Professional Documents

Culture Documents

Biodiesel Processor

Uploaded by

Aleem MuhammadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biodiesel Processor

Uploaded by

Aleem MuhammadCopyright:

Available Formats

Biodiesel Processor System Manual

version 2 June 13, 2014

Jim Leidel

Director of Clean Energy Systems

leidel@oakland.edu

www.oakland.edu/BIOMASS

CONTENTS

Part 1: Introduction (pg.1)

Part 2: Training (pg.6)

Part 3: Safety Protocols (pg.7)

Part 4: Operational Procedure (pg.8)

Part 5: Biodiesel Lab & Quiz (pg.22)

Part 6: Feedstock Supply (pg.26)

PART 1: INTRODUCTION

Biodiesel is a renewable fuel derived from a chemical reaction of alcohol and vegetable

or animal oils, fats, or greases. These oils or fats are chemically altered in order to

allow use in any diesel engine or home oil heating system, with little or no modification.

A process called transesterification removes the glycerin component of the oil (which is

a triglyceride molecule), resulting in a much thinner, or less viscous, product which

stays liquid down to much lower temperatures. Biodiesel can be used in any diesel

engine in pure form or blended with petroleum diesel in any percentage. Existing gas

stations, pumps, and tanks can use biodiesel, providing a near seamless integration into

our vast petroleum infrastructure. Even a commonly used blend of 20% biodiesel and

80% petroleum diesel (B20) will significantly reduce harmful pollutants, as well as

carbon dioxide gas, reducing your vehicles contribution to climate change.

One of the most exciting aspects of biodiesel is the fact that it is readily produced from

used restaurant fryer oils. Restaurants must properly dispose of significant quantities of

waste veggie oil (often referred to as grease, or its trade name, yellow grease). The oil

may therefore be easily be acquired for small scale biodiesel production operation.

Using recycled waste fryer oil to produce biodiesel provides the benefits of a U.S.

grown, renewable fuel, as well as offering a low cost option to recycle a waste product

and put it to good use reducing carbon dioxide and other harmful emissions.

Biodiesel Processor System: Operation, Safety & Training 1

BIODIESEL CHEMISTRY

Biodiesel use should not be

confused with the combustion of

straight vegetable oil, or SVO.

SVO may be used directly into a

diesel engine. However, the fuel

supply system must be modified

by the addition of a second fuel

tank, heating systems, and fuel

switching to accommodate SVO

(see Appendix B).

In the case of biodiesel, the engine and fuel systems are not modified, but we instead

modify the fuel so that it can be used in any stock diesel engine. A typical vegetable oil

consists of a triglyceride molecule as shown below.

There are many types of fatty acid chains, and the makeup of these will determine both

the properties of the vegetable oil AND the final biodiesel product. Being a “tri”-

glyceride, there are three fatty acid chains bound to one alcohol molecule, a molecule of

glycerin (or glycerol). To produce biodiesel, the glycerol is split away with the aid of a

catalyst, and the remaining free-floating fatty acid chains are then capped off with a

lower level alcohol molecule such as methanol or ethanol. Methanol is presently the

lowest cost option, as well as a bit easier to use. However, methanol is currently

produced from natural gas, while ethanol is typically produced from corn, or other

renewable feedstocks making it a more attractive feedstock from a renewable or

sustainable perspective..

Fatty Acid

FA Alcohol

Glycerin

FA FA

FA Biodiesel

Vegetable Oil Alcohol

Glycerol

In its most simple form, the transesterification process, shown above, is merely a

heated mixing process, where warm veggie oil is mixed in the presence of a catalyst.

The glycerol molecule is striped away, and replaced with three individual methanol

molecules to make there biodiesel molecules. This is called transesterification since the

Biodiesel Processor System: Operation, Safety & Training 2

both the starting triglyceride and

resulting biodiesel molecules fall

into the organic chemistry

category of an ester. Therefore,

they are trans - ester - ified.

Next, we the startup of a

number of different sized

production and distribution

operations including some a

business model for a 1/8 million gallon per year cooperative. This will be followed by

the discussion of the logistics and technologies required to bring biodiesel fuel to your

local region. Although this report focuses on the State of Michigan, most of the

information presented pertains equally to any location throughout the country.

PRODUCTION TECHNOLOGY

The major steps required to synthesize biodiesel are as described below.

Purification of Waste Oil Feedstock

If waste vegetable oil is used, it is filtered to remove dirt, charred food, and other non-oil

material often found. Water is removed because its presence causes the triglycerides

to hydrolyze to give salts of the fatty acids instead of undergoing transesterification to

give biodiesel.

At home, this is often accomplished by heating the filtered oil to approximately 120°C.

At this point, dissolved or suspended water will boil off. When the water boils, it spatters

(chemists refer to it as "bumping"). To prevent injury, this operation should be done in a

sufficiently large container (at most two thirds full) which is closed but not sealed.

In the laboratory, the crude oil may be stirred with a drying agent such as magnesium

sulfate to remove the water in the form of water of crystallization. The drying agent can

be separated by decanting or by filtration. However, the viscosity of the oil may not

allow the drying agent to mix thoroughly.

Neutralization of free fatty

acids

A sample of the cleaned oil is

titrated against a standard solution

of base in order to determine the

concentration of free fatty acids

present in the waste vegetable oil

Biodiesel Processor System: Operation, Safety & Training 3

sample. The quantity of additional base catalyst required to neutralize the acid is

calculated.

