Professional Documents

Culture Documents

DAR - Unit-3 - Week-3 - Reyes, Shiela Marie S.

Uploaded by

Geo Castaneto0 ratings0% found this document useful (0 votes)

12 views3 pagesOriginal Title

DAR_Unit-3_Week-3_Reyes, Shiela Marie S.

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views3 pagesDAR - Unit-3 - Week-3 - Reyes, Shiela Marie S.

Uploaded by

Geo CastanetoCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Daily Accomplishment Report

Cadet Engineer: Reyes, Shiela Marie S.

Company: Masinloc Power Plant Co. Ltd. Unit 3

Designation: Boiler

DAILY WORK ACTIVITIES

WEEK 3

NO. OF

DAY DATE DAILY ACCOMPLISHMENTS WORKING

HOURS

Reading/Monitoring of

Pressures, Temperatures, Oil

Levels for Air & Gas System and

Fuel Coal System

October 3, Visual Inspection of Coal

Monday 8

2022 Feeder, Pulverizer, Primary Air

Fan, Forced Draft Fan and

Induced Draft Fan for

vibrations, abnormal sound and

leaks

Tuesday October 4, Checked on vibration, abnormal 8

2022 sound, and leaks of the

equipment which includes Coal

Feeder, Pulverizer, Primary Air

Fan, Forced Draft Fan and

Induced Draft Fan

Line traced the boiler start up

valves which includes 384 valve

located at 3rd floor, 382 Valve

for BCP Recirculation located at

2.5th floor, 380 Bypass Valve

located at 2.5th floor, 381 Valve

located at 6th floor before

entering the economizer inlet,

383B and 383 Valve for BCP

Subcooling, 302 Valve located

at 10th floor from economizer

vent to VSS and the main feed

and subfeed valve from HP

Heater 9 to economizer inlet

located at 6.5th floor.

Reading/Monitoring of

Pressures, Temperatures, Oil

Levels for Air & Gas System and

Fuel Coal System

Reading/Monitoring of

Pressures, Temperatures, Oil

Levels for Air & Gas System and

Fuel Coal System

Assisted the mechanical team

to conduct their monthly

testing of Soot blowers

Checked the maintenance team

October 5, on their on-going repair for the

Wednesday

2022

8

hydrojet leakage.

Familiarization of equipment

specifically in soot blowers. 64

soot blowers for the main

boiler and 2 soot blowers for air

preheater

Conducted coal sample for coal

feeders E, C, B, A for 0800H

through the coupling cam lock

Thursday October 6, Reading/Monitoring of 8

2022 Pressures, Temperatures, Oil

Levels for Air & Gas System and

Fuel Coal System

Visual Inspection of Coal

Feeder, Pulverizer, Primary Air

Fan, Forced Draft Fan and

Induced Draft Fan for

vibrations, abnormal sound and

leaks

Reading/Monitoring of

Pressures, Temperatures, Oil

Levels for Air & Gas System and

Fuel Coal System

Conducted Fire Fighting

Surveillance Test.

Checked/Tested the following

equipment: Jockey Pump A,

Jockey Pump B, Electric Driven

Pump, Diesel Driven Pump, Fire

October 7, Water Booster Pump A and Fire

Friday

2022

8

Water Booster Pump B.

Conducted Emergency Diesel

Generator Surveillance Test.

The items to be inspected are:

Damper temperature, Oil

Temperature (oil pan), Coolant

temperature, Exhaust

temperature, fuel tank level,

engine oil level, engine speed,

frequency and engine running

hours.

TOTAL NO. OF HOURS: 40 HOURS

Certified by:

Engr. Noel Ladringan

Immediate Supervisor

You might also like

- Daily Accomplishment Report Boiler AreaDocument3 pagesDaily Accomplishment Report Boiler AreaGeo CastanetoNo ratings yet

- An Introduction To Controls For Steam Power Plants R1Document30 pagesAn Introduction To Controls For Steam Power Plants R1Ram HingeNo ratings yet

- An Introduction To Controls For Steam Power Plants: Course No: D02-003 Credit: 2 PDHDocument30 pagesAn Introduction To Controls For Steam Power Plants: Course No: D02-003 Credit: 2 PDHMKE3 HEROESNo ratings yet

