Professional Documents

Culture Documents

Hydro MPCE 2 CRE152 U2 AAGA

Uploaded by

KrrishOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydro MPCE 2 CRE152 U2 AAGA

Uploaded by

KrrishCopyright:

Available Formats

Company name: Orient Energy Systems (Pvt.) Ltd.

Created by: Ahmed Raza

Phone: +92-345-8229405

Email: raza.ahmed@orient-power.com

Date: 22/01/2020

Qty. Description

1 Hydro MPC-E 2 CRE15-2 U2 A-A-G-A

Note! Product picture may differ from actual product

Product No.: 99187158

The pressure booster system Hydro MPC-E, supplied as compact assembly, maintains a constant pressure

through continuous adjustment of the speed of the pumps.

The system performance is adapted to the demand through cutting in/out the required number of pumps and

through parallel control of the pumps in operation.

Pump changeover is automatic and depends on load, time and fault.

From 0.37 to 11 kW, the booster set is equipped with CRE pumps with electronically commutated permanent

magnet motor with extremely high efficiency. The total efficiency of this motor including the frequency converter is

better than the IE4 level in IEC60034-31, even though this standard only applies for the motor.

From 15 to 22 kW the booster is equipped with CRE pumps with integrated frequency controlled motors. The total

efficiency of this motor including the frequency converter is better than the IE3 level in IEC60034-31, even though

this standard only applies for the motor.

From 30 kW the booster is equipped with CR pumps connected to an external Grundfos CUE frequency converter

(one per pump).

The system consists of these parts:

The pumps are equipped with a service-friendly cartridge shaft seal, HQQE (SiC/SiC/EPDM).

- Two manifolds of galvanized steel.

Base frame of galvanized steel up to CR 90; above CR90 the pumps are placed

on a galvanized I-Beam frame.

One non-return valve and two isolating valves for each pump.

Adapter with isolating valve for connection of diaphragm tank.

Pressure gauge and pressure transmitter (analog output 4-20 mA).

Control MPC in a steel cabinet, IP 54, including main switch, all required fuses,

motor protection, switching equipment and microprocessor-controlled CU 352.

Dry-running protection and diaphragm tank are available according to the list of accessories.

Pump operation is controlled by Control MPC with the following functions:

- Intelligent multi-pump controller, CU 352.

Constant pressure control through continuously variable adjustment of the speed

of each individual pump.

PID controller with adjustable PI parameters (Kp + Ti).

Constant pressure at setpoint, independent of inlet pressure.

On/off operation at low flow.

Automatic cascade control of pumps for optimum efficiency.

Selection of min. time between start/stop, automatic pump changeover and pump

priority.

Automatic pump test function to prevent idle pumps from seizing up.

Possibility of standby pump allocation.

Possibility of backup sensor (redundant primary sensor).

Manual operation.

Possibility of external setpoint influence

Log function

Setpoint Ramp

Possibility of digital remote-control functions:

Printed from Grundfos Product Centre [2020.01.001] 1/6

Company name: Orient Energy Systems (Pvt.) Ltd.

Created by: Ahmed Raza

Phone: +92-345-8229405

Email: raza.ahmed@orient-power.com

Date: 22/01/2020

Qty. Description

system on/off,

max., min. or user-defined duty

up to 6 alternative setpoints.

Digital inputs and outputs can be configured individually.

Pump and system monitoring functions:

minimum and maximum limits of current value

inlet pressure

motor protection.

Sensors monitored against malfunction.

Alarm log with the previous 24 warnings/alarms.

Display and indication functions:

Colour screen display

green indicator light for operating indications and red indicator light for fault

indications

potential-free changeover contacts for operation and fault.

Grundfos bus communication.

It is possible to add CIM communication modules for communicating with Scada/BMS.

Pumps, piping, cabling complete as well as Control MPC are mounted on the base frame.

The booster system has been preset and tested.

Flow media: Water

Liquid temperature: 5 °C .. 60 °C

Max operating pressure: 16 bar

Mains supply: 380-415 V

Starting main: Electronically

Rated current: 12.4 A

Suction port: DN 80

Discharge port: DN 80

Net weight: 214 kg

Gross weight 324 kg

Printed from Grundfos Product Centre [2020.01.001] 2/6

Company name: Orient Energy Systems (Pvt.) Ltd.