Transesterification

While adding the base, a slight excess is factored in to provide the catalyst for the

transesterification.

The calculated quantity of base (sodium or potassium hydroxide) is added slowly to the

alcohol and it is stirred until it dissolves. Sufficient alcohol is added to make up three

full equivalents of the triglyceride, and an excess is added to drive the reaction to

completion.

The solution of sodium hydroxide in the alcohol is then added to a warm solution of the

waste oil, and the mixture is heated (typically 50 °C) while agitating with a mechanical

paddle or mix pump for several hours (2 to 4 typically) to allow the transesterification to

proceed.

Once the reaction is complete, the glycerol will precipitate out and fall to the bottom.

The bottom glycerol may then be drained off from the bottom, leaving approximately

85% of the original reactants as a top layer of biodiesel and some remaining alcohol.

The excess alcohol can be distilled off from the crude biodiesel and/or the crude

glycerol. More excess alcohol remains in the glycerol than the biodiesel, and often the

alcohol in the crude biodiesel is not reclaimed for small scale operations. This residual

alcohol can be extracted with a water wash, or merely by evaporation (either passive, or

via an air bubble wash). If water washed, the biodiesel must then be dried by

distillation, evaporation, or with a drying agent.

The Reaction

CH2COOR1

|

CH2COOR1 + (3) CH3OH → (CH2OH)2CHOH + (3) CH3COOR1

|

CH2COOR1

Triglyceride + (3) Methanol → Glycerol + (3) Biodiesel Esters

Where the R1, R2, and R3 represent the long fatty acid chains different for the various

oil feedstock. We typically see soy and sometimes canola in the restaurant used oil

market.

During the transesterification process, the triglyceride is reacted with alcohol in the

presence of the catalyst. The main reason for doing a titration to produce biodiesel, is to

find out how much additional alkaline is needed to ensure a complete transesterification

in the presence of additional free fatty acids found in used oils. Experimentally, 6.25 gm

Biodiesel Processor System: Operation, Safety & Training 4

per liter of NaOH produces a very usable fuel. From field experience, a

recommendation (without titrating) might be to use about 6 g NaOH when the waste

vegetable oil is light in color and about 7 g NaOH when it is dark in color.

The alcohol reacts with the fatty acids to form the mono-alkyl ester (or biodiesel) and

crude glycerol. The reaction between the lipid (fat or oil) and the alcohol is a reversible

reaction so the alcohol must be added in excess to drive the reaction towards the right

and ensure complete conversion.

Base catalyzed mechanism

This reaction is base catalyzed using a chemical such as dry sodium hydroxide (also

called NaOH, caustic soda, or lye), dry potassium hydroxide (KOH, or caustic potash),

or a prepared solution of sodium or potassium methoxide. The dry catalyst (KOH or

NaOH) is dissolved in the alcohol to make a convenient method of dispersing the

otherwise solid catalyst into the oil. The catalyst needs to be very dry, and exposure to

free air will allow it to absorb moisture. Therefore, minimize the amount of time that any

containers are left open, and tightly seal lids for storage. Any water in the process

promotes the production of unwanted soaps and inhibits the transesterification reaction.

Once the alcohol / catalyst mixture is made, it is added to the triglyceride. There are

several competing reactions, so care must be taken to ensure the desired reaction

pathway occurs. Most methods do this by using an excess of alcohol.

The acid / base catalyzed method is a slight variant and is not covered here.

The Process

• Preparation: care must be taken to monitor the amount of water and free fatty

acids in the incoming biolipid (oil or fat). If the free fatty acid level or water level is

too high it may cause problems with soap formation (saponification) and the

separation of the glycerin by-product downstream.

• Catalyst is dissolved in the alcohol using a standard agitator or mixer.

• The alcohol/catalyst mix is then charged into a closed reaction vessel and the

biolipid (vegetable or animal oil or fat) is added. The system from here on is

totally closed to the atmosphere to prevent the loss of alcohol.

The reaction mix is kept just below the boiling point of the methanol (which is

64.5°Celcius, or 148°Fahrenheit ) to speed up the reaction. The reaction will

take place at room temperature, but approximately 130 °F is recommended as a

compromise of speed and safety. By no means do you want to exceed the

boiling point of the alcohol, or you will build up pressure and emit toxic vapors.

Recommended reaction time varies from 1 to 8 hours; under normal conditions

the reaction rate will double with every 10 °C increase in reaction temperature.

Biodiesel Processor System: Operation, Safety & Training 5

Excess alcohol is normally used to ensure complete reaction. Typically 20%

methanol is used.

• The glycerin phase is more dense than biodiesel phase and the two can be

gravity separated with glycerin simply drawn off the bottom of the settling vessel.

In some cases, a centrifuge is used to separate the two materials faster.

• Once the glycerin and biodiesel phases have been separated, the excess alcohol

in each phase is removed with a flash evaporation process or by distillation. In

other systems, the alcohol is removed and the mixture neutralized before the

glycerin and esters have been separated. In either case, the alcohol is recovered

using distillation equipment and is re-used. Care must be taken to ensure no

water accumulates in the recovered alcohol stream.

• The glycerin by-product contains unused catalyst and soaps that are neutralized

with an acid and sent to storage as crude glycerin (water and alcohol are

removed later, chiefly using evaporation, to produce 80-88% pure glycerin).

