Professional Documents

Culture Documents

A2020m12d23 Design & Execution of Cable Anchord For Reinforced Solope - Geoxchange

Uploaded by

Luiz Antonio Naresi JuniorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A2020m12d23 Design & Execution of Cable Anchord For Reinforced Solope - Geoxchange

Uploaded by

Luiz Antonio Naresi JuniorCopyright:

Available Formats

250

Nov.-Dec. 2020

Vol.01 Issue.03

Chritophe Balg Rudra Budhbhatti

Geobrugg Maccaferri

The Need of the Hour

IN THE LAST FEW DECADES, TREMENDOUS GROWTH HAS BEEN WITNESSED IN

THE TECHICAL AVALANCHE PROTECTION SYSTEMS AND IT HAS EVOLVED AS AN

INDEPENDENT ENGINEERING BRANCH IN ASIAN, EUROPEAN AND AMERICAN COUNTRIES

INDEX 4

60. Interview -

A candid chat with Mr. Katikeya

Kalani, President Flexituff International

Limited on application of geosynthetics

in river training works

63. Interview -

In Conversation with Mr. Manish

Barot, Head-Technical Sales and

Business Development at TechFab

India

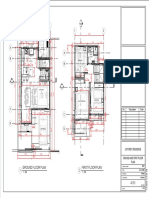

66. Case Study -

Design & Execution Of Cable Anhord

For Reinforced Slope – An In-depth

study on the construction of reinforced

walls for prevention and mitigation of

landslide using cable anchors

75. Webinar –

Excerpts from the live webinar

on Avalanche Protection – The

Need of The Hour

80. Interview -

Rendezvous with Dr. TN Singh,

Vice Chancellor at Mahatma

Gandhi Kashi Vidyapith

WWW.GEO-XCHANGE.COM | VOL..01 ISSUE .03

LETTER

5

The year 2020 has been full of unexpected

FROM THE EDITOR

turn of events to say the least, being hit by a

pandemic is something neither of us ever

anticipated. While we are still getting accustomed

to the “new normal” for me the year 2020 will

be a memorable one since this was the year

“GeoXchange” was born. Today, writing this note

on a warm winter afternoon, I am humbled by

how welcoming this industry has been of our

endeavor. We at GeoXchange are grateful

to each and every member of this fraternity

who has shown faith in us and given us the

opportunity to tell their story. With the third

NEHA BAJAJ

issue of our magazine ready for publication, Editor-in-Chief

I am proud to say that we have been able to coversations to the fore front will get you one

achieve, 4000 + downloads of our first two step closer to knowing more about successes,

editions and a tremendous response to the series of projects and players of this industry. I would like

webinars that we have been hosting. With every to extend my thanks to everyone who helped

issue and webinar, I can see us grow from us put this issue together, your contribution is

strength to strength and achieve global greatly valued.

recognition in countries like Switzerland, USA, We are also gearing up for our next webinar

Italy and more. in January. Stay tuned to know more about it

The world is a land of diverse terrains, which along with compelling news features from the

also means that we are constantly dedicating industry by subscribing to our website

resources to mitigate a multitude of plausible www.geo-xchange.com and following us on our

disasters that can greatly impact the global social media handles.

economy. With the onset of winters every year, As we all gear up for the coming year, here’s

my newsfeed is drowned with incidents of heavy hoping that 2021 brings in health and happiness

snowfall, avalanches and stories about regions to everyone around us and may we get success

that are cut-off from civilization for almost six on COVID Vaccine soon so we can be assured of

months because of it. As a conscious global safety of our loved ones. With the New Year, we

citizen, these stories have often led to a at GeoXchange are also geared up and excited

profound awareness of this plight, with the to further diversify our portfolio and bring to you

heartbreaking understanding that perhaps not more in-depth conversations and stories with

much can be done about it. When I extended my leaders and stakeholders that go beyond the

communications business and dived into the realms of natural hazard mitigation. I sincerely,

journalistic world of Geohazard mitigation hope you continue to enjoy this new chapter of

earlier this year, I was surprised at how little we our journey with us. On that note it’s time to

get to know about the efforts made by so many be merry and welcome the new year! Feel free

players in this industry to mitigate risks relate d to write to me should you have any

to high altitude terrains around the world. As an queries / recommendations.

ode to the voices that haven’t been heard, the

third issue of GeoXchange is dedicated towards Merry Christmas and a Happy and Prosperous

navigating the world of Avalanche Protection New Year!

which is truly a need of the hour.

