Professional Documents

Culture Documents

Making of JP-10 From Furfural

Uploaded by

Owais AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Making of JP-10 From Furfural

Uploaded by

Owais AhmedCopyright:

Available Formats

Angewandte

A Journal of the Gesellschaft Deutscher Chemiker

International Edition Chemie www.angewandte.org

Accepted Article

Title: Making JP-10 Superfuel Affordable with Lignocellulosic Platform

Component

Authors: Guangyi Li, Baolin Hou, Aiqin Wang, Xuliang Xin, Yu Cong,

Xiaodong Wang, Ning Li, and Tao Zhang

This manuscript has been accepted after peer review and appears as an

Accepted Article online prior to editing, proofing, and formal publication

of the final Version of Record (VoR). This work is currently citable by

using the Digital Object Identifier (DOI) given below. The VoR will be

published online in Early View as soon as possible and may be different

to this Accepted Article as a result of editing. Readers should obtain

the VoR from the journal website shown below when it is published

to ensure accuracy of information. The authors are responsible for the

content of this Accepted Article.

To be cited as: Angew. Chem. Int. Ed. 10.1002/anie.201906744

Angew. Chem. 10.1002/ange.201906744

Link to VoR: http://dx.doi.org/10.1002/anie.201906744

http://dx.doi.org/10.1002/ange.201906744

Angewandte Chemie International Edition 10.1002/anie.201906744

COMMUNICATION

Making JP-10 Superfuel Affordable with Lignocellulosic Platform

Component

Guangyi Li+,[a] Baolin Hou+,[a] Aiqin Wang,[a,b] Xuliang Xin,[c] Yu Cong,[a] Xiaodong Wang,[a] Ning Li,*[a,b]

and Tao Zhang*[a]

Dedicated to the 70th anniversary of Dalian Institute of Chemical Physics, Chinese Academy of Sciences

Abstract: The synthesis of renewable jet fuel with lignocellulosic which has been considered as a superfuel for military jets,

platform components has drawn a lot of attention in recent years. So missiles, and supersonic combustion ramjets. [4] Compared with

Accepted Manuscript

far, most of work was concentrated on the production of conventional jet fuels, JP-10 fuel has many attractive properties

conventional jet fuels. JP-10 is an advanced jet fuel which is (such as high-energy density, good thermal stability, low

obtained from fossil energy nowadays. Due to its excellent freezing point, etc.). For example, the higher density of JP-10

properties, JP-10 has been widely used in military aircraft. However, fuel makes it have a higher volumetric heat (39.6 MJ/L) than

the high price and low availability limit its application in civil aviation. those of conventional jet fuels (~34.8 MJ/L). In practical

Here, we reported a new strategy for the synthesis of bio-JP-10 fuel application, it can increase the flight range and/or payload of

with furfuryl alcohol which has been produced in industrial scale with aircraft without changing the volume of oil tank. This is

agricultural and forestry residues. Under the optimized conditions, advantageous for long-distance flight because it can save the

high overall carbon yields (~65%) of bio-JP-10 fuel were achieved. A travel time and decrease the CO2 emission during the taking off

preliminary economic analysis indicates that the price of bio-JP-10 and landing of airplanes.[5] Nowadays, the JP-10 fuel is

fuel can be greatly decreased from ~7,091 US$/ton (by fossil route) produced with cyclopentadiene which was obtained at low yields

to less than 5,600 US$/ton using our new strategy. This work makes from coal tar (10-20 g/ton) or by the steam cracking of naphtha

the practical application of bio-JP-10 fuel in sight. (~14 kg/ton).[6] Moreover, the high price (~7,091 US$/ton) of JP-

10 fuel also limited its application in civil aviation. [7] Therefore, it

is highly desirable to develop some technologies for the

With the increase of social concern about renewable energy and

synthesis of bio-JP-10 fuel with more available feedstocks.

CO2 reduction, the utilization of biomass as an alternative

feedstock for fuels[1] and

chemicals[2] has drawn tremendous

attention. Lignocellulose is the

cheapest and the most abundant

biomass. Jet fuel is one of the

three important transportation fuels.

During the past decade, many

routes have been developed for

the synthesis of bio-jet fuel with

lignocellulosic platform

components.[3] However, most of

the literature work was

concentrated on the production of

conventional jet fuels. JP-10 fuel

(i.e. exo-

tetrahydrodicyclopentadiene) is a

single component advanced jet fuel

Scheme 1. Strategy for the synthesis of bio-JP-10 fuel with furfuryl alcohol.

Furfuryl alcohol is a bulk chemical which has been produced in

[a] Dr. G. Li,[+] Dr. B. Hou,[+] Prof. A. Wang, Prof. Y. Cong, Prof. X. industrial scale with agricultural and forestry residues. Herein,

Wang, Prof. N. Li,* Prof. T. Zhang*

we developed a new strategy for the synthesis of bio-JP-10 fuel

CAS Key Laboratory of Science and Technology on Applied

Catalysis, Dalian Institute of Chemical Physics, Chinese Academy of with furfuryl alcohol (Scheme 1). To explore the possibility for its

Sciences, Dalian 116023, China future application, we also conducted a preliminary economic

E-mail: lining@dicp.ac.cn (N. Li); taozhang@dicp.ac.cn (T. Zhang). analysis to this strategy.

