Professional Documents

Culture Documents

Simulation of Thermo-Mechanical Forming Process With LS-DYNA

Uploaded by

Peter ZubarikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulation of Thermo-Mechanical Forming Process With LS-DYNA

Uploaded by

Peter ZubarikCopyright:

Available Formats

9.

LS-DYNA Forum, Bamberg 2010 Metallumformung I

Simulation of Thermo-Mechanical Forming Process

with LS-DYNA

David Lorenz

DYNAmore GmbH, Stuttgart, Germany

Abstract:

In the recent past hot stamping simulation has established itself more and more within the press

hardening community. However the requirements on a simulation software are continuously increasing

due to an increasing complexity of the manufacturing processes. The focus in process simulation is

not merely on the workpiece and its final properties, but also on the forming dies. To keep pace with

all recent and even more with all future developments in press hardening LS-DYNA offers several

features to deal with different aspects of press hardening processes. Nevertheless only a proper set of

numerical parameters can make a simulation model an effective and efficient tool for a process

designer. Based on recent experiences some useful parameter settings and modelling techniques are

presented.

Keywords:

metalforming, thermo-mechanical coupling, multiphysics

© 2010 Copyright by DYNAmore GmbH C - I - 35

Metallumformung I 9. LS-DYNA Forum, Bamberg 2010

1 Introduction

Within the automotive industry the trend towards an increased application of ultra high strength steels

for structural car body applications is continuing. During the last years the simulation of hot stamping

processes has established itself more and more within the press hardening community. The results of

the 2008 Numisheet benchmark have shown that feasibility studies of hot stamping processes can be

performed with a sufficient accuracy. However the continuously increasing requirements from car body

design have induced more complex press hardening parts which in turn require more complicated

manufacturing processes. Thus different process strategies have recently been developed to

manufacture parts with tailored properties such as partial austenization of blanks, tailored tempering

with partially heated dies or advanced tool materials for a better control of the cooling effect. These

continuous advancements of processes technology are raising the bar for a CAE based process

development. The simulation technology must keep pace with all recent and even more with all future

developments in press hardening. It is obvious that a close cooperation with customers is an

indispensable prerequisite to achieve this goal. In the current Version R5 LS-DYNA has a lot of

features to face the challenges of the up-to-date press hardening technology. Beside all this

technological context an equally important point is often forgotten. A simulation software can only be a

helpful tool for a process designer if a both effective and efficient method for model setup and process

modelling is available. A prerequisite to set up an efficient process model is to figure out the main

tasks of the actual development phase. An efficient simulation model deals with all necessary

objectives of the respective task, but it should leave all other aspects of the process unconsidered.

DYNAmore can offer a broad experience in modelling and simulation of thermal-mechanical coupled

manufacturing processes and ca help customers to find optimal modelling methods individually

adapted to their processes and workflow.

2 Forming Simulation

Since the Numisheet2008 benchmark it is recognised that typical feasibility studies can be carried out

with LS-DYNA. During the feasibility study the process designer checks if the thickness reduction is

acceptable and if wrinkle formation during the forming operation is critical. The fundamental

requirements for an accurate prediction of the thickness distribution is an accurate representation of

the temperature and strain rate dependent yield stress of the blank material. Therefore an advanced

table definition has been added to be used with MAT_106. The temperature dependent quasistatic

yieldcurves had been accessed by a DEFINE_TABLE definition and the rate effects were considered

by temperature dependent Cowper-Symonds parameters so far. A new keyword DEFINE_TABLE_3D

has been implemented in the current version. DEFINE_TABLE_3D points for each temperature to a

DEFINE_TABLE definition with yieldcurves for different strain rates at a fixed temperature. Yieldcurves

fitted from tensile test data can be written directly in the inputdeck.

In a real life press hardening process the hot blank remains for a few seconds on the lower die and/or

binder until the upper die firstly hits the blank.

Figure 1: Temperature drop of ~100 °C at support points (lower curves) during gravity simulation

This time period should be recognized in the simulation, because it can cause considerable

temperature gradients in the blank. This is demonstrated in figure 1, where a 1.5mm thick blank

remains on the binder for ~1.5 s until the upper die impacts.

