHalo Outdoor slmt1000 - slmt1000wFrank MoyaNo ratings yet

- Enabling Keycloak Metrics - KeycloakDocument3 pagesEnabling Keycloak Metrics - Keycloakhisyam darwisNo ratings yet