[b] Prof. A. Wang, Prof. N. Li

First of all, we synthesized bio-JP-10 fuel with furfuryl

Dalian National Laboratory for Clean Energy

Dalian 116065, China. alcohol by the route 1 in Scheme 1. This process contains six

[c] Mr. X. Xin steps: aqueous phase rearrangement of furfuryl alcohol (1) to 4-

ACRE Coking and Refractory Engineering Consulting Corporation, hydroxy-cyclopent-2-enone (2), hydrogenation of 2 to 1,3-

MCC, Dalian 116023, China.

cyclopentanediol (3), dehydration of 3 to cyclopentadiene (4),

[+] These authors contributed equally to this work.

self-Diels-Alder reaction of 4 to dicyclopentadiene (5),

Supporting information for this article is given via a link at the end of hydrogenation of 5 to endo-tetrahydro-dicyclopentadiene (6),

the document.

and isomerization of 6 to exo-tetrahydro-dicyclopentadiene (i.e.

This article is protected by copyright. All rights reserved.

Angewandte Chemie International Edition 10.1002/anie.201906744

COMMUNICATION

bio-JP-10 fuel or 7).

439 K

The first two steps were carried out by the methods which

have been reported in our previous work.[8] Under the optimized 616 K

H-b

reaction conditions, high carbon yields of 2 (77.6%) and 3

(92.8%) were achieved over the commercially available CaO

and Raney Ni catalysts, respectively (see supporting

information). The dehydration of 3 was carried out over solid

acid catalysts using a fixed-bed reactor. According to our

465 K

analysis, 4, 5 and cyclopent-3-enol (i.e. 9) were identified as the H-ZSM-5

products from this reaction. The reaction pathways for the

682 K

generation of 4, 5 and 9 from the dehydration of 3 were

proposed in Scheme 2. Form the results illustrated in Table 1, it

was found that H-USY, H-ZSM-5 and H-β zeolites exhibited

Intensity / a. u.

Accepted Manuscript

higher activity than that of amorphous SiO2-Al2O3. Based on the

NH3-TPD and NH3 chemisorption results illustrated in Figure 1 455 K

and Table 2, this phenomenon can be explained by the stronger H-USY

654 K

acidity of zeolite catalysts than that of SiO2-Al2O3. Over H-USY,

58.4% carbon yield of 4 was achieved under the investigated

conditions. After being separated with 4 by distillation, the

partially dehydrated product (i.e. 9) and residual 3 was used

again as the feedstock for the second dehydration. Under the

same reaction conditions, high carbon yield of 4 (94.9%) was 440 K

obtained (Table 1). This means 93.8% carbon yield of 4 can be SiO2-Al2O3

achieved by the dehydration of 3 over H-USY zeolite (the

calculation method was shown in Figure S1 note). The stability

of H-USY in the dehydration of 3 was evaluated as well. During

the 24 h continuous test, the carbon yield of 4 over H-USY

decreased from 58.4% to 40.9% (Supplementary Figure S1),

which may be explained by the carbon deposition generated 400 500 600 700

during the reaction. T/K

Figure 1. NH3-TPD profiles of the solid acid catalysts.

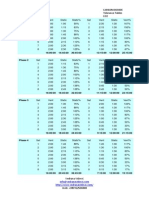

Table 2. Acid amounts of solid acid catalysts.

Catalyst Acid amount Weak acid amount Strong acid amount

[mmol/g][a] [mmol/g][b] [mmol/g][c]

SiO2-Al2O3 0.151 0.151 0.000

Scheme 2. Reaction pathways for the generation of different products from H-β 0.391 0.202 0.189

the dehydration of 3.

H-ZSM-5 1.089 0.669 0.420

Table 1. Carbon yields of 4, 5 and 9 from the dehydration of 3 over solid acid

catalysts.[a]

H-USY 1.087 0.534 0.553

Catalyst Conversion of 3 Carbon yield [%] Carbon [a] Measured by NH3 chemisorption. [b] Calculated according to the NH 3

[%] balance [%]

desorbed at the temperatures lower than 523 K. [c] Calculated based on the

4 5 9

NH3 desorbed at the temperatures higher than 523 K.

SiO2-Al2O3 26.0 4.6 0 4.0 82.6

Cyclopentadiene is widely used in the production of a variety

H-USY 92.4 58.4 0.7 20.2 86.9

of chemicals and fuels.[4,6] To the best of our knowledge, this is

H-β 99.9 53.1 0 41.6 94.8 the first report about the synthesis of renewable cyclopentadiene

with lignocellulose derived feedstock.

H-ZSM-5 99.0 57.6 0 35.3 93.9 The self-Diels-Alder reaction of 4 to 5 can take place

spontaneously. After reacting at 393 K for 2 h, 95.5% of 4 was

H-USY[b] 97.6 94.9 0.2 1.2 98.7

converted to 5 without using any catalyst (Supplementary Table

S1). The residual cyclopentadiene can be easily recycled.

[a] Reaction condition: 523 K, 0.1 MPa; 2.5 wt% 3 in tetrahydrofuran (THF)

flow rate: 0.04 mL/min, N2 flow rate: 120 mL/min, 0.15 g catalyst was used in Therefore, the theoretical yield of 5 from this reaction can reach

each test. [b] The partially dehydrated product (i.e. 9) and residual 3 were 100%. The synthesis of 7 with 5 or 6 has been reported by

recycled and used again as feedstock for the second dehydration. literature.[9] The hydrogenation of 5 is a two-step reaction which

can occur very easily. First, a C=C bond in 5 is statured, which

This article is protected by copyright. All rights reserved.

