Professional Documents

Culture Documents

Swagingmachineriskmgtform

Uploaded by

Siyadarakkalmajeed ArakkalmajeedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Swagingmachineriskmgtform

Uploaded by

Siyadarakkalmajeed ArakkalmajeedCopyright:

Available Formats

1.

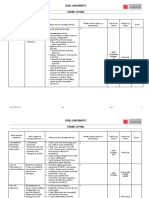

Hazard Management Details – General

Plant/Equipment Item: Swaging Machine Make/Model No.: Serial No.:

School / Work Location: Region:

Name of Person(s) Conducting Activity: Date Conducted:

Description of Use: Summary of Key Risks:

(refer to appropriate subsections)

A swaging machine is used to bend or

shape cold metal items (e.g., It can be Entanglement

used to reduce the diameter, produce

a taper, or add point to a round work Impact and cutting

piece). Slips/trips/falls

The machine alters the dimensions of

an item by using a die onto which the

item is forced.

Plant and Equipment Risk Management Form

Plant and Equipment Risk Management Form

2. Documentation

Relevant Legislation/Standards Y/N Comments

Is plant required to be registered? Y N

Is a user license required? Y N

Key Reference material

Plant Documentation Y/N Comments

Are operator’s manuals accessible? Y N

Is this a restricted use item? Y N

Does this item require safe use Y N

documents/test?

3. Hazard Identification

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ENTANGLEMENT Minor Possible Medium Long hair, loose Ensure hair, loose clothing,

Can anyone’s hair, clothing, gloves, clothing, rags, cleaning rags and jewellery is kept

cleaning brushes, tools, rags or other brushes and jewellery clear of moving parts when in

materials become entangled with moving could become use.

parts of the plant or materials? entangled in the Aprons can be used to

moving parts of the restrict loose clothing.

Y N equipment. Hair ties/hair nets can be

used to secure long hair.

Ensure jewellery and

accessories (e.g.

bracelets) are not worn

when operating

equipment.

Swaging Machine Risk Management Form Page | 2

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

IMPACT AND CUTTING Machine could slip off Ensure swaging machine is

Can anyone be crushed/cut/struck etc. work surface and strike securely anchored to work

due to: the operator/observer. surface prior to use.

Material falling off the plant? Y N

Exposed moving parts Ensure operator’s hands and

Uncontrolled/unexpected movement Minor Possible Medium body parts are kept clear of

Y N pose a potential

of plant/load? moving parts during the

pinching/crushing

Lack of capacity to slow, stop or hazard to the operator’s operation of the swaging

Y N

immobilise plant? hands and body parts. machine.

The plant tipping or rolling over? Y N Minor Possible Medium

Parts of the plant disintegrating or Work piece may have Ensure appropriate PPE (e.g.

Y N sharp edges. gloves) are used.

collapsing?

Contact with moving parts during Moderate Possible Medium

testing, inspection, operation, Y N

maintenance, cleaning or repair?

Being thrown off or under the plant? Y N

Contact with sharp or flying objects? Moderate Rare Low

Y N

(e.g. work pieces being ejected)

The mobility of the plant? Y N

Inappropriate parts and accessories

Y N

being used?

Other Y N

Swaging Machine Risk Management Form Page | 3

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SHEARING

Can anyone’s body parts be sheared

between two parts of plant, or between a Y N

part of the plant and a work piece or

structure?

PRESSURISED CONTENT

Can anyone come into contact with

Y N

fluids or gases under high pressure, due

to plant failure or misuse of the plant?

ELECTRICITY

Can anyone be injured or burnt due to:

Live electrical conductors? (e.g.

Y N

exposed wires)

Working in close proximity to

Y N

electrical conductors?

Access to electricity?

Y N

Damaged or poorly maintained

Y N

electrical leads, cables or switches?

Water near electrical equipment?

Y N

Lack of isolation procedures?

Y N

Other

Y N

Swaging Machine Risk Management Form Page | 4

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ERGONOMICS

Can anyone be injured due to:

Poorly designed workstation?

Y N

Repetitive body movement?

Y N

Constrained body posture or the

Y N

need for excessive effort?

Design deficiency causing

Y N

psychological stress?

Inadequate or poorly placed lighting?