The best way to include this effect in a model is a coupled static implicit gravity simulation. Unlike in

cold forming the mechanical solution should be done in several static implicit time steps. This works

C - I - 36 © 2010 Copyright by DYNAmore GmbH

9. LS-DYNA Forum, Bamberg 2010 Metallumformung I

well with an automatic time stepping in both thermal and mechanical solution using the keywords

CONTROL_IMPLICIT_AUTO and CONTROL_THERMAL_TIMESTEP. The coupling scheme in LS-

DYNA starts with a thermal time step since there are forcing boundary conditions in the initial state. It

is beneficial to start with a small initial time step for both thermal and mechanical solution. As a rule of

thumb 0.005*endtime can be taken as initial step size.

The temperature rise of the die and binder at the support area be included with the thermal thick shell

by setting TSHELL=1 on the CONTROL_SHELL card ITHOFF=1 on CONTROL_CONTACT. If the die

surface heating is included it is mandatory to give all dies a reasonable thickness on the

SECTION_SHELL card. The thickness depends on the blank thickness and on the thermal

conductivity of the tool material. A simple 1D-model can be used to calibrate the artificial thickness for

the dies. The results for a 1.5 mm thick USIBOR blank against a die made of Rovalma HTCS-117 tool

steel is shown in Figure 2.

8

10

12

14

Figure 2: Calibration of artificial die thickness with simple 1D-model. Reference solid model left and

four shell models with different thickness (8, 10, 12, 14 mm). Graph shows absolute error for shells.

A good compromise between small error for short and longer contact times is an artificial thickness of

10 mm, which gives a maximum absolute error of 10°C for the die surface temperature within 5 s

contact time. The time period from insertion of the hot blank into the press to reaching bottom dead

center is within 5s for most real life press hardening processes. Such a calibration takes a few minutes

and it has the great advantage that the tool surface temperature is included in the analysis. This gives

more accurate results for contact heat transfer with negligible additional CPU cost.

In some hot stamping processes a process designer has to cope with a realistic consideration of guide

pins in his model (figure 3). The guide holes are in regions where a bigger hole will be trimmed after

forming.

Figure 3: Consideration of guide pins in a hot stamping simulation. Blank with guide pin after gravity

simulation (left), hole before and after forming (middle), deformed hole (right)

Due to the high temperatures during forming the blank material is weak and the guide holes can be

severely deformed. The simulation must be able to predict if the deformed guide hole is still within the

© 2010 Copyright by DYNAmore GmbH C - I - 37

Metallumformung I 9. LS-DYNA Forum, Bamberg 2010

trimcurve. The contact between the guide pin and the blank seems to be very difficult, but experience

has shown that a FORMING_ONE_WAY contact is sufficient. To get the contact work properly a

negative thickness offset of 110…150% of the blank thickness is necessary.

Another problem which can arise during a hot stamping simulation is severe element distortion in

areas where the blank has a concave outline. In figure 4 such a situation is shown at a semicircular

cut out for a guide pin. In this case the whole solution ran idle over night caused by one single

element. The problem was solved by setting a critical plastic failure strain EFAIL=4.0 in the MAT_106

definition.

Figure 4: Severe Element deformation at a semicircular cut out. Blank with guide pin on the

punch(upper left), cut out location in detail (upper right top), cut out after forming with critical area

(upper right bottom), fringes of plastic strain with eroded element (lower)

This value is an unrealistic high number which will never be reached inside the blank. The deleted

element is situated outside the final parts trimline, so there is no disturbing influence on a feasibility

study. With the activation of element erosion the job ran within 3 hours even with a high level of mesh

refinement.

A great simplification in model setup can be achieved if as demonstrated in [1] the new keyword

CONTROL_FORMING_AUTOPOSITION_PARAMETER is used together with PART_MOVE to

automatically position the dies to initial contact with the blank. The user has to provide only the

meshes of the dies in the bottom dead center position. All positioning is done by LS-DYNA during the

initialization. Since each travel distance from auto positioning is stored in a parameter, this parameters

can be accessed e.g. within a DEFINE_CURVE_SMOOTH definition to prescribe the die velocity. It

should be noted that the auto position keywords must be located after the ELEMENT, NODE and

PART keywords.