I sincerely hope our efforts in bringing these See you in February.

GEOXCHANGE | DECEMBER 2020

TEAM 6

OUR TEAM BOARD

GEOXCHANGE is guided by an advisory board comprising industry veterans and professionals from

IIT, having vast knowledge & experience in geotechnical engineering and more.

nerjee

m Arundhati Ba ator

ambhir Yash Sundaraator ontent Coordin

C

Meenakshi G nt Coordin

Conte

Sr. Copy Editor

g

agi Saanvi Dan aliser

Abhishek Ty Illustrator & V

isu

awadi

Senaara Ail Web Develop

er

ector

Marketing Dir

All materials printed in this publication is the sole property of GXG Publishing House Private

Limited. All printed matter contained in the magazine is based on the information provided by the

writers/authors. The views, comments, and opinions expressed are solely of the

writers/authors or those featured in the articles and the Editors, Printers, & Publishers do not

necessarily subscribe to the same.

In relation to any advertisements appearing in this publication, readers are advised to make

appropriate enquiries before entering into any commitments. GXG Publishing House Pvt. Ltd.

does not vouch for any claims made by the advertisers of products and services. The printers,

publishers, and Editors of the publication shall not be held liable for any consequences arising

out of any reliance placed on any such advertisements in the print or digital editions

of the publication.

Copyright of GXG Publishing House Pvt. Ltd. All rights reserved. Reproduction in any manner is

prohibited. All disputes are subject to the jurisdiction of competent courts and forums in

Gurgaon only. GXG Publishing House Pvt. Ltd. does not accept responsibility for returning unsolicited

manuscripts and photographs.

Public Relations, Social Media, Digital Media Marketing, Web development service and Design

handled by Scroll Mantra Private Limited, Gurugram, India.

WWW.GEO-XCHANGE.COM | VOL..01 ISSUE .03

CASE STUDY 66

DESIGN & EXECUTION OF

CABLE ANCHORD FOR

REINFORCED SLOPE

Luiz Antonio Naresi Junior (Author)

PROGEO, BELO HORIZONTE, BRASIL

RESUME:

This project focusses on the use ofconstruction of reinforced walls for

prevention and mitigation of landslide using cable anchors in a envi-

ronmently friendly way with the highest safety for the workers involved

in accordaince to the guidelines of Brazil.

Cable anchors is a specialized engineering application used to an-

chor reinforced concrete structures to the ground in order to contain a

slope, we will describe some executive methods for the construction of

a reinforced slope. It is one of the active containment solution for slope

stabilization which addresses the issue of global stability, by introduc-

ing a force corresponding to a stabilizing thrust that reacts against

unstable masses.

The execution of a cable anchor, as well as reinforced concrete slope,

are part of the stabilizing solution of massifs and involve various en-

gineering activities such as drilling in soil, alteration of rock and rock,

injection of cement grout under pressure, execution of form, frame

and concreting and finally the prestressing of the strands, these works

are generally performed on scaffolding with manual and mechanical

excavations. All services present in the execution of cable anchors in-

volve serious risks to worker safety.

In most situations, site conditions involve other engineering risks such

as; working at height, trench excavations and sliding slopes.

