Professional Documents

Culture Documents

Oil Analysis Report Explanation

Uploaded by

Febriyanto FebriyantoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Analysis Report Explanation

Uploaded by

Febriyanto FebriyantoCopyright:

Available Formats

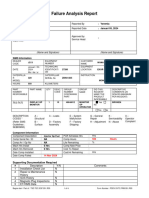

EXPLANATION OF OIL ANALYSIS REPORT Page 1

Oil Analysis Report

XYZ Plant Hire PROBLEM SEVERITY

PO Box 123 KWAZULU-NATAL

PO BOX 15108 This block indicates the sample severity status,

Johannesburg WESTMEAD 3608

using the four descriptions listed here.

2000 TEL: 031 700 5460

FAX: 031 700 5471

GAUTENG critical

PO BOX 284 urgent

ISANDO 1600

TEL: 011 392 6322 caution

FAX: 011 392 6340 normal

Vehicle : Registration or fleet number Code : Customer computer code

Alt ID : Alternate or optional identification number Job No : WearCheck job number

Model : Make of component Site : Location of vehicle

Comp : Type of component Oil : Oil brand and grade

Model : Model of component Queries : Queries the customer might have

DIAGNOSIS DEBRIS PAD IMAGE

Sample Number / Date of sample / Sample meter reading

Interpretation of the results of your current sample

will be displayed here.

Results will indicate the state or condition of the component at the

time of sampling.

Oil condition and any abnormal situation caused by either overheating,

overfueling or contamination will be reported here, eg. dust or water

entry, incomplete combustion (sludging).

Result interpretation is user-friendly and easy to understand.

PREVIOUS HISTORY

DIAGNOSIS FEEDBACK

Sample Number / Date of sample / Sample meter reading When WearCheck detects a problem in a sample from a vehicle we

supply a job card which informs maintenance staff what checks should

This section of the report supplies you with the diagnostic history

be made or action taken.

of the vehicle, displaying four sample results.

The information is returned to WearCheck and entered in this section

for your records.

Issued subject to Standard Conditions (avaliable on request)

ISO 9001 and ISO 14001 Registered

e support@wearcheck.co.za t +27 (0) 31 700 5460 | +27 (0) 11 392 6322 f +27 (0) 31 700 5471 | +27 (0) 11 392 6350

The leaders in Oil & Fuel Analysis www.wearcheck.co.za

EXPLANATION OF OIL ANALYSIS REPORT Page 2

VEHICLE MAKE AND COMPARTMENT WILL DISPLAY HERE

SAMPLE DATE LAB OIL SMR UNITS OIL IN FILTER OIL

NUMBER SAMPLED DATE CONSUMPTION 156 000 km SERVICE CHANGE DRAIN

1234567 25/01/07 25/01/07 Normal 15 000 Yes No

This section displays sample details and records dates, kilometres or hours

as well as the amount of top-up oil used and our recommended re-sampling interval (RRI).

WEAR METALS

Aluminium

Wear metals identify the source of wear, eg. from pistons, rings, bearings,

Tungsten

Chrome

Bushes, thrustwashers Copper

Anti-friction, bearings, Nickel

Silver

gears, etc. The value of the elements is recorded in parts per million.

Iron

Our technical staff interpret the data and note their findings and

recommendations in the diagnosis block on the front page.

Plain bearings, rings

Cooling system,

Current results are compared with previous findings.

Anti-friction,

silver solder

Liners, gears

This method of interpretation is called trend analysis.

bearings

Pistons

valves

Monitoring wear metals allows you to ‘'see’'

a problem long before the engine wears out!

CONTAMINANTS

Particle count

Contaminants are measured in parts per million or percentages and are

Sulphation

Oxidation

Nitration

used to establish the cause of abnormal wear.

Lithium

Sodium

Silicon

Soot

Dilution by fuel Fuel

Severe contamination will lead to reduced engine life!

Overcooling

Overheating

Combustion

Combustion

Cleanliness

Coolant

Grease

Dirt

ADDITIVES AND LUBRICANT CONDITION

Phosphorous

This section is used to check the oil in use and evaluate the properties

Magnesium

Viscosity

of the lubricant.

Calcium

TAN

TBN

Zinc

PQ

Additives Oil condition Wear elements

GRAPHICAL REPRESENTATION OF KEY DATA

Our technical staff note any deviations in trends and display these results graphically. Oil in service and iron arealways displayed.