A well defined model can become a very useful tool for a process designer, but only if it runs CPU cost

efficient. Within the metal forming community it is state of the art to reduce CPU time by both time and

mass scaling. Time scaling is applied by increasing the die travel velocity up to 5 m/s. Mass scaling is

introduced to increase the critical time step. In a thermal-mechanical coupled simulation the thermal

C - I - 38 © 2010 Copyright by DYNAmore GmbH

9. LS-DYNA Forum, Bamberg 2010 Metallumformung I

model has to be scaled according to the mechanical model. Thus the real die velocity in the press

must be known. The velocity scale factor can be directly entered in CONTROL_THERMAL_SOLVER

as parameter TSF instead of manually scaling all thermal velocity terms in the input file. A drastic

performance increase can be achieved by using selective mass scaling [2, 3] and run the model with

very high explicit time steps. In [4] an example is discussed in detail which shows that with this feature

a model can be ran much faster without loosing any accuracy, as it would be the case for conventional

mass scaling. The selective mass scaling is invoked by setting IMSCL=1 on the

CONTROL_TIMESTEP card. The time step size can be increased to 2…8 µs in a forming simulation,

but the sliding energy in the glstat file should be observed with care. In some cases the sliding energy

went negative indicating a contact instability. In this cases the penalty scale factor should be reduced.

As a rule of thumb one can set SLSFAC=0.05 in CONTROL_CONTACT, if selective mass scaling is

used with a high time step size of 2…8 µs.

3 Cooling Simulation

The model setup of a cooling simulation can become very time consuming if a detailed heat transfer

analysis of the forming dies should be carried out. Therefore the dies must be represented with a 3-

dimensional volume mesh. The meshing can become very complicated because of the complex

internal geometry of the cooling system. Furthermore the mesh of the contact surface should be as

fine as in a forming simulation in order to accurately describe the contact situation between die and

blank. A simple and effective method is to mesh the dies with tetrahedron elements with an adequate

mesh size for heat transfer. For the contact surfaces of the dies the shell meshes from the forming

simulation can be used. Each die consists of 2 parts, the surface shells and the volume mesh. Both

parts can be connected using CONSTRAINED_RIGID_BODIES keyword. In addition thermal contact

is necessary to enable a heat dissipation from the surface shells into the volume mesh. This can be

done by using an AUTOMATIC_ONE_WAY_SURFACE_TO_SURFACE_THEMAL contact and setting

2

the heat transfer coefficient HCONT to 5.0e+4 W/m K. Figure 5 shows a model setup for an A-pillar

cooling simulation. The model consists of 284602 shells, 2946238 tetrahedrons and 634193 nodes.

Since the contact heat transfer coefficient is a function of the contact pressure the model must ran

thermal-mechanical coupled in to get an accurate prediction of the heat transfer from the blank into the

dies. The mechanical solution was run in explicit mode with a high amount of mass scaling. Since we

have no free motions there is no danger of unphysical inertia effects.

Figure 5: 3D model of a cooling simulation. Full set of dies (left), surface and volume meshing of lower

die (middle), detail view of surface and volume meshing (right)

The total CPU time was for this model was 20 minutes using mpp971_d_R5.0 on one 8 CPU node.

Compared to the time consuming mesh generation the computation time of a cooling simulation can

be neglected. The most important parameter settings in the model are the explicit time step size,

ramped up press forces and the application of rigid body stoppers. The simulation must be regarded in

two major phases. In the first face the forces are ramped up and the contact forces reach the

stationary level. In this phase to high amounts of mass scaling can negatively influence the generation

of the contact forces. In the second phase the contact forces are stationary and the kinetic energy can

be neglected. In this phase the time step size and thus the amount of mass scaling can be drastically

increased. This is done with a load curve prescribing the time step over the solution time.

