Professional Documents

Culture Documents

Direct Fired 2100

Uploaded by

Ehab MassoudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Direct Fired 2100

Uploaded by

Ehab MassoudCopyright:

Available Formats

11/09

2100 SERIES HTR® HOT AIR BURNER

CAPABILITIES

High thermal release

High temperature radiation without

flame impingement

Ability to place heat where required

High turndown capacity

Nominal capacity range 70,000 to

3.5 mm Btu/hr

FEATURES APPLICATIONS

High temperature radiation through Reheat Furnaces

high speed combustion

Batch Anneal Furnaces

Extra rugged port block and mounting

plate construction Forging Furnaces

Continuous Strip Heating Furnaces

CONTROL Drying Ovens

Pressure Balance Ratio Regulator Aluminum Melting Furnaces

Volumetric Air Ratio Control Galvanizing Furnaces

Tandem Valves Tube Upsetters

Glass Bending and Melting

FLAME MONITORING Sinter Hoods

Provisions for Flame Monitoring Clay Calcining

See 2100 Bulletin Page 3 Many other Applications

BURNER IGNITION FUEL CAPABILITIES

Pilot Natural Gas

Direct Spark Coke Gas

Manual LP Gas

Low Btu Mixed Gas

Distillate Fuel Oils

#6 Fuel Oil

OPTIONS

Mounting plate designs including lug type for See bulletins for optional block lengths

roof mounting, square for sidewall mounting

and curved for cylindrical furnace walls

CAUTION: The improper use of combustion equipment can result in a condition hazardous to people and property. Users are

urged to comply with National Safety Standards and/or Insurance Underwriters recommendations

© Bloom Engineering Co 2009 1

11/09

2100 SERIES HTR® HOT AIR BURNER

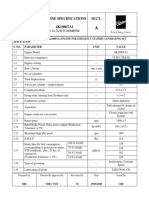

CAPACITY CHART

Air Flow at 20” water column (50 mBar)1,2

3

Atomizing Air Cooling Air

4

Catalog Capacity Air Flow at Direct Pilot Part LP Oil Flow at Flow at

No. Option 800°F/427°C Spark No. Burner 32 OSI 2 OSI

2100- Ignitor Size (137 mBar) (9 mBar)

Part No. 1920- Static Press. Static Press.

SCFH

3

Nm /hr (optional) SCFH Nm /hr

3

SCFH Nm /hr

3

008 A 399 11 3500-210 3001-010 -- -- -- -- --

010 A 880 24 3500-210 3001-010 -- -- -- -- --

015 A 1,464 39 3500-210 3001-010 -- -- -- -- --

A 2,820 76 3500-210 3001-010 -- -- -- -- --

020

B 3,488 94 -- -- -- -- --

A 4,510 121 3500-210 3001-030 -- -- -- -- --

025

B 5,970 160 -- -- -- -- --

A 5,970 160 -- -- -- -- --

B 7,190 193 -- -- -- -- --

030 3500-210 3001-030

C 9,860 264 -- -- -- -- --

D 11,660 313 -- -- -- -- --

A 11,200 300 008 1,200 32 300 8

B 14,270 383 008 1,200 32 300 8

040 3500-210 3001-030

C 15,310 410 008 1,200 32 300 8

D 17,700 475 008 1,200 32 300 8

A 23,970 643 015 1,600 43 400 11

B 27,210 729 015 1,600 43 400 11

060 C 29,590 793 3500-210 3001-030 015 1,600 43 400 11

D 32,580 873 015 1,600 43 400 11

E 18,590 498 015 1,600 43 400 11

1

2

Gas pressure is approximately 0.7 times air pressure.

Piping system should be received to insure delivery of this pressure. On occasion, the approach to the

burner should be increased one size including valves, flexible nipples, etc.

3

Recommended when firing as with 1920 LP atomizer in place.

4

Direct spark ignition for natural gas only. For dual fuel mode, burners must be ignited on natural gas

and then switched over to light oil.