Created by: Ahmed Raza

Phone: +92-345-8229405

Email: raza.ahmed@orient-power.com

Date: 22/01/2020

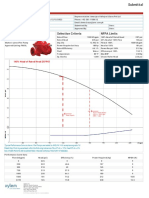

99187158 Hydro MPC-E 2 CRE15-2 U2 A-A-G-A 50 Hz

H Hydro MPC-E 2 CRE15-2 U2 A-A-G-A, 50Hz eta

[ft] [%]

None

Losses in fittings and valves not included

Q = 100 US GPM

H = 80 ft

n = 95 % / 3336 rpm

Pumped liquid = Water

140 Liquid temperature during operation = 20 °C

100 % Density = 998.2 kg/m³

130

120 95 %

110 90 %

100 100

90 90

80 %

80 80

70 70

70 %

60 60

50 60 % 50

40 40

50 %

30 30

40 %

20 20

10 25 % 10

16 % Eta pump = 68.7 %

Eta pump+motor+freq.converter = 62.5 %

0 0

0 20 40 60 80 100 120 140 160 180 200 220 Q [US GPM]

P NPSH

[kW] [ft]

7 35

6 P1 (motor+freq.converter)30

5 P2 25

4 20

3 15

2 10

1 P1 (motor+freq.converter) = 2.408 kW 5

P2 = 2.194 kW

NPSH = 10.58 ft

0 0

Printed from Grundfos Product Centre [2020.01.001] 3/6

Company name: Orient Energy Systems (Pvt.) Ltd.

Created by: Ahmed Raza

Phone: +92-345-8229405

Email: raza.ahmed@orient-power.com

Date: 22/01/2020

H Hydro MPC-E 2 CRE15-2 U2 A-A-G-A, 50Hz eta

Description Value [ft] [%]

None

General information: Losses in fittings and valves not included

Hydro MPC-E 2 CRE15-2 U2 Q = 100 US GPM

Product name: A-A-G-A 140 H = 80 ft

100 %

n = 95 % / 3336 rpm

130

Product No: 99187158 Pumped liquid = Water

120 95 % Liquid temperature during operation = 20 °C

EAN number: 5712608336010 Density = 998.2 kg/m³

5712608336010 110 90 %

Technical: 100 100

Actual calculated flow: 100 US GPM 90 80 % 90

Max flow: 250 US GPM 80 80

Max flow system: 125 US GPM 70 70

70 %

Resulting head of the pump: 80 ft

60 60

Head max: 135.8 ft

50 60 % 50

Main pump name: CRE15-2

40 40

Main pump No: 99071524 50 %

30 30

Number of pumps: 2 40 %

Non-ret. valve: at discharge side 20 20

Materials: 10 25 % Eta pump = 68.7 % 10

16 %

Eta pump+motor+freq.converter = 62.5 %

Manifolds: Galvanized steel 0 0

0 50 100 150 200 Q [US GPM]

Installation:

P NPSH

Maximum operating pressure: 16 bar [kW] [ft]

Maximum permissible inlet

pressure: 11.9 bar 6 P1 (motor+freq.converter)

30

Manifold inlet: DN 80 5 P2 25

Manifold outlet: DN 80 4 20

Pressure rating: PN 16

DN 16

PN 80

1160

755

1150

950

210

3 15

Earth connection: PE

2 10

Liquid: P1 (motor+freq.converter) = 2.408 kW

Pumped liquid: Water 1 P2 = 2.194 kW 5

NPSH = 10.58 ft

Liquid temperature range: 5 .. 60 °C 0 0

Selected liquid temperature: 20 °C

Density: 998.2 kg/m³

Electrical data: 210

Power (P2) main pump: 3 kW

Mains frequency: 50 Hz

Rated voltage: 3 x 380-415 V

Rated current of system: 12.4 A

Start. method: electronically

1460

Enclosure class (IEC 34-5): IP54

825

EMC Certificate - Hydro MPC 1

Radio interference supression:

DN 80

PN 16

[2007]

Controls:

160

Control type: E 755 950

Tank: 1160 1150

Diaphragm tank: No

Others:

Basis plant: Y

Net weight: 214 kg

Gross weight: 324 kg L1 L1

Product range: South Europe L2 RCD L2

L3 L3

PE

Control cabinet

Printed from Grundfos Product Centre [2020.01.001] 4/6

Company name: Orient Energy Systems (Pvt.) Ltd.