- Steam Power PlantDocument30 pagesSteam Power PlantRichard GrahamNo ratings yet

- Energy Audit and Energy Efficient Recommendations With Payback Period For Industrial BoilerDocument7 pagesEnergy Audit and Energy Efficient Recommendations With Payback Period For Industrial BoilerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 05 VruDocument17 pages05 VruSergio RodriguezNo ratings yet

- 1 - DMX9402 - Unit 2 - Lect 5 - Boiler Op - Eff - 16 - 12 - 2023Document51 pages1 - DMX9402 - Unit 2 - Lect 5 - Boiler Op - Eff - 16 - 12 - 2023Sharath BogaNo ratings yet

- Ennaar Energy Systems Offers 1500 Kg/Hr BoilerDocument5 pagesEnnaar Energy Systems Offers 1500 Kg/Hr BoilerGobi NathNo ratings yet

- Boiler Uptake Fire and Exhaust Gas Economiser FireDocument2 pagesBoiler Uptake Fire and Exhaust Gas Economiser FireAVINASH ANAND RAO100% (1)

- Chapter 2 Boiler Design PDFDocument6 pagesChapter 2 Boiler Design PDFFernando Sandoval RuedaNo ratings yet

- Boiler Light Up ChecklistDocument8 pagesBoiler Light Up ChecklistHolly SmithNo ratings yet

- EPRF Report Com Fulton Steam BoilersDocument13 pagesEPRF Report Com Fulton Steam BoilersBlackzero68No ratings yet

- Op Eff 16 12 2023Document45 pagesOp Eff 16 12 2023Sharath BogaNo ratings yet

- Operating Mannua2Document96 pagesOperating Mannua2Ajay Kumar0% (1)

- 1 Boiler Cold Start UpDocument77 pages1 Boiler Cold Start UpSiddhant Satpathy100% (1)

- CH-17 Boiler Protections and InterlocksDocument21 pagesCH-17 Boiler Protections and InterlocksRavi ShankarNo ratings yet

- Boiler Operation Engineer (BOE) Viva QDocument12 pagesBoiler Operation Engineer (BOE) Viva QChetram Meena100% (1)

- 16 - Mortuary Freezer PDFDocument19 pages16 - Mortuary Freezer PDFWan Arif Wan NasirNo ratings yet

- Process Measurements ScheduleDocument25 pagesProcess Measurements ScheduleShivesh RanjanNo ratings yet

- GSFC Thermal FinalDocument46 pagesGSFC Thermal FinalKuldeep RupareliaNo ratings yet

- EN-FAB Capability StatementDocument1 pageEN-FAB Capability Statementcarmel BarrettNo ratings yet

- BKC On Economizer & WHRDocument56 pagesBKC On Economizer & WHRB K. ChoudhuryNo ratings yet

- Lecture - 1 - Thermal Equipment Design - IntroductionDocument14 pagesLecture - 1 - Thermal Equipment Design - IntroductionAbed Baayoun100% (2)

- Gas Networks - Technical OverviewDocument93 pagesGas Networks - Technical OverviewLamHotNo ratings yet

- Thermal Power Plant AuditingDocument29 pagesThermal Power Plant Auditingsenthil1386100% (3)

- EPA GPP Criteria Heating 2022 03Document58 pagesEPA GPP Criteria Heating 2022 03OYAESPETAHNo ratings yet

- Product Information: Solarbayer-BoilerDocument56 pagesProduct Information: Solarbayer-BoilerNoname RNo ratings yet

- Boost Boiler Efficiency with Proper Fuel SelectionDocument15 pagesBoost Boiler Efficiency with Proper Fuel SelectionOm Prakash DubeyNo ratings yet

- The warm way to choose an oil, gas, and dual fuel burnerDocument20 pagesThe warm way to choose an oil, gas, and dual fuel burnerbkprodhNo ratings yet

- Modular Refinery 10000 Offer PDFDocument10 pagesModular Refinery 10000 Offer PDFBIELDEL100% (2)

- Practical Guide To Industrial Boiler SystemsDocument375 pagesPractical Guide To Industrial Boiler Systemssumeet0827100% (19)