Angewandte Chemie International Edition 10.1002/anie.201906744

COMMUNICATION

leads to dicyclopentene (10, Table S2). Subsequently the 10 is can be accelerated by increasing the reaction temperature. For

further hydrogenated to 6. After reacting at room temperature example, ~60% carbon yield of 8 could be achieved after the

under 4 MPa H2 for 3 h, a high carbon yield (97.5%) of 6 was reaction was carried out at 353 K for 1 h (Supplementary Table

obtained (Supplementary Table S2). According to our S4). By recycling the unreacted 2 in the feedstock, the

measurement, 6 has high density (0.894 g/mL). Therefore, it can theoretical yield of 8 can reach 100%.

be potentially used as additive to improve the volumetric heat Table 3. Carbon yields of different compounds from the HDO of 8.[a]

value of current jet fuels. However, it can’t be used as a single

component advanced jet fuel due to its high freezing point (350

K).[10] To overcome this problem, 6 has to be further isomerized

to 7 which has much lower freezing point (194 K). [11] The

isomerization reaction was carried out over La-Y zeolite under

solvent-free conditions. After reacting at 433 K for 4 h, a high

carbon yield (96.1%) of 7 was achieved (Supplementary Table

Accepted Manuscript

S3). Besides 7, small amount of adamantine (11) was also

identified in the products. This is consistent with what has been

reported by literature over other catalysts.[12] Based on the

above results, the overall carbon yield of bio-JP-10 fuel from

furfuryl alcohol by route 1 was estimated as 63.3%.

As another option (route 2), we first reported the synthesis of Reaction Conversion Carbon yield [%] Carbon

temperature [K] of 8 [%] balance [%]

bio-JP-10 fuel with furfuryl alcohol and the cyclopentadiene (i.e.

6 7 12

4 in Figure 1) which can be derived from either fossil routes or

bio-route (i.e. route 1). This process contains four steps: 473 100 6.2 0.0 0.7 6.9

aqueous phase rearrangement of 1 to 2, cross Diels-Alder

reaction of 2 with 4 to produce 3-hydroxy-2,3,3a,4,7,7a- 493 100 12.4 0.0 1.1 13.5

hexahydro-1H-4,7-methanoinden-1-one (i.e. 8 in Figure 1),

513 100 64.1 8.4 1.8 74.3

hydrodeoxygenation (HDO) of 8 to 6, and isomerization of 6 to 7.

The cross Diels-Alder reaction of 2 with the 4 that can be 513[b] 100 84.8 9.5 1.8 96.1

obtained in this work (by bio-route) was carried out in a batch

reactor at the initial 2/4 molar ratio of 1:1 (see Figure 2). After [a] Reaction condition: 4 MPa H2, 2 h; 200 mg 8, 30 mg 5 wt% Ru/C, 50

the reaction was conducted at room temperature and mg H-USY zeolite (SiO2/Al2O3 molar ratio = 12:1), 28 g cyclohexane, 0.3

g decalin were used in each test. [b] Reaction condition: 4 MPa H2, 4 h;

atmospheric pressure for 12 h, 48.7% carbon yield of 8 was 200 mg 8, 30 mg 5 wt% Ru/C, 50 mg H-USY zeolite (SiO2/Al2O3 molar

achieved in the absence of catalyst. By extending the reaction ratio = 12:1), 28 g cyclohexane, 0.3 g decalin were used in each test.

time to 72 h, 75.0% carbon yield of 8 was reached. Meanwhile, 5

was also obtained in carbon yield of 19.3% (by the self-Diels- Subsequently, the 8 as obtained was hydrodeoxygenated to

Alder reaction of 4). 6 under the co-catalysis of Ru/C and H-USY. After reacting at

513 K and 4 MPa H2 for 4 h, 8 was completely converted and a

100 Conversion of 2 high total carbon yield (94.3%) of 6 and 7 was achieved

Yield of 8

Conversion of 4 (Supplementary Table S5). Under the catalysis of La-Y, 6 can be

80 Yield of 5 easily converted to 7 (or bio-JP-10 fuel) in a carbon yield of

Conversion or yield / %

96.1% (Entry 4, Supplementary Table S3). Based on the

experimental results we obtained in this work, the overall carbon

60

yield of bio-JP-10 fuel by the route 2 was estimated as 65.5%.

Finally, we also conducted a preliminary economic analysis

40 for the two routes we developed and compared them with the

conventional fossil route (Supplementary Figures S4-S5 and

20 Tables S5-S21). The process flow diagram was simulated by

Aspen Plus V8.8, assuming the plant capacity is 10 kiloton bio-

JP-10 per year and the working time is 8,000 h per year. The

0 energy was supplied by steam at the price of 18 US$/ton (see

12 24 72

Reaction time / h Tables S7, S13, S18). The overall carbon yields of bio-JP-10

fuel by the route 1 and route 2 are 63.2% and 64.7%,

Figure 2. Conversions of substrates and the yields of different products from

the reaction of 2 and 4 at room temperature and atmospheric pressure.

respectively. These yields are slightly lower than the overall

Reaction condition: 393 K, 0.6 g 2, 1.0 g or 0.45 g mixture of 4 and 5 (contains carbon yields shown in Scheme 1, which is due to the loss of the

92 wt% of 4 and 8 wt% of 5) and 0.2 g decalin were used for each test. product during the separation process.

According to the current unit price of furfuryl alcohol (~1,500

When we doubled the amount of 4 in the feedstock, higher

US$/ton), the unit production costs for bio-JP-10 fuel produced

carbon yield (85.3%) of 8 was obtained after the reaction was

by route 1 and route 2 were estimated as 5,031 US$/ton and

carried out at room temperature for 72 h (Supplementary Table

5,538 US$/ton (see Figure 3), respectively. These values are

S4 and Figure S2). The cross Diels-Alder reaction of 2 with 4

lower than the price of JP-10 fuel (~7,091 US$/ton) derived from

This article is protected by copyright. All rights reserved.