In this project, the author, who is a Civil Engineer with specialiation

in Occupational Safety Engineer and Environmental Analyst, and has

been working since he graduated with the art of Geotechnics, man-

aged to address in detail about all the executive procedures and the

corresponding approach to work with safety and prevent any damage

to the environment. Protecting environment is one of the highest pri-

ority for geotechnical engineers, designers, executors, occupational

safety engineers and occupational safety technicians.

KEYWORDS: CALCULATION, EXECUTION, ANCHORTIRANTE,

ANCHORS, SLOPE STABILIZATION, LANDSLIDE MITIGATION

WWW.GEO-XCHANGE.COM | VOL..01 ISSUE .03

67 CASE STUDY

1. PRESENTATION OF THE It is as if we made a hole in all the books, pass-

TIE ROD ing a threaded screw and putting a nut on each

side and tightening, as shown in Figure 04.

1.1. Prestressing

If we want to take a lot of books at once, we

“squeeze” them as shown in Figure 01 and thus

transport them to the place we want. If we don’t

press the books against each other, as shown in

Figure 02, they will fall to the floor.

Figure 3: The impressed fort

Figur1 1: Strong – Horizontal Force

Figure 4: Horizontal Effort

Source: Own Collection

This screw is nothing more than a type of tie rod.

Figure 2: Weak – Horizontal Force

Source: Own Collection 2.2 Tie-in rod

The riser takes a little more work, but the idea is

This squeeze, we call “prestressing”. the same.

Do you know why our foot is forward?

GEOXCHANGE | DECEMBER 2020

CASE STUDY 68

to the slide, not letting the bank or mountain slip.

This operation of “pulling out” the bar from the

ground is called “prestressing”, and when we re-

quest the bar, it “presses” the ground (as in the

books on the table).

This force that we apply to the bar is called “trac-

tion” or “tensioning” and the bar (can be one, or

several grouped together) is called tie rod.

Figure 5: Foot Support - Efforts that work.

Source: Own collection.

If we cut off the tip of our foot, we will fall be-

cause we lose our support.

On a mountain, the same thing happens. If we

dig the foot of the mountain, it loses its support,

and it slides: at the top it collapses at the bottom.

If soon after we cut the mountain, we can put

pressure on it (as in the books on the table), the

mountain will not fall.. Figure 7: Principle of the draped curtain

Source: Own Collection

2. WHAT IS AN ANCHOR FOR

As we saw above, risers are therefore elements

that support tensile forces and serve to balance

the forces exerted by earth masses.

As we have seen, we must not delay in its

execution: in general the terrains are weak

Figure 6: Slope collapse (when compared to the strength of steel and

Fonte: Own collection concrete) and with the help of water, which is

always present, they easily collapse.

But, how to make this squeeze, if there is no one Therefore, the speed and perfection in the

to hold on the other side? execution of a tie, in all its phases (drilling of

Then someone had an idea: he drilled a hole in the land, assembly and installation inside the

the ravine, tilted downwards, filled the hole with hole, injection of cement grout and pretension)

a mixture of water and cement and put an iron are essential conditions, both for the work and

bar inside. for the safety of people who are running the

When the cement hardened, it “pulled” the iron same.

rod out, as if it wanted to pull it out: the sticky

section did not let the rod out. Then it made a 2.1 Type of Tie rods

floor of wood, or of steel or concrete profiles, and Nowadays there is a huge variation of types of

built a device that would not let the bar return to tie rods, we mention below the most usual ones

its original position, and released the bar. When that can be summarized in:

the bar was released, it “pushed” the bank, with 2.1.1 Wire tie rods

a force in the opposite direction to the slide, not 2.1.2 Wire rope tie rods

letting the bank or mountain slip. 2.1.3 Rod risers

WWW.GEO-XCHANGE.COM | VOL..01 ISSUE .03

69 CASE STUDY

Figure 8: Layout of a bar tie rod

Source: Own Collection

Figure 11: 8 Wire Rope dia 8mm

Source: Own collection

Figure 9: Tie Rod Figure 12: Detail of the free section

Source: Own Collection Source: Own collection

Figure 10: Wire/Strand Holders Figura 13: Middle of Anchored & Free Section

Source: Own Collection Source: Own collection

GEOXCHANGE | DECEMBER 2020

CASE STUDY 70

Figure 17: Bench injection tie rod

Source: Own collection

3.ELEMENTS THAT MUST BE IN

Figure 14: Protection detail

Source: Own collection

THE WORK

For the execution of risers, we must be in

possession of the work, obligatorily of the

elements that concern the execution.

