Professional Documents

Culture Documents

Skrip MRP

Uploaded by

Iskandar ShahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Skrip MRP

Uploaded by

Iskandar ShahCopyright:

Available Formats

Assalamualaikum and a very Good Morning to our lecturer Dr Habibah and my fellow

classmates.

We will be presenting Seminar 1, for the topic MATERIAL REQUIREMENT PLANNING

(MRP).

So, first let me introduce my group member.

For the purpose of this presentation, our focus is mainly on:

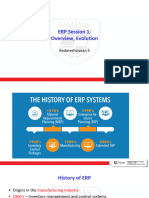

Before we go further let me briefly explain the history of development Material

Requirements Planning (MRP)

• Inventory was manually recorded until computer-engineered systems developed in the

commercial world.

• Users finally realized how ineffective hand-kept inventory was, which contributed to a

market demand for the most productive approach.

• The first processor computer based MRP inventory management systems developed

in the 1940s and 1950s, extrapolating data from a bill of materials for a specific finished

product into a production and purchasing plan.

• Information feedback systems were added to MRP systems so that production

managers may modify and update the system input as required.

• Since 1975, the MRP system has been regularly developed to improve corporate

efficiency.

• The MRP inventory system's adoption and ongoing innovation had a long-term impact

that can still be seen today.

Next, The Definition of Material Requirements Planning (MRP)

• Material requirements planning (MRP) is a computer-based inventory management

system, it is developed with the goal of increasing corporate productivity.

• Systems for planning material requirements are used by businesses to plan deliveries

and forecast raw material quantities.

• Furthermore, MRP is a method for determining the materials and components needed

to manufacture a product.

• It consists of three major steps which are inventorying current resources and

components, determining which additional ones are needed, and organizing for their

manufacturing or acquisition.

Next slide, The Objective of Material Requirements Planning (MRP)

Firstly, it is very important to ensure that raw materials are readily available for

production and products are readily available for delivery to consumers.

• When the manufacturing business knows how much goods to manufacture based on

actual demand, they will know exactly how much to keep on hand.

• As a result, MRP enhances manufacturing operations' efficiency, flexibility, and

profitability.

Secondly, MRP can helps to sustain the lowest raw materials and finished products

levels in store.

• MRP empowers inventory managers to reduce the number of component and raw

materials in hand.

• This helped the industrial operation to better monitor inventory levels while also

lowering costs.

• It can increase team productivity, enhance product quality, and reduce material and

labour expenses.

Thirdly, MRP also helps to organize manufacturing, delivery schedules, and purchasing

activities.

• It will assist businesses in responding more quickly to rising product demand, reducing

production delay and inventory stockouts which can result in lost consumers.

• Additionally, by reducing the time needed to handle the order from customers, the

production and packing stages will proceed more smoothly and reliably.

You might also like

- John Paul Jackson Prophecies of The FutureDocument15 pagesJohn Paul Jackson Prophecies of The FutureMeranda Devan100% (9)

- Design and Implementation of Hotel Management SystemDocument36 pagesDesign and Implementation of Hotel Management Systemaziz primbetov100% (2)

- Dimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringDocument22 pagesDimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringUCSC Students100% (1)

- Enterprise Resource Planning (Erp) the Great Gamble: An Executive’S Guide to Understanding an Erp ProjectFrom EverandEnterprise Resource Planning (Erp) the Great Gamble: An Executive’S Guide to Understanding an Erp ProjectRating: 4.5 out of 5 stars4.5/5 (5)

- SIOP (Sales Inventory Operations Planning)Document31 pagesSIOP (Sales Inventory Operations Planning)Harish GopalanNo ratings yet

- 033 - Flight Planning Monitoring - QuestionsDocument126 pages033 - Flight Planning Monitoring - QuestionsEASA ATPL Question Bank100% (4)

- Multidimensional Scaling Groenen Velden 2004 PDFDocument14 pagesMultidimensional Scaling Groenen Velden 2004 PDFjoséNo ratings yet

- Material Requirements PlanningDocument5 pagesMaterial Requirements PlanningNiño Rey LopezNo ratings yet

- Yangon University of Economics Department of Commerce: Material Requirements Planning (MRP) and ErpDocument15 pagesYangon University of Economics Department of Commerce: Material Requirements Planning (MRP) and ErpmyamonpNo ratings yet

- ERP EvolutionDocument45 pagesERP EvolutionSoumyajyoti Kundu100% (1)

- Session 01Document23 pagesSession 01Anket SinghNo ratings yet

- Unit IIIDocument22 pagesUnit IIIdangerous saifNo ratings yet

- Material Requirement Plannin1Document4 pagesMaterial Requirement Plannin1Shikha ThapaNo ratings yet

- MRP - I &iiDocument12 pagesMRP - I &iiNeelangshu GhoshNo ratings yet

- Understanding Materials Requirement Planning (MRP) : Gul FarazDocument5 pagesUnderstanding Materials Requirement Planning (MRP) : Gul FarazIqra MaroofNo ratings yet

- CIM Presentation 1-5-2021Document23 pagesCIM Presentation 1-5-2021Sanket TitarmareNo ratings yet