YES, I would like more information about WearCheck products and training courses. Please contact me.

(Fax to WearCheck in Johannesburg on 011 392 6340 or Durban on 031 700 5471)

Name: Company Name:

Telephone: Fax:

Cell: E-mail:

ISO 9001 and ISO 14001 Registered

e support@wearcheck.co.za t +27 (0) 31 700 5460 | +27 (0) 11 392 6322 f +27 (0) 31 700 5471 | +27 (0) 11 392 6350

The leaders in Oil & Fuel Analysis www.wearcheck.co.za

You might also like

- Mercury-Mariner Service Manual 2 5 To 275hp 1990-2000-17350802Document403 pagesMercury-Mariner Service Manual 2 5 To 275hp 1990-2000-17350802Marco Diaz100% (2)

- Yamaha XVZ13 Venture Royale Service Manual 86-93Document496 pagesYamaha XVZ13 Venture Royale Service Manual 86-93Joshua Vinyard50% (2)

- Raw Material Specification Sheet - Petroflo 20Y3437 NewDocument2 pagesRaw Material Specification Sheet - Petroflo 20Y3437 NewBasty Tejano67% (3)

- 8-2: Identification of Cations in Solution - Flame TestsDocument3 pages8-2: Identification of Cations in Solution - Flame TestsEmmanuel ChidiacNo ratings yet

- Zaxis 280-5 Excavator Operators ManualDocument430 pagesZaxis 280-5 Excavator Operators ManualKeron Trotz100% (2)

- s2s CEI WorkbookDocument9 pagess2s CEI WorkbookmrsurantoNo ratings yet

- 1hpomg 764012545Document3 pages1hpomg 764012545jean-pierre joubertNo ratings yet

- Not The Latest Sample: Mobile EquipmentDocument6 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- Not The Latest Sample: Mobile EquipmentDocument8 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- Wearcheck Oil Analysis ReportDocument2 pagesWearcheck Oil Analysis Reportapi-105696388100% (1)

- Not The Latest Sample: Mobile EquipmentDocument10 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- Not The Latest Sample: Mobile EquipmentDocument2 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- FAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Document7 pagesFAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Fros DiamonNo ratings yet

- Subject: ZX-All-288Document4 pagesSubject: ZX-All-288Halil KaraNo ratings yet

- M250-C47e OmmDocument11 pagesM250-C47e OmmturboshaftNo ratings yet

- Commissioning Procedure For The 797F and The 797F XQ Off-Highway Truck (0374, 1000, 7000, 7961)Document154 pagesCommissioning Procedure For The 797F and The 797F XQ Off-Highway Truck (0374, 1000, 7000, 7961)Blenz HQNo ratings yet

- Jeep Wrangler 2004 Repair ManualDocument20 pagesJeep Wrangler 2004 Repair Manualbillie100% (51)

- MOV DatasheetDocument98 pagesMOV Datasheetsrik11No ratings yet

- Technical Service Report: PT Pama Persada Nusantara Distric Topb Kalimantan TengahDocument18 pagesTechnical Service Report: PT Pama Persada Nusantara Distric Topb Kalimantan TengahNanang AgustyaNo ratings yet

- Far ZBN41205Document4 pagesFar ZBN41205yeremia kristianNo ratings yet

- C15 Additional Part Bushing Cam ShaftDocument7 pagesC15 Additional Part Bushing Cam ShaftYeremiaNo ratings yet

- TH460 Service Report 023832Document1 pageTH460 Service Report 023832eskully92No ratings yet

- Not The Latest Sample: Mobile EquipmentDocument30 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- PM 1 (250 Hour Interval)Document2 pagesPM 1 (250 Hour Interval)Hendra MonoNo ratings yet

- PV Vent Valves: Data Card For PV Vents Valves Test Report and History Sheet For PV Vent ValvesDocument3 pagesPV Vent Valves: Data Card For PV Vents Valves Test Report and History Sheet For PV Vent ValvesJahnavi VijaykumarNo ratings yet

- Mobile Equipment: Problem SeverityDocument2 pagesMobile Equipment: Problem SeverityHakim AmmorNo ratings yet

- Thermal Spray Prodeces OHT Brake Anchor PDFDocument11 pagesThermal Spray Prodeces OHT Brake Anchor PDFalan gonzalezNo ratings yet

- 1kz-Te Engine Sup. (Rm790e) PDFDocument284 pages1kz-Te Engine Sup. (Rm790e) PDFวัฒน์ ยอดแหลม100% (7)