With this efficient cooling model it is possible to run several cooling cycles to analyze the process start

up time. Such a simulation can give a deeper understanding of the cooling system. The result of a the

A-pillar tool after 10 strokes is shown in figure 6. The cooling system has been modelled by convection

© 2010 Copyright by DYNAmore GmbH C - I - 39

Metallumformung I 9. LS-DYNA Forum, Bamberg 2010

boundary conditions on the cooling passage surfaces. The convection coefficients were calculated

with the Dittus-Boelter equation as shown in [5]. The use of this equation is a conservative approach

since it is for perfectly smooth pipes. In a technical rough pipe the convection coefficients are higher

due to a friction correction factor.

temperature

time

Figure 6: die surface temperature at 3 different locations after 10 strokes

At 3 significant locations on the die surface the evolution of the surface temperature shows that a

steady state can be reached within a few strokes. This result demonstrates that the cooling system

works very effective. The simulations have been automatically started one after each other using a

simple shell script. After each simulation a time shift has been applied on all d3plot files using the

DYNAmore tool plotcprs. Finally the d3plot files were renamed and copied all together.

4 Advanced Cooling Simulation

The main target in each press hardening process is to achieve a predefined microstructure in the final

part. LS-DYNA offers the new material model MAT_UHS or MAT_244 [6] to consider the

decomposition of the austenite into the bainite pearlite and ferrite phase during press hardening. This

enables the process designer to adapt the cooling effect to give the final product more strength or

more ductility. The material model can predict the vickers hardness number and the yield strength of

the final product. It requires the chemical decomposition of the used steel grade, the austenite grain

size and the activation energy of the diffusion driven phase change reactions. The model is absolutely

necessary if advanced press hardening processes which aim to parts with tailored properties should

be analyzed in detail by simulation. If MAT_UHS is used in a simulation no time scaling of the

mechanical model is allowed since the reaction kinetic inside the material can not be time scaled.

Nevertheless if an ordinary hardening process is analyzed where the aim is a fully hardened part a

simple analysis of the parts local cooling curves with a CCT diagram is sufficient.

Figure 7: Cooling curves plotted in CCT diagram

In figure 7 the cooling curves at 3 noticeable points of the A-pillar are printed in a CCT diagram of the

blank material. Since the cooling curves are in a safe distance from the bainite nose it can be

C - I - 40 © 2010 Copyright by DYNAmore GmbH

9. LS-DYNA Forum, Bamberg 2010 Metallumformung I

concluded that the part is completely hardened. In this case the use of MAT_UHS would be using a

sledge-hammer to crack a nut.

Beside the cooling of the dies in recent developed process technologies a partial heating of the dies is

required to control the cooling effect of the blank. Therefore LS-DYNA offers the keyword

LOAD_HEAT_CONTROLLER where a PI-controlled heat source can be applied. In the recent version

of ls971_d_R5 up to 10 heat controllers can be used. The control function is

t

q q 0 GP Tset Tnode GI T set Tnode dt

t 0

The required user input are the proportional and integral gain, a set point temperature and the node ID

for the location of the set point.

5 Conclusions

It has been shown that with an adequate choice of modelling features together with a proper set of

numerical parameters a simulation model can become both efficient and accurate. Some special

program settings for gravity and forming simulations were presented. Some stumbling blocks in hot

stamping simulation were pointed out and pragmatic remedies were described. Some experiences of

the computational performance in a real life process simulation were outlined. Finally the use of the

advanced material model MAT_UHS and the use of LOAD_HEAT_CONTROLLER for local die

heating were discussed.

6 References

[1] Zhu, X.,: " Recent Developments of LS-DYNA in Stamping Simulation", DYNAmore Infoday,

November 2009, http://www.dynamore.de/dokumente/infotage/2009-falltest-infotag/recent-

developments-of-ls-dyna-in-stamping-simulation

[2] Olovsson L., Simonsson K., Unosson M.: “Selective Mass Scaling for explicit finite element

analysis”, International Journal for Numerical Methods in Engineering, 2005

[3] Olovsson L., Simonsson K.: “Iterative Solution Technique in Selective Mass Scaling analysis,

Communications in Numerical Methods in Engineering”, 2006

[4] Lorenz, D., Haifa, A.: “Recent Advances and New Developments in Hot Forming Simulation with

LS-DYNA”, Numisheet2008 Proceedings, 2008

[5] Shapiro, A.: “Using LS-DYNA To Model Hot Stamping”, DYNAmore Infoday, November 2009,

http://www.dynamore.de/dokumente/infotage/2009-falltest-infotag/ using-ls-dyna-to-model-hot-

stamping

[6] T. Olsson, “An LS-DYNA Material Model for Simulations of Hot Stamping Processes of Ultra

