Professional Documents

Culture Documents

Model HAN-L5 Wall Control Wiring Diagram

Uploaded by

onealOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model HAN-L5 Wall Control Wiring Diagram

Uploaded by

onealCopyright:

Available Formats

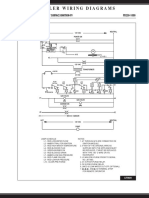

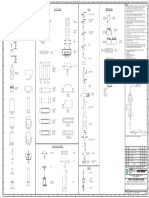

MODEL HAN-L5 WALL CONTROL

LEGEND

ELECTRICAL WIRING DIAGRAM WITH HAN-L5 CONTROL WITH

FL - LOW FAN SPEED AUTO HIGH MED LOW

FAN/COOL/AUTO/HEAT AND AUTO CONTINUOUS FAN OPTION.

RUN

BROKEN LINES INDICATE FM - MEDIUM FAN SPEED

FAN COOL AUTO HEAT

FH - HIGH FAN SPEED

FIELD WIRING. RH - HEAT / REV. VALVE TIMER

N

RC - DO NOT USE FUSE

L1

CO - COMPRESSOR RELAY 10 A

L2

N - NEUTRAL TERMINAL

L3

A - 240V ACTIVE TERMINAL E

OPTIONAL REMOTE SENSOR 24 - SUPPLY TERMINAL ON

OFF CAP CAP

FOR "COMP" & "HEAT"

THE REMOTE SENSOR IS SUPPLIED WITH LF - ON FOR CONTINUOUS

A 10 METRE CABLE AND A PLUG TO FAN ON HEAT. YELLOW YELLOW

CMC

CONNECT THE SENSOR TO THE PCB-058 REMOVE FOR AUTO OFM M OFM M

POWER BOARD.

NGE E

NGE E

FAN ON HEAT.

W RED

W RED

PL

PL

PLUG

H

R

R

BROWN

BROWN

IT

IT

WHEN USING A REMOTE SENSOR DIP SW 9

PU

PU

E

E

ON THE REAR OF THE CONTROL MUST BE

ORA

ORA

ON. TO DISABLE THE SENSOR IN THE HAN-L5 CM M

SWITCH DIP SW 8 OFF. IF DIP SW 8 & SW 9

ARE BOTH SWITCHED ON THE TEMPERATURE

SENSORS WILL BOTH BE ACTIVE AND AVERAGE.

CONTROLLER POWER BOARD

CCH HI MED LOW HI MED LOW

FOR FURTHER INFORMATION REFER TO HAN-L5

INSTALLATION INSTRUCTIONS. INSTALLED AT INDOOR FAN

COIL UNIT.

PLUG CN-2 - REVERSING VALVE SELECTION PLUG.

SELECT HERE WITH 2 PIN JUMPER FOR EITHER CONNECT SPEED SELECTED ONLY.

REVERSE ON HEAT (AS SUPPLIED) OR MOVE JOINING OF UNUSED WIRES

JUMPER TO BRIDGE LOWER 2 PINS FOR REVERSE WILL DAMAGE THE MOTOR.

NOTE 1 - LINKS. ON COOL.

HEAT ACTIVE

WHEN USING FAN OUTPUTS TO OPERATE FOR CONTINUOUS FAN OPERATION

FOR FULL 240V CONTROL, LEAVE LINKS ON HEAT, MOVE JUMPER TO BRIDGE

BETWEEN TERMINALS L-F-24. EXTERNAL FAN RELAYS OR LOW VOLTAGE

PINS LF.

PCB. REMOVE JUMPER SK.

FOR SYSTEMS REQUIRING 24V OUTPUTS

CN-F CONNECT PLUG FOR PARALLEL FAN RV

FOR COMPRESSOR & REVERSING VALVE, ACCESSORY CONTROL BOARD t

S.K 2 1

REMOVE LINK BETWEEN F & 24 AND LOW M

2S RSD OPTION (RELAY SHUT DOWN).