Created by: Ahmed Raza

Phone: +92-345-8229405

Email: raza.ahmed@orient-power.com

Date: 22/01/2020

99187158 Hydro MPC-E 2 CRE15-2 U2 A-A-G-A 50 Hz

PN 16

DN 80

210

1150

950

1460 1160

755

160

825

Note! All units are in [mm] unless others are stated.

Disclaimer: This simplified dimensional drawing does not show all details.

Printed from Grundfos Product Centre [2020.01.001] 5/6

Company name: Orient Energy Systems (Pvt.) Ltd.

Created by: Ahmed Raza

Phone: +92-345-8229405

Email: raza.ahmed@orient-power.com

Date: 22/01/2020

99187158 Hydro MPC-E 2 CRE15-2 U2 A-A-G-A 50 Hz

L1

L2

L3

Control cabinet

RCD

PE

L1

L2

L3

Note! All units are in [mm] unless others are stated.

Printed from Grundfos Product Centre [2020.01.001] 6/6

You might also like

- Hydro Mpce 2 Crie203Document6 pagesHydro Mpce 2 Crie203KrrishNo ratings yet

- Hydro Mpce 4 Crie 204Document5 pagesHydro Mpce 4 Crie 204KrrishNo ratings yet

- Grundfos Hydro MPC e Cre 32-5-2 Articulo 96941373 Motor MobDocument6 pagesGrundfos Hydro MPC e Cre 32-5-2 Articulo 96941373 Motor MobRicardo Ostos LopezNo ratings yet

- Poziţie Cant. Descriere Hydro MPC-F 2 CR5-20 U2 D-B-G-A: Nume Companie: Creat De: Telefon: DateDocument4 pagesPoziţie Cant. Descriere Hydro MPC-F 2 CR5-20 U2 D-B-G-A: Nume Companie: Creat De: Telefon: Datekimik47No ratings yet

- Hydro MPC-F 2 CR32-3 U2 D-B-G-ADocument8 pagesHydro MPC-F 2 CR32-3 U2 D-B-G-ADiana SubaricNo ratings yet

- HyMPCE G 3CRE 101 3x4005060 DLDocument10 pagesHyMPCE G 3CRE 101 3x4005060 DLRidken SdddNo ratings yet

- Hydro Mpc-E 2 Crie20-4Document3 pagesHydro Mpc-E 2 Crie20-4kimik47No ratings yet

- Hydro MPC-E 2 CRIE3-5 Pressure Booster SystemDocument5 pagesHydro MPC-E 2 CRIE3-5 Pressure Booster SystemMajid RezaeiNo ratings yet

- User Manual: HGM1780 Genset ControllerDocument19 pagesUser Manual: HGM1780 Genset Controlleralfan nashNo ratings yet

- INJkon 01 4.0 ManualDocument93 pagesINJkon 01 4.0 ManualJansirani SelvamNo ratings yet

- Data Download HGM1770 V1.6 enDocument19 pagesData Download HGM1770 V1.6 enJohn GarnetNo ratings yet

- INJkon 00 ManualDocument27 pagesINJkon 00 ManualJam AnjumNo ratings yet

- Dkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionDocument2 pagesDkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionJorge Omar ToroNo ratings yet

- BLOkon 01 ManualDocument34 pagesBLOkon 01 ManualNeimar Topanotti DagostinNo ratings yet

- QSK60 Series: Diesel Generator SetDocument4 pagesQSK60 Series: Diesel Generator Setkumar aNo ratings yet

- Electroni ManualDocument44 pagesElectroni ManualMukuru Nto MwongoNo ratings yet

- HGM6300D V2.1 enDocument34 pagesHGM6300D V2.1 enSteven BaynesNo ratings yet

- C250D5PDocument4 pagesC250D5PQuỳnh KhaNo ratings yet

- User Manual: HGM1790N Genset ControllerDocument27 pagesUser Manual: HGM1790N Genset Controllereduardoguerra155_604No ratings yet

- Operation Manual: For Intelligent Dispensing Peristaltic Pump WT300F, WT600FDocument48 pagesOperation Manual: For Intelligent Dispensing Peristaltic Pump WT300F, WT600FWilliams RobinsonNo ratings yet

- QSK19 Series: Diesel Generator SetDocument4 pagesQSK19 Series: Diesel Generator SetGrace RuthNo ratings yet

- Manual Smartgen HGM 6320 - Ced 100ksDocument35 pagesManual Smartgen HGM 6320 - Ced 100ksddedaniel80% (5)