Angewandte Chemie International Edition 10.1002/anie.201906744

COMMUNICATION

fossil energies. Therefore, we believe that the production of bio- 21690082), DNL Cooperation Fund, CAS (DNL180301), the

JP-10 fuel is economically possible. In fact, the situation will be Strategic Priority Research Program of the Chinese Academy of

even better with the technological innovation of furfural Sciences (XDB17020100; XDA 21060200), the National Key

production. In the recent work of Huber et al.,[13] a cost-effective Projects for Fundamental Research and Development of China

technology was developed. It was proposed that the furfuryl (2016YFA0202801), Dalian Science Foundation for

alcohol unit price can be greatly decreased to ~400 US$/ton by Distinguished Young Scholars (no. 2015R005).

the utilization of their new process. Based on this information,

the future unit production costs for bio-JP-10 fuel by route 1 and Keywords: Lignocellulose • jet fuel • JP-10 • furfuryl alcohol •

route 2 can be decreased to 2,547 US$/ton and 2,887 US$/ton,

cost-effective

respectively. These prices are about 2-3 times of conventional

jet fuel (or the same level as other current bio-jet fuels).

[1] a) G. W. Huber, S. Iborra, A. Corma, Chem. Rev. (Washington, DC, U.

However, they are much lower than the current price of JP-10 S.) 2006, 106, 4044-4098; b) D. M. Alonso, S. G. Wettstein, J. A.

fuel (~7,091 US$/ton). Therefore, we believe that the future Dumesic, Chem. Soc. Rev. 2012, 41, 8075-8098; c) Q. Xia, Z. Chen, Y.

Accepted Manuscript

commercialization of bio-JP-10 fuel is very promising especially Shao, X. Gong, H. Wang, X. Liu, S. F. Parker, X. Han, S. Yang, Y.

taking policy support and exemption of CO2 emission tax into Wang, Nat. Commun. 2016, 7, 11162; d) S. Shylesh, A. A. Gokhale, C.

consideration. R. Ho, A. T. Bell, Acc. Chem. Res. 2017, 50, 2589-2597; e) Z. Cao, M.

Dierks, M. T. Clough, I. B. Daltro de Castro, R. Rinaldi, Joule 2018, 2,

7000 Route 1 Route 2 1118-1133.

[2] a) M. Besson, P. Gallezot, C. Pinel, Chem. Rev. (Washington, DC, U.

Furfuryl alcohol cost

6000 S.) 2014, 114, 1827-1870; b) A. Wang, T. Zhang, Acc. Chem. Res.

Production cost / US$ per ton

Hydrogen cost

Fixed cost 2013, 46, 1377-1386; c) C. Li, X. Zhao, A. Wang, G. W. Huber, T.

5000 Catalyst cost

Zhang, Chem. Rev. (Washington, DC, U. S.) 2015, 115, 11559-11624;

Utilities cost

d) Y. L. Wang, W. P. Deng, B. J. Wang, Q. H. Zhang, X. Y. Wan, Z. C.

4000 Tang, Y. Wang, C. Zhu, Z. X. Cao, G. C. Wang, H. L. Wan, Nat.

Commun. 2013, 4, 2141; e) R. De Clercq, M. Dusselier, B. F. Sels,

3000

Green Chem. 2017, 19, 5012-5040; f) I. Scodeller, S. Mansouri, D.

2000 Morvan, E. Muller, K. de Oliveira Vigier, R. Wischert, F. Jérôme, Angew.

Chem., Int. Ed. 2018, 57, 10510-10514.

1000 [3] a) G. W. Huber, J. N. Chheda, C. J. Barrett, J. A. Dumesic, Science

2005, 308, 1446-1450; b) J. Q. Bond, D. M. Alonso, D. Wang, R. M.

0 West, J. A. Dumesic, Science 2010, 327, 1110-1114; c) B. G. Harvey,

400 1500 400 1500 R. L. Quintana, Energy Environ. Sci. 2010, 3, 352-357; d) A. Corma, O.

Furfuryl alcohol unit price / US$ per ton de la Torre, M. Renz, N. Villandier, Angew. Chem., Int. Ed. 2011, 50,

2375-2378; e) P. Anbarasan, Z. C. Baer, S. Sreekumar, E. Gross, J. B.

Figure 3. Production costs of bio-JP-10 fuel by route 1 and route 2 at different

Binder, H. W. Blanch, D. S. Clark, F. D. Toste, Nature 2012, 491, 235-

furfuryl alcohol unit prices. The definitions and calculation methods of different

239; f) C. Zhao, D. M. Camaioni, J. A. Lercher, J. Catal. 2012, 288, 92-

costs were given in Tables S11 and S22.

103; g) J. Xin, S. Zhang, D. Yan, O. Ayodele, X. Lu, J. Wang, Green

In summary, we reported two routes for the synthesis of bio- Chem. 2014, 16, 3589-3595.

JP-10 fuel with furfuryl alcohol. Both routes have their own [4] H. S. Chung, C. S. H. Chen, R. A. Kremer, J. R. Boulton, G. W.

features. For example, the last three steps of route 1 are same Burdette, Energy Fuels 1999, 13, 641-649.

[5] in AVIATION AND CLIMATE CHANGE, Produced by the Environment

as what were used in conventional route for the production of

Branch of the International Civil Aviation Organization (ICAO), 2016.