The 2100 Series burner is primarily designed for slightly oxidizing to slightly reducing air to fuel ratios

and is not intended as an excess air burner. Careful consideration should be given to the turndown

requirements so that the minimum air pressure requirement is approximately 0.3” W.C. All burners,

except direct spark ignited models, have an integral machined gas distribution orifice, which eliminates

the need for individual gas balancing or throttle valves. This gas distribution orifice insures burner

distribution throughout a given zone. Each burner except the direct spark ignited model, has an integral

machined gas distribution orifice which eliminates the need for individual gas balancing or throttle valves.

The spark ignited model uses an orifice installed in the supply line. The gas distribution orifice insures

burner distribution throughout a given zone.

CAUTION: The improper use of combustion equipment can result in a condition hazardous to people and property. Users are

urged to comply with National Safety Standards and/or Insurance Underwriters recommendations

© Bloom Engineering Co 2009 2

11/09

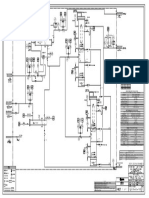

2100 SERIES HTR® HOT AIR BURNER

Mininum & Maximum

Port Block Lengths

for Flame Rod & U.V. Cell Applications

Min/Max Port Block Lengths

Square Plate

Burner Size Lug Type Plate Round Block Square Block

2.5 & 3 9"/9" 9.25/10.25" 9.25"/10.25"

4" 9"/9" 9.25/10.25" 9.25"/10.25"

6" 9"/11.5" 9"/13.5" 9"/13.5"

2100 SERIES BURNERS

Catalog Model No.

2110 Preheated Air, Roof Mount, Gas Only

2116 Preheated Air, Roof Mount, Gas and Light Oil

2120 Preheated Air, Wall Mount, Gas Only

2126 Preheated Air, Wall Mount, Gas and Light Oil

NOTE: GENERAL DIMENSION INFORMATION. SEE BLOOM REPRESENTATIVE FOR CERTIFIED DIMENSIONS FOR CONSTRUCTION.

CAUTION: The improper use of combustion equipment can result in a condition hazardous to people and property. Users are

urged to comply with National Safety Standards and/or Insurance Underwriters recommendations

© Bloom Engineering Co 2009 3

You might also like

- Data Sheet 3196 MT-i - 3X4-13 - 130 m3h X 47 M GBQ - 49.991 - 14Document10 pagesData Sheet 3196 MT-i - 3X4-13 - 130 m3h X 47 M GBQ - 49.991 - 14Vinícius Toni MartinsNo ratings yet

- 218 1 DataSheet Tech Info SHE GBDocument6 pages218 1 DataSheet Tech Info SHE GBGerman Samuel Vacaflor LarrazábalNo ratings yet

- 1029 Series Fuel Energy Cold AIR Baffle Burner: CapabilitiesDocument4 pages1029 Series Fuel Energy Cold AIR Baffle Burner: CapabilitiesSubhra SinhaNo ratings yet

- Volute Pumps Sihi: SupernovaDocument10 pagesVolute Pumps Sihi: SupernovaLuis Fernando collazosNo ratings yet

- GB162 TL3 Cascade Frame Kit Technical Data Sheet COM011 (2013-01) AUSDocument1 pageGB162 TL3 Cascade Frame Kit Technical Data Sheet COM011 (2013-01) AUSarminsarajevoNo ratings yet

- Aux Boiler Final DWG Kangrim PA0501P32Document507 pagesAux Boiler Final DWG Kangrim PA0501P32Dario LušaNo ratings yet

- Compresor Aire Piso TechoDocument5 pagesCompresor Aire Piso TechoManuel Angulo MendozaNo ratings yet

- Avk Air & Vacuum Valve, PN 16 701/30: For Water, Ductile Iron, DN 100 and 200-300 020Document2 pagesAvk Air & Vacuum Valve, PN 16 701/30: For Water, Ductile Iron, DN 100 and 200-300 020lan bautistaNo ratings yet