- Combustion Laboratory Unit C492: P.A.Hilton LTDDocument6 pagesCombustion Laboratory Unit C492: P.A.Hilton LTDVictor Hugo Valqui LopezNo ratings yet

- 1015t/h Subcritical Pressure Natural Circulation Boiler InstructionDocument74 pages1015t/h Subcritical Pressure Natural Circulation Boiler InstructioncynaiduNo ratings yet

- Ijmra 14668Document14 pagesIjmra 14668ffgffhggfNo ratings yet

- Oil and Gas Static Equipment OperationsDocument93 pagesOil and Gas Static Equipment OperationssajiNo ratings yet

- Boiler InstallationDocument268 pagesBoiler InstallationJessie MitchellNo ratings yet

- Wesman Thermal Engineering Processes Pvt Ltd Fuel Firing Equipment Operation and Maintenance ManualDocument23 pagesWesman Thermal Engineering Processes Pvt Ltd Fuel Firing Equipment Operation and Maintenance ManualSaibabu Sai100% (1)

- Universidad Nacional de Ingeniería Facultad de Ingeniería MecánicaDocument23 pagesUniversidad Nacional de Ingeniería Facultad de Ingeniería MecánicaDiego Andrés Jamanca DurandNo ratings yet

- Wagga Industry WorkshopDocument27 pagesWagga Industry WorkshoponlynameNo ratings yet

- BoilersDocument43 pagesBoilersMadanKarkiNo ratings yet

- PWR1059 Thermal Power Plant Performance Testing - May 2022Document11 pagesPWR1059 Thermal Power Plant Performance Testing - May 2022nguyenhuutan91No ratings yet

- Energy Audit Technical Detail FormatDocument6 pagesEnergy Audit Technical Detail FormatGreen BusinessNo ratings yet

- Turbine Inlet Air Cooling System (Bob Omdivar) Keuntungan Dan Kelebihan Sistem PendinginDocument41 pagesTurbine Inlet Air Cooling System (Bob Omdivar) Keuntungan Dan Kelebihan Sistem Pendingindimas100% (2)

- Required readiness for Blr. Light upDocument8 pagesRequired readiness for Blr. Light upIEPL BELANo ratings yet

- Gas TurbineInlet Air CoolingDocument41 pagesGas TurbineInlet Air CoolingDurjoy ChakrabortyNo ratings yet

- CDI - Concept NoteDocument34 pagesCDI - Concept NoteRitche Lim BragaisNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Dev Energy - GASIFIERDocument33 pagesDev Energy - GASIFIERvinay1999No ratings yet

- Kota Super Thermal Power Station: A Presentation OnDocument19 pagesKota Super Thermal Power Station: A Presentation OnGaurav GuptaNo ratings yet

- Power Plant Types and ComponentsDocument32 pagesPower Plant Types and ComponentsmarlitoNo ratings yet

- Furnace Atmosphere Control: Eurotherm ControlsDocument5 pagesFurnace Atmosphere Control: Eurotherm ControlsefasaravananNo ratings yet

- Thermal Power Plant: Design and OperationFrom EverandThermal Power Plant: Design and OperationRating: 4.5 out of 5 stars4.5/5 (23)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Audel HVAC Fundamentals, Volume 2: Heating System Components, Gas and Oil Burners, and Automatic ControlsFrom EverandAudel HVAC Fundamentals, Volume 2: Heating System Components, Gas and Oil Burners, and Automatic ControlsNo ratings yet

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Daily Time Record for January 2022Document1 pageDaily Time Record for January 2022Geo CastanetoNo ratings yet

- Evaluation training programDocument2 pagesEvaluation training programGeo CastanetoNo ratings yet

- MPPCL Work Activity Observation ReportDocument1 pageMPPCL Work Activity Observation ReportGeo CastanetoNo ratings yet

- DAR - Week-1 Turbine Castañeto, Geomarc Yvann A.Document4 pagesDAR - Week-1 Turbine Castañeto, Geomarc Yvann A.Geo CastanetoNo ratings yet

- Chiller - Wikipedia, The Free EncyclopediaDocument7 pagesChiller - Wikipedia, The Free EncyclopediaPushpendra KumarNo ratings yet

