Professional Documents

Culture Documents

EEM2021 Abstract MS

Uploaded by

milicaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EEM2021 Abstract MS

Uploaded by

milicaCopyright:

Available Formats

VII International Congress “Engineering, Environment and Materials in Process Industry“

BRIDGING THE GAP BETWEEN SUSTAINABILITY AND DYE REMOVAL

PROCESSES: DYE BIODEGRADATION BY PEROXIDASE FROM

AGROINDUSTRIAL WASTE

Milica Svetozarević1,*, Nataša Šekuljica1, Ana Dajić1, Marina Mihajlović1, Zorica Knežević-

Jugović2, Dušan Mijin2

1

Innovation Center of the Faculty of Technology and Metallurgy, Karnegijeva 4, 11000 Belgrade,

Serbia, msvetozarevic@tmf.bg.ac.rs

2

University of Belgrade, Faculty of Technology and Metallurgy, Karnegijeva 4, 11000 Belgrade,

Serbia

Abstract

Textile manufacturing is among the industries with the highest adverse environmental impact as

the greatest consumers and contaminants of water. One of the main pollutants are dyes used in

the coloring process, which concentration in effluents range 10-200 mg/L. The spent textile dyes

released in wastewater can cause pH imbalance, eutrophication, and photosynthesis

deterioration, suppression of growth, development and reproduction of aquatic biota. According

to their chemical structure, dyes can be classified as azo, anthraquinone, nitro, nitroso,

phtalocyanine, acridine, oxazine, triphenylmethane, methane etc. Anthraquinone dyes are the

second most used dyes in textile industry. Their application includes dyeing of silk, wool and

poliamide materials with fine properties such as color fastness, brilliance and thermal stability.

Although their application is widespread, their complex structure of fused aromatic rings makes

them difficult for degradation. Therefore plenty of physical, chemical, biological and combined

methods have been developed. Most common physical methods are based on adsorption with

activated charcoal as adsorbent. Even though its production is simple, this methods leads to

solid waste generation. Chemical method involve mostly the use of harsh chemicals. Methods

including microorganisms are time consuming with sludge generation. Enzymes are an effective

alternative due to the reduction of sludge volume and degradation products that are less toxic. In

anticipation of “greener” and cost effective process, agroindustrial waste may serve as an

enzyme source. In this study, a crude enzyme extract from agroindustrial waste- potato peel and

soybean hull, is obtained for biodegradation of anthraninone dye Acid Violet 109. In order to

achieve maximum biodegradation, the process parameters: contact time, pH, enzyme, hydrogen

peroxide, dye concentration and temperature were optimized. Apart from this, kinetic

parameters are the key factors for designing an efficient process. With the kinetic parameters,

the right enzyme or enzyme source can be selected. Eventually, it leads to substantial

acceleration of the process with minimal inhibition of the biocatalyst. Thus, the initial kinetics of

the given enzymes was inspected and later the experimentally acquired values were modelled by

the kinetic of bisupstrate reactions.

Key words: peroxidase, agroindustrial waste, dye treatment, ping pong bi-bi, Acid Violet 109

You might also like

- EDIP Summary Notes PDFDocument256 pagesEDIP Summary Notes PDFfrancis100% (11)

- Corrugated Paper BoardDocument37 pagesCorrugated Paper BoardParveen ParveenNo ratings yet

- ICCAS BreakdownStructuresThroughLifecycleStagesDocument15 pagesICCAS BreakdownStructuresThroughLifecycleStagesJoey Zamir Huerta MamaniNo ratings yet

- Hospital Wastes Management PlanDocument4 pagesHospital Wastes Management PlanRPh Krishna Chandra Jagrit100% (1)

- Project Report On Self Compacting ConcreteDocument94 pagesProject Report On Self Compacting ConcreteSunilkumar Ce100% (3)

- EMSC5103 Assignment - Sustainable ConstructionDocument156 pagesEMSC5103 Assignment - Sustainable ConstructionIzam Muhammad100% (2)

- Sewer Design PDFDocument57 pagesSewer Design PDFZac Francis Daymond100% (2)

- Recycled Waste Into Building Construction MaterialsDocument23 pagesRecycled Waste Into Building Construction MaterialsShamnas P MNo ratings yet

- Research TeamDocument25 pagesResearch TeamTuesday SacdalanNo ratings yet

- BT Road From Akshitha Hospital (Srinivasapuram Road) To By-Pass RoadDocument12 pagesBT Road From Akshitha Hospital (Srinivasapuram Road) To By-Pass Roadsasidharkatari91572No ratings yet

- Tugas Bahasa Inggris Tentang Global WarmingDocument10 pagesTugas Bahasa Inggris Tentang Global WarmingRahmatHidayatNo ratings yet