3.1.The Survey Report

It describes the type of soil or rock that we are

going to drill, whether it is soft or hard,whethere

there is water and if there is a ripple, etc.

This drilling report is very important which

informs us, what type of equipment we are going

to use, what drill or hammer we are going to

use and, whether or not we have to cover the

hole, the way to inject the rod, the pressures

to be applied, the care to be taken so that

neighboring buildings are not damaged, etc.

Figure 15: End of the anchored section

Source: Own collection 3.2.Tie-rod design

It shows where we should start drilling: so many

meters from the top, so many meters from the

ground.

Placing the tie rod in the wrong position can

cause inconvenience later. For this it is very

important to know where the head of the tie is

in relation to the ravine.

3.3.Drawing informing the characteristic

of the tie

a) If it is made of bar, wire or cordage;

b) How many bars, wires or strings;

c) How long the tie rod: free, anchored and left

over (out of the ground);

Figure 16: Prestressed wire rope d) What is the inclination to be given when drilling?

Source: Own collection e) What type of corrosion protection:

WWW.GEO-XCHANGE.COM | VOL..01 ISSUE .03

71 CASE STUDY

f) The. painting: type of paint, how many coats; 4.MASSEMBLY PROCEDURE OF A

a. sheath: individual and / or collective. TIE-ROD

3.4. Execution bulletins First, let’s list the materials that will make up the

Execution reports record the history of each tie. tie: steel wires; the spacers; the hems; plastic

That is why it is essential to complete and correct masses; the paints; the central tube, with injection

filling, which are: drilling, assembly, injection valves; the wire.

and pretension.

4.1. Steel wires

You have to arrive at the construction site with

a certificate. The certificate shows his resistance,

which we must compare with the resistance

marked in the project.

4.2. Spacers

The function of the spacers is to assemble the

wires or strands separately from each other, so

that at the time of injection, the syrup uniformly

envelops them in the anchorage area. They are

placed every 0.5 meters of wire / strand or 2.5

Figure 18: Boult assembly,drilling & injection bulletin meters in bar tie rod.

Source: Own collection

4.3. Sheaths

The sheath can be individual, collective or joint.

The sheath will insulate the wires along the free

stretch, from contact with the cement grout. The

individual sheath is a plastic tube that we place

on each rod or wire on the rod.

The collective sheath is a tube or hose that wraps

all of the wires simultaneously.

The joint sheath is the use of two sheaths,

individual and collective, at the same time.

The hem must also not tear. Therefore, the tie

rod must be handled with care, especially when

it is placed inside the hole.

4.4. Plastics

They are placed in the passage from the free

zone to the anchoring zone on all ties, whether

permanent or temporary. At the bottom of the

tie, put the plastic putty only when the tie is final.

No temporary tie rod is necessary.

4.5. The paints

Before painting, the wires or strands must be

carefully cleaned on the entire surface to remove

Figure 19: Presetressing bulletin areas of oxidation, rust spots, grease and resins.

Source: Own Collection Cleaning should be done by manual brushing or

GEOXCHANGE | DECEMBER 2020

CASE STUDY 72

electric circular whip brush, until total removal of 4.MASSEMBLY PROCEDURE OF A

the aforementioned residues. Immediately after TIE-ROD

cleaning, the wires / strands should receive the

first coat of paint. This ink is composed of two First, let’s list the materials that will make up the

components, plus the solvent. This solvent, after tie: steel wires; the spacers; the hems; plastic

mixing components A and B should be added masses; the paints; the central tube, with injection

in a minimum and gradually, as necessary and valves; the wire.

sufficient, to allow applicability to the surface of

the wires / strands. Do not forget to touch up 4.1. Steel wires

the support points of the elements on the bench. You have to arrive at the construction site with

After light sanding, when the paint on the first a certificate. The certificate shows his resistance,

coat shows sufficient grip, that is, it does not which we must compare with the resistance

come off the surface of the steel, it should be marked in the project.

applied to the second coat.