- Manufacturing Resource PlanningDocument4 pagesManufacturing Resource PlanningMiguel HernándezNo ratings yet

- Material Requirements Planning FinalDocument16 pagesMaterial Requirements Planning Finalniharika95323100% (2)

- BME1 Operations MGT Chapter 7Document8 pagesBME1 Operations MGT Chapter 7Cristina maeNo ratings yet

- Aterial Equirement Lanning: Research Paper OnDocument21 pagesAterial Equirement Lanning: Research Paper Onjain8687No ratings yet

- Erp Systems DefinedDocument9 pagesErp Systems DefinedNeeraj KumarNo ratings yet

- Material Requirement Planning PresentationDocument26 pagesMaterial Requirement Planning PresentationAshutosh PareekNo ratings yet

- Mba 3rd Semester, Material ManagementDocument61 pagesMba 3rd Semester, Material ManagementVikash KumarNo ratings yet

- ERP-A Manufacturing PerspectiveDocument13 pagesERP-A Manufacturing Perspectivesubhash.bansode1790No ratings yet

- Sop SBT 1 RakeshDocument9 pagesSop SBT 1 RakeshEnglish sub animeNo ratings yet

- Materials Requirement PlanningDocument5 pagesMaterials Requirement PlanningJohn Yaoto100% (1)

- 5.6 Notes On Material Requirements PlanningDocument2 pages5.6 Notes On Material Requirements PlanningsaisenthNo ratings yet

- MRP I, MRP Ii, MRP Iii Y El ERPDocument4 pagesMRP I, MRP Ii, MRP Iii Y El ERPCarlos MerinoNo ratings yet

- MRP and ERPDocument6 pagesMRP and ERPAshley LumbaoNo ratings yet

- S Chapter 01Document33 pagesS Chapter 01Ederlyn Pangilinan RamosNo ratings yet

- Assignment: Course: TopicDocument13 pagesAssignment: Course: TopicjpearlNo ratings yet

- Out Source ConsiderationsDocument14 pagesOut Source Considerationsashish.bms9No ratings yet

- P&OM Unit 3.1Document48 pagesP&OM Unit 3.1Tom CruiseNo ratings yet

- Man - Planning and Control 25-FEB-21Document29 pagesMan - Planning and Control 25-FEB-21Ramesh Kavitha Sanjit 18BME0677No ratings yet

- Material Requirements Planning (MRP)Document11 pagesMaterial Requirements Planning (MRP)MD.Jobaer Ibne RayhanNo ratings yet

- بِسْمِ ٱللَّٰهِ ٱلرَّحْمَٰنِ ٱلرَّحِيمِ,Document21 pagesبِسْمِ ٱللَّٰهِ ٱلرَّحْمَٰنِ ٱلرَّحِيمِ,Sohail NaveedNo ratings yet

- MRP and ERP ModelDocument12 pagesMRP and ERP ModelAmandeep SinghNo ratings yet

- Material Requirement PlanningDocument23 pagesMaterial Requirement Planningsangaleabhi100% (1)

- Module-4: Material Requirement Planning (MRP)Document10 pagesModule-4: Material Requirement Planning (MRP)DhiyaneshNo ratings yet

- Material Requirements Planning (MRP) : By: K.N.D.Gopal Krishna 18HP5A0326Document14 pagesMaterial Requirements Planning (MRP) : By: K.N.D.Gopal Krishna 18HP5A0326Roopasri BattulaNo ratings yet

- What Is MRPDocument15 pagesWhat Is MRPParag Narkhede100% (1)

- ERP Assignment 1Document10 pagesERP Assignment 1Ankit SinghNo ratings yet

- Introduction To: MRP & ErpDocument42 pagesIntroduction To: MRP & ErpAnupama P Shankar100% (1)

- Cp-4 Erp A Manufacturing PerspectiveDocument32 pagesCp-4 Erp A Manufacturing PerspectiveMinu SahNo ratings yet

- DDMRP: An Overview Deena Dayalan THIRUPATHIDocument20 pagesDDMRP: An Overview Deena Dayalan THIRUPATHIjavierNo ratings yet

- MRP, MRP II N ERPDocument10 pagesMRP, MRP II N ERPmanonmani_mktg8423No ratings yet

- Materials Planning: Unit IiDocument56 pagesMaterials Planning: Unit IiSownthariya T100% (1)

- Material Requirements PlanningDocument56 pagesMaterial Requirements Planningcheldulceconstan28No ratings yet

- 5th Unit SlidesDocument24 pages5th Unit Slidesgayatrimeghana32516No ratings yet

- Unit - 1: - What Is Enterprise ? - Business Functions and Business ProcessDocument59 pagesUnit - 1: - What Is Enterprise ? - Business Functions and Business ProcessDhrumil MistryNo ratings yet

- MRP, Jit, ErpDocument26 pagesMRP, Jit, ErpRupendra TripathiNo ratings yet

- Session 05-Supply Chain Coordination and Use of TechnologyDocument12 pagesSession 05-Supply Chain Coordination and Use of TechnologyUmair Hussain KhanNo ratings yet