• Once separated from the glycerin, the biodiesel is sometimes purified by washing

gently with warm water to remove residual catalyst or soaps, dried, and sent to

storage.

PART 2: TRAINING

1. Read this entire manual

2. Watch the operations video (located at www.oakland.edu/BIOMASS)

3. Perform the one liter biodiesel lab process, including wash & dry of product

4. Take the Biodiesel Production Quiz, below and turn in to lab admin.

5. Assist with a qualified operator on one full process from oil to dry product

6. Verify all of the above has been done and then you will be added to the trained

operator list. After logging (5) five processes runs, you are eligible to become a

qualified trainer for new users.

Biodiesel Processor System: Operation, Safety & Training 6

PART 3: SAFETY PROTOCOLS

Emergency Contact Numbers

• Training Requirements (see Part 2) • Jim Leidel, Director, 248-765-2027 cell

• Operating Procedure (see Part 4) • OU Police, 911

• Steve Kent, Operations, 248-765-4800

Safety Data Sheets (SDS) will be located at the biodiesel processor as well as with the

OU INC operations management. SDS’s for the following chemicals will be available for

review: biodiesel, methanol, ethanol, glycerin, sodium hydroxide, & potassium

hydroxide

Apparel: When operating any step of the biodiesel, or any other CERC equipment,

please wear Closed Toe Shoes. The following additional Protective Clothing must be

worn in individual steps when handling chemicals:

o Dust Mask (when handling NaOH or KOH)

o Goggles and Gloves (when handling methanol, ethanol, NaOH or KOH)

Emergency Safety Equipment

Be familiar with the locations of all of

the following emergency gear:

• Safety Shower

• Eye Wash

• Spill Kit

• Fire Extinguishers: for biodiesel,

use the FOAM type, or silver

canister, not the red ones. There

are two as shown here on the map)

Chemical Storage Cabinet

must be used to store excess

methanol and all KOH & NaOH. One

drum of methanol may be kept out by

the processor, sealed.

Cleanup

• Leave the area cleaner then how

you found it. Spend at least 15% of your time on cleanup duties and organization. Put

tools & chemicals away and dispose of trash.

• Disposal of oily rags: Dispose of oily rags in a plastic trash bag and place in dumpster

outside the pavilion. Do not place oil soaked rags in indoor trash bins.

• Sheets of fibrous Absorbent Pads are available and should be used strategicly around

the biodiesel space. We have been obtaining absorbent pads from Eco Paper, Bill

Icikson, 1150 W Hamlin Drive, Rochester Hills, (248) 652-3602

• Shutdown Procedure: Refer to “Operating Procedure” (see Part 4, below)

• Lock out / tag out process: (under review for next revision of this document)

Biodiesel Processor System: Operation, Safety & Training 7

PART 4: OPERATIONAL PROCEEDURE

Note: At least one authorized & trained individual must be present during operation of

the biodiesel system. A list of trained personnel will be on file with the OU Clean

Energy Research Center management.

To be certified to operate, you must complete all Training Items listed in Part 2.

The following pages illustrate and detail the Oakland University processor and its

operation.

Biodiesel Processor System: Operation, Safety & Training 8

Biodiesel System Schematic

Valve List:

V1: waste oil inlet valve V8: transfer T1-T2 valve V15: wash tank T3 bottom valve

V2: process tank T1 bottom valve V9: wash tank T2 inlet valve V16: wash tank T3 drain valve

V3: process tank T1 recirculation valve V10: wash tank T2 drain valve V17: tank T2-T3 recirculation valve

V4: glycerin drain valve V11: wash tank T2 bottom valve V18: wash tank T3 inlet valve

V5: methoxide transfer valve V12: wash tank T2 recirculation valve V19: biodiesel product outlet valve

V6: pump 2 drain valve V13: pump P3 drain valve

V7: process tank T1 inlet valve V14: wash tank T3 recirculation valve

Biodiesel Processor System: Operation, Safety & Training 9

Drum-3

P-4 spill containment clean

pallet wash

B100 water Used

Drum-1

Biodiesel Vegetable Oil

Tote waste used Tote

glycerin wash

water

Drum-2

Containment Skid

P-1

P-3

Wash Wash

Processor

Tank Tank

P-2 Tank

3 2

Meth-

1

oxide

Tank 4

Control

Panel

methanol

Drum-4

Biodiesel System Layout

Biodiesel Processor System: Operation, Safety & Training 10

Biodiesel unit working Procedure

Processor Oil Fill

• POWER:

o Turn ON the main Circuit Breaker, if it is off.

o Turn ON the Biodiesel unit (Unit) circuit breaker, if it is off.

• Place the oil supply suction tube into the oil supply Tote

• Turn unit master panel control ON.

• Open valves V-1,3,7 to suction oil though P1 into the processor Tank 1.

• Close valves V-2,4,5,8

• Turn ON processor pump P1 at panel (If prime required, prime the pump).

• Fill the Processor tank to 60 gallon mark.

• Once achieve the required volume shut off the pump P1.

• Close valve V-1.

• Open process tank bottom valve V-2

• Start the processor pump again.

• Turn ON the heater Power from main Panel.

• Allow circulation until the temperature indicator on control panel indicates 120o F

Titration of Used Oil

• Refer to separate titration procedure & calculate total catalyst needed for batch

Preparation of Methoxide Tank

• Remove lid from Tank T4

• Go to chemical storage cabinet and retrieve methanol if a drum is not located at the

processor. Only one drum of methanol is allowed to be out on the floor.