- BC01C1-Soot Blower Spec - R0Document6 pagesBC01C1-Soot Blower Spec - R0JKKNo ratings yet

- 42131300102Document5 pages42131300102jean_carlos_abreu_rNo ratings yet

- Self-Priming Pumps: Type Series Booklet CTI-2100/0 2 (07-2016)Document32 pagesSelf-Priming Pumps: Type Series Booklet CTI-2100/0 2 (07-2016)mohsen aminiNo ratings yet

- Pan American Silver: MODEL:3700 10th Edition (ISO13709) LA SIZE:3x4-16S QTY: 2Document6 pagesPan American Silver: MODEL:3700 10th Edition (ISO13709) LA SIZE:3x4-16S QTY: 2wilsonNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- Ó Chi PDFDocument16 pagesÓ Chi PDFGỗ MộcNo ratings yet

- Single and Two-Stage Industrial Reciprocating Air CompressorsDocument4 pagesSingle and Two-Stage Industrial Reciprocating Air CompressorsGeetesh MakadiaNo ratings yet

- BOX BD 1010 M4 059kWDocument4 pagesBOX BD 1010 M4 059kWAiman AliNo ratings yet

- Ace3 1122.03 GB PDFDocument16 pagesAce3 1122.03 GB PDFArpit VermaNo ratings yet

- DS - Co - 0003 - en - BM LPGDocument2 pagesDS - Co - 0003 - en - BM LPGNikola VeleskiNo ratings yet

- Matushima Servicemanual UkDocument30 pagesMatushima Servicemanual Ukgeorge dimopoulosNo ratings yet

- Hibon - SN Ingersoll Rand BlowerDocument7 pagesHibon - SN Ingersoll Rand BlowermarquezsiemNo ratings yet

- Rah 563 Ce Heating Element 35 Non Enamelled 1566626618Document4 pagesRah 563 Ce Heating Element 35 Non Enamelled 1566626618Senthil KumarNo ratings yet

- Process Pump Technical OfferDocument53 pagesProcess Pump Technical OfferHisham ElsayedNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- Acf5 1103.01 GBDocument16 pagesAcf5 1103.01 GBPedro Javier Medina CornejoNo ratings yet

- Electric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Document1 pageElectric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Manuel SerranoNo ratings yet

- 1384 3942 00 en General Arrangement Drawing Omega 50 HZDocument32 pages1384 3942 00 en General Arrangement Drawing Omega 50 HZmohamed ghareebNo ratings yet

- HM 30 MetersDocument16 pagesHM 30 MetersAlbert NajjarNo ratings yet

- Newco Cast Steel Valves Tech DataDocument86 pagesNewco Cast Steel Valves Tech Dataeduardo goveaNo ratings yet

- Boiler MIURA - LX-300-16Document2 pagesBoiler MIURA - LX-300-16LuizPauloCostaNo ratings yet

- Bbas Agua CalienteDocument12 pagesBbas Agua CalienteErich ThomasNo ratings yet

- 2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Document2 pages2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Jennifer FigueroaNo ratings yet

- LH AD CatálogoDocument3 pagesLH AD CatálogoAlanNo ratings yet

- ECON 3-Piece Firesafe Ball ValveDocument6 pagesECON 3-Piece Firesafe Ball ValveKunming WangNo ratings yet

- Water Charge-Air Cooling: Diesel Genset - 50 HZDocument2 pagesWater Charge-Air Cooling: Diesel Genset - 50 HZMehrdad saeediNo ratings yet

- Avcon Solenoid IndiaDocument2 pagesAvcon Solenoid Indiajhon manurungNo ratings yet

- Ebara Price ListDocument61 pagesEbara Price ListDileep C Dileep50% (6)

- Itt Fluid Technology Asia: Model:3196 Xlti Size:8X10-13 Qty: 3Document9 pagesItt Fluid Technology Asia: Model:3196 Xlti Size:8X10-13 Qty: 3Suriyachai NiamsornNo ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- Avk Ball Float ValveDocument2 pagesAvk Ball Float ValveDota NgNo ratings yet