- Review On Recent Technologies For Industrial Wastewater TreatmentDocument8 pagesReview On Recent Technologies For Industrial Wastewater TreatmentIJRASETPublicationsNo ratings yet

- Adsorption of Methylene Blue From Textile Industrial Wastewater Using Activated Carbon Developed From Rumex Abyssinicus PlantDocument17 pagesAdsorption of Methylene Blue From Textile Industrial Wastewater Using Activated Carbon Developed From Rumex Abyssinicus Plantceo.didansiNo ratings yet

- Effluent Treatment of Textile Industrial Waste Using Treated Sugarcane BagasseDocument7 pagesEffluent Treatment of Textile Industrial Waste Using Treated Sugarcane BagasseIJRASETPublicationsNo ratings yet

- Effluent Treatment of Textile Industrial Waste Using Treated Sugarcane BagasseDocument7 pagesEffluent Treatment of Textile Industrial Waste Using Treated Sugarcane BagasseIJRASETPublicationsNo ratings yet

- Journal of Environmental Chemical Engineering: SciencedirectDocument17 pagesJournal of Environmental Chemical Engineering: SciencedirectNicholas YeohNo ratings yet

- Removal of Methylene Blue Using Low Cost Adsorbent: A ReviewDocument12 pagesRemoval of Methylene Blue Using Low Cost Adsorbent: A ReviewDishantNo ratings yet

- Detoxification of Malachite Green and Textile Industrial Ef Uent by Penicillium OchrochloronDocument10 pagesDetoxification of Malachite Green and Textile Industrial Ef Uent by Penicillium OchrochloronJuan Diego CárdenasNo ratings yet

- Green Synthesis of Ferric Oxide Nano Particles Using Manilkara Zapota Plant Leaves and Study Its Effect On Dyes in Textile Waste WaterDocument10 pagesGreen Synthesis of Ferric Oxide Nano Particles Using Manilkara Zapota Plant Leaves and Study Its Effect On Dyes in Textile Waste WaterEditor IJTSRDNo ratings yet

- Akdogan2014 Article StudiesOnDecolorizationOfReactDocument7 pagesAkdogan2014 Article StudiesOnDecolorizationOfReactZeynep Nur ALEMDAĞNo ratings yet

- IRP 166SingareJEnvChemEngiDocument12 pagesIRP 166SingareJEnvChemEngimaaahiiNo ratings yet

- Textile Wastewater Characterization and ReductionDocument8 pagesTextile Wastewater Characterization and ReductionAriskaNo ratings yet

- Photocatalytic Degradation Study of Rhodamine-B by Green Synthesized Nano Tio2Document6 pagesPhotocatalytic Degradation Study of Rhodamine-B by Green Synthesized Nano Tio2Nguyễn Quang ThanhNo ratings yet

- Application of Bioadsorbents For The Wastewater Treatment of A Composite Knit Industry PDFDocument9 pagesApplication of Bioadsorbents For The Wastewater Treatment of A Composite Knit Industry PDFKelly RamosNo ratings yet

- 1 s2.0 S2949839223000445 MainDocument17 pages1 s2.0 S2949839223000445 Mainali abdulrahman al-ezziNo ratings yet

- Aden Uga 2019Document9 pagesAden Uga 2019Scream MTANo ratings yet

- Molecules 26 02241Document19 pagesMolecules 26 02241SHELLA VERINA PUTRI I2O27OO6ONo ratings yet

- Physico-Chemical Parameters of Residual Water From Different Scouring Treatments of Hemp/Cotton FabricDocument7 pagesPhysico-Chemical Parameters of Residual Water From Different Scouring Treatments of Hemp/Cotton FabricHenry Pelayo RemacheNo ratings yet

- 10 11648 J Ajese 20170103 11Document5 pages10 11648 J Ajese 20170103 11thiago felixNo ratings yet

- Application of Bioremediation Process For Textile Wastewater Treatment Using Pilot PlantDocument7 pagesApplication of Bioremediation Process For Textile Wastewater Treatment Using Pilot PlantGovind ManglaniNo ratings yet

- Krishnamurthy 2020Document18 pagesKrishnamurthy 2020JESUS ENRIQUE UTANO REYESNo ratings yet

- 生化工程 IntroductionDocument3 pages生化工程 Introductiongn0033609212No ratings yet

- Environmental Bioremediation of Industrial Effluent: Imedpub JournalsDocument3 pagesEnvironmental Bioremediation of Industrial Effluent: Imedpub JournalsNoviana RohmatinNo ratings yet

