Professional Documents

Culture Documents

35 - Inert Ig-55 System VDS Approval

Uploaded by

itskittylim0 ratings0% found this document useful (0 votes)

18 views9 pagesLPG Inert gas VdS certification

Original Title

35- INERT IG-55 SYSTEM VDS APPROVAL (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLPG Inert gas VdS certification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views9 pages35 - Inert Ig-55 System VDS Approval

Uploaded by

itskittylimLPG Inert gas VdS certification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

vs Certificate

Components and Systems

Facer ote Noproval

LPG Técnicas en Extincién de Incendios S.A.

Mestre Joan Corrales, 107-109

ES-08950 Esplugues de Llobregat, Barcelona

Tis epprovat

seechecaorporeniayaen — “@mmval Ne ee eed ate

submited or moieet ——§ 305012 7 19.02.2008 28.09.2011

Aiogener wee cts sted

Supt ote oF he Rea

1G5S Fire Extinguishing System

Type "IGSS 300 bar"

“pe Lea

atte

in fixed IGS

ee ee igh Pressure Fire Extinguishing Systems

hen Apphost er

Bass erano

Procedure for the approval and testing of fire protection and

ines lfencosses 8 security equipment, components and systems - VdS 2344:

canotions of nS aor 2005-12 (06)

by

feet are Requirements and test methods - VdS 2454 : 1998-12 (draft)

reculed docuenseat

poyadeereing

Kéln (Cologne), 19. Februar 2008

Mugs = fale

Schiingel ppa. Stahl

Manga Broce —~—S~S~SCW the WS Ceroation Boy

companies)

VdS'

Enclosure 1 Sheet 1

To Cerificate of Approval No. S 305012 Date 19. Februar 2008

‘The approved componentisystem comprises the following pats

RpprovaT number

‘of component

Description of component Type Applicants Registration No. | (oly complete for

system approval)

Non-electrical Disable Device ‘Type ‘MX’ G301010

High-Pressure Container Valve and_| Type LPG 6300018

Actuator 128-xx"

High-Pressure Container Valve and | Type ‘LPG 300020

Actuator 128-xx"

Nozzle Type 1180" 6304007

and Type

"360°"

Pressure Reduction Device Type G304008

‘Restrictor’

314" 2!

Check Valve Type '3/4"" 304009

Hose Type "1/4 6302017

PTFE’

Hose Type '48-H 6302018

Pressure switch W/Locking device } 30330010

Manufacturer: LPG Técnicas en

Extincién de Incendios $.A.

Pressure gauge 315 bar 3021316B

Extinguishant cylinder 200 bar @

15°C

Pressure gauge 415 bar 30245002

Extinguishant eylinder 300 bar @

15°C

Depressurisation valve G ¥4" 20007020

Manufacturer: LPG Técnicas en

Extincién de Incendios S.A

VdS

Enclosure 2

To Certificate of Approval No, S 305012 ate 19, Februar 2008

“The approved componentisystem is described a follows:

Number

Type of document Manufacture’ identfication Date of

Pages

Nitrogen system description SCHIG200 Rev. 01 30.11.2007 ]1

single zone installation without

increased safety measures

‘Nitrogen system description SCHIG300 Rev. 01 30.11.2007

single zone installation without

increased safety measures

Technical manual MU/IG/OMIIN Rev. 01 May/2005.|109

Manual for installation, maintenance

and use of LPG Inert Gas fire

extinguishing Systems

VdS

Enclosure 3 Sheet 1

‘To Certiieae of Approval No: S 305012 bate 19, Februar 2008

tnstrctons forthe application of he approval cmeonentsystem (see enclosure 1)

As to approval G300018:

‘The maximum working pressure of the Ga

type LPG 128-80" is 240 bar.

high pressure container valves type ‘LPG 128-60’ and

The maximum working pressure of the Gas high pressure container valves type ‘LPG 128-65", type

"LPG 128-66" and type ‘LPG 128-85" is 370 bar,

The triggering pressure of the pneumatic actuator shall be at least 50 % of the container pressure

and shall not exceed 140 bar.

The nominal voltage of the electrical actuator is 24 V DC.

Every replacement of the puncture disc requires that the screw and the puncture needle shall also be

replaced at the same time.

The flow characteristics are not specified (admissible option).

When using the valves an additional facility shall be installed which can be used to separately test

each group of containers actuated at the same time whether the necessary type and level of power is

provided,

As to approval G300020:

‘The gas-high pressure container valves type Typ 'LPG 128-xx' may be used only in CO2-high

pressure-, Inertgas-, HFC-227ea-, NAF-S227ea-, HFC-125-, NAF-S125- and HFC-23 ~ fire

extinguishing systems.

‘The maximum working pressure of the Gas High Pressure Container Valves type 'LPG 128-xx' for

the use in gas high pressure fire extinguishing systems is as follows:

Type ‘LPG 128-00': 73 bar

Type 'LPG 128-00 UL': 73 bar

‘Type ‘LPG 128-05": 40 bar

‘Type LPG 128-13': 142 bar.

