Professional Documents

Culture Documents

42CrMo4 Rev 1

42CrMo4 Rev 1

Uploaded by

j.k.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

42CrMo4 Rev 1

42CrMo4 Rev 1

Uploaded by

j.k.Copyright:

Available Formats

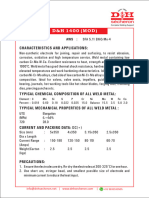

TECHNICAL CARD 42CrMo4

PRINCIPAL APPLICATION FIELDS

Heat treatable steel:

Alloyed heat treatable steel with a typical tensile strength of 900 -1200 N/mm².

Used for highly stressed components, where the combination of high strength with

tenaciousness is of utmost importance.

EX: axles, drive rods, crankshafts, pinions, gearwheels, linings, springs, saw blades, knifes

and scissors, bolt.

EUROPEAN GRADE: EN10083-3 / EN10277-5

42CrMo4 1.7225 42CrMoS4 1.7227

COMPARABLE GRADE

China USA Japan Germany India Korea Russia

GB SAE -AISI JIS DIN IS KS GOST

42CrMo 4140 SCM 440 42CrMo4 42Cr4Mo2 SCM 440 38ChM

CHEMICAL COMPOSITION

Element C% Si% Mn% P% S% Cr% Mo%

MIN 0.38 - 0.60 - 0.020 0.90 0.15

MAX 0.45 0.40 0.90 0.025 0.035 1.20 0.30

MECHANICAL PROPERTIES – Peeled +SH or Peeled and ground +SH+SL

Treatment Quenched and tempered +QT Soft annealed +A

Ø mm Rm (MPa) Rp0.2 (MPa) A5% Z% KV(J at 20°C) Hardness (HB)

16<Ø≤40 1000-1200 > 750 > 11 >45 >35 < 241

40<Ø≤100 900-1100 > 650 > 12 > 50 > 35 < 241

100<Ø≤160 800-950 > 550 > 13 >50 >35 < 241

160<Ø≤200 750-900 > 500 > 14 >55 >35 < 241

Different characteristics may be agreed (EX: B7 ASTM A193, EN 20898-1 class 10.9, 8.8,…)

HARDENABILITY (850°C - hardness HRC – distance mm)

HRC-mm Type 1.5 3 6 7 9 11 13 15 20 25 30 35 40 45 50

MAX 61 61 61 60 60 59 59 58 56 53 51 48 47 46 45

+H

MIN 53 53 52 51 49 43 40 37 34 32 31 30 30 29 29

HRC-mm Type 1.5 3 6 7 9 11 13 15 20 25 30 35 40 45 50

MAX 61 61 61 60 60 59 59 58 56 53 51 48 47 46 45

+HH

MIN 56 56 55 54 52 48 46 44 41 39 38 36 36 35 34

HIGH TEMPERATURE YIELD STRENGHT Rp0.2 EN 10269 QT condition (for information only)

°C 50 100 150 200 250 300 350 400 450 500

Rp0.2

720 702 677 640 602 562 5158 475 420 375

(MPa)

LOW TEMPERATURE IMPACT TEST EN 10269 QT condition (only for information)

°C +20 -40 -100

KV (J) > 50 > 40 > 27

STRUCTURE – Austenite grain size 5 or finer (EN ISO 643)

Degree of purity 8<Ø≤17 17<Ø≤35 35<Ø≤70 70<Ø≤100 100<Ø≤140 140<Ø≤200

DIN 50602 - K

K3≤30 K3≤40 K4≤35 K4≤40 K4≤45 K4≤50

Oxides

The data contained herein are intended as reference only and are subject to constant change.