- 307 DataDocument2 pages307 DataynadeemNo ratings yet

- Dkg-307 Automatic Mains Failure Unit: DescriptionDocument2 pagesDkg-307 Automatic Mains Failure Unit: DescriptionThao Nguyen XuanNo ratings yet

- User Manual: MGC120 Petrol Genset ControllerDocument20 pagesUser Manual: MGC120 Petrol Genset ControlleraltieresmirandaNo ratings yet

- L8.9 Series: Diesel Generator SetDocument4 pagesL8.9 Series: Diesel Generator SetVIET TRIEU HUYNHNo ratings yet

- Smart Gen AmericaDocument20 pagesSmart Gen AmericaDenny KusumaNo ratings yet

- B2-Lehe4748-01 - Emcp3.3Document8 pagesB2-Lehe4748-01 - Emcp3.3Ali H. Al-ZowayedNo ratings yet

- Hritik Baral - ES - CaseStudyDocument10 pagesHritik Baral - ES - CaseStudyHemanga RanaNo ratings yet

- Secure Meters CatalogueDocument40 pagesSecure Meters CatalogueHarman Preet100% (1)

- 250kva Diesel Generator SetDocument4 pages250kva Diesel Generator SetZez SamuelNo ratings yet

- Diesel Generator Set PDFDocument4 pagesDiesel Generator Set PDFudhayNo ratings yet

- DG 180 - 225 kVADocument4 pagesDG 180 - 225 kVAmuraliNo ratings yet

- QSN14 Series: Diesel Generator SetDocument4 pagesQSN14 Series: Diesel Generator SetHemant KumarNo ratings yet

- Diesel Generator Set QSK60 Series: Specification SheetDocument4 pagesDiesel Generator Set QSK60 Series: Specification Sheetkrish659No ratings yet

- ST500M/H Series Motor ControllerDocument42 pagesST500M/H Series Motor Controllertulube12350% (4)

- DKG 509 - UserDocument56 pagesDKG 509 - Userhackerland_1No ratings yet

- Genset AMF Controller DKG-309Document2 pagesGenset AMF Controller DKG-309SAMEERNo ratings yet

- Microtapper controller operational manualDocument49 pagesMicrotapper controller operational manualgorakhdagade100% (7)

- Dkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesDocument59 pagesDkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesAziz ArrahalNo ratings yet

- TMC5072 Datasheet Rev1.25Document106 pagesTMC5072 Datasheet Rev1.25Florian OuvrardNo ratings yet

- Dkg-507-J Automatic Mains Failure Unit With J1939 Interface: DescriptionDocument2 pagesDkg-507-J Automatic Mains Failure Unit With J1939 Interface: DescriptionThao Nguyen XuanNo ratings yet

- Kg-545 Automatic Mains Failure UnitDocument35 pagesKg-545 Automatic Mains Failure UnitJack GehlotNo ratings yet

- Course Code: CSE360 Course Title: Computer Architecture Section: 02 Project Title: Suggest and Design A Minimal CPU Group NumberDocument7 pagesCourse Code: CSE360 Course Title: Computer Architecture Section: 02 Project Title: Suggest and Design A Minimal CPU Group NumberrimonNo ratings yet

- Dkg-507 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocument54 pagesDkg-507 Automatic Mains Failure Unit: Canbus and Mpu VersionsFuqqi BhaiNo ratings yet

- Dkg-707 Multi Genset Parallelling Unit With J1939 Interface: Standard FeaturesDocument4 pagesDkg-707 Multi Genset Parallelling Unit With J1939 Interface: Standard FeaturesnebiyouNo ratings yet

- Generator 307 USERDocument54 pagesGenerator 307 USERLiviu PopaNo ratings yet

- Dkg-547 Automatic Mains Failure Unit With J1939 Interface: DescriptionDocument2 pagesDkg-547 Automatic Mains Failure Unit With J1939 Interface: DescriptionabotalebNo ratings yet

- 3500B Generator Set Adem Ii EcmDocument4 pages3500B Generator Set Adem Ii Ecmcastor201086% (7)

- Controlador Bomba Jockey Fta 550fDocument7 pagesControlador Bomba Jockey Fta 550fRubén VélezNo ratings yet

- HGM1780 V1.4 enDocument19 pagesHGM1780 V1.4 enSergio Ricardo IbañezNo ratings yet