- Not The Latest Sample: Mobile EquipmentDocument12 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- Shell RLA Step 4Document2 pagesShell RLA Step 4jonbilbaoNo ratings yet

- 12g GravelyDocument24 pages12g GravelylarryNo ratings yet

- Medidas Del Anclaje de FrenoDocument10 pagesMedidas Del Anclaje de FrenoMiguel FloresNo ratings yet

- Recuperacion de CarrierDocument57 pagesRecuperacion de Carrierariel avalosNo ratings yet

- Oil Analysis Report ExplanationDocument2 pagesOil Analysis Report Explanationzrcjsyll100% (1)

- Technical Bulletin: SectionDocument1 pageTechnical Bulletin: Sectionfuad jakicNo ratings yet

- S7-Lxje05a 4Document563 pagesS7-Lxje05a 4Andres GomezNo ratings yet

- Forma 8070-1Document2 pagesForma 8070-1api-520977931No ratings yet

- 5051 - TR & Tool Kit CAMP CardsDocument2 pages5051 - TR & Tool Kit CAMP CardsMarty SmallwoodNo ratings yet

- Section 6 Pre-Delivery PDFDocument15 pagesSection 6 Pre-Delivery PDFTOSHANo ratings yet

- APS1 Ops Manual 883325 - BDocument359 pagesAPS1 Ops Manual 883325 - BbatumiestateNo ratings yet

- Captura de Tela 2021-04-18 À(s) 22.15.38Document128 pagesCaptura de Tela 2021-04-18 À(s) 22.15.38lukkinhasmattosNo ratings yet

- 00-01 XR1800Document188 pages00-01 XR1800wilsonmoto15No ratings yet

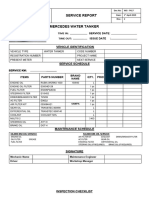

- Mercedes 1735 (WT-16)Document2 pagesMercedes 1735 (WT-16)nalanliyanage008No ratings yet

- PT WBK 777e Kdp00831 Wht019 Smu 5217 Seal Yoke LeakDocument1 pagePT WBK 777e Kdp00831 Wht019 Smu 5217 Seal Yoke LeakNasirKodratNo ratings yet

- Comisionado - 793fDocument157 pagesComisionado - 793fPercy Herrera ZeballosNo ratings yet

- SB 10058826 3770Document2 pagesSB 10058826 3770Costel CovaliNo ratings yet

- Escavadora 110Document678 pagesEscavadora 110Gilberto TorresNo ratings yet

- New Holland 700j Crawler Dozer Operation and TestDocument20 pagesNew Holland 700j Crawler Dozer Operation and Testlorraine100% (48)

- SR 8500070836 GOH Engine Rig Maera 3516 73Z00324 PT ApexindoDocument45 pagesSR 8500070836 GOH Engine Rig Maera 3516 73Z00324 PT ApexindoRachmad HidayatNo ratings yet

- Toyota A40a41 A43da43de Aw70 Aw71 Atsg Automatic Transmission Service GroupDocument112 pagesToyota A40a41 A43da43de Aw70 Aw71 Atsg Automatic Transmission Service Groupanon_575426223100% (2)

- SIMS Report TerbaruDocument1 pageSIMS Report TerbaruEcha FaraNo ratings yet

- Escavadora John Deere 120CDocument553 pagesEscavadora John Deere 120CGilberto Torres83% (6)

- SIMS REPORT All CYLINDERDocument14 pagesSIMS REPORT All CYLINDEREdo FedricoNo ratings yet

- Service Sheet Tadano Cto1Document4 pagesService Sheet Tadano Cto1ainul arifNo ratings yet

- Curso Tecnico Camion Caterpillar 797FDocument328 pagesCurso Tecnico Camion Caterpillar 797FCatalina Alexandra Cárdenas100% (2)

- Before/After: Service LetterDocument6 pagesBefore/After: Service Lettercjl08No ratings yet

- Test and Inspection Data: Warning!Document2 pagesTest and Inspection Data: Warning!MuratOguz UcakNo ratings yet

- Yamaha EF1000iS Service ManualDocument108 pagesYamaha EF1000iS Service ManualPaulo MendesNo ratings yet

- Service Manual 2004 - SR230 PDFDocument354 pagesService Manual 2004 - SR230 PDFDemetriNo ratings yet

