Professional Documents

Culture Documents

Bond 200

Uploaded by

aiswarya k vijayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bond 200

Uploaded by

aiswarya k vijayCopyright:

Available Formats

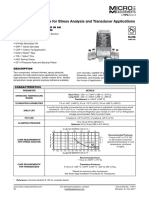

M-Bond 200

Strain

Strain Gage Adhesive

Gage Adhesive

OTHER ACCESSORIES USED IN AN

M-BOND 200 INSTALLATION:

• CSM Degreaser or GC-6 Isopropyl Alcohol

• Silicon Carbide Paper

• M-Prep Conditioner A

• M-Prep Neutralizer 5A

• GSP-1 Gauze Sponges

• CSP-1 Cotton Applicators

• PCT-2M Gage Installation Tape

DESCRIPTION

For routine experimental stress analysis applications The user should note that the performance of the

under temperate environmental conditions, M-Bond 200 adhesive can be degraded by the effects of time,

adhesive is ordinarily the best choice. This adhesive humidity conditions, elevated temperature, and moisture

is very easy to handle, and cures almost instantly to absorption. Because of the latter effect, strain gage

produce an essentially creep-free, fatigue-resistant bond, installations should always be covered with a suitable

with elongation capability of five percent or more. protective coating. When necessitated by more rigorous

test requirements and/or environmental conditions,

M-Bond 200 is a cyanoacrylate that has been pretested consideration should be given to one of the M-Bond

and certified for use in bonding strain gages. It is an epoxy adhesives, using the “Recommended Adhesives/

excellent general-purpose adhesive for laboratory and Strain Gage Series” chart.

short-term field applications. The procedure for making a

strain gage installation with M-Bond 200 is illustrated and

described in detail in Instruction Bulletin B-127 included in

each kit of adhesive.

CHARACTERISTICS

PARAMETER DETAILS

One-minute thumb pressure, followed by a minimum two-minute delay before tape removal.

CURE

Bond strength increases rapidly during first five minutes. Cure time must be extended under conditions of

REQUIREMENTS*

low temperature [<70°F (<21°C)] or low humidity (<40% RH).

OPERATING

Short Term: Long Term:

TEMPERATURE

–300° to +200°F (–185° to +95°C). –25° to +150°F (–32° to +65°C).

RANGE

ELONGATION

>5% at +75°F (+24°C), 3% at +75°F (+24°C) when used with CEA or EA/Option E strain gages.

CAPABILITIES

Minimum 12 months when stored unopened at +40°F (+5°C)

or minimum 9 months when stored unopened at +75°F (+24°C).

SHELF LIFE Note: To ensure a proper seal, wipe bottle spout clean and dry before replacing cap.

Note: Condensation rapidly degrades adhesive performance and shelf life; if refrigerated, allow adhesive

to reach room-temperature before opening. Refrigeration after opening is not recommended.

Maximum 3 months at +75°F (+24°C) (not to exceed date of expiration) after opening.

POT LIFE

Replace the cap immediately after each use.

PACKAGING OPTIONS

KIT BULK

1 bottle (1 oz/28 g) Adhesive

1 bottle (1 oz/28 g) Adhesive 5 tubes (2 g each) Adhesive

1 brush-cap bottle (30 ml) Catalyst 16 bottles (1 oz/28 g each) Adhesive

12 brush-cap bottles (30 ml each) Catalyst

*Reference: Instruction Bulletin B-127 for complete details.

www.micro-measurements.com For technical questions, contact Document No.: 11010

20 mm@vpgsensors.com Revision: 17-May-2017

Legal Disclaimer Notice

Vishay Precision Group, Inc.

Disclaimer

ALL PRODUCTS, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Vishay Precision Group, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “VPG”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein or in

any other disclosure relating to any product.

The product specifications do not expand or otherwise modify VPG’s terms and conditions of purchase, including but

not limited to, the warranty expressed therein.

VPG makes no warranty, representation or guarantee other than as set forth in the terms and conditions of purchase.

To the maximum extent permitted by applicable law, VPG disclaims (i) any and all liability arising out of the

application or use of any product, (ii) any and all liability, including without limitation special, consequential or

incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular purpose,

non-infringement and merchantability.

Information provided in datasheets and/or specifications may vary from actual results in different applications and

performance may vary over time. Statements regarding the suitability of products for certain types of applications

are based on VPG’s knowledge of typical requirements that are often placed on VPG products. It is the customer’s

responsibility to validate that a particular product with the properties described in the product specification is suitable for

use in a particular application. You should ensure you have the current version of the relevant information by contacting

VPG prior to performing installation or use of the product, such as on our website at vpgsensors.com.