JP-10 fuel. Therefore, it is possible to use the conventional

[6] M. Claus, E. Claus, P. Claus, D. Honicke, R. Fodish, M. Olson,

facility for the production of bio-JP-10 fuel. Furthermore, the ULLMANN'S Encyclopedia of Industrial Chemistry, Wiley-VCH Verlag

cyclopentadiene produced in route 1 can also be used as a GmbH & Co. KGaA, 2016.

chemical or feedstock for the production of other high-density jet [7] www.asbca.mil/Decisions/2011/57594_101111_WEB.pdf

fuels (such as RJ-5, RJ-7, etc.). In contrast, route 2 has fewer [8] G. Li, N. Li, M. Zheng, S. Li, A. Wang, Y. Cong, X. Wang, T. Zhang,

steps (4 steps vs. 6 steps) than route 1. Moreover, route 2 is Green Chem. 2016, 18, 3607-3613.

economically more flexible. Based on the price of feedstock, we [9] a) C.-m. Sun, G. Li, Appl. Catal., A 2011, 402, 196-200; b) Y.-H. Cho, C.

H. Kim, S. H. Lee, J. Han, T. S. Kwon, K.-Y. Lee, Fuel 2018, 221, 399-

can either choose the cyclopentadiene from fossil resources or

406; c) W. Wang, J.-G. Chen, L.-P. Song, Z.-T. Liu, Z.-W. Liu, J. Lu, J.

use the one from biomass to produce the JP-10 fuel with lower

Xiao, Z. Hao, Energy Fuels 2013, 27, 6339-6347; d) H. Han, J.-J. Zou,

cost. A preliminary analysis indicates that the two routes X. Zhang, L. Wang, L. Wang, Appl. Catal., A 2009, 367, 84-88; e) Q.

developed in this work are economically advantageous than the Deng, X. Zhang, L. Wang, J.-J. Zou, Chem. Eng. Sci. 2015, 135, 540-

conventional one. This work makes the practical application of 546; f) J.-J. Zou, Y. Xu, X. Zhang, L. Wang, Appl. Catal., A 2012, 421-

bio-JP-10 fuel in sight. 422, 79-85.

[10] E. Xing, Z. Mi, C. Xin, L. Wang, X. Zhang, J. Mol. Catal. A: Chem. 2005,

231, 161-167.

[11] L. Wang, J. J. Zou, X. W. Zhang, L. Wang, Fuel 2012, 91, 164-169.

Acknowledgements [12] L. Wang, J.-J. Zou, X. Zhang, L. Wang, Fuel 2012, 91, 164-169.

[13] R. Xing, A. V. Subrahmanyam, H. Olcay, W. Qi, G. P. van Walsum, H.

This work was supported by the National Natural Science Pendse, G. W. Huber, Green Chem. 2010, 12, 1933-1946.

Foundation of China (no. 21506213; 21776273; 21721004;

This article is protected by copyright. All rights reserved.

Angewandte Chemie International Edition 10.1002/anie.201906744

COMMUNICATION

Entry for the Table of Contents

RESEARCH ARTICLE

A new strategy was first reported for Cheaper Guangyi Li, Baolin Hou, Aiqin Wang,

Renewable and

the synthesis of bio-JP-10 fuel with more available Xuliang Xin, Yu Cong, Xiaodong Wang,

furfuryl alcohol which has been Ning Li,* and Tao Zhang*

produced in industrial scale with

agricultural and forestry residues. Page No. – Page No.

Compared with the conventional fossil Our bio-route

Current fossil route

((Insert TOC Graphic here)) < 5,600 US$/ton

Making JP-10 Superfuel Affordable

route, the new synthetic strategy has

Accepted Manuscript

~7,091 US$/ton Civil aviation fuel

Military aviation fuel with Lignocellulosic Platform

evident advantage at lower cost and

Component

higher feedstock availability.

This article is protected by copyright. All rights reserved.

You might also like

- Vivadinar_2021_IOP_Conf._Ser.__Mater._Sci._Eng._1143_012045_removedDocument10 pagesVivadinar_2021_IOP_Conf._Ser.__Mater._Sci._Eng._1143_012045_removedLelosPinelos123No ratings yet

- Biohydrogen III: Renewable Energy System by Biological Solar Energy ConversionFrom EverandBiohydrogen III: Renewable Energy System by Biological Solar Energy ConversionNo ratings yet

- The Production of Renewable Transportation Fuel Through Fed-Batch and Continuous Deoxygenation of Vegetable Oil Derived Fatty Acids Over PD - C CatalystDocument11 pagesThe Production of Renewable Transportation Fuel Through Fed-Batch and Continuous Deoxygenation of Vegetable Oil Derived Fatty Acids Over PD - C CatalystMarcos TavaresNo ratings yet

- Direct Steam Reforming of Diesel and Diesel Ebiodiesel Blends For Distributed Hydrogen GenerationDocument10 pagesDirect Steam Reforming of Diesel and Diesel Ebiodiesel Blends For Distributed Hydrogen GenerationhgjNo ratings yet

- Hydrolysis Rate Improvement in Hydrogen Generation System Fueled by Powdery Sodium Borohydride For Fuel-Cell VehicleDocument8 pagesHydrolysis Rate Improvement in Hydrogen Generation System Fueled by Powdery Sodium Borohydride For Fuel-Cell VehicleNomi WahlaNo ratings yet

- Coproducts and Co-HydrotreatingDocument10 pagesCoproducts and Co-HydrotreatingPauline BLAISNo ratings yet

- Biogas As Alternative SOFC Fuel: Research and ImplementationDocument8 pagesBiogas As Alternative SOFC Fuel: Research and ImplementationAsim IdreesNo ratings yet

- Energies 15 00938 v3Document20 pagesEnergies 15 00938 v3dumboraghavNo ratings yet

- Hydrogen Production From Biomass Combining Pyrolysis and The Secondary DecompositionDocument6 pagesHydrogen Production From Biomass Combining Pyrolysis and The Secondary DecompositionBiruk GetachewNo ratings yet