SUPPLY 24V TO TERMINAL 24. FL PINS MUST BE BRIDGED WHEN DE-ICE

FOR SYSTEMS REQUIRING 24V FAN MEDIUM NOT REQUIRED. CONTROL

FM

CN-F

COMP2 COMP

OUTPUTS, REMOVE LINK BETWEEN L & HIGH CN-12V PLUG.

F AND SUPPLY 24V TO TERMINAL F. FH PLUG HERE WHEN USING HANWEST

RSD CN-12V CN-TH2

FOR SYSTEMS REQUIRING 24V ON ALL ZSU-040 ZONE SWITCH UNIT. PINS

RV 1 & 2 MUST BE BRIDGED WHEN HP

OUTPUTS, REMOVE LINK BETWEEN L & NOT REQUIRED.

F, LEAVE LINK BETWEEN F & 24 AND CO RH SYSTEM WARM UP HP/LP

SUPPLY 24V TO EITHER TERMINAL F CN-TH2 PLUG. EVAP. COIL

SENSOR

N

CN-2

SENSOR

BEAD

OR 24. CO-2

RELAY

L RC LP CMC

CN-TH1 CSD

F OPTIONAL REMOTE SENSOR

24 CN-TH1 PLUG. DELAY ON HP

STANDARD REMOTE SENSOR PLUG. MAKE TIMER

NOTE 2 - SYSTEM WARM UP ACCELERATOR OPTIONAL. HP/LP

LINKS CSD OPTION - (CONTROL SHUT DOWN).

FUSE

SENSING BULB LOCATION. PLUG PINS MUST BE BRIDGED WHEN

NOT REQUIRED

IT IS ESSENTIAL THAT THE SENSOR IS LOCATED WHERE THE LP CMC2

HOT GAS ENTERS ONE OF THE REFRIGERANT CIRCUITS IN THE 10 OR 25 METRE LEAD

EVAPORATOR. GENTLY OPEN THE FINS IN THE INDOOR COIL

ON THE LEAVING AIR SIDE AND IMPLANT THE SENSOR IN THE

BROWN

HIGH

COIL AS CLOSE AS POSSIBLE TO THE COPPER TUBES. IT IS NOT PLUG

RECOMMENDED THAT THE SENSOR BE CLIPPED TO A RETURN IFM CAP

BEND AS POOR HEAT TRANSFER WILL PREVENT CORRECT

MED

OPERATION OF THE CONTROL. DO NOT INSTALL ON THE RED

INDOOR COIL SUCTION (LARGE) HEADER OR PREMATURE FAN YELLOW/WHITE

START MAY OCCUR. THE WARM UP ACCELERATOR DOES

LOW

NOT OPERATE ON THE COOLING CYCLE. WHITE

PCB-058V2/2S BLUE

NEUT

You might also like

- U Board 2Document2 pagesU Board 2PERABNo ratings yet

- Boiler wiring diagram decoderDocument2 pagesBoiler wiring diagram decoderDhenil ManubatNo ratings yet

- NCC Limited Project Documents For ApprovalDocument16 pagesNCC Limited Project Documents For Approvalnutral powertechNo ratings yet

- P68C Cockpit PanelsDocument2 pagesP68C Cockpit PanelsHistoric ArchivesNo ratings yet

- Diagrama ElectricoDocument1 pageDiagrama ElectricoLuis Angel Calderon AlarconNo ratings yet

- HT 34 VVVF Ups Control PanelDocument12 pagesHT 34 VVVF Ups Control Panelganesh panditNo ratings yet

- Onkyo SL105_HTP-2 Subwoofer system smDocument19 pagesOnkyo SL105_HTP-2 Subwoofer system smlasser22832165No ratings yet

- Block Diagram, Ex-800: Power Amp Board, Both CHDocument6 pagesBlock Diagram, Ex-800: Power Amp Board, Both CHcesar mierNo ratings yet

- HFDSR - 1500kw 6kv Drwg.Document4 pagesHFDSR - 1500kw 6kv Drwg.Sulistyono SulistyonoNo ratings yet

- BX 524Document18 pagesBX 524Александр КарпецNo ratings yet

- Marantz SR 4500 Service ManualDocument84 pagesMarantz SR 4500 Service ManualsrinivasanNo ratings yet

