Professional Documents

Culture Documents

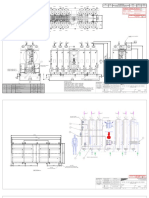

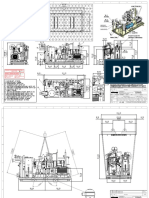

FP-5515 P&ID CTGPs TRANVÍA

Uploaded by

Zander MctrevorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FP-5515 P&ID CTGPs TRANVÍA

Uploaded by

Zander MctrevorCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A A

Control panel & MCC

B B

Powder addition

.... kg/h

Electrical Room

Field

0,18 Kw

FC M17 Polymer preparer

PP02

Powder addition

.... kg/h OV 0,37 Kw

OV OV 0,37 Kw 0,37 Kw

M1 1,5 Kw V01 M16 ... Kw V05 V06 HH

M18 M19 M20 LS H

L06 L

500 µm 500 µm LL

0,18 Kw

LS

C C

V01 V05 V06

Fresh Water F01 Water F02

FC M3 Polymer preparer

PP01 P01 P09

Washwater pump Water pump M21 2,2 Kw

Flow: 6,6 m³/h Flow: ... m³/h

OV OV 0,37 Kw 0,37 Kw 0,37 Kw Pressure: 8 bar Pressure: 2,5 - 4,5 bar

M2 ... Kw V02 V03

HH ID 25

M4 M5 M6 LS H

L01 L

500 µm LL

Polymer

P10

LS Option Polymer Pump

V02 V03

Water F02 Option Flow: 3,0 m³/h

Pressure: 3,0 bar

P02

Static Mixer

FI Emergency Stop

Water pump M7 2,2 Kw HZ

F1

Flow: ... m³/h FC

Pressure: 2,5 - 4,5 bar X5

B

7,5 Kw

Polymer

F1 Option to pump for decanter 2 M24

Emergency Stop Emergency Stop

P03

DN 2"

LS H HZ HZ OV

Polymer Pump L02

Flow: 3,0 m³/h

X1 X2

M22 3,7 Kw V07

Pressure: 3,0 bar 3-Way Feed Head

Option 500 µm 30,0 Kw

D GS

Power Drain

PDXL2000

LS

L03

H

L

LL

V07

ID 25

DN 40 PN 10

Centrifuge

D4L M25 D

G1 Fresh Water F01 Water

LS P11

DN 100

LS FC

Washwater pump

Air extraction Flow: 8-16 m³/h

Pressure: 4 bar

DN 100 M9 FC

To downstream

2,2 Kw

DN 200

DN 200

conveying equipment

50 mm

114.3 mm

114.3 mm

Option Fresh Water

DV

Thickned sludge

V08

M8 15,0 Kw

FI M23 5,5 Kw

X01

F2

A

X03

ID 50

Air from compressor

Washing Water

F2 Drain Sludge

Sludge Wash water drain

.... m³/h P04 P12 Sediment Outlet

.... Gew.% Sludge Pump

Sludge Pump

E E

Stand-by Sludge Pump

Flow: 14,5 m³/h

Flow: 40,0 m³/h Dewatered sludge cake

Pressure: 3,0 bar

Pressure: 3,0 bar Filtrate

Sludge tank

M14 15,0 Kw

To Drain

Fresh Water

Sludge

.... m³/h P08 Exhaust Air

.... Gew.% Sludge Pump

OV Thickned sludge DN 150 PN 10

Flow: 40,0 m³/h

Pressure: 3,0 bar M10 1,5 Kw V04

DN 100

500 µm Deaerator

SP

V04

Fresh Water Fresh Water F01

P05

Washwater pump

DN 100 PN 10

Flow: 6,6 m³/h Biodigestor Centrate

Pressure: 8 bar

F F

Option M26 5,5 Kw

Option

ID 50

Static Mixer

FI

M11 2,2 Kw

F3

Sludge

P13

Sludge Pump

Flow: 14,5 m³/h

F3 Option Pressure: 3,0 bar

P06 Emergency Stop

DN 2"