- Design of Gas Turbine Combustion ChamberDocument11 pagesDesign of Gas Turbine Combustion ChamberSai Rahul100% (1)

- Air Blower Pipe Sizing Calculation Common Main HeaderDocument7 pagesAir Blower Pipe Sizing Calculation Common Main HeaderEngFaisal AlraiNo ratings yet

- Final Year ProjectDocument23 pagesFinal Year ProjectManjunath Mj100% (1)

- PSV Calculations FlareDocument0 pagesPSV Calculations FlareSrinivas BobbyNo ratings yet

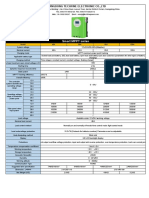

- Techfine MPPT DatasheetDocument1 pageTechfine MPPT DatasheetpeterNo ratings yet

- Pre-Start Up and Check List1Document4 pagesPre-Start Up and Check List1MechanicalLatestNo ratings yet

- Knowledge Management Series-Low Vacuum in Steam Turbine PDFDocument4 pagesKnowledge Management Series-Low Vacuum in Steam Turbine PDFMadhusudhan Pasumarty100% (1)

- Laboratory Manual MEC334: Internal Combustion Engine and Refrigeration LaboratoryDocument39 pagesLaboratory Manual MEC334: Internal Combustion Engine and Refrigeration LaboratoryManish JainNo ratings yet

- Hydrogen Production and DeliveryDocument2 pagesHydrogen Production and DeliveryAnkitPatel90No ratings yet

- Sp520 Off Grid Solar Inverter v1.01 - 副本Document5 pagesSp520 Off Grid Solar Inverter v1.01 - 副本Haitao YinNo ratings yet

- Tank SizingDocument1 pageTank SizingMohamad.NahhasNo ratings yet

- SOLTEQ Bench Cooling Tower TestDocument13 pagesSOLTEQ Bench Cooling Tower TestAlohaaSwezzNo ratings yet

- BE3255 Basic Civil and Mechanical Engineering Important QuestionsDocument6 pagesBE3255 Basic Civil and Mechanical Engineering Important Questionssar019987No ratings yet

- IMG - 0026 PSME Code 2012 24Document1 pageIMG - 0026 PSME Code 2012 24Bugoy2023No ratings yet

- Tutorial 3 TMDocument1 pageTutorial 3 TMGunjan MudgalNo ratings yet

- 15.8.3 Brochure - Priming System Trokomat Plus - OptDocument2 pages15.8.3 Brochure - Priming System Trokomat Plus - OptNurul Fyzi FauziahNo ratings yet

- Ecostar Ecostar Auto Eng SDocument40 pagesEcostar Ecostar Auto Eng Ssasko gorgievskiNo ratings yet

- Lecture Sheet PDFDocument65 pagesLecture Sheet PDFFaruk abdullahNo ratings yet

- Samsung Vivace Wall Mounted Heat PumpsDocument3 pagesSamsung Vivace Wall Mounted Heat Pumpse-ComfortUSANo ratings yet

- Codes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety ConceptsDocument14 pagesCodes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety Conceptsjose_sebastian_2No ratings yet

- M.tech Project ListDocument6 pagesM.tech Project Listsatya_vanapalli3422No ratings yet

- Calcutta University Faculty ProfileDocument3 pagesCalcutta University Faculty Profilemunro_85No ratings yet

- Research Paper Chapter 1-3Document22 pagesResearch Paper Chapter 1-3johnis19dcNo ratings yet

- PTC 6 Asme Flow NozzleDocument2 pagesPTC 6 Asme Flow NozzleAbdel HamidNo ratings yet

- Complex Engineering Problem: Mohammad Hussain Submitted To: BSME: 18-22 Roll: 19 Dr. Rab NawazDocument11 pagesComplex Engineering Problem: Mohammad Hussain Submitted To: BSME: 18-22 Roll: 19 Dr. Rab NawazMohammad HussainNo ratings yet

- Pi 313PDocument3 pagesPi 313PmustafaNo ratings yet

- Rice PlumbingDocument2 pagesRice PlumbingDigital MediaNo ratings yet

- Design Practice Piping Around EquipmentDocument4 pagesDesign Practice Piping Around EquipmentdevNo ratings yet