- Biodegradación de Violeta Básica 3 y Azul Ácido 93 Por Pseudomonas PutidaDocument6 pagesBiodegradación de Violeta Básica 3 y Azul Ácido 93 Por Pseudomonas PutidaYazdhrik SilvaNo ratings yet

- Role of Nanoparticles in Dye DegradationDocument6 pagesRole of Nanoparticles in Dye DegradationEditor IJTSRDNo ratings yet

- PH WastewaterDocument12 pagesPH WastewaterMohamed Saddek SalmiNo ratings yet

- Chowdhury 2011Document10 pagesChowdhury 2011Efraín QuevedoNo ratings yet

- A Comparative Study of ZnO-PVP and ZnO-PEG Nanoparticles ActivityDocument8 pagesA Comparative Study of ZnO-PVP and ZnO-PEG Nanoparticles ActivityVũ Hải NamNo ratings yet

- The Degradation of Textile Industry Dyes Using The EffectiveDocument10 pagesThe Degradation of Textile Industry Dyes Using The EffectiveShirley ramosNo ratings yet

- Development of Alternate Cleaner Technologies Using BiotechnologyDocument6 pagesDevelopment of Alternate Cleaner Technologies Using BiotechnologyNeeraj AnsalNo ratings yet

- Biosorption: Technology For Colour RemovalDocument11 pagesBiosorption: Technology For Colour RemovalAmit ShelarNo ratings yet

- Current Approaches Toward The Removal of Methylene Blue Dye From Syn - 2023 - HeDocument14 pagesCurrent Approaches Toward The Removal of Methylene Blue Dye From Syn - 2023 - Hepo hongNo ratings yet

- Pelendridou Et Al. 2013Document9 pagesPelendridou Et Al. 2013demclassychiczNo ratings yet

- 5.5. Newly Isolated Ligninolytic Bacteria and Its Applications For Multiple Dye Degradation - CSDocument13 pages5.5. Newly Isolated Ligninolytic Bacteria and Its Applications For Multiple Dye Degradation - CSFarida RahayuNo ratings yet

- PublicationDocument15 pagesPublicationEva BorschNo ratings yet

- FungiDocument20 pagesFungiShirley ramosNo ratings yet

- A04 - 23-RESB-Waste AdsorbentDocument18 pagesA04 - 23-RESB-Waste AdsorbentCarol HernándezNo ratings yet

- 15 Makale-Int J Sec MetaboliteVol 4-3-pp 77-84-2017 PDFDocument8 pages15 Makale-Int J Sec MetaboliteVol 4-3-pp 77-84-2017 PDFMaharani PuspaningrumNo ratings yet

- Ridzuan 2018Document5 pagesRidzuan 2018Soumitra DasNo ratings yet

- Biogenic Nanoparticles and Their Environmental Applications in Bioremediation and Pollution ControlDocument9 pagesBiogenic Nanoparticles and Their Environmental Applications in Bioremediation and Pollution ControlInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Removal of Methylene Blue Using Moss Grass and AlgaeDocument37 pagesRemoval of Methylene Blue Using Moss Grass and Algaesamar_biotech100% (2)

- Chemical Catalytic Reaction and Biological Oxidation For Treatment of Non-Biodegradabletextile EffluentDocument7 pagesChemical Catalytic Reaction and Biological Oxidation For Treatment of Non-Biodegradabletextile EffluentIrina Natalena OsantiNo ratings yet

- Sample Format For Pilot TestingDocument9 pagesSample Format For Pilot TestingAziel VillapandoNo ratings yet

- Nur Hidayati OthmanDocument9 pagesNur Hidayati OthmanEstudiante2346No ratings yet

- Conferinte Sectiunea V - cnc2018Document8 pagesConferinte Sectiunea V - cnc2018Cristina IoanaNo ratings yet

- 10 1016@j Psep 2020 05 034Document82 pages10 1016@j Psep 2020 05 034Kevin SalvatierraNo ratings yet

- 59 Comparison Study of Congo Red Dye Degradation Process Using Fenton's Reagent and Tio2Document6 pages59 Comparison Study of Congo Red Dye Degradation Process Using Fenton's Reagent and Tio2Jorellie PetalverNo ratings yet

- Publication 21Document12 pagesPublication 21Iheoma Chukwujike NwuzorNo ratings yet

- Production Characterization and Treatment of Textile Effluents A Critical Review 2157 7048.1000182 PDFDocument18 pagesProduction Characterization and Treatment of Textile Effluents A Critical Review 2157 7048.1000182 PDFKhoaNo ratings yet

- Articles Related To Green ChemistryDocument11 pagesArticles Related To Green ChemistryAlina SajjadNo ratings yet

- Environmental Assignment 2 FinalDocument14 pagesEnvironmental Assignment 2 Finalmee chuenNo ratings yet