- Pembuatab KatalisDocument8 pagesPembuatab Katalisyusniya skNo ratings yet

- HPU/06 - Hydrogen Production from Fossil and Biomass FuelsDocument4 pagesHPU/06 - Hydrogen Production from Fossil and Biomass FuelsMazen OthmanNo ratings yet

- Production of Gaseous Carriers Via Biomass GasificDocument10 pagesProduction of Gaseous Carriers Via Biomass GasificNicholas WilliamNo ratings yet

- A Comparative Study Between Propane Dehydrogenation (PDH) Technologies and Plants in Saudi ArabiaDocument16 pagesA Comparative Study Between Propane Dehydrogenation (PDH) Technologies and Plants in Saudi ArabiaBihina HamanNo ratings yet

- Fixed Bed Journal 3Document11 pagesFixed Bed Journal 3Daniel EdohNo ratings yet

- Synthesis of High-Quality Diesel With Furfural and 2-Methylfuran From HemicelluloseDocument10 pagesSynthesis of High-Quality Diesel With Furfural and 2-Methylfuran From HemicelluloseOwais AhmedNo ratings yet

- 11 ACV HidrogenoDocument15 pages11 ACV Hidrogenoluis felipe hernandez capachoNo ratings yet

- Application of Numerical Simulation On Biomass GasDocument6 pagesApplication of Numerical Simulation On Biomass GasJoseph OtengNo ratings yet

- A Comparison of Sol-Gel and Impregnated PT or and Ni Based - Alumina CatalystsDocument14 pagesA Comparison of Sol-Gel and Impregnated PT or and Ni Based - Alumina CatalystsMahdy HajienayatiNo ratings yet

- Ribeiro 2009Document11 pagesRibeiro 2009chen19111005 KFUEITNo ratings yet

- Alves 2013Document11 pagesAlves 2013Atif zahoorNo ratings yet

- Abrahamsson 2015Document8 pagesAbrahamsson 2015Siddhartha MitraNo ratings yet

- Retrofitting An Isopropanol Process Based On Reactive Distillation and Propylene-Propane SeparationDocument10 pagesRetrofitting An Isopropanol Process Based On Reactive Distillation and Propylene-Propane SeparationHadis ShojaeiNo ratings yet

- 2009 - Glycerol Reforming For Hydrogen ProductionDocument7 pages2009 - Glycerol Reforming For Hydrogen ProductionIsraelPala-RosasNo ratings yet

- Experimental Study of The OxidativeDocument13 pagesExperimental Study of The OxidativeRafael RíosNo ratings yet

- A Comparative Study Between Propane Dehydrogenation (PDH) Technologies and Plants in Saudi ArabiaDocument15 pagesA Comparative Study Between Propane Dehydrogenation (PDH) Technologies and Plants in Saudi ArabiaManojNo ratings yet

- Development of Fludized Bed Reactor To Enhance Hydrogen YieldDocument18 pagesDevelopment of Fludized Bed Reactor To Enhance Hydrogen Yieldmickymech012No ratings yet

- 1 s2.0 S0360319920329396 MainDocument13 pages1 s2.0 S0360319920329396 MainSadegh AhmadiNo ratings yet

- Wasiur-Energy NexusDocument11 pagesWasiur-Energy Nexusazmiwasi_867013700No ratings yet

- Chemical Physics LettersDocument7 pagesChemical Physics LettersAnonymous Wcj4C3jNo ratings yet

- Techno-Economic Analysis of Innovative ProductionDocument12 pagesTechno-Economic Analysis of Innovative ProductionTep B 21083 Luki LoviandiNo ratings yet

- Facile Preparation of N-Doped Activated Carbon Produced From Rice Husk For CO2 CaptureDocument12 pagesFacile Preparation of N-Doped Activated Carbon Produced From Rice Husk For CO2 CaptureZackkNo ratings yet

- Applied Energy: SciencedirectDocument18 pagesApplied Energy: SciencedirectAbhimanyu YadavNo ratings yet

- 10 1016@j Renene 2020 05 126Document11 pages10 1016@j Renene 2020 05 126Sergio Andres Guevara RengifoNo ratings yet

- 10.1007@s13399 011 0004 4 PDFDocument7 pages10.1007@s13399 011 0004 4 PDFJaydeep PatelNo ratings yet

- 4244 12672 1 PB PDFDocument15 pages4244 12672 1 PB PDFVinh Do ThanhNo ratings yet

- 4244-Article Text-12672-1-10-20180730Document15 pages4244-Article Text-12672-1-10-20180730bilal canitezNo ratings yet

- 1 s2.0 S0360319917300198 MainDocument10 pages1 s2.0 S0360319917300198 MainIslombek TurgunboevNo ratings yet

- Artigo 2Document19 pagesArtigo 2Tiffany RansdorfNo ratings yet

- 2-Methoxyhydroquinone from Vanillin for Aqueous Redox-Flow batteriesDocument6 pages2-Methoxyhydroquinone from Vanillin for Aqueous Redox-Flow batteriesCarlos Bathuel Ramirez P.No ratings yet

- Microporous and Mesoporous Materials: SciencedirectDocument10 pagesMicroporous and Mesoporous Materials: SciencedirectmekkutardeNo ratings yet

- Paper Mill Sludge BiocharDocument16 pagesPaper Mill Sludge BiocharTommy LauNo ratings yet

- Zainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsDocument17 pagesZainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsAbraham AvNo ratings yet

- Simulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel CellsDocument18 pagesSimulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel Cellswww.beatricechongNo ratings yet