- RP14 MRP and ErpDocument5 pagesRP14 MRP and ErpGerline MaeNo ratings yet

- Pom Unit 4-1Document16 pagesPom Unit 4-1Rakesh ChebroluNo ratings yet

- ERP - Past Present and FutureDocument17 pagesERP - Past Present and Futurekrati12No ratings yet

- Week 11 & 12 (MRP - Information Technology & SCM, ERP)Document27 pagesWeek 11 & 12 (MRP - Information Technology & SCM, ERP)HAMNA SYEDNo ratings yet

- Chapter 4Document17 pagesChapter 4Joao NegreirosNo ratings yet

- CH 5 MRPDocument20 pagesCH 5 MRPahsanzia62No ratings yet

- What Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Document31 pagesWhat Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Faisal AlharbiNo ratings yet

- MODULE 3 - OM CombinedDocument18 pagesMODULE 3 - OM Combinedchristy bijuNo ratings yet

- Assignment 1 ERP: Submitted To - Prof Suhail Anwar. Nift, DelhiDocument13 pagesAssignment 1 ERP: Submitted To - Prof Suhail Anwar. Nift, DelhiDebasis BhowmikNo ratings yet

- Unit III ErpDocument16 pagesUnit III ErpSûrèndhár ChîYān RàsígânNo ratings yet

- Jharkhand August 2014Document61 pagesJharkhand August 2014Ron 61No ratings yet

- Physiology of Eye. Physiology of VisionDocument27 pagesPhysiology of Eye. Physiology of VisionSmartcool So100% (1)

- ASM NetworkingDocument36 pagesASM NetworkingQuan TranNo ratings yet

- Poster@IcepeDocument1 pagePoster@IcepeAakash NawabNo ratings yet

- Veris Case StudyDocument2 pagesVeris Case StudyPankaj GargNo ratings yet

- Caracterisation D'une Entreprise anglosaxonne-ETLV - STMG1.Document2 pagesCaracterisation D'une Entreprise anglosaxonne-ETLV - STMG1.meredith.licagaNo ratings yet

- Ojt HRMDocument7 pagesOjt HRMArlyn Joy NacinoNo ratings yet

- PhysioEx Exercise 1 Activity 1Document3 pagesPhysioEx Exercise 1 Activity 1edvin merida proNo ratings yet

- Rubber DamDocument78 pagesRubber DamDevanshi Sharma100% (1)

- Sci5 q3 Module3 NoanswerkeyDocument22 pagesSci5 q3 Module3 NoanswerkeyRebishara CapobresNo ratings yet

- Indiana Property Tax Benefits: (This Form Must Be Printed On Gold or Yellow Paper)Document2 pagesIndiana Property Tax Benefits: (This Form Must Be Printed On Gold or Yellow Paper)abramsdcNo ratings yet

- Formula BookletDocument2 pagesFormula BookletOm PatelNo ratings yet

- CFA L1 Ethics Questions and AnswersDocument94 pagesCFA L1 Ethics Questions and AnswersMaulik PatelNo ratings yet

- 面向2035的新材料强国战略研究 谢曼Document9 pages面向2035的新材料强国战略研究 谢曼hexuan wangNo ratings yet

- Available Online Through: International Journal of Mathematical Archive-4 (12), 2013Document4 pagesAvailable Online Through: International Journal of Mathematical Archive-4 (12), 2013Gwen WalkerNo ratings yet

- The Latest Open Source Software Available and The Latest Development in IctDocument10 pagesThe Latest Open Source Software Available and The Latest Development in IctShafirahFameiJZNo ratings yet

- CHAPTER I KyleDocument13 pagesCHAPTER I KyleCresiel Pontijon100% (1)

- TMIS07 - Kalam Internship - S7 Tesla MindsDocument3 pagesTMIS07 - Kalam Internship - S7 Tesla MindsDMJ JonesNo ratings yet

- Granulometry of ClinkerDocument18 pagesGranulometry of ClinkerNael100% (12)

- Financial/ Accounting Ratios: Sebi Grade A & Rbi Grade BDocument10 pagesFinancial/ Accounting Ratios: Sebi Grade A & Rbi Grade Bneevedita tiwariNo ratings yet

- LLB IV Sem GST Unit I Levy and Collection Tax by DR Nisha SharmaDocument7 pagesLLB IV Sem GST Unit I Levy and Collection Tax by DR Nisha Sharmad. CNo ratings yet

- International Beach Soccer Cup Bali 2023 October 4-7 - Ver 15-3-2023 - Sponsor UPDATED PDFDocument23 pagesInternational Beach Soccer Cup Bali 2023 October 4-7 - Ver 15-3-2023 - Sponsor UPDATED PDFPrincess Jasmine100% (1)

- MBF100 Subject OutlineDocument2 pagesMBF100 Subject OutlineMARUTI JEWELSNo ratings yet

- Syllabus Math 305Document4 pagesSyllabus Math 305Nataly SusanaNo ratings yet

- Problem Solving Questions: Solutions (Including Comments)Document25 pagesProblem Solving Questions: Solutions (Including Comments)Narendrn KanaesonNo ratings yet