- BBRC Vol 14 No 04 2021-30Document7 pagesBBRC Vol 14 No 04 2021-30Dr Sharique AliNo ratings yet

- Applied SciencesDocument13 pagesApplied SciencesShirley ramosNo ratings yet

- Chouchane Et Al.. 2020. Unravelling The Characteristics of A Heteropolysaccharide-Protein From An Haloarchaeal Strain With FlocculationDocument38 pagesChouchane Et Al.. 2020. Unravelling The Characteristics of A Heteropolysaccharide-Protein From An Haloarchaeal Strain With FlocculationAzb 711No ratings yet

- Accepted Manuscript: Process Safety and Environment ProtectionDocument37 pagesAccepted Manuscript: Process Safety and Environment ProtectionNestor Garay CahuanaNo ratings yet

- Photocatalytic Activity of Cu Ag BNCs Synthesized by The Green Method Photodegradation Methyl Orange and Indigo CarmineDocument12 pagesPhotocatalytic Activity of Cu Ag BNCs Synthesized by The Green Method Photodegradation Methyl Orange and Indigo Carminelucas italoNo ratings yet

- Potential Use of Eco-Enzyme For The Treatment of Metal Based EffluentDocument7 pagesPotential Use of Eco-Enzyme For The Treatment of Metal Based EffluentAdvennie NuhujananNo ratings yet

- Se Tools IntroDocument2 pagesSe Tools IntroDhanush RasiNovNo ratings yet

- Green Chemistry for Dyes Removal from Waste Water: Research Trends and ApplicationsFrom EverandGreen Chemistry for Dyes Removal from Waste Water: Research Trends and ApplicationsNo ratings yet

- MSDS Citric Acid 6 10Document2 pagesMSDS Citric Acid 6 10Chern YuanNo ratings yet

- Hmws & SB: ReactorsDocument6 pagesHmws & SB: ReactorsMaku RajkumarNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument18 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingThorbjörn AnderssonNo ratings yet

- activity sheet q4natresourcesDocument2 pagesactivity sheet q4natresourcesNoralyn Ngislawan-GunnawaNo ratings yet

- GPCB Infor CcaDocument4 pagesGPCB Infor CcaTejas PatelNo ratings yet

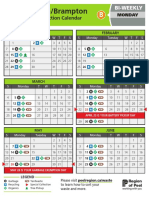

- Mississauga/Brampton: 2018 Waste Collection CalendarDocument2 pagesMississauga/Brampton: 2018 Waste Collection CalendarjoeNo ratings yet

- U3M-Albania Project Conference Book PDFDocument152 pagesU3M-Albania Project Conference Book PDFNatalie NegrónNo ratings yet

- Dairy IndustryDocument28 pagesDairy IndustryAjay Kumar100% (1)

- Vertical Shaft Brick KIln Technology VSBDocument53 pagesVertical Shaft Brick KIln Technology VSBDragos NojeaNo ratings yet

- Understanding The Composting Process: Agriculture and Natural ResourcesDocument4 pagesUnderstanding The Composting Process: Agriculture and Natural ResourcesDedy LesmanaNo ratings yet

- Vacuum Tech Manufacturing (Malaysia) Sdn. BHD.: Checklist/DateDocument2 pagesVacuum Tech Manufacturing (Malaysia) Sdn. BHD.: Checklist/DateAfiq JuwaidiNo ratings yet

- 0628 2 Eaton-BPM-UGDocument28 pages0628 2 Eaton-BPM-UGalstomNo ratings yet

- Bio Mass & Bio Fuels: R.Somasundaram M.TechDocument31 pagesBio Mass & Bio Fuels: R.Somasundaram M.Techvivek rameshNo ratings yet

- Green Economy Arab Report 2011Document321 pagesGreen Economy Arab Report 2011Gill Wallace HopeNo ratings yet

- Revised Development of Automatic Floating Waste Collector For Waterways ManuscriptDocument109 pagesRevised Development of Automatic Floating Waste Collector For Waterways ManuscriptFredesminda QuilangNo ratings yet

- Soal Un Bahasa Inggris Xii (Lat 4)Document12 pagesSoal Un Bahasa Inggris Xii (Lat 4)hasanlina2007No ratings yet

- Enabling The FutureDocument89 pagesEnabling The FutureAbhisek BhattacharyaNo ratings yet

- Industry Analysis - SCHMDocument11 pagesIndustry Analysis - SCHMAnanthi ChristinaNo ratings yet

- Deloitte Fashioning Sustainability 2013Document24 pagesDeloitte Fashioning Sustainability 2013Harsh SarafNo ratings yet