- Rooftop Service Manula (Heat Pump) - 190411Document151 pagesRooftop Service Manula (Heat Pump) - 190411Kyc IndustrialNo ratings yet

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- Everest Blowers M5125 Technical Specs GADrawingw FiltraDocument4 pagesEverest Blowers M5125 Technical Specs GADrawingw FiltraKELVIN TECHNOLOGIESNo ratings yet

- Service Instruction 1037KDocument8 pagesService Instruction 1037KLuis AmayaNo ratings yet

- Boiler SpecificationDocument18 pagesBoiler SpecificationAtul Jain100% (3)

- Catalogo GROFE IngDocument50 pagesCatalogo GROFE IngAlvaro Antonio Cristobal AtencioNo ratings yet

- 2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Document2 pages2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Jennifer FigueroaNo ratings yet

- Bulldog Torch: Heavy Duty Scrap Cutting TorchDocument2 pagesBulldog Torch: Heavy Duty Scrap Cutting TorchShyam ShrishNo ratings yet

- كتالوج الشيلراتDocument54 pagesكتالوج الشيلراتFathy RakhaNo ratings yet

- Selfeeder ElectricDocument32 pagesSelfeeder Electricasta seikiNo ratings yet

- R2 00 MGS2800HV (50Hz 10kV)Document4 pagesR2 00 MGS2800HV (50Hz 10kV)luat1983No ratings yet

- Vitogas 100-gs1 TDMDocument12 pagesVitogas 100-gs1 TDMigaoua.coordefNo ratings yet

- Tma FC: MiserDocument15 pagesTma FC: MiserJim JonesjrNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Anderson BombistaNo ratings yet

- ABS Submersible Mixer RW 200, 50HzDocument2 pagesABS Submersible Mixer RW 200, 50Hzalisya.blwsNo ratings yet

- Operation 490BDocument60 pagesOperation 490BYe Min Htike100% (1)

- 3010-PS003 - 3 Valve ScheduleDocument61 pages3010-PS003 - 3 Valve ScheduleMichael adu-boahenNo ratings yet

- Technical OfferDocument50 pagesTechnical OfferHisham ElsayedNo ratings yet

- Technical OfferDocument50 pagesTechnical OfferHisham ElsayedNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BF01087562Document4 pagesBF01087562Ehab MassoudNo ratings yet

- CATALOGO IRON STEEL ENG TED ITA X SITO WEB SmallDocument36 pagesCATALOGO IRON STEEL ENG TED ITA X SITO WEB SmallEhab MassoudNo ratings yet

- Millenium 2022-23 - NCO Extract pg.82-85Document5 pagesMillenium 2022-23 - NCO Extract pg.82-85Ehab MassoudNo ratings yet

- Bloom Engineering Overview BrochureDocument10 pagesBloom Engineering Overview BrochureEhab MassoudNo ratings yet

- Analisis Kinerja Turbin Uap Unit 3 BerdasarkanDocument12 pagesAnalisis Kinerja Turbin Uap Unit 3 BerdasarkanfebriansyahNo ratings yet

- Abstract-Piezoelectric Energy HarvestingDocument2 pagesAbstract-Piezoelectric Energy HarvestingGanesh Venugopal100% (5)

- Mech-Engg., Thermal EngineeringDocument8 pagesMech-Engg., Thermal Engineeringnims1964No ratings yet

- User Operational Guide - 90 Liter Autoclave EN-ARDocument6 pagesUser Operational Guide - 90 Liter Autoclave EN-ARمحمدقائد الذبحانيNo ratings yet

- RT Series 75 11 KW Oil Flooded Rotary Screw Compressors CatalogueDocument3 pagesRT Series 75 11 KW Oil Flooded Rotary Screw Compressors Cataloguedouglas guedezNo ratings yet

