Professional Documents

Culture Documents

VBR Hot Section and Major Overhaul Process Overview

VBR Hot Section and Major Overhaul Process Overview

Uploaded by

addinulichsanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VBR Hot Section and Major Overhaul Process Overview

VBR Hot Section and Major Overhaul Process Overview

Uploaded by

addinulichsanCopyright:

Available Formats

Independent hot section & major overhaul expertise for LM2500(+) and LM6000

Hot section or major overhaul coming up for your LM2500(+) or LM6000?

Hot section & major overhauls account for the biggest share of all LM maintenance budgets.

Realistic indications of the investments required for these crucial maintenance projects are:

Engine Type of maintenance Project cost Maintenance interval

LM2500(+) Hot section overhaul € 550.000 - € 1.200.000 3 to 4 years

LM2500(+) Major overhaul € 1.800.000 - € 2.500.000 6 to 8 years

LM6000 Hot section overhaul € 1.300.000 - € 2.200.000 3 to 4 years

LM6000 Major overhaul € 3.500.000 - € 4.500.000 6 to 8 years

Question: can more structured project management and smarter decision making

lead to significant quality benefits and cost savings in overhaul projects?

Answer: Yes they can! Adding independent VBR expertise will realize significant

quality and costs benefits for any LM hot section or major overhaul process.

Involving independent VBR expertise will obviously require an additional investment...

However:

This additional investment will be less than 1% of the total HS or MO project cost;

This additional investment will pay itself back multiple times by the end of the overhaul process.

How can the involvement of VBR LM overhaul expertise generate this very quick

return on investment?

By providing in-depth expertise & experience about LM overhauls which will deliver:

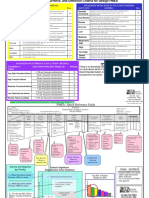

Overview hot section &

A more effective risk management on project scope, budget and turnaround time.

A more professional, more controlled and more predictable overhaul process supported by major overhaul process

smarter decision making.

A far better tailored HS or MO project completed at a much better quality & price than you

would have achieved without the support of an independent VBR expert. LM2500(+) LM6000

Looking for an LM overhaul solution specifically tailored towards your business profile and operating

purposes? Or interested in the most cost-effective LM overhaul solution available in the market today?

Contact VBR to request a complimentary knowledge session with a

VBR overhaul expert to address the questions that you or your on-site

operation & maintenance staff might have around LM overhauls.

E-mail: consultancy@vbr-turbinepartners.com | Phone: +31 88 010 90 84

Contact details Industrieweg Oost 6 +31 88 010 9030

VBR Turbine Partners 6662 NE Elst sales@vbr-turbinepartners.com

Main office & warehouse The Netherlands www.vbr-turbinepartners.com

Impact of VBR independent expertise on LM hot section & major overhaul process

>20 YEARS

Overview LM overhaul process LM owner Transport Overhaul depot VBR expertise Predictability Quality Turnaround Cost saving

& control time

Preparation phase

Define goal & planning LM hot section or major overhaul

Define preliminary overhaul scope

90 days

Tender out preliminary overhaul scope to licensed depots

Review overhaul depot quotations for preliminary scope

Decide on preliminary overhaul budget

Decide on overhaul depot

Execution phase

Remove LM engine from enclosure

Transport engine to selected depot

Disassemble engine into modules

Disassemble modules into component parts

Assess all component parts

Decide on component parts replacement vs. repair

Agree on semi-final overhaul scope & price

Replacement & repair of component parts

120 days

Monitor turnaround times replacement & repair parts

Decide on unexpected findings during this process

Agree on final overhaul scope & price

Rebuild the modules

Rebuild the engine

Monitor turnaround times modules & engine rebuild

Perform engine test

Witness engine test

Transport engine back to operator site

Reinstall LM engine in enclosure

Reporting phase

45 days

Perform scrap review

Depot submits overhaul report and final invoice

Review of depot overhaul report and final invoice

Submit overhaul evaluation report & recommendations

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EpsonDocument2 pagesEpsonaddinulichsanNo ratings yet

- Antigen Addinul 1 Jan 23Document1 pageAntigen Addinul 1 Jan 23addinulichsanNo ratings yet

- Kwitansi Addinul PCR 17 April 23Document3 pagesKwitansi Addinul PCR 17 April 23addinulichsanNo ratings yet

- DOD STD 2183 Hole 4Document1 pageDOD STD 2183 Hole 4addinulichsanNo ratings yet

- VBR General TCsDocument6 pagesVBR General TCsaddinulichsanNo ratings yet

- 6 - Condition Monitoring and Dynamic Balancing of A Hot Air Circulation Blower by Vibration Tool PDFDocument10 pages6 - Condition Monitoring and Dynamic Balancing of A Hot Air Circulation Blower by Vibration Tool PDFaddinulichsanNo ratings yet

- Boklet 0.1 PulangKamppus2023Document32 pagesBoklet 0.1 PulangKamppus2023addinulichsanNo ratings yet

- E85 24° - DatasheetDocument6 pagesE85 24° - DatasheetaddinulichsanNo ratings yet

- Severity, Occurrence, and Detection Criteria For Design FMEADocument2 pagesSeverity, Occurrence, and Detection Criteria For Design FMEAaddinulichsanNo ratings yet