Professional Documents

Culture Documents

Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7

Uploaded by

Nilton Santillan OrtegaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7

Uploaded by

Nilton Santillan OrtegaCopyright:

Available Formats

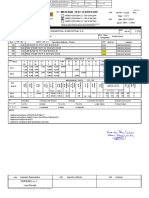

PAGE:1/7

QUANTITY AND

MAG GENERAL BUSINESS CERTIFICATE NO.: FRMH211112 DATE: JUN.13,2022

QUALITY

P/O NO.: FR22-018

CERTIFICATE S/C NO.: FRMH211112

THE BUYER: FIORELLA REPRESENTACIONES S.A.C.

CALLE OMICRON Nro. 215, CALLAO PERU

(EN 10204/3.1) C/I NO.: FRMH211112

RUC NRO. 20101256422

TOTAL: 66001 PCS SURFACE PROTECTION: SANDBLAST AND BLACK PAINT

DESCRIPTION OF GOODS: SEAMLESS CARBON STEEL BUTT-WELDING PIPE FITTINGS (ASTM A234 WPB, ANSI B16.9)

MATERIAL HEAT TREATMENT

NO. ITEM SIZE UNIT QUANTITY HEAT NO. SURFACE QUALITY GEOMETRY DIMENSION

STANDARD CONDITION

1 SCH40 ELBOW 45° LR 3" A234 WPB PCS 500 1103 SATISFACTION SATISFACTION

2 SCH40 ELBOW 45° LR 5" A234 WPB PCS 70 1105 SATISFACTION SATISFACTION N910°C × 2.0H

3 SCH40 ELBOW 45° LR 8" A234 WPB PCS 120 1108 SATISFACTION SATISFACTION

4 SCH40 ELBOW 45° LR 10" A234 WPB PCS 120 1110 SATISFACTION SATISFACTION NONDESTRUCTIVE

5 SCH40 ELBOW 90° LR 1" A234 WPB PCS 10000 1101 SATISFACTION SATISFACTION TEST

6 SCH40 ELBOW 90° LR 1.1/4" A234 WPB PCS 20000 1125 SATISFACTION SATISFACTION

7 SCH40 ELBOW 90° LR 1.1/2" A234 WPB PCS 20000 1115 SATISFACTION SATISFACTION -

8 SCH40 ELBOW 90° LR 2" A234 WPB PCS 10000 1102 SATISFACTION SATISFACTION

CHEMICAL COMPOSITION AND MECHANICAL PROPERTY OF THE RAW MATERAL

CHEMICAL COMPOSITION(%) MECHANICAL PROPERTY

NO.

C Mn P S Si Cr Mo Ni Cu V OTHER (σbMpa) (σSMpa) (δ%) HARDNESS

TENSION YIELD ELONGA- HB

MIN 0.29 0.10 - - TEST STRENGTH TION

MAX 0.30 1.06 0.050 0.058 0.40 0.15 0.40 0.40 0.080 - - 415-585 240(min) 22(min) 197(max)

1 0.21 0.45 0.032 0.042 0.31 0.080 0.090 0.039 0.090 0.065 - - 460 249 27 171

2 0.19 0.45 0.032 0.042 0.25 0.080 0.090 0.039 0.090 0.065 - - 465 248 28 170

3 0.15 0.52 0.032 0.035 0.16 0.100 0.050 0.037 0.090 0.060 - - 465 247 27 162

4 0.18 0.53 0.027 0.035 0.19 0.070 0.060 0.033 0.110 0.065 - - 462 249 26 165

5 0.18 0.53 0.027 0.035 0.20 0.070 0.060 0.033 0.110 0.065 - - 462 249 28 168

6 0.16 0.52 0.032 0.035 0.16 0.100 0.050 0.037 0.090 0.060 - - 461 246 27 162

7 0.17 0.52 0.027 0.035 0.22 0.070 0.060 0.033 0.110 0.075 - - 465 249 27 169

8 0.19 0.31 0.032 0.035 0.26 0.090 0.090 0.041 0.100 0.065 - - 463 249 26 167

1.Above fitting were hot formed and final forming operation is complete at a temperature above 620℃ and below 980℃ and cooled in still air.

2.We hereby certify that material described herein has been manufactured and tested with satisfactory results in accordance with the requirement of above material code and purchase specification.

3.We hereby certify that material described above has been successfully tested and complies with the terms of the order.

4.We hereby certify the certificate comply with EN10204/3.1.