• Obtain Battery Operated Siphon pump off storage shelf

• Remove bung from stopper on Methanol drum

• Add 20% methanol to Tank T4 (12 gallons for a 60 gallon batch), and Replace T4

Lid and methanol drum bung

• If using any small containers, return methanol to Chemical Storage Cabinet.

However, one 55 gallon drum may remain out near processor.

• Using the digital scale, weight the proper amount of NaOH or KOH wearing gloves

and googles.

• Turn ON Methoxide pump P2.

• Slowly pour in the catalyst into methanol in T4. Put in only a cup or two at a time so

as to not clog up the flow of methanol.

• Allow P2 to run for an additional 15 minutes after adding all catalyst, to ensue ALL

catalyst is completely dissolved.

• ON to circulate materials for 10 minutes

Transfer Methoxide to Processor Tank

• With both processor pump, P1 and methoxide pump, P2 ON, Partially open

methoxide transfer valve, V-5 (about ¼ open) to flow Methoxide into suction side of

P1, and continue until all contents of Methoxide tank are drained out.

Biodiesel Processor System: Operation, Safety & Training 11

• Turn OFF Methoxide Pump, P2

• Close Methoxide Valve, P5 completely

Timed Process Mix

• Continue processing with Circulating Pump, P1 ON for 3 hours via the time delay

relay installed in the control panel. P1 will continue to run until the timer

automatically shuts off.

• Turn Off Electric Heat.

• The

Drain Glycerin from Processor Tank T1

• Place empty Glycerin holding tank next to hose connected to Gylcerin Drain Valve,

V4

• Continue to drain Glycerin into tank until all Glycerin is removed from Processing

Tank, T1

• Close Valve, V4

Transfer Methoxide mixture from Processor Tank T1 to Wash Tank T2

• Close Valve V7

• Open Connect Valve, V8

• Open Washer Intake Valve, V9

• Turn ON Processor Pump, P1

• Transfer Processor Contents

• Turn OFF, Processor Pump, P1

• Close Valve V2, V8 and Valve V9

Wash Methoxide Mixture

• Hook Garden Hose Reel to Sink Faucet

• Unroll Hose to Biodiesel Processor

• Attached Hose to Wash Tank Lid Misting Valve

• Turn Water Slowly On and control Misting via brass valve on end of hose

• Mist 10 gallons of water (see fluid level on side of tank)

• Turn off Water

• Place Wash Water Jug next to hose connected to Valve 10, Water Drain Valve

• Open Valve V11

• Turn on Valve 10 - Empty all water slowly to ensure no spillage

• Repeat Above steps at TOTAL of 3 Times (30 Gallon Wash)

• Test Mixure (SEE PROCEDURE)

• Close Valve V10

Biodiesel Processor System: Operation, Safety & Training 12

Transfer Mixture from Wash Tank T2 to Bubbling/Settling Tank T3

• Open Biodeisel Transfer Valve, V12

• Open Biodiesel Transfer Valve, V13

• Turn ON Transfer Pump, P3

• Fully Transfer all Biodiesel from Wash Tank, T2 to Bubbling/Settling Tank T3

• Turn OFF Transfer Pump P3

• Close Transfer Valves V11, V12

Bubble Wash of Biodiesel

• Open Lid To Tank T3

• Place Bubbling hose and rock in Tank T3 and submerge 1 foot

• Turn ON Bubbling Compressor

• Bubble for 4 or more hours

Transfer Biodiesel to Biodiesel Holding Tank

• Place Diesel Transfer Hose connected to Drain Valve V15 into Diesel Holding

Container

• Open Diesel Drain Valve V15

• Turn Transfer Pump P3, ON and Transfer contents of Tank T3 to Diesel Holding

Tank

• Turn Transfer Pump T3 OFF

• Close Valves V13, V16 and Valve V16

Shutdown Procedure

• ENSURE ALL VALVES CLOSED

• TURN OFF MAIN POWER

• SPEND SOME TIME CLEANING UP. Yes, that means YOU.

Biodiesel Processor System: Operation, Safety & Training 13

Front view of processor

Control Panel

Underside of wash /

settle Tanks 2 & 3 have

a fine mist spray nozzle

Biodiesel Processor System: Operation, Safety & Training 14

Main processor Tank 1

The red electrical box is

the electric heating

element

Valve assembly on the

bottom of Processor

Tank 1.

Main Processor Pump 1

is located on the bottom

right of the photo.

Biodiesel Processor System: Operation, Safety & Training 15

Valve assembly on the

bottom of wash Tank 2.

Valve 10 can be used as

a drain.

Biodiesel Processor System: Operation, Safety & Training 16

Valve assembly on the

bottom of wash Tank 3.

Valve 16 can be used as

a drain.

V-9 is the intake valve

for Wash Tank 2

Biodiesel Processor System: Operation, Safety & Training 17

Used vegetable oil tote

with the suction drop

tube, suctioned by main

Pump 1.

Main processor Pump 1

Biodiesel Processor System: Operation, Safety & Training 18

Transfer Pump 3

Leave the waste

glycerine and other

drums on the spill

containment pallet.

Biodiesel Processor System: Operation, Safety & Training 19

Methoxide mix pump 2

Final product export to

tote, via two inline filters

Biodiesel Processor System: Operation, Safety & Training 20

The biodiesel product

Pump 4 is 12VDC

powered by a battery.