No license, express, implied, or otherwise, to any intellectual property rights is granted by this document, or by any

conduct of VPG.

The products shown herein are not designed for use in life-saving or life-sustaining applications unless otherwise

expressly indicated. Customers using or selling VPG products not expressly indicated for use in such applications do

so entirely at their own risk and agree to fully indemnify VPG for any damages arising or resulting from such use or sale.

Please contact authorized VPG personnel to obtain written terms and conditions regarding products designed for such

applications.

Product names and markings noted herein may be trademarks of their respective owners.

Copyright Vishay Precision Group, Inc., 2014. All rights reserved.

Document No.: 63999 www.vpgsensors.com

Revision: 15-Jul-2014 1

You might also like

- 1424-D6580 Red #181Document3 pages1424-D6580 Red #181christianNo ratings yet

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamFrom EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamNo ratings yet

- Strain Gage Adhesive: M-Bond 200Document2 pagesStrain Gage Adhesive: M-Bond 200pietro zugnoniNo ratings yet

- Other Accessories Used in An M-Bond Ae-10 InstallationDocument2 pagesOther Accessories Used in An M-Bond Ae-10 InstallationvolkovwNo ratings yet

- Other Accessories Used in An M-Bond Ae-10 InstallationDocument2 pagesOther Accessories Used in An M-Bond Ae-10 Installationpietro zugnoniNo ratings yet

- Other Accessories Used in An M-Bond Ae-10 InstallationDocument2 pagesOther Accessories Used in An M-Bond Ae-10 InstallationvolkovwNo ratings yet

- Other Accessories Used in An M-Bond Ae-15 InstallationDocument2 pagesOther Accessories Used in An M-Bond Ae-15 Installationpietro zugnoniNo ratings yet

- M-Bond 300: Other Accessories Used in An M-Bond 300 InstallationDocument2 pagesM-Bond 300: Other Accessories Used in An M-Bond 300 Installationpietro zugnoniNo ratings yet

- Adhesive General PurposeDocument2 pagesAdhesive General PurposeAnonymous einnF2hzJ6No ratings yet

- M-Bond 600: Other Accessories Used in An M-Bond 600 InstallationDocument2 pagesM-Bond 600: Other Accessories Used in An M-Bond 600 Installationpietro zugnoniNo ratings yet

- 2377 MM DS 2377-EN M-Bond A-12 LRDocument2 pages2377 MM DS 2377-EN M-Bond A-12 LRpietro zugnoniNo ratings yet

- Bond 610Document3 pagesBond 610aliNo ratings yet

- Strain Gage Adhesive For Stress Analysis and Transducer ApplicationsDocument3 pagesStrain Gage Adhesive For Stress Analysis and Transducer Applicationspietro zugnoniNo ratings yet

- Other Accessories Used in An Epy-500 InstallationDocument2 pagesOther Accessories Used in An Epy-500 Installationpietro zugnoniNo ratings yet

- 2460 MM DS 2460-EN RTC-2 Epoxy LRDocument2 pages2460 MM DS 2460-EN RTC-2 Epoxy LRpietro zugnoniNo ratings yet

- H Cement: Other Accessories Used in An H Cement InstallationDocument2 pagesH Cement: Other Accessories Used in An H Cement Installationpietro zugnoniNo ratings yet

- Other Accessories Used in An M-Bond Ga-61 InstallationDocument2 pagesOther Accessories Used in An M-Bond Ga-61 Installationpietro zugnoniNo ratings yet

- Totalseal 1169Document2 pagesTotalseal 1169thiagomcasimiroNo ratings yet

- Technical Data: Three Bond 1207CDocument3 pagesTechnical Data: Three Bond 1207CVictorEkaSetiawanNo ratings yet

- GC Cement: Other Accessories Used in A GC Cement InstallationDocument2 pagesGC Cement: Other Accessories Used in A GC Cement Installationpietro zugnoniNo ratings yet

- Bayhydrol UH 2864 - en - 84271470 17531907 20681591Document3 pagesBayhydrol UH 2864 - en - 84271470 17531907 20681591Feridun CaglarNo ratings yet

- Dispercoll C84: CharacterizationDocument3 pagesDispercoll C84: Characterizationmufid_ainunNo ratings yet

- Desmodur VLR20: CharacterizationDocument3 pagesDesmodur VLR20: Characterizationsriatul2006No ratings yet

- Desmoseal S 2876 - en - 86215381 21016647 21016675Document3 pagesDesmoseal S 2876 - en - 86215381 21016647 21016675Kiên PhùngNo ratings yet

- WC-16 Ceramic Cement: Other Accessories Used in An Wc-16 Cement InstallationDocument2 pagesWC-16 Ceramic Cement: Other Accessories Used in An Wc-16 Cement Installationpietro zugnoniNo ratings yet

- Ce550 Sba TD 6.17Document3 pagesCe550 Sba TD 6.17Aditya WiratamaNo ratings yet

- Desmoseal S XP 2636 - en - 06366759 00002403 00056640Document3 pagesDesmoseal S XP 2636 - en - 06366759 00002403 00056640Kiên PhùngNo ratings yet

- TDS Braskem Polypropylene C705-44NA HPDocument2 pagesTDS Braskem Polypropylene C705-44NA HPVinayak AryanNo ratings yet

- 6233 Data SheetDocument2 pages6233 Data SheetAlpian SaputraNo ratings yet

- 3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111Document4 pages3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111HugoNo ratings yet

- Desmoseal M 280 - en - 04993179 00010145 00045758Document3 pagesDesmoseal M 280 - en - 04993179 00010145 00045758колодинский геннадийNo ratings yet

- HG-1 Ceramic Cement: Other Accessories Used in An Hg-1 Cement InstallationDocument2 pagesHG-1 Ceramic Cement: Other Accessories Used in An Hg-1 Cement Installationpietro zugnoniNo ratings yet

- DS Flex Rev7 0309 PDFDocument2 pagesDS Flex Rev7 0309 PDFDavid GonzaloNo ratings yet

- Bayflex 110-50 BMSDocument2 pagesBayflex 110-50 BMSGareth Kenworthy100% (1)

- 3M Super 77 Multipurpose Cylinder Spray AdhesiveDocument4 pages3M Super 77 Multipurpose Cylinder Spray Adhesivevivek jayswalNo ratings yet

- TDS Foam SystemDocument3 pagesTDS Foam SystemAbdullah SahlyNo ratings yet

- Denex #3: Other Accessories Used in A Denex #3 InstallationDocument2 pagesDenex #3: Other Accessories Used in A Denex #3 Installationpietro zugnoniNo ratings yet

- Amercoat ABC 3Document0 pagesAmercoat ABC 3Stefano CostaNo ratings yet

- Ps 870 Class CDocument2 pagesPs 870 Class CDaniel AndersonNo ratings yet

- Molykote (R) in India From Project Sales Corp SMS +91-98851-49412Document339 pagesMolykote (R) in India From Project Sales Corp SMS +91-98851-49412Project Sales CorpNo ratings yet

- Gip Panel AdhesiveDocument2 pagesGip Panel AdhesivevnunezNo ratings yet

- Craybond 85-22 (PIR) - 18-03-23Document3 pagesCraybond 85-22 (PIR) - 18-03-23YASHICA VAITTIANATHANNo ratings yet

- Desmophen NH 2850 XP PDFDocument3 pagesDesmophen NH 2850 XP PDFsriatul2006No ratings yet

- Desmophen C 2100 - en - 06363857 17959237 20766545Document3 pagesDesmophen C 2100 - en - 06363857 17959237 20766545Max TranNo ratings yet

- Tdse 7703Document2 pagesTdse 7703Caio OliveiraNo ratings yet

- BETASEAL™ 57502: Urethane AdhesiveDocument1 pageBETASEAL™ 57502: Urethane AdhesiveRaymundoNo ratings yet

- Interbond 600Document4 pagesInterbond 600Trịnh Minh KhoaNo ratings yet

- MBond 200 Strain Gage Installation GuideDocument4 pagesMBond 200 Strain Gage Installation GuideChetan B ArkasaliNo ratings yet

- Bayhydrol U XP 2755 - enDocument3 pagesBayhydrol U XP 2755 - enAllanNo ratings yet

- Desmodur H - en - 00409340 17844232 19840272Document3 pagesDesmodur H - en - 00409340 17844232 19840272Tasos PapadopoulosNo ratings yet

- Acclaim Polyol 18200 N_en_05483778 00001501 00043633 (1)Document3 pagesAcclaim Polyol 18200 N_en_05483778 00001501 00043633 (1)Như HồNo ratings yet

- NeoCryl B 728 - en - 50000025 23375393 23489049Document2 pagesNeoCryl B 728 - en - 50000025 23375393 23489049DewiNo ratings yet

- Acclaim Polyol 12200 N_en_06064388 17471573 21029595 (2)Document3 pagesAcclaim Polyol 12200 N_en_06064388 17471573 21029595 (2)Như HồNo ratings yet

- Sikagrout - 200 PtidDocument3 pagesSikagrout - 200 Ptidfandy sipataNo ratings yet

- Basf Masterflow 678 TdsDocument4 pagesBasf Masterflow 678 Tdsgazwang478No ratings yet