You might also like

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- MTC Forged Fitting ElbowDocument1 pageMTC Forged Fitting Elbowfreeman11072000No ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Document1 pageASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Document3 pagesMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasNo ratings yet

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- LF' JLRDocument1 pageLF' JLRIslam SahafayatNo ratings yet

- 075P80-321 TubacexDocument1 page075P80-321 Tubacexsakshi patilNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

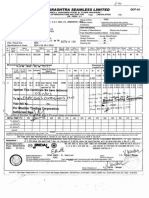

- MAHARASHTRA SEAMLESS LIMITED CERTIFICATE OF MANUFACTURE AND TEST FOR PIPESDocument1 pageMAHARASHTRA SEAMLESS LIMITED CERTIFICATE OF MANUFACTURE AND TEST FOR PIPESPetroPower OilandgasNo ratings yet

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- Neway Gate 6 X 150 RFDocument6 pagesNeway Gate 6 X 150 RFcomercial 3No ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- Weflo Valve Co., LTD.: Material Test CertificateDocument1 pageWeflo Valve Co., LTD.: Material Test CertificateCarlosEduardoMorenoManceraNo ratings yet

- SS304-1 2THK PDFDocument1 pageSS304-1 2THK PDFrajNo ratings yet

- Ball Valve MTCDocument1 pageBall Valve MTCAdnanAtifNo ratings yet

- Raw Material MTC - API 5L GR B PSL 2Document3 pagesRaw Material MTC - API 5L GR B PSL 2ClarkFedele27No ratings yet

- MTC FITTINGSDocument5 pagesMTC FITTINGSAzee TitouNo ratings yet

- MTC Elbow 6inDocument1 pageMTC Elbow 6inhenryNo ratings yet

- OMR pipe fittings certificate analysisDocument1 pageOMR pipe fittings certificate analysisslimane AIT-IDIRNo ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocument1 pageTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- 4140 Material For TubeDocument2 pages4140 Material For Tubesharafudheen_sNo ratings yet

- T T - Tubacex Ubos Inox Dables S A: Mill Test C T IcateDocument3 pagesT T - Tubacex Ubos Inox Dables S A: Mill Test C T IcatePRANAY OMTECHNo ratings yet

- 622888Document1 page622888DeepakNo ratings yet

- Material Test Report: ISO EN 10204 2004-3.1Document4 pagesMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- 2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14Document8 pages2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14JORGE BAENA100% (1)

- No. A-14-401751 Rev 00Document3 pagesNo. A-14-401751 Rev 00Adrian CeplinschiNo ratings yet

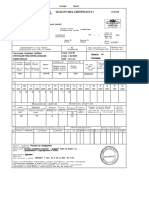

- QUALITY MILL CERTIFICATE FOR HOT ROLLED STEEL ROUND, ANNEALED GRADE AISI4140Document1 pageQUALITY MILL CERTIFICATE FOR HOT ROLLED STEEL ROUND, ANNEALED GRADE AISI4140Mohamed NabeilNo ratings yet

- Quality Certificated 123Document1 pageQuality Certificated 123Zaid Raslan Ayoub100% (1)

- QD62-H-103 DocumentationDocument16 pagesQD62-H-103 DocumentationAlam MD SazidNo ratings yet

- Essar MTCDocument1 pageEssar MTCGowtham Vishvakarma33% (3)

- WNRF 2 MFF ItalyDocument1 pageWNRF 2 MFF ItalyMohamed RaafatNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- 9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFDocument1 page9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFantonio larotta100% (1)

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- TV 100x100x5#S235JRDocument5 pagesTV 100x100x5#S235JRRazvan CristeaNo ratings yet

- MTC - 274470Document2 pagesMTC - 274470sreejith123456No ratings yet

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech099200No ratings yet

- IS 10748_2004 Compliant HR Steel Coils CertificateDocument1 pageIS 10748_2004 Compliant HR Steel Coils CertificateravigurajapuNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Check Valve 6in HT 6YF4Document1 pageCheck Valve 6in HT 6YF4Juan Pablo Perdomo OrtizNo ratings yet

- Test Certificate Hot Rolled, Medium High Tensile Steel: SailDocument3 pagesTest Certificate Hot Rolled, Medium High Tensile Steel: SailJignesh Jagjivanbhai PatelNo ratings yet

- MTC PDFDocument170 pagesMTC PDFShoukat Zaki0% (2)

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- MTCDocument6 pagesMTCNauman Zia100% (1)

- M 001 22Document1 pageM 001 22LUISNo ratings yet

- Tr-33 Generic Butt Fusion Joining Gas PipeDocument32 pagesTr-33 Generic Butt Fusion Joining Gas PipeLuis QuinoNo ratings yet

- Mag General Business: Quality CertificateDocument1 pageMag General Business: Quality CertificateNilton Santillan OrtegaNo ratings yet

- MAG GENERAL BUSINESS QUALITY CERTIFICATEDocument1 pageMAG GENERAL BUSINESS QUALITY CERTIFICATENilton Santillan OrtegaNo ratings yet