The battery needs to be

checked for voltage and

charged occasionally.

If voltage is below

11.5VDC, please charge

for a few hours.

Biodiesel Processor System: Operation, Safety & Training 21

PART 5: BIODIESEL LAB and QUIZ

Estimated time to complete: ½ hour Pre-lab reading

1 hour Day One lab time

½ hourDay Two lab time

¼ hour Post lab Q & A

General Description

For more information, you can visit www.kitchen-biodiesel.com and www.biomich.com

In this lab, you will practice the biodiesel process by making a one liter batch of vegetable

oil derived biodiesel in a 2 liter soda bottle. The lab uses NaOH (sodium hydroxide), but

you may substitute KOH (potassium hydroxide) if you properly adjust the amounts used.

The glycerol layer will settle out as a bottom layer due to its higher specific gravity. The

biodiesel, or methyl ester, will float above since it is lighter. The glycerol can then be

carefully drained off leaving a crude biodiesel product.

The fun part is that all of the materials and ingredients may be obtained from your local

department store, or online (if you cannot find Red Devil lye, the NaOH may be found on

soap making or animal hide tanning web sites).

Items required from student (one per lab group):

• One 2 liter (preferably clear) soda bottle, rinsed and completely dry.

• One liter of vegetable oil. Be creative if you choose, any veggie oil will do….

Items that will be provided for you:

• Gloves & goggles (please take care not to get NaOH on clothing, it will burn a hole)

• Pint mason jar & lid

• 200 mL of methanol

• 5 grams NaOH

• Funnel

• 2000 mL beaker

• Hot plate

• Digital scale

Biodiesel Processor System: Operation, Safety & Training 22

Vegetable oil

any oil will work,

but Canola is one

of the best for

cold weather

properties

Catalyst

NaOH - Sodium

Hydroxide

Sold as Drain Cleaner in

Hardware and Grocery

Stores. Look by the

Drano. Make sure the can

reads "Contains Sodium

Hydroxide"

Biodiesel Processor System: Operation, Safety & Training 23

1 liter

Start Here

of oil 5 KITCHEN

BIODIESEL

6

10

120 oF

200

ml pour

4 7 oil in

bottle

biodiesel

shake vigorously

1 with TIGHT lid glycerin

shake and let

3 react for 1 hour

8 add

lye –

2 one full tsp (5g)

meth.

9

Images courtesy of www.kitchen-biodiesel.com

Proper safety is important here. We are working with poisonous methanol and caustic lye.

DAY 1 1 & 2. Measure 200 mL of methanol directly into the mason jar. Our jars have gradations

on the side.

3. Measure in 5 grams of NaOH, sodium hydroxide on the digital scale.

4. Screw on the lid very tightly and carefully. This is the most dangerous step. One partner can

shake to dissolve the NaOH. It will generate some heat, but not too much pressure.

5 & 6. Measure 1 liter of your oil into the beaker and heat on the hot plate to 120 deg F.

7 & 8. Use funnel to pour carefully into the 2 liter plastic bottle. Then carefully pour in the

methanol and NaOH mixture.

9. Close cap tightly. Shake vigorously off and on for about 20-30 minutes.

10. Crack the cap a bit to let air in as the mixture cools. Set aside. The glycerin should begin to

separate and settle out in 20-30 minutes. The top portion is crude biodiesel.

DAY 2 11. A day or two later, return to inspect the glycerin separation.

12. Drain off the glycerin by inverting with your thumb over the top and slowly draining out. 13.

Slowly add a ½ liter to liter of water. It will get milky as it absorbs the soaps and remaining NaOH.

Repeat 3-5 times until the water remains somewhat clear. If you overly agitate the mixture

(especially on the 1st & 2nd washes, you could create a permanent emulsion, so go slowly.

14. Pour biodiesel into an open container and set out to dry for a few days. It could be

microwave’d, but take care to remove any residual water droplets from the bottom that will still boil

and make a steam explosion & mess.

15. Once crystal clear, the biodiesel is ready to use.

Biodiesel Processor System: Operation, Safety & Training 24

Quiz and Signature Page

In the space below, briefly describe your transesterification results, successful or not.

(Just a few sentences) Describe any problems or special observations.

Questions:

1. What type of oil did you use? ____________________

2. Was the glycerin separation clearly visible? And what color is the glycerin?

3. What is the most common blend of biodiesel found in retail fuel stations? __________

4. What is the most common oil feedstock for U.S. biodiesel production? _____________

5. What is the most common oil feedstock for European biodiesel? __________________

6. In the OU processor, how many gallons of used oil is processed per batch? ______

7. In the OU processor, what step are you required to wear a face filter mask?

8. What is the most suitable type of fire extinguisher for a liquid or oil fire? __________

and how many of these type are near the OU processor? _____________

9. What’s the minimum time that you spend on cleanup after every use? ____________

Please print and sign your name below:

_______________________ ____________________________

Printed name Signature

_______________________ ____________________________

Email Phone Number

Biodiesel Processor System: Operation, Safety & Training 25

PART 6: FEEDSTOCK SUPPLY (more info to come…..)

The primary cost of biodiesel is the oil feedstock. For a soy oil base operation, the oil

feedstock is typically 70-80% of the total cost of production. It takes about 7.3 pounds of

fresh or used vegetable oil to produce one gallon of biodiesel.