- Fuel Processing Technology: Qiang Deng, Jisheng Xu, Peijuan Han, Lun Pan, Li Wang, Xiangwen Zhang, Ji-Jun ZouDocument6 pagesFuel Processing Technology: Qiang Deng, Jisheng Xu, Peijuan Han, Lun Pan, Li Wang, Xiangwen Zhang, Ji-Jun ZoucligcodiNo ratings yet

- A Novel Process Simulation Model For Hydrogen Production Via Reforming of Biomass Gasification TarDocument10 pagesA Novel Process Simulation Model For Hydrogen Production Via Reforming of Biomass Gasification TarSirikul BoontermNo ratings yet

- #0003 - 2014 - Tebibel - Design and Sizing of Stand-Alone Photovoltaic Hydrogen System For HCNG ProductionDocument12 pages#0003 - 2014 - Tebibel - Design and Sizing of Stand-Alone Photovoltaic Hydrogen System For HCNG ProductionMarkZhaiNo ratings yet

- Energies: Renewable Hydrogen Carrier - Carbohydrate: Constructing The Carbon-Neutral Carbohydrate EconomyDocument22 pagesEnergies: Renewable Hydrogen Carrier - Carbohydrate: Constructing The Carbon-Neutral Carbohydrate EconomyuripatinNo ratings yet

- Simulation Study For Production of Hydrocarbons From WasteDocument9 pagesSimulation Study For Production of Hydrocarbons From WasteeduardoNo ratings yet

- Intensification of A Hydrotreating Process To Produce Biojet Fuel Using Thermally Coupled DistillationDocument8 pagesIntensification of A Hydrotreating Process To Produce Biojet Fuel Using Thermally Coupled DistillationLaura RDNo ratings yet

- 1 s2.0 S0165237022000687 MainDocument11 pages1 s2.0 S0165237022000687 Mainhadush2002No ratings yet

- Econ AnalysisDocument11 pagesEcon Analysisadityachoumal07No ratings yet

- Journal Pre-Proof: Chemical Engineering and ProcessingDocument52 pagesJournal Pre-Proof: Chemical Engineering and ProcessingPratikNo ratings yet

- Hydrogen Production From Biomass Combining Pyrolysis and The Secondary DecompositionDocument6 pagesHydrogen Production From Biomass Combining Pyrolysis and The Secondary Decompositioncosmicbabe_2000No ratings yet

- Spe 142855-PPDocument9 pagesSpe 142855-PPHeron Gachuz Muro100% (1)

- Enhanced Recycle Split VapourDocument19 pagesEnhanced Recycle Split VapourMaythee SaisriyootNo ratings yet

- Ravendran 2019 IOP Conf. Ser. Mater. Sci. Eng. 702 012001Document9 pagesRavendran 2019 IOP Conf. Ser. Mater. Sci. Eng. 702 012001Alishba NadeemNo ratings yet

- Catalytic Hydrogenation of - Xylose Over Ru Decorated Carbon Foam Catalyst in A Spinchem Rotating Bed ReactorDocument13 pagesCatalytic Hydrogenation of - Xylose Over Ru Decorated Carbon Foam Catalyst in A Spinchem Rotating Bed ReactorDavid BaronNo ratings yet

- 1 s2.0 S1540748910003950 MainDocument23 pages1 s2.0 S1540748910003950 Mainكداده آدم جلبهNo ratings yet

- Thesis GasificationDocument9 pagesThesis GasificationEmma Burke100% (2)

- US20200325402A1Document25 pagesUS20200325402A1Owais AhmedNo ratings yet

- BN-EG-UE109 Guide For Vessel SizingDocument28 pagesBN-EG-UE109 Guide For Vessel Sizingeulalio_méndezNo ratings yet

- LEL and UELDocument1 pageLEL and UELOwais AhmedNo ratings yet

- Reactor TemplateDocument2 pagesReactor TemplateOwais AhmedNo ratings yet

- ES TDC 001 - Rev - 01 2021 12 10 04 - 13 - 44Document58 pagesES TDC 001 - Rev - 01 2021 12 10 04 - 13 - 44Owais AhmedNo ratings yet

- OA17038ADocument28 pagesOA17038AOwais AhmedNo ratings yet

- SYSTEM AND METHOD FOR COLD CRACKING WITH STEAMDocument13 pagesSYSTEM AND METHOD FOR COLD CRACKING WITH STEAMOwais AhmedNo ratings yet

- Verezemskii 1997Document5 pagesVerezemskii 1997Owais AhmedNo ratings yet

- AU2012301471B2Document33 pagesAU2012301471B2Owais AhmedNo ratings yet

- Mina Abdulla Refinery Experience With Atmospheric Residue Desulfurization (Ards)Document10 pagesMina Abdulla Refinery Experience With Atmospheric Residue Desulfurization (Ards)Owais AhmedNo ratings yet

- Synthesis of High-Quality Diesel With Furfural and 2-Methylfuran From HemicelluloseDocument10 pagesSynthesis of High-Quality Diesel With Furfural and 2-Methylfuran From HemicelluloseOwais AhmedNo ratings yet

- Synthesis of Diesel Range Alkanes With 2-Methylfuran and Mesityl Oxide From Lignocellulose (Catalysis Today, Vol. 234) (2014)Document9 pagesSynthesis of Diesel Range Alkanes With 2-Methylfuran and Mesityl Oxide From Lignocellulose (Catalysis Today, Vol. 234) (2014)Owais AhmedNo ratings yet

- Modeling and simulating hydrodesulfurization reactionsDocument21 pagesModeling and simulating hydrodesulfurization reactionsOwais AhmedNo ratings yet

- An Investigation of The Effect of Catalyst Type and Operating Severity On Product Oil QualityDocument5 pagesAn Investigation of The Effect of Catalyst Type and Operating Severity On Product Oil QualityOwais AhmedNo ratings yet