High Strength Steels”, ERAB, April 2009, tobias.olsson@erab.se

© 2010 Copyright by DYNAmore GmbH C - I - 41

Metallumformung I 9. LS-DYNA Forum, Bamberg 2010

C - I - 42 © 2010 Copyright by DYNAmore GmbH

You might also like

- Die Life Optimization by Numerical ModelingDocument9 pagesDie Life Optimization by Numerical ModelingBasavaraju K NNo ratings yet

- State of Cold Forging Technology in Global CompetitionDocument20 pagesState of Cold Forging Technology in Global CompetitionEldori1988No ratings yet

- Design and Optimisation of Conformal Cooling Channels in Injection Moulding ToolsDocument8 pagesDesign and Optimisation of Conformal Cooling Channels in Injection Moulding ToolsEbd RahmanNo ratings yet

- Deform PaperDocument14 pagesDeform PaperSample RajNo ratings yet

- Design of Hot Forging Process of Parts With Complex Geometry in Digital EnvironmentDocument4 pagesDesign of Hot Forging Process of Parts With Complex Geometry in Digital Environmentsandeep5No ratings yet

- Additive ManufacutingDocument12 pagesAdditive ManufacutingGautam SharmaNo ratings yet

- Finite Element Modeling of High Speed Machining Processes: Arno Behrens, Bert WesthoffDocument6 pagesFinite Element Modeling of High Speed Machining Processes: Arno Behrens, Bert WesthoffGatyo GatevNo ratings yet

- Numerical_Simulation_using_Finite_ElemenDocument6 pagesNumerical_Simulation_using_Finite_ElemenBelay AyalewNo ratings yet

- Finite Element Modeling of Multi-Pass Welding and Shaped Metal Deposition ProcessesDocument17 pagesFinite Element Modeling of Multi-Pass Welding and Shaped Metal Deposition ProcessesDuarte NetoNo ratings yet

- Page 66-68 Die and Mould NTTF GibsonDocument3 pagesPage 66-68 Die and Mould NTTF GibsonRahul NambiarNo ratings yet

- 2018 - New Die Engineering Capabilities Are Changeing Extrusion Shape FeasibilityDocument2 pages2018 - New Die Engineering Capabilities Are Changeing Extrusion Shape FeasibilityzhaomingbaoNo ratings yet

- Accuracy and Distortion of Composite Parts and ToolsDocument20 pagesAccuracy and Distortion of Composite Parts and ToolsMike DunhamNo ratings yet

- Sysweld Welding ReportDocument23 pagesSysweld Welding ReportAsiahKuzaimanNo ratings yet

- Failure Analysis of Cold Forging Dies Using Fea: Conor Maccormack, John MonaghanDocument7 pagesFailure Analysis of Cold Forging Dies Using Fea: Conor Maccormack, John Monaghancurtin100% (1)

- Sigmasoft LSRDocument6 pagesSigmasoft LSRMarta PalenzonaNo ratings yet

- Recent Developments in Process Simulation For Bulk Forming ProcessesDocument8 pagesRecent Developments in Process Simulation For Bulk Forming Processesth34560No ratings yet

- Codl and Hot Forging ArticleDocument12 pagesCodl and Hot Forging Articleİlter KilerciNo ratings yet

- Calibrating an FDM 3D Printer for Enhanced AccuracyDocument10 pagesCalibrating an FDM 3D Printer for Enhanced AccuracyJose HuertaNo ratings yet

- Kuo2021 Article CharacterizationsOfPolymerInjeDocument18 pagesKuo2021 Article CharacterizationsOfPolymerInjeAsad UllahNo ratings yet

- From Rotation To Swiveling: Injection MoldingDocument4 pagesFrom Rotation To Swiveling: Injection Moldingweb312_twNo ratings yet

- Franziska Neubauer, Tobias Reil, Konstantin Hofmann and Marion MerkleinDocument1 pageFranziska Neubauer, Tobias Reil, Konstantin Hofmann and Marion MerkleinRoberto HernandezNo ratings yet

- Process Description and Potential MaterialsDocument10 pagesProcess Description and Potential MaterialsSaddy DipoNo ratings yet

- Compression Injection MouldingDocument4 pagesCompression Injection MouldingTanushka SarangNo ratings yet