- Service Manual: L1G/N1G /N1B/U1B /N1SDocument100 pagesService Manual: L1G/N1G /N1B/U1B /N1SLeapfrogNo ratings yet

- Skema Audio CarDocument1 pageSkema Audio CarValentVeeNo ratings yet

- Diagram - Cummins ISC/ISL Electrical Schematic P94-6015 C 01Document6 pagesDiagram - Cummins ISC/ISL Electrical Schematic P94-6015 C 01eng_hamada_4u100% (1)

- MONO & BIFASICO Diagrama de LigacaoDocument2 pagesMONO & BIFASICO Diagrama de LigacaoAlessandro GuimaraesNo ratings yet

- HT34 Control PanelDocument19 pagesHT34 Control PaneljhfbtyNo ratings yet

- Legends and Symbols: Legends and Symbols:: Lighting Layout Plan Power Layout PlanDocument3 pagesLegends and Symbols: Legends and Symbols:: Lighting Layout Plan Power Layout PlanRoel Dylan A. MesiasNo ratings yet

- Porsche 928 1979 Current Flow DiagramDocument23 pagesPorsche 928 1979 Current Flow DiagramOscar HamerNo ratings yet

- Ocp-100 Operation Us 01Document46 pagesOcp-100 Operation Us 01Javier Sanchez SanchezNo ratings yet

- Refueling PanelDocument1 pageRefueling PanelAri WibowoNo ratings yet

- Tesla Model YDocument1 pageTesla Model YlinzeNo ratings yet

- Av 9000Document49 pagesAv 9000srinivasanNo ratings yet

- Electrical Symbols Legend and AbbreviationsDocument5 pagesElectrical Symbols Legend and AbbreviationsjorgeNo ratings yet

- 757 Schematics Layout 1Document25 pages757 Schematics Layout 1hariharanjack100% (7)

- GE AMX4 Block DiagramsDocument9 pagesGE AMX4 Block Diagramszach tuttle100% (1)

- Well Area ModifiedDocument10 pagesWell Area ModifiedMuhammad IjazNo ratings yet

- As DG Nfpa Vacuum SystemsDocument1 pageAs DG Nfpa Vacuum SystemsZulfan STNo ratings yet

- الرموز الكهربائية المستخدمة في رسم المخططات الكهربائية PDFDocument12 pagesالرموز الكهربائية المستخدمة في رسم المخططات الكهربائية PDFAbdullah TalibNo ratings yet

- Schematic Hxhd200a8 - PipDocument1 pageSchematic Hxhd200a8 - PipPaulKajzerNo ratings yet

- Caja Fusible KiaDocument4 pagesCaja Fusible KiaAndrésNo ratings yet

- Mir d245s & d45ks Rev.2Document1 pageMir d245s & d45ks Rev.2open hartigNo ratings yet

- MV Agusta 910 989 1078 Brutale Motorcycles Wiring Diagram PDFDocument2 pagesMV Agusta 910 989 1078 Brutale Motorcycles Wiring Diagram PDFmotoadictostallerNo ratings yet

- 1x85kw Gulmi MHPDocument34 pages1x85kw Gulmi MHPPritam SinghNo ratings yet

- Marantz SR-8002 Service ManualDocument203 pagesMarantz SR-8002 Service ManualManoel CesarNo ratings yet

- SD921 - Head LampsDocument2 pagesSD921 - Head Lampsjanuar1983No ratings yet

- Toyota Avensis Verso 2001 TVSS IV-S RHD Electrical Wiring DiagramDocument6 pagesToyota Avensis Verso 2001 TVSS IV-S RHD Electrical Wiring Diagram1percentninjaNo ratings yet

- 3a Prof Ata 71 Thru 80 Jt9dDocument88 pages3a Prof Ata 71 Thru 80 Jt9dDiego Ruddy Arcaine ZegarrundoNo ratings yet

- Your Basic Refrigeraion System: SVASD - MAY 26, 2011Document71 pagesYour Basic Refrigeraion System: SVASD - MAY 26, 2011RASHEED YUSUFNo ratings yet