The price of soybean oil varies widely but over the last few years has tended to stay in the

range of $0.25 to $0.35/lb. This means the virgin feedstock cost will be between $1.75 and

$2.56/gallon. The cost of yellow grease, or used & purified waste restaurant oil has tended

to stay in the range of $0.15 to $0.20/lb. This means the virgin feedstock cost will be

between $1.10 and $1.46/gallon.

The business model described here incorporates restaurant oil collections as part of the

operations. A zero cost for oil is carried for the first years of operation, but labor and

equipment costs are required to incorporate oil collections in the coop model. Presently,

most restaurants pay a fee for a waste oil company to dispose of their used oil. The oil

then makes its way to a rendering company who purifies it, and resells it as a commodity

called “yellow grease” for the prices mentioned above.

The option to purchase a stable supply of yellow grease should be fully investigated during

the coop planning phases. This would vastly simplify operations and startup logistics, but

would also increase the cost of the final product.

Studies are available which have reviewed waste oil availability per person and per

restaurant. One such study is available at www.biodieselmichigan.com. By studying 30

metropolitan areas across the United States, it was found that yellow grease production

averaged 1.2 gallons / year / person and 847 gallons / year / restaurant.

Therefore, to support a 1/8 million gallon per year operation, 147 average restaurants will

be needed for waste oil collections.

Biodiesel Processor System: Operation, Safety & Training 26

You might also like

- Biodiesel Production Techniques PDFDocument4 pagesBiodiesel Production Techniques PDFatomixmanNo ratings yet

- Production of Biodiesel From Waste Cooking OilDocument5 pagesProduction of Biodiesel From Waste Cooking OilIJMERNo ratings yet

- Synthèse de Biodiesel en Utilisant Des Huiles Végétales UsagéesDocument6 pagesSynthèse de Biodiesel en Utilisant Des Huiles Végétales UsagéesKa HinaNo ratings yet

- 4 AAC BLOCKS Other Sample Project Report Laxmi Tpe2jwDocument28 pages4 AAC BLOCKS Other Sample Project Report Laxmi Tpe2jwDhruVikas & AssociatesNo ratings yet

- Production of Biodiesel From Vegetable Oil Using Homogeneous CatalysisDocument2 pagesProduction of Biodiesel From Vegetable Oil Using Homogeneous CatalysisNidia CaetanoNo ratings yet

- Research Proposal Computer - WORD-1Document11 pagesResearch Proposal Computer - WORD-1Allycel ChiucoNo ratings yet

- Chemical Interesterification of Palm, Palm KernelDocument8 pagesChemical Interesterification of Palm, Palm KernelAfsoon QNetNo ratings yet

- Bio Based LubricantDocument13 pagesBio Based LubricantWahyu JatiNo ratings yet

- 2016 likozar Transesterification of oil to biodiesel in a continuous tubular reactor with static mixers- Modelling reaction kinetics, mass transfer, scale-up and optimization considering fatty acid composition.pdfDocument11 pages2016 likozar Transesterification of oil to biodiesel in a continuous tubular reactor with static mixers- Modelling reaction kinetics, mass transfer, scale-up and optimization considering fatty acid composition.pdfTlaltenco FC PonyNo ratings yet

- Egg Storage and Supply: Trupti EnterprisesDocument33 pagesEgg Storage and Supply: Trupti Enterprisesomkar maharana100% (1)

- Biodiesel Production: Data 1. Biofuel Production in The PhilippinesDocument31 pagesBiodiesel Production: Data 1. Biofuel Production in The Philippinesliezl_catapangNo ratings yet

- DSOME Bio DieselDocument28 pagesDSOME Bio DieselManish PatilNo ratings yet

- Granules India PDFDocument29 pagesGranules India PDFP VinayakamNo ratings yet

- 2007 Lee, Owens - Composition of Herbaceous Biomass Feedstocks PDFDocument16 pages2007 Lee, Owens - Composition of Herbaceous Biomass Feedstocks PDFskakind100% (1)

- Sunflower: Prepared By: Mudita ShahDocument8 pagesSunflower: Prepared By: Mudita Shahmayank27933No ratings yet

- Fuel Cell BrochureDocument8 pagesFuel Cell BrochureImam SaputraNo ratings yet

- FACTORY PERFORMANCE (KPI) JULY 2021 TO MAY 2022 (Version 1) .XLSB Rev1 PDFDocument2 pagesFACTORY PERFORMANCE (KPI) JULY 2021 TO MAY 2022 (Version 1) .XLSB Rev1 PDFGeorge oburaNo ratings yet

- Power Plants Lab: Assignment 2Document7 pagesPower Plants Lab: Assignment 2Faseeh GhaziNo ratings yet

- Refining Crude Glycerol into Pharmaceutical GradeDocument7 pagesRefining Crude Glycerol into Pharmaceutical GradeDwiki SaputraNo ratings yet

- Oils Fats and Waxes NotesDocument3 pagesOils Fats and Waxes NotesArianne BatallonesNo ratings yet

- Seminar PresentationDocument36 pagesSeminar PresentationjagadisharmaNo ratings yet

- Bioresource Technology: M.A. Olutoye, B.H. HameedDocument6 pagesBioresource Technology: M.A. Olutoye, B.H. Hameedrow4rexNo ratings yet

- Project Report On Coal BriquettesDocument10 pagesProject Report On Coal BriquettesSachin SharmaNo ratings yet