LS H Emergency Stop Emergency Stop

Polymer Pump HZ HZ

L04 HZ FC

Flow: 3,0 m³/h X3 X4 X6

Pressure: 3,0 bar

Option 7,5 Kw

Fresh Water

Power Drain LS H

L M29

GS PDXL2000 L05 LL

G2 OV

LS M27 3,7 Kw

DN 100

LS V09

3-Way Feed Head

G G

Air extraction 500 µm 30,0 Kw

ID 25 Centrifuge

DN 100 M15 FC DN 40 PN 10

D4L M30

V09

Fresh Water F01 Water

To downstream

2,2 Kw

P14

DN 200

DN 200

conveying equipment

114.3 mm

114.3 mm

50 mm

FC

Washwater pump

Flow: 8-16 m³/h

Option Pressure: 8 bar

Thickned sludge

FI

M12 15,0 Kw

X02

F4

F4 Drain

Sludge Wash water drain DV

.... m³/h P07 M28 2,2 Kw V10

.... Gew.% Sludge Pump

Flow: 40,0 m³/h

ID 25 A

Pressure: 3,0 bar Filtrate B X04

Air from compressor

From polymer preparer Polymer Washing Water

P15

H H

Polymer Pump

Fresh Water Flow: 3,0 m³/h Sediment Outlet

Option Pressure: 3,0 bar

PSL

A81V01.P1 Dewatered sludge cake

Compressor

M13

Exhaust Air

... Nm³/h at 6bar DN 150 PN 10

DN 100

A

Deaerator

Compressed Air SP

to decanter flap box

DN 100 PN 10

Centrate

J To Drain J

K K

Product Type Product Code

Initial Revision Actual Revision

Drawn C. Reinicke pomcle01 25.11.2020 Replacement for Drawing No Rev

R. karsten pomrog01 25.11.2020 ---- ----

L

Checked

Copy from Drawing No Rev L

Old Drawing No Rev

Revision

express authorization is prohibited. Offenders will be held liable

Description Drawing No Rev

as well as the communication of its contents to others without

The reproduction, distribution and utilization of this document

for the payment of damages. All rights reserved in the event

of the grant of a patent, utility model or design. (ISO 16016)

P&ID - CTGPs TRANVÍA FP-5515 -

DECANTER D4L + PDXL2000 Size Sheet/Sheets Scale

A1 1 /1 SE

M M

Ver.: 2.0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Drawing sheet ISO 5457:1999 - A1

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Detail E: Issued by Greenlane BiogasDocument4 pagesDetail E: Issued by Greenlane BiogasZander MctrevorNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMDocument2 pagesMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Isometric: 2395 Vacuum SystemDocument1 pageIsometric: 2395 Vacuum SystemZander MctrevorNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Model FGV (B, D) FEV (B, D) : Issued by Greenlane BiogasDocument1 pageModel FGV (B, D) FEV (B, D) : Issued by Greenlane BiogasZander MctrevorNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- IndiceDocument10 pagesIndiceZander MctrevorNo ratings yet

- PrefaceDocument4 pagesPrefaceZander MctrevorNo ratings yet

- Cartas para Mazo Requeridas)Document3 pagesCartas para Mazo Requeridas)Zander MctrevorNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- AMCA 210 - Laboratory Methods of Testing Fans For RatingsDocument3 pagesAMCA 210 - Laboratory Methods of Testing Fans For RatingsZander MctrevorNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Form 1 1 MicroscopeDocument46 pagesForm 1 1 MicroscopeHarshil PatelNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Sunrise - 12 AB-unlockedDocument81 pagesSunrise - 12 AB-unlockedMohamed Thanoon50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Highway Journal Feb 2023Document52 pagesHighway Journal Feb 2023ShaileshRastogiNo ratings yet