- Whitepaper Pressfit 072014Document16 pagesWhitepaper Pressfit 072014jav_ra993986No ratings yet

- 3D FEM Analysis of Cutting ProcessesDocument6 pages3D FEM Analysis of Cutting ProcessesbbsampleNo ratings yet

- Effect of Sintering Parameters and Flow Agent on Tensile Properties of Elastomer PartsDocument12 pagesEffect of Sintering Parameters and Flow Agent on Tensile Properties of Elastomer PartsmakrsnakminesNo ratings yet

- Optimization of Sheet Metal Forming Processes by The Use of Numerical SimulationsDocument6 pagesOptimization of Sheet Metal Forming Processes by The Use of Numerical SimulationsRaghu VenkatNo ratings yet

- SIGMASOFT Overview NewDocument7 pagesSIGMASOFT Overview Newespirhal100% (1)

- 2001 - Problems of Accuracy Control in Cold FormingDocument6 pages2001 - Problems of Accuracy Control in Cold FormingNguyen Hoang DungNo ratings yet

- 3D Printing Optimization for Automotive BracketsDocument57 pages3D Printing Optimization for Automotive BracketsAkshay bypNo ratings yet

- Forjado de MaterialesDocument12 pagesForjado de MaterialesMari MatzNo ratings yet

- Quality Prediction Through Combined Simulation of Ingot Casting and ForgingDocument10 pagesQuality Prediction Through Combined Simulation of Ingot Casting and ForgingMarcusNo ratings yet

- The Heat Treatment Solution Overview 180306Document16 pagesThe Heat Treatment Solution Overview 180306amd mhmNo ratings yet

- International Journal of Computational Engineering Research (IJCER)Document8 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- Investigation On Hot Stamping Process For Door Beam of Ultra-High Strength SteelDocument9 pagesInvestigation On Hot Stamping Process For Door Beam of Ultra-High Strength SteelselvinNo ratings yet

- Matecconf Iceaf2021 01008Document8 pagesMatecconf Iceaf2021 01008Della MonicaNo ratings yet

- Proc Ese 1233Document4 pagesProc Ese 1233Carlos ArenasNo ratings yet

- The Influence of Cavity Deformation On The Shrinkage and Warpage of An Injection-Molded PartDocument11 pagesThe Influence of Cavity Deformation On The Shrinkage and Warpage of An Injection-Molded Part박지원No ratings yet

- Procast - ESI - Casting SimulationsDocument14 pagesProcast - ESI - Casting Simulationsvmgobinath100% (2)

- 2 MankovaDocument4 pages2 MankovaBehailu FelekeNo ratings yet

- Virtual Try-Outs Compensate Tool DeformationDocument9 pagesVirtual Try-Outs Compensate Tool DeformationSangHak LeeNo ratings yet

- Improving Mechanical Seal ReliabilityDocument4 pagesImproving Mechanical Seal ReliabilityBala MuruganNo ratings yet

- Comparison Between Dry and Wet Machining of Stainless Steel N. I. Galanis, D. E. Manolakos, N. M. VaxevanidisDocument8 pagesComparison Between Dry and Wet Machining of Stainless Steel N. I. Galanis, D. E. Manolakos, N. M. VaxevanidisaeroprinceNo ratings yet

- Finite Element Investigation in The Forming Process of Aluminium Aerosol CansDocument5 pagesFinite Element Investigation in The Forming Process of Aluminium Aerosol CansMuhammed Furkan ŞahinNo ratings yet

- Investment Casting Simulation: Figure 1: Trial and Error Development Versus Computer Assisted DevelopmentDocument8 pagesInvestment Casting Simulation: Figure 1: Trial and Error Development Versus Computer Assisted Developmentpareshpatelb7232No ratings yet

- Ink WashandWarpageDefectPredictionfromthein MoldDecorationProcessSimulation PDFDocument8 pagesInk WashandWarpageDefectPredictionfromthein MoldDecorationProcessSimulation PDFrishi memaneNo ratings yet

- Thermo-Mechanical Model of A TIG Welding Process FDocument6 pagesThermo-Mechanical Model of A TIG Welding Process FGiustNo ratings yet