- Literature Review 2.1 BiodieselDocument18 pagesLiterature Review 2.1 BiodieselRichard ObinnaNo ratings yet

- Oil Extraction Processes: Screw Pressing, Solvent Extraction & Extruding-ExpellingDocument6 pagesOil Extraction Processes: Screw Pressing, Solvent Extraction & Extruding-ExpellingNahid Akhter KathaNo ratings yet

- Development of Solid Catalyst For Transesterification of Croton Megalocarpus Hutch Oil in Biodiesel Production and Blending With KeroseneDocument99 pagesDevelopment of Solid Catalyst For Transesterification of Croton Megalocarpus Hutch Oil in Biodiesel Production and Blending With KeroseneNiraj KumarNo ratings yet

- KOF Oilseeds Federation ProfileDocument44 pagesKOF Oilseeds Federation Profilekp vineetNo ratings yet

- Safety Hiblack 30LDocument3 pagesSafety Hiblack 30Lalfa twoNo ratings yet

- Alfa Laval Webinar - 3mcpd and Ge Mitigation - PresentationDocument42 pagesAlfa Laval Webinar - 3mcpd and Ge Mitigation - PresentationImam DarmantoNo ratings yet

- Energy MixDocument10 pagesEnergy MixPara DiseNo ratings yet

- Understanding The Glycerol MarketDocument22 pagesUnderstanding The Glycerol MarketredNo ratings yet

- Edible Oil SourcesDocument22 pagesEdible Oil Sourcesshym hjrNo ratings yet

- Fractional Condensation of Multicomponent Vapors From Pyrolysis of Cotton StalkDocument8 pagesFractional Condensation of Multicomponent Vapors From Pyrolysis of Cotton StalkEvansChombaNo ratings yet

- Biodiesel Production - A Mini Review PDFDocument13 pagesBiodiesel Production - A Mini Review PDFyohannesNo ratings yet

- Aquaculture TechniquesDocument9 pagesAquaculture TechniquesSukhdeep DhillonNo ratings yet

- Enrollment No.:-1814320004: Electrical EngineeringDocument29 pagesEnrollment No.:-1814320004: Electrical EngineeringGavit AniketNo ratings yet

- Fuel Ethanol From CornDocument19 pagesFuel Ethanol From CornHan ChauNo ratings yet

- Main YasinDocument88 pagesMain YasinsreenuNo ratings yet

- Lab BiodieselDocument7 pagesLab Biodieselskb89No ratings yet

- Dr. Mushtaq Ahmad Biodiesel PPT-Jan 2020Document99 pagesDr. Mushtaq Ahmad Biodiesel PPT-Jan 2020Malik Zain Awan100% (1)

- A Review On Recent Advancement in Catalytic Materials For Biodiesel Production 2015Document23 pagesA Review On Recent Advancement in Catalytic Materials For Biodiesel Production 2015ʚïɞShymaMasȜoodʚïɞNo ratings yet

- SERVO Cut S - PDSDocument1 pageSERVO Cut S - PDSVENKATNo ratings yet

- 9.evaluation of Oil Sludge As An Alternative Fuel in The ProductionDocument6 pages9.evaluation of Oil Sludge As An Alternative Fuel in The ProductionRati YuliarningsihNo ratings yet

- Module 1: Fiber Board Types and UsesDocument51 pagesModule 1: Fiber Board Types and UsesSanal SamsonNo ratings yet

- Cobra or Floor Polish-1Document1 pageCobra or Floor Polish-1hondo tinemi dNo ratings yet

- Industrial Biotech J ProjectDocument39 pagesIndustrial Biotech J Projectchelsea charlesNo ratings yet

- Paper73 PDFDocument6 pagesPaper73 PDFMatichon ChamchooklinNo ratings yet

- NACES 2015 – Poultry Waste Plant DesignDocument2 pagesNACES 2015 – Poultry Waste Plant DesignVentrue LeongNo ratings yet

- Soy Milk: Nutrition and Health InformationDocument8 pagesSoy Milk: Nutrition and Health InformationRahul JadhavNo ratings yet

- Production of Acetealdehyde ProcessingDocument141 pagesProduction of Acetealdehyde Processingpratik rulesNo ratings yet

- Battery Swapping For E2Ws in IndiaDocument25 pagesBattery Swapping For E2Ws in IndiaRahul DeshpandeNo ratings yet

- "Soybean Volatile Week Ends in Red: Analyst SpeaksDocument10 pages"Soybean Volatile Week Ends in Red: Analyst Speaksapi-234732356No ratings yet

- Working Paper 271: Feedstock For The Petrochemical IndustryDocument30 pagesWorking Paper 271: Feedstock For The Petrochemical IndustryPaolo SNo ratings yet

- Fuel Biomass Biomass Heating Systems Greenhouse Gas Energy SecurityDocument20 pagesFuel Biomass Biomass Heating Systems Greenhouse Gas Energy SecuritypayalmalayNo ratings yet

- Soybean Motor OilDocument12 pagesSoybean Motor OilJessica FernandesNo ratings yet

- A Universal Procedure For Crude Glycerol Puri Fication From Different Feedstocks in Biodiesel Production: Experimental and Simulation StudyDocument6 pagesA Universal Procedure For Crude Glycerol Puri Fication From Different Feedstocks in Biodiesel Production: Experimental and Simulation StudyjeremyNo ratings yet