- GeminiDocument397 pagesGeminiJohnnyJC86No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Calculus of Finite Differences: Andreas KlappeneckerDocument30 pagesCalculus of Finite Differences: Andreas KlappeneckerSouvik RoyNo ratings yet

- Normal Consistency of Hydraulic CementDocument15 pagesNormal Consistency of Hydraulic CementApril Lyn SantosNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- KV4BBSR Notice ContractuaL Interview 2023-24Document9 pagesKV4BBSR Notice ContractuaL Interview 2023-24SuchitaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Solution Documentation For Custom DevelopmentDocument52 pagesSolution Documentation For Custom DevelopmentbayatalirezaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Auditing Multiple Choice Questions and Answers MCQs Auditing MCQ For CA, CS and CMA Exams Principle of Auditing MCQsDocument30 pagesAuditing Multiple Choice Questions and Answers MCQs Auditing MCQ For CA, CS and CMA Exams Principle of Auditing MCQsmirjapur0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Geology, Logging, Drilling ReportDocument53 pagesGeology, Logging, Drilling Reportwisam alkhooryNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Bomba Manual Hidraulica - P 19 LDocument2 pagesBomba Manual Hidraulica - P 19 LBruno PachecoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AAPG 2012 ICE Technical Program & Registration AnnouncementDocument64 pagesAAPG 2012 ICE Technical Program & Registration AnnouncementAAPG_EventsNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- A Project Diary-Wps OfficeDocument4 pagesA Project Diary-Wps OfficeSameer ShaikhNo ratings yet

- Beginning Cosmetic ChemistryDocument1 pageBeginning Cosmetic ChemistrySergio Rugerio0% (1)

- Exam TimetableDocument16 pagesExam Timetablenyarko_eNo ratings yet

- SAP Environment, Health, and Safety (EHS)Document13 pagesSAP Environment, Health, and Safety (EHS)SAFETY VOFPLNo ratings yet

- IMS - Integrated Management System Implementation Steps-Sterling - Rev00-240914 PDFDocument28 pagesIMS - Integrated Management System Implementation Steps-Sterling - Rev00-240914 PDFNorman AinomugishaNo ratings yet

- 103-Article Text-514-1-10-20190329Document11 pages103-Article Text-514-1-10-20190329Elok KurniaNo ratings yet

- Sample TRM All Series 2020v1 - ShortseDocument40 pagesSample TRM All Series 2020v1 - ShortseSuhail AhmadNo ratings yet

- Chapter 3: Verbal Communication SkillsDocument14 pagesChapter 3: Verbal Communication SkillsFares EL DeenNo ratings yet

- Starex Is BTSDocument24 pagesStarex Is BTSKLNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Directorate of Technical Education, Maharashtra State, MumbaiDocument57 pagesDirectorate of Technical Education, Maharashtra State, MumbaiShubham DahatondeNo ratings yet

- Birth Trauma and Post Traumatic Stress Disorder The Importance of Risk and ResilienceDocument5 pagesBirth Trauma and Post Traumatic Stress Disorder The Importance of Risk and ResilienceMsRockPhantomNo ratings yet

- Schematic Circuits: Section C - ElectricsDocument1 pageSchematic Circuits: Section C - ElectricsIonut GrozaNo ratings yet

- Ccie R&s Expanded-BlueprintDocument12 pagesCcie R&s Expanded-BlueprintAftab AlamNo ratings yet

- Week 2 - Sulphur DyesDocument5 pagesWeek 2 - Sulphur DyesRR TNo ratings yet

- Benchmark Leadership Philosphy Ead 501Document5 pagesBenchmark Leadership Philosphy Ead 501api-494301924No ratings yet

- Do I Need A 1PPS Box For My Mulitbeam SystemDocument3 pagesDo I Need A 1PPS Box For My Mulitbeam SystemutkuNo ratings yet

- JOB Performer: Q .1: What Is Permit?Document5 pagesJOB Performer: Q .1: What Is Permit?Shahid BhattiNo ratings yet

- EHVACDocument16 pagesEHVACsidharthchandak16No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)