- End-To-End Virtualization of The Development and Production of VehiclesDocument10 pagesEnd-To-End Virtualization of The Development and Production of VehiclesCadcamdestek CukurocaNo ratings yet

- University of Technology, Sydney Faculty of Engineering: Manufacturing Report Hydraulic Garage JackDocument13 pagesUniversity of Technology, Sydney Faculty of Engineering: Manufacturing Report Hydraulic Garage JackJohnLa100% (1)

- Fea PDFDocument9 pagesFea PDFVeerasamy SureshbabuNo ratings yet

- Sheet Metal Forming Simulation in IndustryDocument8 pagesSheet Metal Forming Simulation in IndustrysscamdNo ratings yet

- Sheet Incremental Forming: Advantages of Robotised Cells vs. CNC MachinesDocument23 pagesSheet Incremental Forming: Advantages of Robotised Cells vs. CNC MachinesManolo GipielaNo ratings yet

- Reduced Wear and Higher Corrosion Resistance by Combined Heat-Treatment and Coating Procedures Using Plasma-Assisted ProcessesDocument3 pagesReduced Wear and Higher Corrosion Resistance by Combined Heat-Treatment and Coating Procedures Using Plasma-Assisted Processesmp87_ingNo ratings yet

- Altan 1993Document10 pagesAltan 1993Moez BellamineNo ratings yet

- SMT Seminar ReportDocument26 pagesSMT Seminar ReportShruthi Uppar100% (1)

- NovaStress - Compensate Patterns Before CastingDocument3 pagesNovaStress - Compensate Patterns Before CastingSašaSnješka GojkovicNo ratings yet

- Numerical Cutting Modeling with AbaqusDocument15 pagesNumerical Cutting Modeling with Abaqusklomps_jrNo ratings yet

- Productivity of Butt FusionDocument7 pagesProductivity of Butt FusionalensumNo ratings yet

- FULLTEXT01Document75 pagesFULLTEXT01Peter ZubarikNo ratings yet

- Jresv41n4p279 A1bDocument7 pagesJresv41n4p279 A1bPeter ZubarikNo ratings yet

- 05 2016 02 DYNAmore Infotag Implizit TipsTricksDocument32 pages05 2016 02 DYNAmore Infotag Implizit TipsTricksPeter ZubarikNo ratings yet

- Polymers 13 00492 v2 DelaminationDocument18 pagesPolymers 13 00492 v2 DelaminationPeter ZubarikNo ratings yet

- Using LS-DYNA For Hot FormingDocument6 pagesUsing LS-DYNA For Hot FormingPeter ZubarikNo ratings yet

- Cure History Dependent Viscoelastic Modeling of Adhesively Bonded Joints Using Mat 277 in Ls Dyna RDocument12 pagesCure History Dependent Viscoelastic Modeling of Adhesively Bonded Joints Using Mat 277 in Ls Dyna RPeter ZubarikNo ratings yet

- Conference Paper: Residual Stress Modeling of Induction-Bent PipesDocument10 pagesConference Paper: Residual Stress Modeling of Induction-Bent PipesPeter ZubarikNo ratings yet

- Final Thesis - AC Imp To Exp Convert!!!!!!!Document103 pagesFinal Thesis - AC Imp To Exp Convert!!!!!!!Peter ZubarikNo ratings yet

- Daftar PustakaDocument3 pagesDaftar PustakaPutri Meylia An NajiyahNo ratings yet

- TEGO Sulfosuccinate DO 75 - DS - A - 2014 - 03Document2 pagesTEGO Sulfosuccinate DO 75 - DS - A - 2014 - 03Chintan Navin Vora100% (1)

- Reinjeksi PabumDocument34 pagesReinjeksi PabumSkolastikaPradiptaNo ratings yet

- Bresle Test - Chloride Test Kit: Product DescriptionDocument3 pagesBresle Test - Chloride Test Kit: Product DescriptionHarikesh PandeyNo ratings yet

- JCI Data Sheet Template Letter Rev. 11Document2 pagesJCI Data Sheet Template Letter Rev. 11Navin RobertNo ratings yet

- Justin Brian Chiongson, M. SC., RCH Relicardo M. Coloso, Ph. D., RCHDocument23 pagesJustin Brian Chiongson, M. SC., RCH Relicardo M. Coloso, Ph. D., RCHAiza CeciliaNo ratings yet