- A New Residual Desulfurization ProcessDocument8 pagesA New Residual Desulfurization ProcessOwais AhmedNo ratings yet

- Relation Between Feed Quality and Coke Formation in A Three-Stage Atmospheric Residue Desulfurization (ARDS) ProcessDocument10 pagesRelation Between Feed Quality and Coke Formation in A Three-Stage Atmospheric Residue Desulfurization (ARDS) ProcessOwais AhmedNo ratings yet

- Simulation of An Atmospheric Residue Desulfurization Unit by Quasi-Steady State Modeling (Chemical Engineering & Technology, Vol. 21, Issue 2) (1998)Document1 pageSimulation of An Atmospheric Residue Desulfurization Unit by Quasi-Steady State Modeling (Chemical Engineering & Technology, Vol. 21, Issue 2) (1998)Owais AhmedNo ratings yet

- Column SizingDocument4 pagesColumn SizingOwais AhmedNo ratings yet

- Effect of The Operating Pressure On Residual Oil HydroprocessingDocument6 pagesEffect of The Operating Pressure On Residual Oil HydroprocessingOwais AhmedNo ratings yet

- Best Dual Extruder 3d Printer: Quick OverviewDocument14 pagesBest Dual Extruder 3d Printer: Quick OverviewOwais AhmedNo ratings yet

- Commercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryDocument15 pagesCommercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryOwais AhmedNo ratings yet

- Static Electricy RevisedDocument3 pagesStatic Electricy RevisedOwais AhmedNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- Selecting Lubricant Viscosity for Gas CompressorsDocument7 pagesSelecting Lubricant Viscosity for Gas CompressorsOmer Nauman TariqNo ratings yet

- The Reinforcement of DenturesDocument10 pagesThe Reinforcement of DenturesmarishaNo ratings yet

- Test Bank Chapter 3Document10 pagesTest Bank Chapter 3mrbookoNo ratings yet

- Balance Steam Supply With Demand - Then Save Energy and Reduce Carbon FootprintDocument8 pagesBalance Steam Supply With Demand - Then Save Energy and Reduce Carbon FootprintmansoursabicNo ratings yet

- F64B, F64L, FFB64 - Olympian Plus Plug-In System Ultra High Efficiency Coalescing FilterDocument4 pagesF64B, F64L, FFB64 - Olympian Plus Plug-In System Ultra High Efficiency Coalescing Filterمصطفى الكوتNo ratings yet

- Fuels and CombustionDocument143 pagesFuels and CombustionJhudiel Angelo CelimenNo ratings yet

- Poly Phenylene Oxide (PPO) : Corporate Training and PlanningDocument27 pagesPoly Phenylene Oxide (PPO) : Corporate Training and PlanningAkash YadavNo ratings yet

- MCQDocument4 pagesMCQJ Jeshwitha JosefaNo ratings yet

- Gas LubricationDocument13 pagesGas LubricationSachin Meshram0% (1)

- Achievement Test g7Document4 pagesAchievement Test g7Yllan AlcoroqueNo ratings yet

- Metal FuelsDocument15 pagesMetal FuelsWillem vdaaNo ratings yet

- Objective Qus WD AnswerDocument98 pagesObjective Qus WD Answeradhitya100% (2)

- Designing and Calculation of MufflerDocument7 pagesDesigning and Calculation of MufflerPravin Patil100% (1)

- Test Information Guide: College-Level Examination Program 2012-13Document21 pagesTest Information Guide: College-Level Examination Program 2012-13j2thec07100% (1)

- Bs8485-2015+a1-2019 - (2019-02-20 - 01-27-50 PM) PDFDocument96 pagesBs8485-2015+a1-2019 - (2019-02-20 - 01-27-50 PM) PDFJonny Swindells100% (2)

- GENERAL SCIENCE 50 MCQsDocument8 pagesGENERAL SCIENCE 50 MCQsKhabir IslamNo ratings yet

- Estimated Emplacement Temperatures For A 69b9ed38Document11 pagesEstimated Emplacement Temperatures For A 69b9ed38Ismail 18513373No ratings yet

- Co2 O2 Table - 2012 PDFDocument5 pagesCo2 O2 Table - 2012 PDFIgor LainovicNo ratings yet

- Gen Chem Practice Exam 2 BrownDocument7 pagesGen Chem Practice Exam 2 Brownkaleb16_2No ratings yet

- PSA Nitrogen PlantsDocument4 pagesPSA Nitrogen PlantsIdo Aprilian TariganNo ratings yet

- De Kiem Tra Hoc Ky 12 8783 MergeDocument20 pagesDe Kiem Tra Hoc Ky 12 8783 MergeKate221192No ratings yet

- Carbon Black For WeatherstripsDocument8 pagesCarbon Black For WeatherstripsLucianoNo ratings yet

- Answer: B: Selected/modified From Brown Et Al: Chemistry The Central Science, 10e, 12e, 13e TestbanksDocument10 pagesAnswer: B: Selected/modified From Brown Et Al: Chemistry The Central Science, 10e, 12e, 13e Testbanksفاطمة كليبNo ratings yet

- TAnh Chuyên 2016 2017Document4 pagesTAnh Chuyên 2016 2017Nguyễn Thị Việt BắcNo ratings yet

- Nanotechnology Advances Water TreatmentDocument16 pagesNanotechnology Advances Water TreatmentSivamani SelvarajuNo ratings yet

- 5070 w05 QP 1Document16 pages5070 w05 QP 1mstudy123456No ratings yet

- AllotropesDocument7 pagesAllotropesHarsh YadavNo ratings yet