- Mag General Business: Quality CertificateDocument1 pageMag General Business: Quality CertificateNilton Santillan OrtegaNo ratings yet

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateNilton Santillan OrtegaNo ratings yet

- Astm A48 PDFDocument5 pagesAstm A48 PDFPhan Linh100% (1)

- Isométrico Línea 2040-9856-Aa1b-8"-Rw-N MQ13-173-DR-2040-PD2008Document1 pageIsométrico Línea 2040-9856-Aa1b-8"-Rw-N MQ13-173-DR-2040-PD2008Nilton Santillan OrtegaNo ratings yet

- Certificados de Calidad TintesDocument3 pagesCertificados de Calidad TintesNilton Santillan OrtegaNo ratings yet

- A108Document4 pagesA108Mathew CherianNo ratings yet

- Rolled Floor Plate, Stainless Steel: Standard Specification ForDocument4 pagesRolled Floor Plate, Stainless Steel: Standard Specification ForNilton Santillan OrtegaNo ratings yet

- ASTM A 6m-01a PDFDocument63 pagesASTM A 6m-01a PDFLizz EstradaNo ratings yet

- A002 Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocument3 pagesA002 Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDaniel Alonso Flores MezaNo ratings yet

- Astm g57 95aDocument5 pagesAstm g57 95aNilton Santillan OrtegaNo ratings yet

- Astm G82 PDFDocument7 pagesAstm G82 PDFVenreplast PueblaNo ratings yet

- Steel Forgings, General Requirements: Standard Specification ForDocument9 pagesSteel Forgings, General Requirements: Standard Specification ForNilton Santillan OrtegaNo ratings yet

- ASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDocument30 pagesASME B36 10M-2015 Welded and Seamless Wrought Steel PipeDaniel Diaz PrietoNo ratings yet

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocument11 pagesHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesNilton Santillan OrtegaNo ratings yet

- D6910 Marsh Funnel Test BentoniteDocument3 pagesD6910 Marsh Funnel Test BentoniteTanvir Hasan100% (2)

- Astm A790Document6 pagesAstm A790revelkNo ratings yet

- Steel Castings, Stainless, Instrument Calibration, For Estimating Ferrite ContentDocument4 pagesSteel Castings, Stainless, Instrument Calibration, For Estimating Ferrite ContentNilton Santillan OrtegaNo ratings yet

- Installing Factory-Made Corrugated Steel Pipe For Sewers and Other ApplicationsDocument6 pagesInstalling Factory-Made Corrugated Steel Pipe For Sewers and Other ApplicationsNilton Santillan OrtegaNo ratings yet

- Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessDocument6 pagesSteel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessNilton Santillan OrtegaNo ratings yet

- Maximum Index Density and Unit Weight of Soils Using A Vibratory TableDocument14 pagesMaximum Index Density and Unit Weight of Soils Using A Vibratory TableNilton Santillan OrtegaNo ratings yet

- Structural Design of Corrugated Steel Pipe, Pipe-Arches, and Arches For Storm and Sanitary Sewers and Other Buried ApplicationsDocument20 pagesStructural Design of Corrugated Steel Pipe, Pipe-Arches, and Arches For Storm and Sanitary Sewers and Other Buried ApplicationsNilton Santillan OrtegaNo ratings yet

- ASME B107.100-2010 Flat WrenchesDocument68 pagesASME B107.100-2010 Flat WrenchesNilton Santillan Ortega100% (1)

- A795Document6 pagesA795Ron HarmonNo ratings yet

- ASME B107.100-2010 Flat WrenchesDocument68 pagesASME B107.100-2010 Flat WrenchesNilton Santillan Ortega100% (1)

- ASME B107.100-2010 Flat WrenchesDocument68 pagesASME B107.100-2010 Flat WrenchesNilton Santillan Ortega100% (1)

- API 12B Bolted Tanks For Storage LiquidsDocument30 pagesAPI 12B Bolted Tanks For Storage LiquidsNilton Santillan OrtegaNo ratings yet

- En 13237-2003 Terms and Definitions For Equipment and Protective Systems Intended For Use in Potentially Explosive AtmospheresDocument26 pagesEn 13237-2003 Terms and Definitions For Equipment and Protective Systems Intended For Use in Potentially Explosive AtmospheresGargiulo AnitaNo ratings yet

- Fitoremediasi Tanah Tercemar Logam Berat CD Menggunakan TANAMAN HANJUANG (Cordyline Fruticosa)Document9 pagesFitoremediasi Tanah Tercemar Logam Berat CD Menggunakan TANAMAN HANJUANG (Cordyline Fruticosa)Ayulian SaraNo ratings yet

- Ni ComplexDocument11 pagesNi ComplexJ Luis MlsNo ratings yet

- HEAT TRANSFER LAB REPORTDocument45 pagesHEAT TRANSFER LAB REPORTnighatNo ratings yet