- CH 5 - ProblemsDocument8 pagesCH 5 - ProblemsKhris Griffis89% (18)

- HAZOP Worksheet - Case2Document6 pagesHAZOP Worksheet - Case2jenish parekhNo ratings yet

- WPS PQR For S 1 S Piping 02Document5 pagesWPS PQR For S 1 S Piping 02ravi00098No ratings yet

- Draft StructuralSteel DesignGuideDocument79 pagesDraft StructuralSteel DesignGuideSheila Rose Bacerra-VillafloresNo ratings yet

- PE Health 11 Ist Semester Module 2 Energy System Version 3Document21 pagesPE Health 11 Ist Semester Module 2 Energy System Version 3Leary John TambagahanNo ratings yet

- DS HLTP 60 Rev12 1107Document2 pagesDS HLTP 60 Rev12 1107Luisito Aguilar RojasNo ratings yet

- Lakshya JEE 2.0 (2024) : SolutionDocument5 pagesLakshya JEE 2.0 (2024) : SolutionAyush KumarNo ratings yet

- HSE Training PlanDocument1 pageHSE Training PlanBro Kichy100% (2)

- Safety Data Sheet: Section 1: Identification of The Chemical and of The SupplierDocument8 pagesSafety Data Sheet: Section 1: Identification of The Chemical and of The SupplierFikriey AbdullahNo ratings yet

- Contenido de Fosforo ASTM D4951Document8 pagesContenido de Fosforo ASTM D4951Coordinador LaboratorioNo ratings yet

- Bacteria Nutrition RequirementsDocument14 pagesBacteria Nutrition RequirementsFuad Hasan Pranto 1921147049No ratings yet

- Industrial Hazards and Safety Management in Pharmaceutical IndustryDocument7 pagesIndustrial Hazards and Safety Management in Pharmaceutical IndustryShmmon AhmadNo ratings yet

- Chapter 6 - Chemical BondsDocument41 pagesChapter 6 - Chemical BondsDn ZackNo ratings yet

- Calibration of PH MeterDocument4 pagesCalibration of PH MeterMg H75% (4)

- End of Course Chemistry: Form S0119, CORE 1Document24 pagesEnd of Course Chemistry: Form S0119, CORE 1kristymadimikeNo ratings yet

- Resonance StructuresDocument4 pagesResonance StructuresSmyra100% (1)

- Application of Chitosan Shells Meti Batissa ViolacDocument12 pagesApplication of Chitosan Shells Meti Batissa Violacnia herianiNo ratings yet

- Nanomechanical Testing of Gum Metal: # Society For Experimental Mechanics 2009Document9 pagesNanomechanical Testing of Gum Metal: # Society For Experimental Mechanics 2009yerly ramirezNo ratings yet

- MPFM Response and Validation in Heavy Oil WellsDocument12 pagesMPFM Response and Validation in Heavy Oil Wellsjuan carlosNo ratings yet

- Chemistry of Hydrocarbon Experiment 16: ObjectiveDocument10 pagesChemistry of Hydrocarbon Experiment 16: ObjectiveWena Sta Maria100% (1)

- Automation Basics - Combustible Gas Detector Sensor Drift - Catalytic vs. Infrared - ISA PDFDocument1 pageAutomation Basics - Combustible Gas Detector Sensor Drift - Catalytic vs. Infrared - ISA PDFAnas AzzedineNo ratings yet

- Medicines 03 00025Document16 pagesMedicines 03 00025Syed Iftekhar AlamNo ratings yet

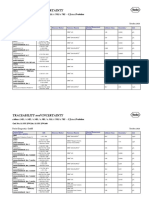

- Traceability and Uncertainty: Cobas C 501 / C 502 / C 503 / C 303 / C 311/ C 701/ C 702 - C.F.A.S. ProteinsDocument3 pagesTraceability and Uncertainty: Cobas C 501 / C 502 / C 503 / C 303 / C 311/ C 701/ C 702 - C.F.A.S. ProteinsLaura Puentes JiménezNo ratings yet

- Aama 2603-13Document14 pagesAama 2603-13Van Hien LeNo ratings yet