Read the instructions for using the paint on the 4.2. Spacers

outside of the can to check the recommended The function of the spacers is to assemble the

curing time between coats. wires or strands separately from each other, so

Never a permanent tie must be installed without that at the time of injection, the syrup uniformly

the bar, wires or strands being painted and envelops them in the anchorage area. They are

cured. placed every 0.5 meters of wire / strand or 2.5

meters in bar tie rod.

4.6. The central tube

The central PVC tube is the “column” or 4.3. Sheaths

“backbone” of the tie. It is around him that The sheath can be individual, collective or joint.

everything will be done. It should have the length The sheath will insulate the wires along the free

of the rod plus one left over. In the free zone, stretch, from contact with the cement grout. The

it is smooth. In the anchoring zone, it is drilled individual sheath is a plastic tube that we place

with an electric drill, every 500 mm. There are 8 on each rod or wire on the rod.

6.3 mm holes. These holes will be covered by a

rubber tube 100 mm long by 2 mm thick, with The collective sheath is a tube or hose that wraps

side stops (collars) to prevent their displacement all of the wires simultaneously.

along the tube. The joint sheath is the use of two sheaths,

This tube is what we call a headline valve. individual and collective, at the same time.

The assembly sequence is:

1. cut the wires to the size that the project The hem must also not tear. Therefore, the tie

sends. Pay attention to add (increase) the length rod must be handled with care, especially when

by another 1 meter or as much as the project it is placed inside the hole.

requires;

2. sand the wires with sandpaper or with a wire 4.4. Plastics

brush. If it is corded, clean the cracks well; They are placed in the passage from the free

3. paint the threads with two coats of paint, as zone to the anchoring zone on all ties, whether

described; permanent or temporary. At the bottom of the

4. pass the bar, wires or strings through the tie, put the plastic putty only when the tie is final.

spacers spaced every 50 cm or 2.5 meters on No temporary tie rod is necessary.

the bar. Install the injection tube (central PVC)

with the bottom plug and secure the assembly 4.5. The paints

with the wire. Then, install the individual sheaths Before painting, the wires or strands must be

on the free section of the tie, securing them firmly carefully cleaned on the entire surface to remove

with the wire. If the tie is permanent, place the areas of oxidation, rust spots, grease and resins.

collective sheath. Cleaning should be done by manual brushing or

WWW.GEO-XCHANGE.COM | VOL..01 ISSUE .03

73 CASE STUDY

5. ANCHOR INJECTION Diagram of the acting pressures:

PROCEDURE

The rod injection serves to transfer the load by

adhering the bars / wires / strands to the ground,

in addition to creating an additional protective

layer to the paint so that they do not oxidize over

time in direct contact with the water in the subsoil.

This work step is carried out in two phases.

6. PROCEDURE FOR TENSION

AND PRETENSION

After 7 (seven) full days of the curing of the

injected cement (CP-II-E-32) or 3 (three) full days

when using the initial high strength cement (CP-

V-ARI), the tie rod may be intended . Figure 44: Actuating

Every tie must be tested with a load greater than pressure diagram

the one it will actually work on. Source: Own Collection

Containment pushes:

7. CALCULATION OF SLOPE E1 = 0,624 x 5,00 = 3,120 tf / ml

STABILITY: E2 = 3,514 x 5,00 = 8,785 tf / ml

2,0

For the calculation and dimensioning of the Total active Thrust:

containment system, we will take into account the 3,120 + 8,785 = 11,905 tf / ml

section of the thrown curtain that has a height of Curtain length: 20,00 m

5.00 m and comprises 20.00 m in length. Buoyancy Total:

11,905 tf/m x 20,00 m = 238,10 tf

Calculation of active active thrusts: For the uses of SAS Prestressing – CT= 35 tf,

238,10 tf : 35 tf/anchor = 6,80 anchors

Soil 1: y (kN/m³) = 1,8 Adopted 16 anchors - FS= 2,35 - ok!