Novacciai S.P.A. disclaims any and all liability for any consequences that may result from their use

You might also like

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- 37R 06Document8 pages37R 06mirakul100% (2)

- En 19Document1 pageEn 19CharminNo ratings yet

- About En19Document1 pageAbout En19ramanamurtytv7176No ratings yet

- Lastek 90 Ceweld - Croni 29-9 S - 2013-06-27Document1 pageLastek 90 Ceweld - Croni 29-9 S - 2013-06-27Niksa ZekicNo ratings yet

- Etchant Test On CastingsDocument2 pagesEtchant Test On CastingsHarshaVeeragandhamNo ratings yet

- Uporedna Tabela Za CelikeDocument6 pagesUporedna Tabela Za Celikesnuffit11No ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKiranNo ratings yet

- SINOXX 4116 Steel: Designation by StandardsDocument2 pagesSINOXX 4116 Steel: Designation by StandardsSamirNo ratings yet

- Mim-Material Specification and Applications: Material: Heat Treatable Steel Standards: Aisi 4140, Din 42crmo4, 1.7225Document1 pageMim-Material Specification and Applications: Material: Heat Treatable Steel Standards: Aisi 4140, Din 42crmo4, 1.7225ducthien_80No ratings yet

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsNo ratings yet

- En 19Document1 pageEn 19Parvee K Nakwal100% (1)

- Aerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Document6 pagesAerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Leandro González De CeccoNo ratings yet

- Charla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoDocument39 pagesCharla Ing. Andreas Hunger - Nuevas Tendencias en El ProcesoWalter-uniNo ratings yet

- Limarosta 312Document2 pagesLimarosta 312Burag HamparyanNo ratings yet

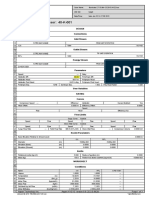

- DH 1400modDocument1 pageDH 1400modGopiNathNo ratings yet

- 1.7225 Material 42CrMo4 +QT Steel Chemical Composition, Equivalent, PropertiesDocument7 pages1.7225 Material 42CrMo4 +QT Steel Chemical Composition, Equivalent, PropertiesAdrian D.RazvanNo ratings yet

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDocument3 pagesDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadNo ratings yet

- High Tensile: Nearest StandardDocument4 pagesHigh Tensile: Nearest StandardtdfsksNo ratings yet

- Our Products: About Us What We Do About Us What We Do About Us What We Do About Us What We DoDocument4 pagesOur Products: About Us What We Do About Us What We Do About Us What We Do About Us What We DoThaw Zin HtayNo ratings yet

- Duplex 1.4662 UKDocument2 pagesDuplex 1.4662 UKtienNo ratings yet

- 42CrMo4 (EN 10083 3)Document2 pages42CrMo4 (EN 10083 3)GABRIEL IORDACHINo ratings yet

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocument1 page308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroNo ratings yet

- Material Specification Sheet Saarstahl - 36crnimo4Document1 pageMaterial Specification Sheet Saarstahl - 36crnimo4Anonymous rYZyQQot55No ratings yet

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- 4340Document1 page4340ralishNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- 3 SpringDocument66 pages3 Springall_meca_allNo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- 6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsDocument1 page6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsMadhu KumarNo ratings yet

- Kaiser Aluminum 6061 Pipe Tube PDFDocument2 pagesKaiser Aluminum 6061 Pipe Tube PDFgerrzen64No ratings yet

- High Tensile Alloy 4140Document1 pageHigh Tensile Alloy 4140browniezboyNo ratings yet

- SS 6mo - 1.4547Document1 pageSS 6mo - 1.4547f_riseNo ratings yet

- En 24Document1 pageEn 24V. A. TripathiNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxNo ratings yet

- UNS R30006 Steel GradesDocument3 pagesUNS R30006 Steel GradesRatnakar PatilNo ratings yet

- High Speed Steel PDFDocument1 pageHigh Speed Steel PDFYogesh PatelNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKarimulla ShaikNo ratings yet

- 4) ASTM A29 GR 4130 PDFDocument1 page4) ASTM A29 GR 4130 PDFchandraNo ratings yet

- Stainless Steel 422 Round BarDocument2 pagesStainless Steel 422 Round BarArun KumarNo ratings yet

- 17 4 PHDocument2 pages17 4 PHzaranrajputNo ratings yet

- Cast Materials: Sulzer PumpsDocument6 pagesCast Materials: Sulzer PumpsElmey Bin JulkeplyNo ratings yet