‘Type 'LPG 128-20’: 140 bar

Type 'LPG 128-40’: 140 bar

VdS

Enclosure 3 Shee

To Certificate of Approval No: $ 305012 bate 19, Februar 2008

Instructions for he application ofthe approval companentsystem (see enclosure 1)

Type 'LPG 128-90° 140 bar

Type 'LPG 128-90 UL’: 140 bar

Type 'LPG 128-95". 175 bar

The triggering pressure of the pneumatic actuator shall be at least 50 % of the container pressure

and shall not exceed 140 bar.

Every replacement of the puncture dise requires that the screw and the puncture needle shall also be

replaced at the same time

The flow characteristics are not specified (admissible option).

The electric actuators are not testable (admissible option).

When using the valves an additional test facility shall be installed which can be used to separately

test each group of containers actuated at the same time whether the necessary type and level of

power is provided.

As to approval G301010:

‘The maximum working pressure of the non electrical disable device type ‘MX’ is 140 bar.

As to approval G302017:

The hose type '1/4'PTFE’ shall be used only as hose for pilot lines in gas fire extinguishing systems.

‘The maximum working pressure of the hose for pilot lines type '1/4’PTFE’ is 260 bar.

Following values have to be taken into consideration during the installation:

Maximum working pressure: 260 bar

Smallest bending radius: 30mm

Maximum bending angle: no limitation

VdS

Enclosure 3 Sheet 3

To Centfeate of Approval No: $ 305012 Date 19. Februar 2008

Instuctions fr the application of the approval componentisystem (see enciosure 1)

As to approval G302018:

The hose type '4S-H' shall only be used as container connection hose in gas fire extinguishing

systems.

‘The maximum working pressure of the container connection hose type '4S-H' is 420 bar.

Following values have to be taken into consideration during the installation:

Maximum working pressure: 420 bar

Smallest bending radius: 280 mm

Maximum bending angle: no limitation

As to approval G304007:

‘The maximum working pressure of the nozzle type '180" and type '360 is 142 bar.

‘The drilling diameter of the orifice shall not exceed 80 % of the pipe’s internal diameter.

As to approval G304008:

‘The maximum working pressure of the pressure reduction device type 'Restrictor’is 370 bar.

‘The drilling diameter of the orifice shall not exceed 80% of the pipe’s internal diameter.

As to approval G304009;

‘The maximum working pressure of the check valve type '3/4" ' is 370 bar,

As to system $305012:

‘The 1GS5-High Pressure Fire Extinguishing Systems shall be built according to the system

documentation as specified in enclosure 2

VdS

Enclosure 3 Sheet 4

To Centfcate of Approval No: $ 305012 Date 19. Februar 2008

Instructions forthe application of the approval componentieystem (see enclosure 1);

Attention should be paid to following details when the fire extinguishing system is built according

to the guidelines VdS CEA 2380 and VdS 2496:

¢ The use of the manual actuator of the container valve is not allowed

¢ The IGSS High Pressure Fire Extinguishing System shall be actuated by a control and indicating

equipment,

‘The control cylinder shall be filled with Inertgas only (¢.g. Nitrogen, Argon, IG-55, IG-541).

4 When using the high pressure valves an additional test facility shall be installed which can be

used to separately test each group of containers actuated at the same time whether the necessary

type and level of power is provided,

The surveillance of the fire extinguishing systems and the transmission of fault reports

according to chapter 11 of VdS 2380 are not part of this approval

oorsinos [fv ‘Oat a

ores | a

[asm] (209 OOS) 3WFHIS WAISAS S¥D LYBN!

7S SoM at ooMIE Me SoM | IEP ar

IMA

‘GOZOIHOS

ov

Dat =

Meow 2nd) Mate

Be|

(20q 002) 3WBHOS WHISAS SVD 143NI

V5 ‘SOIONGDAI 80 NODNILE NE SYOINORL oan

Tope a see a emg Tamar] 10

angen

uebejeun eyosh

Z10S0ES uw

Gon) 1ayssBurveIzyate7

ONNLOHYBANSGVHOS CPA

You might also like

- Grooved Fittings - ShurjointDocument7 pagesGrooved Fittings - ShurjointitskittylimNo ratings yet

- Zero CalDocument1 pageZero CalitskittylimNo ratings yet

- HeroseDocument1 pageHeroseitskittylimNo ratings yet

- Sikagard 177 CE PDSDocument5 pagesSikagard 177 CE PDSitskittylimNo ratings yet

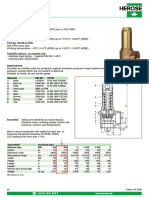

- Model SP Safety ValvesDocument1 pageModel SP Safety ValvesitskittylimNo ratings yet

- 34 - Inert Ig-01 System VDS ApprovalDocument10 pages34 - Inert Ig-01 System VDS ApprovalitskittylimNo ratings yet

- Cylinder Filling - Fill Plant Systems - CryoVationDocument1 pageCylinder Filling - Fill Plant Systems - CryoVationitskittylimNo ratings yet

- DS01071 XNX Universal Transmitter FLR 8-3-11Document4 pagesDS01071 XNX Universal Transmitter FLR 8-3-11itskittylimNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)