- BroucherDocument6 pagesBroucherFraz AhmadNo ratings yet

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Potential of Biomass For Bioenergy in Pakistan BasDocument13 pagesPotential of Biomass For Bioenergy in Pakistan Bastaha zafarNo ratings yet

- Defects of Ductile Iron PipeDocument8 pagesDefects of Ductile Iron PipeUma Koduri100% (1)

- #Tutorial 3 - Fossil Fule Steam Generators TroubleshootingDocument5 pages#Tutorial 3 - Fossil Fule Steam Generators Troubleshootingmohamed EldesokyNo ratings yet

- ColorimetríaDocument4 pagesColorimetríaMiguel Dario Martinez MolinaNo ratings yet

- Feasibility of Modifying Existing Chemistry Demonstrations by Using Substitute MaterialsDocument18 pagesFeasibility of Modifying Existing Chemistry Demonstrations by Using Substitute MaterialsRosalyn TercianoNo ratings yet

- Pawar Public School, Nanded City, Pune Science Class-Vii CH 5. Acids, Bases and Salts Exercises Short Answer QuestionsDocument4 pagesPawar Public School, Nanded City, Pune Science Class-Vii CH 5. Acids, Bases and Salts Exercises Short Answer QuestionsAbhishekNo ratings yet

- Heat Treatment of SteelsDocument162 pagesHeat Treatment of SteelsINSTECH ConsultingNo ratings yet

- BackStop - Sma09047Document18 pagesBackStop - Sma09047Diego PalaciosNo ratings yet

- Lactate Dehydrogenase CharacterizationDocument23 pagesLactate Dehydrogenase CharacterizationAngela Kc100% (3)

- CHPT 11-13Document42 pagesCHPT 11-13Charles Borromeo LiNo ratings yet

- Calculation of K Factor Function For The Carbonation Process of Lime-Based PlastersDocument5 pagesCalculation of K Factor Function For The Carbonation Process of Lime-Based PlastersSaurav BhattacharjeeNo ratings yet

- Ninol 1281: May 2006 Supercedes: Dec. 2001Document2 pagesNinol 1281: May 2006 Supercedes: Dec. 2001Fadhli KusumaNo ratings yet

- Advantages and DisadvantagesDocument4 pagesAdvantages and DisadvantagesvenothNo ratings yet

- Citrus Oil Cleaner Formulations - 083Document1 pageCitrus Oil Cleaner Formulations - 083mndmattNo ratings yet

- Vapour Liquid Equilibrium Data CollectionDocument51 pagesVapour Liquid Equilibrium Data CollectionMirsoNo ratings yet

- Astm C1097Document1 pageAstm C1097pfta_No ratings yet

- List of MinesDocument12 pagesList of Minessabka632No ratings yet

- SPM Kimia Jul12 PDFDocument49 pagesSPM Kimia Jul12 PDFSyazwani RadziNo ratings yet

- Jurnal NanoemulsiDocument12 pagesJurnal NanoemulsiulfiNo ratings yet

- Gilbert - 2005 - REVIEW - Cationic Antiseptics - Diversity of Action Under A Common EpithetDocument13 pagesGilbert - 2005 - REVIEW - Cationic Antiseptics - Diversity of Action Under A Common EpithetDodoNo ratings yet

- Analysis of ToothpasteDocument3 pagesAnalysis of ToothpastepaceabcNo ratings yet

- Organic Chemistry Chap 11 Study GuideDocument49 pagesOrganic Chemistry Chap 11 Study GuideYarys YauNo ratings yet

- 821180-Palmvita SHT WF (1116) MRD 1x15Kg Carton-C331Document4 pages821180-Palmvita SHT WF (1116) MRD 1x15Kg Carton-C331QA RCPINo ratings yet

- Fire and Fire ExtinguishmentDocument28 pagesFire and Fire ExtinguishmentRahul RamachandranNo ratings yet

- My Sore SandalDocument14 pagesMy Sore SandalHarshi AkhilNo ratings yet

- Thermal Cracking of Recycled Hydrocarbon Gas-Mixtures With High Olefins Concentrations in The Feed: Operational Analysis of Industrial FurnacesDocument7 pagesThermal Cracking of Recycled Hydrocarbon Gas-Mixtures With High Olefins Concentrations in The Feed: Operational Analysis of Industrial FurnacesMehul SutariyaNo ratings yet

- Acidchem Bulletin 300-6-0Document1 pageAcidchem Bulletin 300-6-0kanNo ratings yet