- Diffusion Hardfacing PlatesDocument8 pagesDiffusion Hardfacing Platesbalajiprasanna.kNo ratings yet

- Category SMAW Stick Electrodes Type Applications: WC Cr3C2 Fe NBDocument1 pageCategory SMAW Stick Electrodes Type Applications: WC Cr3C2 Fe NBmohamedNo ratings yet

- Stainless Steel Durax: Data SheetDocument2 pagesStainless Steel Durax: Data SheetkdvNo ratings yet

- RATNA 7014: Medium Heavy Coated, Iron Powder & Rutile Type Welding Electrode For High Deposition Efficiency 115% MinDocument1 pageRATNA 7014: Medium Heavy Coated, Iron Powder & Rutile Type Welding Electrode For High Deposition Efficiency 115% MinIkhsani IzaNo ratings yet

- En 8Document1 pageEn 8Devendera TripathiNo ratings yet

- Stianless SteelDocument1 pageStianless SteelusefiNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKiranNo ratings yet

- Tirasteel Machinery SteelDocument36 pagesTirasteel Machinery SteelAndieka Cool AndieNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- Section 2.0 Alloy SteelsDocument10 pagesSection 2.0 Alloy SteelsAloísio NascimentoNo ratings yet

- D.A.Cooper Sons Product Datasheet AISI SAE 4140 1Document1 pageD.A.Cooper Sons Product Datasheet AISI SAE 4140 1Muhamad Wahyu BudiawanNo ratings yet

- Euro 410 Ni MoDocument1 pageEuro 410 Ni MoMustafa OğuzhanNo ratings yet

- Welding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsFrom EverandWelding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsNo ratings yet

- 42 - Pe-P-Roa07114227006-Me-Dwg-003-01-E - Plan LegaturiDocument1 page42 - Pe-P-Roa07114227006-Me-Dwg-003-01-E - Plan LegaturiIoana PopescuNo ratings yet

- Ammonia TankDocument17 pagesAmmonia TankIoana PopescuNo ratings yet

- Air Cooled Heat ExchangersDocument6 pagesAir Cooled Heat ExchangersIoana PopescuNo ratings yet

- DS VFD PDFDocument2 pagesDS VFD PDFIoana PopescuNo ratings yet

- Stress Analysis of Piping SystemsDocument108 pagesStress Analysis of Piping SystemsShijumon KpNo ratings yet

- PSV Calculation Report - Liquid Relief Sizing Case: Const. VarDocument1 pagePSV Calculation Report - Liquid Relief Sizing Case: Const. VarIoana PopescuNo ratings yet

- Pump Sizing Calculation: Data FlowrateDocument4 pagesPump Sizing Calculation: Data FlowrateIoana PopescuNo ratings yet

- PSV Data Sheet UnwettedDocument7 pagesPSV Data Sheet UnwettedIoana PopescuNo ratings yet

- PSV 6r8 Api - 526lDocument1 pagePSV 6r8 Api - 526lIoana PopescuNo ratings yet

- PSV Data Sheet WettedDocument7 pagesPSV Data Sheet WettedIoana PopescuNo ratings yet

- Cars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleDocument5 pagesCars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleIoana PopescuNo ratings yet

- Sala Unirii PDFDocument1 pageSala Unirii PDFIoana PopescuNo ratings yet

- Flow1 PDFDocument1 pageFlow1 PDFIoana PopescuNo ratings yet

- Template - Hold UpDocument1 pageTemplate - Hold UpIoana PopescuNo ratings yet

- Dictionar Tehnic Roman Englez A IDocument798 pagesDictionar Tehnic Roman Englez A IIoana PopescuNo ratings yet

- Compressor: 40-K-001: Stream Name 131Document3 pagesCompressor: 40-K-001: Stream Name 131Ioana PopescuNo ratings yet

- Glycol Reboiler - Still Column PDFDocument3 pagesGlycol Reboiler - Still Column PDFIoana PopescuNo ratings yet

- TM 5 3895 358 14 and PDocument1 pageTM 5 3895 358 14 and PIoana PopescuNo ratings yet