- QSL9 Series: Diesel Generator SetDocument4 pagesQSL9 Series: Diesel Generator Setkumar aNo ratings yet

- C365D5P C400D5PDocument4 pagesC365D5P C400D5PQuỳnh KhaNo ratings yet

- PSBU - 012 - QSN14 365-400kVA - Rev-3 - 3Document4 pagesPSBU - 012 - QSN14 365-400kVA - Rev-3 - 3Ngoc Duy NguyenNo ratings yet

- DKG207 PDFDocument2 pagesDKG207 PDFRoberto MerizaldeNo ratings yet

- 275-300-320 KvaDocument4 pages275-300-320 KvaLankapati RraavanNo ratings yet

- DC100D Genset Controller User Manual V1.1Document56 pagesDC100D Genset Controller User Manual V1.1Carlos Di Martino100% (1)

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Grundfos Pump CRN2 CRN2G Parts D1101Document6 pagesGrundfos Pump CRN2 CRN2G Parts D1101KrrishNo ratings yet

- CCM1 - Sump Pump 1Document4 pagesCCM1 - Sump Pump 1KrrishNo ratings yet

- CCM1 - Sump Pump 1Document4 pagesCCM1 - Sump Pump 1KrrishNo ratings yet

- ECHm4-60-F 2024-03-05 220645 017Document6 pagesECHm4-60-F 2024-03-05 220645 017KrrishNo ratings yet

- CCM1 - Sump Pump 1Document4 pagesCCM1 - Sump Pump 1KrrishNo ratings yet

- Addressing Dewatering Challenges With Intelligent Drive Solutions MiningDocument2 pagesAddressing Dewatering Challenges With Intelligent Drive Solutions MiningKrrishNo ratings yet

- CCM1 - Sump Pump 1Document4 pagesCCM1 - Sump Pump 1KrrishNo ratings yet

- CCM1 - Sump Pump 1Document4 pagesCCM1 - Sump Pump 1KrrishNo ratings yet

- SV 055 iP5A 2 N O L (Class) : Model NumberDocument1 pageSV 055 iP5A 2 N O L (Class) : Model NumberAbdul RafaeNo ratings yet

- Hydro MPCE 2 CRE152 U2 AAGADocument6 pagesHydro MPCE 2 CRE152 U2 AAGAKrrishNo ratings yet

- AC Fire SelectorDocument1 pageAC Fire SelectorKrrishNo ratings yet

- AC Fire SelectorDocument1 pageAC Fire SelectorKrrishNo ratings yet

- AC Fire SelectorDocument1 pageAC Fire SelectorKrrishNo ratings yet

- AC Fire SelectorDocument1 pageAC Fire SelectorKrrishNo ratings yet

- SL1808075451DCDocument10 pagesSL1808075451DCKrrishNo ratings yet

- AC Fire SelectorDocument1 pageAC Fire SelectorKrrishNo ratings yet

- TAX RATE CARD 2021-22 Income Tax Withholding Rates Sales Tax Withholding RatesDocument14 pagesTAX RATE CARD 2021-22 Income Tax Withholding Rates Sales Tax Withholding RatesTax Management ConsultingNo ratings yet

- Flygt A C Series Large Split Case BrochureDocument4 pagesFlygt A C Series Large Split Case BrochureKrrishNo ratings yet

- Technical Data: 10SV08N030TDocument3 pagesTechnical Data: 10SV08N030TKrrishNo ratings yet

- Technical Data: 10SV08N030TDocument3 pagesTechnical Data: 10SV08N030TKrrishNo ratings yet

- Submersible pumps for municipal sewage and surface water applicationsDocument4 pagesSubmersible pumps for municipal sewage and surface water applicationsAhmed RazaNo ratings yet

- Flygt A-C Series: WCXH Axial Flow PumpsDocument4 pagesFlygt A-C Series: WCXH Axial Flow PumpsKrrishNo ratings yet

- Grundfos Distributed Pumping: Intelligent Water-Cooling SystemDocument21 pagesGrundfos Distributed Pumping: Intelligent Water-Cooling SystemKrrishNo ratings yet

- Flygt A-C Series Dry Pit Pumps: Reliable and Efficient Fluid Handling SolutionsDocument4 pagesFlygt A-C Series Dry Pit Pumps: Reliable and Efficient Fluid Handling SolutionsKrrishNo ratings yet