- Polymorph ManualDocument69 pagesPolymorph ManualJa'Maul RedmondNo ratings yet

- Material Caterpillar 793c Mining Truck Off Highway Steering Components PartsDocument21 pagesMaterial Caterpillar 793c Mining Truck Off Highway Steering Components PartsИгорь ИвановNo ratings yet

- 9. نظام التحكم في التدفقDocument1 page9. نظام التحكم في التدفقالمهندسوليدالطويلNo ratings yet

- Diagram, System, Cummins ISX, Model 379 P94-6002 - 01Document10 pagesDiagram, System, Cummins ISX, Model 379 P94-6002 - 01hamilton miranda100% (1)

- Smart BoomDocument10 pagesSmart BoomKevine Khaled100% (1)

- HES Bid Set Fire Protection DrawingsDocument5 pagesHES Bid Set Fire Protection DrawingsMansoor Abdul KhaderNo ratings yet

- Wiring Diagram: DC GeneratorDocument1 pageWiring Diagram: DC GeneratorAndi Ka100% (1)

- VCF FM: Amazing new sounds are now added through this featureDocument13 pagesVCF FM: Amazing new sounds are now added through this featureJohn BaartmanNo ratings yet

- Lightning Audio LA-4200 Car AmplifierDocument8 pagesLightning Audio LA-4200 Car AmplifiervictorNo ratings yet

- GT100 Tubechrt 060628Document2 pagesGT100 Tubechrt 060628DAN PARASCHIVESCUNo ratings yet

- CS 563 Hydraulic PDFDocument2 pagesCS 563 Hydraulic PDFanggieNo ratings yet

- 10 FuelDocument10 pages10 FuelpapachinNo ratings yet

- 94 KW T600 Warning Lamp ModuleDocument1 page94 KW T600 Warning Lamp ModuleElmer Monteagudo BordaNo ratings yet

- Primex Tower Single Line DiagramDocument1 pagePrimex Tower Single Line DiagramMark SorianoNo ratings yet

- Eil Job No.: A545: OwnerDocument35 pagesEil Job No.: A545: OwnerSandip SurNo ratings yet

- Substation Transformers: Primary or Secondary UnitDocument8 pagesSubstation Transformers: Primary or Secondary UnitCarlos Herrera RodriguezNo ratings yet

- Ge Frame 6Document3 pagesGe Frame 6Ali SadiqNo ratings yet

- Interactive Schematic: FeaturesDocument9 pagesInteractive Schematic: FeaturesCM Inversiones Chile100% (1)

- Industrial Sliding Gate Operator: A10 Operating Programming GuideDocument4 pagesIndustrial Sliding Gate Operator: A10 Operating Programming GuideanguiNo ratings yet

- BQrev2a With Rate .Rev 1SSPDocument38 pagesBQrev2a With Rate .Rev 1SSPonealNo ratings yet

- Company ProfileDocument47 pagesCompany ProfileonealNo ratings yet

- T. Windcity (Grandhill) Sales Kit 20220901 (Agents)Document3 pagesT. Windcity (Grandhill) Sales Kit 20220901 (Agents)onealNo ratings yet

- Company ProfileDocument47 pagesCompany ProfileonealNo ratings yet

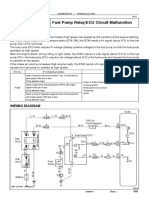

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocument4 pagesDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealNo ratings yet

- GBUGPro (Reader)Document36 pagesGBUGPro (Reader)onealNo ratings yet

- Specification Building Works 2014 PDFDocument329 pagesSpecification Building Works 2014 PDFFaiz AlwiNo ratings yet

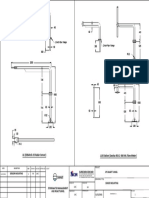

- L6 & L10 Sensor MountingDocument1 pageL6 & L10 Sensor MountingonealNo ratings yet

- General: Brand Identity Quick ReferenceDocument3 pagesGeneral: Brand Identity Quick ReferenceonealNo ratings yet

- Media editing essentials with KinMasterDocument7 pagesMedia editing essentials with KinMasteronealNo ratings yet