- Desmocoll XP 25974 - en - 06480640 00002145 00054306Document3 pagesDesmocoll XP 25974 - en - 06480640 00002145 00054306Fachreza AkbarNo ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- Samsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneFrom EverandSamsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Boomer: Diagrams and DrawingsDocument86 pagesBoomer: Diagrams and DrawingsPedro GarzaNo ratings yet

- Auditing Problems - 001Document2 pagesAuditing Problems - 001Geoff MacarateNo ratings yet

- Player-Agency AgreementDocument4 pagesPlayer-Agency AgreementNour Mohamed100% (1)

- Moot Final Memorial FreshersDocument15 pagesMoot Final Memorial FreshersrajNo ratings yet

- Gupta SirDocument54 pagesGupta Sirshiwani sharmaNo ratings yet

- Philippines Supreme Court Rules on Juvenile Exemption from Criminal LiabilityDocument8 pagesPhilippines Supreme Court Rules on Juvenile Exemption from Criminal Liabilityracel joyce gemotoNo ratings yet

- Amended Complaint: Pardoe V SalazarDocument14 pagesAmended Complaint: Pardoe V Salazarrick siegelNo ratings yet

- Application Form TRAIDocument3 pagesApplication Form TRAIifra ibraheemNo ratings yet

- WT010810 PDFDocument1 pageWT010810 PDFSoftSystem VarnaNo ratings yet

- Right of Disabled PersonsDocument24 pagesRight of Disabled PersonsK Senthil Ram KumarNo ratings yet

- Corporate Law ProjectDocument11 pagesCorporate Law ProjectVanshita GuptaNo ratings yet

- Gujarat HC Order on Anticipatory Bail ApplicationDocument11 pagesGujarat HC Order on Anticipatory Bail ApplicationSreejith NairNo ratings yet

- Electrical Electronic and Communications Contracting Award Ma000025 Pay Guide 2Document19 pagesElectrical Electronic and Communications Contracting Award Ma000025 Pay Guide 2laura anne georgeNo ratings yet

- Asif Hameed v. State of J & KDocument17 pagesAsif Hameed v. State of J & Kswastik groverNo ratings yet

- Notes On Special Corporations (INCLUDE OPC and CVPI)Document13 pagesNotes On Special Corporations (INCLUDE OPC and CVPI)charmagne cuevasNo ratings yet

- IA - 2 Provision, Contingent Liability: Presented By: Renato O. Daquioag CPA, MBA, CFCDocument15 pagesIA - 2 Provision, Contingent Liability: Presented By: Renato O. Daquioag CPA, MBA, CFCaehy lznuscrfbjNo ratings yet

- Judicial Audit Results in DismissalDocument1 pageJudicial Audit Results in DismissalMikMik UyNo ratings yet

- Tenderer Information (Form - 2) : Private Limited CompanyDocument3 pagesTenderer Information (Form - 2) : Private Limited CompanyAsadur RahmanNo ratings yet

- Sybaf Sem 3 Sample McqsDocument14 pagesSybaf Sem 3 Sample Mcqs62 Amisha SawantNo ratings yet

- Mining in Brazil - LexologyDocument20 pagesMining in Brazil - LexologySean AndersonNo ratings yet

- Tingley v. Ferguson 9CA DecisionDocument73 pagesTingley v. Ferguson 9CA DecisionGrant GebetsbergerNo ratings yet

- 24-Ross Rica Sales Center, Inc. Vs Sps - Ong, G.R. No. 132197, August 16, 2005Document4 pages24-Ross Rica Sales Center, Inc. Vs Sps - Ong, G.R. No. 132197, August 16, 2005Elaika OrioNo ratings yet

- Form15h GH01389401 PDFDocument3 pagesForm15h GH01389401 PDFNamme KyarakhahaiNo ratings yet

- Indemnity BondDocument3 pagesIndemnity Bondsimplyarnav90No ratings yet

- Central Vigilance Commission RoleDocument15 pagesCentral Vigilance Commission RoleBharat Joshi100% (1)

- Lease Amendment AgreementDocument3 pagesLease Amendment AgreementSef KimNo ratings yet

- Regala vs. Sandiganbayan GR. NO.105938Document3 pagesRegala vs. Sandiganbayan GR. NO.105938Jel AbogaNo ratings yet

- Municipal Ordinance No. 257 S. 2008Document2 pagesMunicipal Ordinance No. 257 S. 2008Gui Mo IIINo ratings yet

- Registration Dynamic PrintDocument1 pageRegistration Dynamic PrintakhilNo ratings yet

- Carlill v Carbolic Smoke Ball Co: Advertisement as OfferDocument6 pagesCarlill v Carbolic Smoke Ball Co: Advertisement as OfferShashank Shekhar SinghNo ratings yet