C (kPA) = 2,0

0 (º) = 26 8. CONCLUSION:

Active buoyancy coefficient: We conclude that the solution presented has a

• Ka = 0,390 safety factor above that recommended in Global

• √Ka = 0,625 Stability and Containment. In Global Stability,

sha = Z.Ka – 2.C.√Ka + q.Ka the containment system has a safety factor of

1.656, after the insertion of elements resistant

Elevation pressure EL. 99,30 (Top containment) to active efforts, such as rods and piles. The soil

sh = – (2 x 2,0 x 0,625) + (8,0 x 0,390) parameters adopted were described above.

sh = 0,624 tf / m²

Elevation Pressures EL. 94,30 (Toe containment)

sh = (1,8 x 5,0 x 0,390) – (2 x 2,0 x 0,625) +

(8,0 x 0,390)

sh = 4,138 tf / m²

GEOXCHANGE | DECEMBER 2020

CASE STUDY 74

In the Stability of Containment, the risers are REFERENCES

dimensioned with a safety factor of 2.35, also NARESI JR, Luiz Antônio. Curtains with risers.

above the recommended which is 2.0. The 2014. Available at: www.naresi.com. Accessed

section analyzed was the 20.00 m contention, on: 07/04/2015.

which is 5.00 m high with 16 of the SAS Proten- NARESI JR, Luiz Antônio. TRINDADE, Sérgio.

sa Ø 32 mm in diameter CT = 35 tf in the Hillside Containment. Foundations and

lengths indicated in the project. Geotechnical Works Magazine. In focus. Rudder

Publisher. Edition 55. Year 6. p. 66-77, May.

ACKNOWLEDGEMENT 2015.

NARESI JR, Luiz Antônio. Work safety in

To all who directly or indirectly participated in Containment Works with the Use of Tie Rods,

the execution of this work, especially SAS and (2008) Master’s Dissertation, Post-Graduate

Progeo Engenharia Ltda for their contribution. Program in Occupational Safety Engineering,

Department of Civil Engineering, Federal

University of Juiz de Fora, 150 P.

Luiz Antonio Naresi Júnior is a civil engineer with an

emphasis on Sanitation, has a postgraduate degree in

Occupational Safety Engineering, Environmental Analyst from

UFJF (Federal University of Juiz de Fora), and Geotechnical

Engineering from UNICID (University of São Paulo) ). He

specializes in Deep Foundation works, Hillside Containment,

Special Art Works, Containment Projects, Railway and Road

Infrastructure. He is currently a partner at ABMS (Brazilian

Association of Soil Mechanics and Geotechnical Engineering),

director of the Engineering Club of Juiz de Fora (MG), Prof.

do Escalla Cursos - Escola da Construção - JF, consultant,

commercial and advisor to the board of directors of Empresa

Progeo Engenharia Ltda..

WWW.GEO-XCHANGE.COM | VOL..01 ISSUE .03

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Astm F 30 - 96 R02 - RJMWDocument5 pagesAstm F 30 - 96 R02 - RJMWphaindikaNo ratings yet

- Libeskind Daniel - Felix Nussbaum MuseumDocument6 pagesLibeskind Daniel - Felix Nussbaum MuseumMiroslav MalinovicNo ratings yet

- Sabre-Baggage Management and Analysis SystemDocument24 pagesSabre-Baggage Management and Analysis Systemdifaini anugrahNo ratings yet