Y N

Does the plant impact on the

surrounding workplace and create

potential hazards? (Consider Y N

potential impact on the design and

layout of the workplace)

Is the location of the plant

inappropriate? (Consider potential

Y N

effects due to environmental

conditions and terrain)

Other

Y N

Swaging Machine Risk Management Form Page | 5

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

RADIATION

Can anyone using the plant, or in the

vicinity of the plant suffer injury or illness

due to exposure to radiation in the form

of any of the following: Y N

infra-red radiation

ultra violet light

microwaves

NOISE

Can anyone using the plant, or in the

Y N

vicinity of the plant, suffer injury due to

exposure to noise?

VIBRATION

Can anyone be injured or suffer ill-health Y N

from exposure to vibration?

FRICTION

Can anyone be burnt due to contact with

Y N

moving parts, materials or surfaces of

the plant?

SUFFOCATION

Can anyone be suffocated due to lack of Y N

oxygen, or atmospheric contamination?

CONDITION

Is a hazard likely due to the age and

condition of the plant? (Consider how Y N

hard the machine has been worked, and

whether it is used constantly or rarely).

Can anyone be injured as a result of

the plant not serviced appropriately

Y N

and/or maintained in line with

manufacturer’s recommendations?

Swaging Machine Risk Management Form Page | 6

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SLIPS/TRIPS/FALLS Poor housekeeping Ensure appropriate cleaning

Can anyone using the plant, or in the practices allowing the and housekeeping practices

vicinity of the plant, slip, trip or fall due build-up of wood dust or are maintained to ensure the

to: failure to immediately risk of a slip/trip/falls hazard

Uneven, slippery or steep work clean up spills could is kept to a minimum.

Y N

surfaces? result in a slip hazard.

Poor housekeeping, e.g. spillage in Minor Possible Medium Inappropriate placement

Y N

the vicinity? of objects (e.g. spare

Obstacles being placed in the vicinity Minor Possible Medium materials, electrical

Y N cords, school bags etc.)

of the plant?

Inappropriate or poorly maintained in the immediate vicinity

floor or walking surfaces (i.e. lack of of the plant equipment

Y N may result in a trip

a slip-resistant surface, unprotected

holes, penetrations or gaps?) hazard.

If operating or maintaining plant at

height can anyone slip, trip or fall due to:

Use of work platforms, stairs or

Y N

ladders?

Lack of guardrails or other suitable

Y N

edge protection?

Other

Y N

Swaging Machine Risk Management Form Page | 7

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

FIRE AND EXPLOSION

Y N

Can anyone be injured by fire?

Can anyone be injured by explosion

of gases, vapours, liquids, dusts, or Y N

other substances?

TEMPERATURE/MOISTURE

Can anyone come into contact with Y N

objects at high or low temperatures?

Can anyone suffer ill-health due to

exposure to high or low Y N

temperatures?

Can anyone be injured or suffer ill-

Y N

health due to exposure to moisture?

OTHER

Can anyone be injured or suffer ill-health

from exposure to:

Chemicals? Y N

Toxic gases or vapours? Y N

Fumes/Dusts? Y N

Other? (please specify) Y N

4. Risk Assessment Signoff

Authorised By: Signature: Date:

Swaging Machine Risk Management Form Page | 8

Plant and Equipment Risk Management Form

1. Consequence - Evaluate the consequences of a risk occurring according 2. Likelihood - Evaluate the likelihood of an incident occurring according to the

to the ratings in the top row ratings in the left hand column

Descriptor Level Definition

Descriptor Level Definition

Rare 1 May occur somewhere, sometime (“once in a life time /

Insignificant 1 No injury once in a hundred years”)

Minor 2 Injury/ ill health requiring first aid Unlikely 2 May occur somewhere within the Department over an

extended period of time

Moderate 3 Injury/ill health requiring medical

attention Possible 3 May occur several times across the Department or a

region over a period of time

Major 4 Injury/ill health requiring hospital

admission Likely 4 May be anticipated multiple times over a period of time

May occur once every few repetitions of the activity or

Severe 5 Fatality event

Almost 5 Prone to occur regularly

3. Risk level - Calculate the level of risk by finding the intersection between the

Certain It is anticipated for each repetition of the activity of event

likelihood and the consequences

Likelihoo Consequence 4. Risk Level/Rating and Actions

d Insignificant Minor Moderate Major Severe Descripto Definition

Almost Medium High Extreme Extreme Extreme r

Certain

Likely Medium Medium High Extreme Extreme Extreme: Notify Workplace Manager and/or Management OHS

Possible Low Medium Medium High Extreme Nominee immediately. Corrective actions should be taken

Unlikely Low Low Medium Medium High immediately. Cease associated activity.