- StandbyDocument1 pageStandbyKrrishNo ratings yet

- DP DPKDocument70 pagesDP DPKKrrishNo ratings yet

- System Syzer TEH-175ADocument8 pagesSystem Syzer TEH-175AMario JoséNo ratings yet

- Navigational Equipment Stock ListDocument10 pagesNavigational Equipment Stock ListJahangir HosenNo ratings yet

- Generator Power Cable Installation GuideDocument34 pagesGenerator Power Cable Installation GuideLidef SellenrofNo ratings yet

- Toshiba 42pw33q - S Ch. Pw33 SchematicsDocument18 pagesToshiba 42pw33q - S Ch. Pw33 SchematicstodorloncarskiNo ratings yet

- Atlas Copco GA 90 160 AIF 056813 PDFDocument85 pagesAtlas Copco GA 90 160 AIF 056813 PDFjackyt0978% (9)

- Grating Specification PDFDocument14 pagesGrating Specification PDFClint GarciaNo ratings yet

- NC250 Engine ManualDocument60 pagesNC250 Engine ManualTallerSoldaduraAluminioInoxidable67% (3)

- Demo 8Document22 pagesDemo 8Kushal NNo ratings yet

- Schedule of Rate for Standard Stock Materials Common SR 2021-22 (11 kV SystemDocument27 pagesSchedule of Rate for Standard Stock Materials Common SR 2021-22 (11 kV SystemkaleemNo ratings yet

- Liebert LTS Load Transfer SwitchDocument6 pagesLiebert LTS Load Transfer SwitchJavier RuizNo ratings yet

- Datos Planta LL2014LDocument4 pagesDatos Planta LL2014LKelly MàrquezNo ratings yet

- Hidráulica BásicaDocument210 pagesHidráulica BásicaAlfredo GalarzaNo ratings yet

- AO Guia de Semiconductores PDFDocument20 pagesAO Guia de Semiconductores PDFviejojeteNo ratings yet

- Asme B18.6.4Document50 pagesAsme B18.6.4Ramón Roca70% (10)

- Importance of Dies Elongation Matching Machine ElongationDocument2 pagesImportance of Dies Elongation Matching Machine ElongationZeeshan PathanNo ratings yet

- Einaldrawing: Shipyard: Jinling ShipyardDocument29 pagesEinaldrawing: Shipyard: Jinling ShipyardVinay Kumar NeelamNo ratings yet

- EM730UserManual (V100)Document345 pagesEM730UserManual (V100)Salman SakibNo ratings yet

- IRF Inductors: Epoxy Conformal Coated Uniform Roll CoatedDocument3 pagesIRF Inductors: Epoxy Conformal Coated Uniform Roll CoatedΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- Manual S 821 826Document4 pagesManual S 821 826Javi González100% (1)

- 2002 Arctic Cat Pantera 600 EFI SNOWMOBILE Service Repair Manual PDFDocument65 pages2002 Arctic Cat Pantera 600 EFI SNOWMOBILE Service Repair Manual PDFusekjdmmNo ratings yet

- BA7500 ManDocument6 pagesBA7500 Manspyglass187No ratings yet

- Motor Suppression:: ImportantDocument2 pagesMotor Suppression:: ImportantDino NoomNo ratings yet

- Accessories: Test and Training Set Switchgear SimulatorDocument4 pagesAccessories: Test and Training Set Switchgear SimulatorJoseph KrauseNo ratings yet

- Preliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingDocument1 pagePreliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingbarrosojmsNo ratings yet

- Leon MK1 Cruise Control Guide - Pic Heavy - SEAT CupraDocument37 pagesLeon MK1 Cruise Control Guide - Pic Heavy - SEAT CupraProgramkoNo ratings yet

- A It 2005 CatalogDocument64 pagesA It 2005 Catalogcristiannnnnnnnnn100% (6)

- WEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTDocument2 pagesWEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTLuanNo ratings yet

- 7KM31200BA011DA0 Datasheet enDocument6 pages7KM31200BA011DA0 Datasheet enAlfonsNo ratings yet

- Multi-Core Processor Technology:: Maximizing CPU Performance in A Power-Constrained WorldDocument23 pagesMulti-Core Processor Technology:: Maximizing CPU Performance in A Power-Constrained WorldPushpakumara EhrsNo ratings yet

- Mm-Etso-001 (2) - 16 05 13Document36 pagesMm-Etso-001 (2) - 16 05 13Anderson RamalhoNo ratings yet