- Quality Risk ManagementDocument29 pagesQuality Risk ManagementmmmmmNo ratings yet

- 1504805126-HPI - CR-Series Copper Crusher - 04-2021ENDocument1 page1504805126-HPI - CR-Series Copper Crusher - 04-2021ENCaio BittencourtNo ratings yet

- Longitudinal Section Cross Section of AbutmentDocument1 pageLongitudinal Section Cross Section of AbutmentMATHANNo ratings yet

- 5 6176700143207711706Document198 pages5 6176700143207711706abc defNo ratings yet

- Floor Plans & ElevationsDocument6 pagesFloor Plans & Elevationsbryan cardonaNo ratings yet

- En Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARDocument4 pagesEn Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARZhenyuan LiNo ratings yet

- Practice Exam 1Document7 pagesPractice Exam 1425No ratings yet

- RDBMS and HTML Mock Test 1548845682056Document18 pagesRDBMS and HTML Mock Test 1548845682056sanjay bhattNo ratings yet

- Fm-II Quiz 1 19-20 - Section1 - Set1Document2 pagesFm-II Quiz 1 19-20 - Section1 - Set1nivedithashetty0123No ratings yet

- Properties of Building Materials and Their Importance in ConstructionDocument5 pagesProperties of Building Materials and Their Importance in ConstructionDaisy Jane LulabNo ratings yet

- Cane - Sugar - Manufacture - in - India Datos Sobre Producción de AzucarDocument525 pagesCane - Sugar - Manufacture - in - India Datos Sobre Producción de AzucarEnrique Lucero100% (1)

- 2012 LFDDocument943 pages2012 LFDsergioNo ratings yet

- ManpasandDocument16 pagesManpasandJacob MathewNo ratings yet

- App 3.3 Scaffolding Measurement 20200512 FINALDocument15 pagesApp 3.3 Scaffolding Measurement 20200512 FINALharshkumar patelNo ratings yet

- 1.1 Control Philosophy CAS-1 NMDCDocument36 pages1.1 Control Philosophy CAS-1 NMDCkoushik42000No ratings yet

- Research Papers in Mechanical Engineering Free Download PDFDocument4 pagesResearch Papers in Mechanical Engineering Free Download PDFtitamyg1p1j2No ratings yet

- Ijet V3i6p54Document6 pagesIjet V3i6p54International Journal of Engineering and TechniquesNo ratings yet

- CST 336 Final Project Computown DocumentationDocument12 pagesCST 336 Final Project Computown Documentationapi-461214598No ratings yet

- Toyota Vios Ecu Wiring DiagramDocument4 pagesToyota Vios Ecu Wiring DiagramSri Yuniati17% (6)

- Fire Protection Design For Healthcare FacilitiesDocument34 pagesFire Protection Design For Healthcare Facilitiesapi_fabianNo ratings yet

- 2nd Term Physics ReviewerDocument5 pages2nd Term Physics ReviewerAlfredo L. CariasoNo ratings yet

- 229.testing of Ycgf-11 With F6150-FieldFailureDocument13 pages229.testing of Ycgf-11 With F6150-FieldFailureSukant Kumar Mohanty50% (2)

- Porting Relations 2 StrokesDocument10 pagesPorting Relations 2 Strokespistonbreaker100% (8)

- 360-Pungue Iwrm Strategy PresentationDocument30 pages360-Pungue Iwrm Strategy PresentationEdyz Piedadis PereiraNo ratings yet

- NAWTEC18-3507: Comparison of Acid Gas Control Technologies in Efw FacilitiesDocument10 pagesNAWTEC18-3507: Comparison of Acid Gas Control Technologies in Efw FacilitiesPunki KokoNo ratings yet

- L18 PDFDocument8 pagesL18 PDFrashmi sahooNo ratings yet

- Book - Adams Tutorial Ex17 W PDFDocument121 pagesBook - Adams Tutorial Ex17 W PDFKamran ShahidNo ratings yet