- Recovery Nickel From Pregnant Solution by Precipitation Gases HFMDocument19 pagesRecovery Nickel From Pregnant Solution by Precipitation Gases HFMHesga FadiastianNo ratings yet

- ECE Lab Manual Requirements Sep 2021Document10 pagesECE Lab Manual Requirements Sep 2021supinya bieNo ratings yet

- Coagulation of Natural Rubber Latex with Hydrochloric AcidDocument6 pagesCoagulation of Natural Rubber Latex with Hydrochloric Acidchaminda nayanajithNo ratings yet

- Analysis of ToothpasteDocument29 pagesAnalysis of Toothpasteanushka chadha100% (1)

- General Chemistry Lab Qualitative Cation AnalysisDocument22 pagesGeneral Chemistry Lab Qualitative Cation AnalysisJaafar Al-AlusiNo ratings yet

- Sixto Giménez, Juan Bisquert (Eds.) - Photoelectrochemical Solar Fuel Production - From Basic Principles To Advanced Devices-Springer (2016)Document574 pagesSixto Giménez, Juan Bisquert (Eds.) - Photoelectrochemical Solar Fuel Production - From Basic Principles To Advanced Devices-Springer (2016)firox2005No ratings yet

- Hilts 105Document277 pagesHilts 105Wesley CheungNo ratings yet

- Egg Egg: Breaks Does Not BreakDocument3 pagesEgg Egg: Breaks Does Not BreakLily Suhany MahmoodNo ratings yet

- Wondraczek Et Al. - 2022 - Advancing The Mechanical Performance of Glasses PDocument25 pagesWondraczek Et Al. - 2022 - Advancing The Mechanical Performance of Glasses PAlireza BagherpourNo ratings yet

- Organic Electronics Journal Covers Wide ResearchDocument5 pagesOrganic Electronics Journal Covers Wide ResearchRam PrasadNo ratings yet

- 25) 8 ನೇ ತರಗತಿ ವಿಜ್ಞಾನ ಆಂಗ್ಲ ಮಾ.ಮಾ.ಪ್ರ.ಪ-1Document9 pages25) 8 ನೇ ತರಗತಿ ವಿಜ್ಞಾನ ಆಂಗ್ಲ ಮಾ.ಮಾ.ಪ್ರ.ಪ-1Abhisheck JatNo ratings yet

- PHY 201 - Thermodynamics and Kinetic Theory of Gases: Unit Name of The Unit SyllabusDocument1 pagePHY 201 - Thermodynamics and Kinetic Theory of Gases: Unit Name of The Unit SyllabusBhoomi ShettyNo ratings yet

- Amines Amino Acids ProteinsDocument13 pagesAmines Amino Acids ProteinsClifford Dwight RicanorNo ratings yet

- SuspensionDocument31 pagesSuspensionSakandar TalibNo ratings yet

- Fan Et Al. - Solids Mixing - Ind. and Eng. Chemistry (1970) Vol 62 NR 7Document17 pagesFan Et Al. - Solids Mixing - Ind. and Eng. Chemistry (1970) Vol 62 NR 7BerndUmmeNo ratings yet

- Stauff Englisch BT 6 2023Document4 pagesStauff Englisch BT 6 2023PeterNo ratings yet

- Heat Transfer PDFDocument3 pagesHeat Transfer PDFTahmeed AzizNo ratings yet

- 5991 5571enDocument10 pages5991 5571enHoanghanh LequangNo ratings yet

- Electro Cat Alys Is 101Document29 pagesElectro Cat Alys Is 101Vu LeNo ratings yet

- Produced Water OverviewDocument86 pagesProduced Water Overviewsigit cahyonoNo ratings yet

- Effect of Temperature On Wind Forces On Tall Building Using Numerical Approach - Computational Fluid Dynamics (CFD)Document6 pagesEffect of Temperature On Wind Forces On Tall Building Using Numerical Approach - Computational Fluid Dynamics (CFD)Jay KasodariyaNo ratings yet

- Set 1Document18 pagesSet 1RON MARK EDWARD ANDALUZNo ratings yet

- TUTORIAL SHEET 2019 On Hydrostatic PressureDocument5 pagesTUTORIAL SHEET 2019 On Hydrostatic PressureAndrew ChikuselaNo ratings yet

- 11962-Encapsulated Citric AcidDocument10 pages11962-Encapsulated Citric AcidantiquekNo ratings yet

- G.6 Q.1 SCIENCE Lesson 2 Homogeneous MixtureDocument35 pagesG.6 Q.1 SCIENCE Lesson 2 Homogeneous MixturemeguiNo ratings yet

- Skin Effect in Transmission Lines ExplainedDocument13 pagesSkin Effect in Transmission Lines Explainedthilini100% (1)