Rare Low Low Low Medium Medium High: Notify Workplace Manager and/or Management OHS

Nominee immediately. Corrective actions should be taken

within 48 hours of notification.

Medium: Notify Nominated employee, HSR / OHS Committee.

Nominated employee, OHS Representative / OHS Committee

is to follow up that corrective action is taken within 7 days.

Low Notify Nominated employee, HSR / OHS Committee.

Nominated employee, HSR / OHS Committee is to follow up

that corrective action is taken within a reasonable time.

Swaging Machine Risk Management Form Page | 9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SDFSHVGFDJFHDDocument18 pagesSDFSHVGFDJFHDSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Lp-Alez-Kzn-013 Ewt Camp Cabin LiftDocument29 pagesLp-Alez-Kzn-013 Ewt Camp Cabin LiftSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Forklift Operations - Risk Assessment & Hazard IdentificationDocument5 pagesForklift Operations - Risk Assessment & Hazard IdentificationSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- ALEz-01-COSHH Assessment Thioflz ALEz-01Document2 pagesALEz-01-COSHH Assessment Thioflz ALEz-01Siyadarakkalmajeed ArakkalmajeedNo ratings yet

- JHA Bolting Unbolting Servicing Activities PDFDocument5 pagesJHA Bolting Unbolting Servicing Activities PDFSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- RA 004 Crane LiftingDocument3 pagesRA 004 Crane LiftingSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Water Tanker-Trailer Inspection Checklist: ClientDocument2 pagesWater Tanker-Trailer Inspection Checklist: ClientSiyadarakkalmajeed Arakkalmajeed100% (1)

- Service Truck Inspection Checklist: Upper ShuaibaDocument2 pagesService Truck Inspection Checklist: Upper ShuaibaSiyadarakkalmajeed Arakkalmajeed100% (1)

- 02 Lifting Operations R ADocument4 pages02 Lifting Operations R ASiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Deep Compliance Audit Checklist Permit To Work PTWDocument2 pagesDeep Compliance Audit Checklist Permit To Work PTWSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Sewage Tanker Inspection Checklist: HalliburtonDocument2 pagesSewage Tanker Inspection Checklist: HalliburtonSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Roller Weekly Inspection Checklist: Day DateDocument2 pagesRoller Weekly Inspection Checklist: Day DateSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Wheel Loader Inspection Checklist: RemarksDocument2 pagesWheel Loader Inspection Checklist: RemarksSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Tipper/ T. Trailer Inspection Checklist: Day DateDocument2 pagesTipper/ T. Trailer Inspection Checklist: Day DateSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Excavator Weekly Inspection ChecklistDocument2 pagesExcavator Weekly Inspection ChecklistSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Grader Weekly Inspection ChecklistDocument2 pagesGrader Weekly Inspection ChecklistSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Hiab Inspection Checklist: Day DateDocument2 pagesHiab Inspection Checklist: Day DateSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Mess MenuDocument2 pagesMess MenuSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Low Bed Inspection Checklist: Day DateDocument2 pagesLow Bed Inspection Checklist: Day DateSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Faculty of Engineering & Technology: (Lateral Entry-II Year)Document2 pagesFaculty of Engineering & Technology: (Lateral Entry-II Year)Siyadarakkalmajeed ArakkalmajeedNo ratings yet

- Engg Inter Fee 2017 18 InternationalDocument2 pagesEngg Inter Fee 2017 18 InternationalSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Security Classification Project InternalDocument9 pagesSecurity Classification Project InternalSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Chapter 1Document79 pagesChapter 1Siyadarakkalmajeed ArakkalmajeedNo ratings yet

- Chemical Management GuidelinesDocument139 pagesChemical Management GuidelinesSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Introduction To Oil Field and Related IndustriesDocument2 pagesIntroduction To Oil Field and Related IndustriesSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Material Safety Data Sheet (MSDS) Pentane: Product IdentificationDocument3 pagesMaterial Safety Data Sheet (MSDS) Pentane: Product IdentificationSiyadarakkalmajeed ArakkalmajeedNo ratings yet