- Template PPT - HanifaDocument15 pagesTemplate PPT - HanifaYudi R PutraNo ratings yet

- Solution To Mid Term ExamDocument9 pagesSolution To Mid Term ExamMariel MirafloresNo ratings yet

- 4 SS Sistemas y Subsistemas (R)Document17 pages4 SS Sistemas y Subsistemas (R)Yhony Gamarra VargasNo ratings yet

- T Series VRLA Battery PDFDocument4 pagesT Series VRLA Battery PDFsistemsem30No ratings yet

- Design Calculation of 40 MW Francis Turbine RunnerDocument5 pagesDesign Calculation of 40 MW Francis Turbine RunnerEditor IJTSRDNo ratings yet

- 2019 CI Report - KEPRI - HRSG #1Document21 pages2019 CI Report - KEPRI - HRSG #1Gloria Del Carmen Muñoz RamirezNo ratings yet

- JIF 314 - Chap 6Document12 pagesJIF 314 - Chap 6Yus NordinNo ratings yet

- CAT C32 RNY Series Maintenance Interval ScheduleDocument3 pagesCAT C32 RNY Series Maintenance Interval Scheduleharikrishnanpd3327No ratings yet

- Heating Coil in The Main Air Handling UnitDocument13 pagesHeating Coil in The Main Air Handling UnitApurv GoyalNo ratings yet

- Automotive Servicing NCI: Written TestDocument27 pagesAutomotive Servicing NCI: Written Testjayson platinoNo ratings yet

- Systems & Solutions: Renewable Energy Geothermal PowerDocument5 pagesSystems & Solutions: Renewable Energy Geothermal PowerBRIGHT TECH INDUSTRIALS INDIA PVT LTDNo ratings yet

- Phocos Reguladores de Carga Datasheet MPPT100 30 enDocument1 pagePhocos Reguladores de Carga Datasheet MPPT100 30 enMatias AlaffNo ratings yet

- Liquid Rocket Engine Axial Flow Turbo PumpsDocument129 pagesLiquid Rocket Engine Axial Flow Turbo Pumpsapi-3827338100% (1)

- Tutorial 6 - Forces On Tubing PTRL4017Document9 pagesTutorial 6 - Forces On Tubing PTRL4017Hadirah DunglahNo ratings yet

- Experimental Study of Combustion of Hydrogen-Syngas/ Methane Fuel Mixtures in A Porous BurnerDocument9 pagesExperimental Study of Combustion of Hydrogen-Syngas/ Methane Fuel Mixtures in A Porous BurnerTinhNo ratings yet

- ConclusionDocument4 pagesConclusionamolparkaleNo ratings yet

- Spe 10337 MS PDFDocument11 pagesSpe 10337 MS PDFpeterboadaNo ratings yet

- 4H.3866 - 4K1080TA1 - For 100kwe - Specification SheetDocument3 pages4H.3866 - 4K1080TA1 - For 100kwe - Specification SheetAlfonso RivasNo ratings yet

- P2620 CPD SheetDocument1 pageP2620 CPD SheetAlejandra Rodriguez NocuaNo ratings yet

- Section1 1Document46 pagesSection1 1adil_farooq_6No ratings yet

- Line List TemplateDocument3 pagesLine List TemplateMeoNo ratings yet

- HSE - Take Care With AcetyleneDocument5 pagesHSE - Take Care With Acetylenesl1828No ratings yet

- List of Oisd StandardsDocument6 pagesList of Oisd StandardsManish Kumar100% (3)

- Plano Hidraulico Rodillo Vibratorio CS 663E PDFDocument2 pagesPlano Hidraulico Rodillo Vibratorio CS 663E PDFOSCAR LOSADANo ratings yet

- (A1, 2019) Thermochemical Waste-Heat Recuperation by Steam Methane Reforming With Flue Gas AdditionDocument11 pages(A1, 2019) Thermochemical Waste-Heat Recuperation by Steam Methane Reforming With Flue Gas AdditionAsdrubolNo ratings yet