- 2019 Extended Cab Truck Service ManualDocument98 pages2019 Extended Cab Truck Service ManualJùst ZikoNo ratings yet

- Actuated Ball Valve 357 D - BDKDocument4 pagesActuated Ball Valve 357 D - BDKfarhanakhtar ansariNo ratings yet

- WH Compressor Frame OverviewDocument43 pagesWH Compressor Frame OverviewArzyman100% (1)

- ls3 Torque SpecsDocument6 pagesls3 Torque SpecsBascur JuanNo ratings yet

- Compact UNIC Mini-Crawler CraneDocument24 pagesCompact UNIC Mini-Crawler CraneASIJASDNo ratings yet

- Cargo: C3E 100R C3E 130R C3E 150RDocument198 pagesCargo: C3E 100R C3E 130R C3E 150RAntonio NovoNo ratings yet

- OBD II Diagnostic Trouble Code GuideDocument71 pagesOBD II Diagnostic Trouble Code GuideEdgardo RivasNo ratings yet

- Rexnord PT Europe Coupling Overwiev Cpe2 002Document34 pagesRexnord PT Europe Coupling Overwiev Cpe2 002Ajmal ArshadNo ratings yet

- Rotation Control of Servo MotorDocument8 pagesRotation Control of Servo MotorMahesh KumarNo ratings yet

- Certificado Conformidad CarpinterDocument8 pagesCertificado Conformidad CarpinterJefferson VargasNo ratings yet

- STFM05 Listado de RepuestosDocument1 pageSTFM05 Listado de RepuestosJoan Sebastian GaribelloNo ratings yet

- Hydraulic CylinderDocument11 pagesHydraulic Cylindersrinathgudur11No ratings yet

- Modelos Maquina Sicor ItalianaDocument104 pagesModelos Maquina Sicor ItalianaAscensores MbsasNo ratings yet

- Manual BookDocument154 pagesManual BookAnonymous nHT1rzjmcNo ratings yet

- Lista Multiparts-GremioDocument17 pagesLista Multiparts-GremiorubioariasNo ratings yet

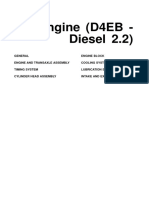

- Hyundai D4EB EM (D4EB - Diesel 2.2) Engine Workshop Manual-1-10Document10 pagesHyundai D4EB EM (D4EB - Diesel 2.2) Engine Workshop Manual-1-10hoàng gia bùiNo ratings yet

- Friction SpinningDocument2 pagesFriction SpinningShailendra MishraNo ratings yet

- Ventrack Control Valve TesterDocument4 pagesVentrack Control Valve TesterStudent ForeignNo ratings yet

- 46 Pdfsam Manual Ep250-450Document44 pages46 Pdfsam Manual Ep250-450Angels Córdova Alegría100% (1)

- Tolerancias de RodamientosDocument3 pagesTolerancias de Rodamientospaolo88No ratings yet

- TerminologyDocument3 pagesTerminologyJorge GalarceNo ratings yet

- EnticerDocument104 pagesEnticerGagan Deol100% (1)

- J616V01 enDocument4 pagesJ616V01 enMartin KratkyNo ratings yet

- Hydraulics Express Component CatalogDocument86 pagesHydraulics Express Component CatalogVictor CifuentesNo ratings yet

- Vanguard 18hp - Engine # 3564470373F1Document61 pagesVanguard 18hp - Engine # 3564470373F1Matias Alfredo Contreras KöbrichNo ratings yet

- Legend Sheet P&ID For As-Built - Drafting On 20210722-1Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-1Ludi D. LunarNo ratings yet

- CD150M Pump CurveDocument1 pageCD150M Pump CurveUrgent HiringNo ratings yet

- Catalago XS120 Single-Drum Vibratory Roller PDFDocument82 pagesCatalago XS120 Single-Drum Vibratory Roller PDFAnonymous 9fCAFynMNo ratings yet

- Kta50 GS8Document3 pagesKta50 GS8Mohiuddin totulNo ratings yet