- BioethanolDocument76 pagesBioethanolMuntazer QasimNo ratings yet

- Analysis of Vegetable Liquid Insulating Medium For Applications in High Voltage TransformersDocument5 pagesAnalysis of Vegetable Liquid Insulating Medium For Applications in High Voltage TransformersSiva Sai MuruganNo ratings yet

- Insecticide Research & Development & Bioassay: Unit 1Document15 pagesInsecticide Research & Development & Bioassay: Unit 1Portgas D. AceNo ratings yet

- Biodiesel Refers To A Vegetable Oil-Or Animal Fat-Based DieselDocument7 pagesBiodiesel Refers To A Vegetable Oil-Or Animal Fat-Based DieselM CHANDRA PRABHANo ratings yet

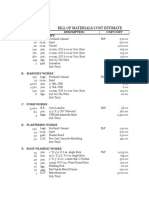

- Sample Bill of Materials For ConstructionDocument33 pagesSample Bill of Materials For ConstructionDarren Dela Cruz67% (3)

- Antimicrobial and Mite Protection in Textiles PresentationDocument43 pagesAntimicrobial and Mite Protection in Textiles Presentation20MT31 - NAAVENDHAN SNo ratings yet

- SPINDO Catalogue New PDFDocument56 pagesSPINDO Catalogue New PDFTitus Deus PrizfelixNo ratings yet

- MPSADocument48 pagesMPSAvalNo ratings yet

- FormulaShell SAE 10W 40 Motor Oil DatasheetDocument3 pagesFormulaShell SAE 10W 40 Motor Oil DatasheetAnonymous YjoCCKNo ratings yet

- PIKOTEK VCXT Data Sheet High TempratureDocument2 pagesPIKOTEK VCXT Data Sheet High Tempraturelalalili85100% (1)

- Unit-3: POLYMERS AND OPTICAL MEMSDocument10 pagesUnit-3: POLYMERS AND OPTICAL MEMSMs.Ezhilarasi ICE DepartmentNo ratings yet

- Size Press Efficiency Factors (Breaks, Strength, MoistureDocument2 pagesSize Press Efficiency Factors (Breaks, Strength, Moisturetsvmpm1765No ratings yet

- 9485 & 926 Transfer Tapes: Product Data SheetDocument3 pages9485 & 926 Transfer Tapes: Product Data SheetvijaygalaxyNo ratings yet

- Getish LemmaDocument83 pagesGetish LemmaMohammedNo ratings yet

- Chemicals From Coal CokingDocument29 pagesChemicals From Coal CokingNatalia MayaNo ratings yet

- Ansi - Apa PRG-320 (2017) Usa PDFDocument32 pagesAnsi - Apa PRG-320 (2017) Usa PDFricardo rubioNo ratings yet

- Supercritical Power Generation-Experiences, Issues & ChallengesDocument85 pagesSupercritical Power Generation-Experiences, Issues & ChallengesVeda SiddharthNo ratings yet

- PigmentDocument13 pagesPigmentAlmanzo AmilNo ratings yet

- Raghu Engineering College: AutonomousDocument12 pagesRaghu Engineering College: Autonomousganesh chowdaryNo ratings yet

- Unit Weight of Building Materials Used in Construction WorksDocument3 pagesUnit Weight of Building Materials Used in Construction WorksifyNo ratings yet

- Lecture 01-03Document15 pagesLecture 01-03Fayaz AhmedNo ratings yet

- Polyamide Selection-NylonDocument24 pagesPolyamide Selection-NylonShivaranjani KuruparanNo ratings yet

- 10.short Questions and AnswersDocument41 pages10.short Questions and Answersananda narayanan100% (1)

- Titan OMB40: Bronze Fire Monitor Nominal Flow 4,000 L/minDocument2 pagesTitan OMB40: Bronze Fire Monitor Nominal Flow 4,000 L/minZhagiNo ratings yet

- TS-1PR X 1.5MMDocument1 pageTS-1PR X 1.5MMmohd darusNo ratings yet

- 1412-RENO - S130 Service Manual (R12)Document60 pages1412-RENO - S130 Service Manual (R12)Jose Rolando Orellana Rodriguez100% (1)

- Bond Strength of Bonded, Fused, and Laminated Apparel FabricsDocument5 pagesBond Strength of Bonded, Fused, and Laminated Apparel FabricsGil MujicaNo ratings yet

- Ferrite Measurement PDFDocument2 pagesFerrite Measurement PDFESWARANM91No ratings yet

- Uses and Properties of The Following Materials DependDocument11 pagesUses and Properties of The Following Materials DependAshly John Galagnara100% (4)

- Non Ferrous Metals and Alloys CH5 DDUDocument97 pagesNon Ferrous Metals and Alloys CH5 DDUPratik ThakerNo ratings yet

- AFLAS Technical DatasheetDocument13 pagesAFLAS Technical DatasheetManual SourceNo ratings yet

- WRN STD 002a PDFDocument1 pageWRN STD 002a PDFJoseph Clemente PahatiNo ratings yet

- NACE MR0175-Circular2 Part2Document3 pagesNACE MR0175-Circular2 Part2romerobernaNo ratings yet

- 0351 Structural Pre-Enginneering Building: Sanofi Factory ProjectDocument8 pages0351 Structural Pre-Enginneering Building: Sanofi Factory ProjectJaime LandinginNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet