Professional Documents

Culture Documents

SSRN Id3076777

Uploaded by

marian almiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SSRN Id3076777

Uploaded by

marian almiaCopyright:

Available Formats

De

te

r

Ge m

ar

Ef if n

i

By

en n

Re

ici

lly

Vic

tor

g

ia

By Pe

tr e

ana sc

u,

lyzi

cy

Flo

ng ria

n

orig cer Ion

Pe

inal tainp

tr e

sc

u,

met a ram an

dN

hod eters

ar c

isa

for d , Po

eter the pe

sc

min aut u

ing hor

the s pr

effic

ienc esent

y of a

gea n

rs.

20 GEAR SOLUTIONS • MARCH 2007 • gearsolutionsonline.com

Electronic copy available at:

Electronic copy available at: https://ssrn.com/abstract=3076777

https://ssrn.com/abstract=3076777

A

bstract: This paper presents an original method for determining the efficiency of the gear. The originality

of this method relies on the eliminated friction modulus. In the following pages we analyze the influence

of a few parameters concerning gear efficiency. These parameters are: z1—the number of teeth for the

primary wheel of gear; z2—the number of teeth of the secondary wheel of gear; αо—the normal pressure angle on the

divided circle; and β—the inclination angle. With the relations presented in this paper, one can synthesize the gear’s

mechanisms. Today, gears are present everywhere in the mechanical world, especially the automotive, electronics, and

energy industries, etc. By optimizing this mechanism, one can improve the functionality of transmission gears.

gearsolutionsonline.com • MARCH 2007 • GEAR SOLUTIONS 21

Electronic copy available at: https://ssrn.com/abstract=3076777

Electronic copy available at: https://ssrn.com/abstract=3076777

Introduction

In presenting this original method for calculating the efficiency of the gear,

the originality consists in the way of determining the gear’s efficiency,

because we haven’t used the friction forces involved in coupling—this new

way eliminates the classical method, in fact. The necessity of determining

the friction coefficients by different experimental methods is eliminated, as

well. The efficiency determinates by the new method are the same as in the

classical method; namely, the mechanical efficiency of the gear. Precisely,

one determines the dynamics efficiency, but at the transmission’s gears,

the dynamics efficiency is the same as the mechanical efficiency.

Determining the Momentary Dynamic (Mechanical)

Efficiency

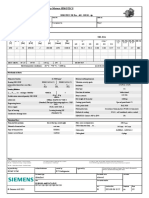

The calculating relations [2, 3], are the next (1-21), (see fig. 1):

with: Fm - the motive force (the driving force);

Fτ - the transmitted force (the useful force);

Fψ - the slide force (the lost force);

v1- the velocity of element 1, or the speed of wheel 1 (the driving wheel);

v2- the velocity of element 2, or the speed of wheel 2 (the driven wheel);

v12- the relative speed of the wheel 1 in relation with the wheel 2 (this is

a sliding speed).

FIGURE 1: THE FORCES OF THE GEAR

The consumed power (in this case the driving power):

22 GEAR SOLUTIONS • MARCH 2007 • gearsolutionsonline.com

Electronic copy available at: https://ssrn.com/abstract=3076777

The useful power (the transmitted power from the profile 1 to the

profile 2) will be written: The Geometrical Elements of the Gear

One determines the next geometrical elements of the external gear,

[2,3], (for the right teeth, β=0):

The lost power will be written: The radius of the basic circle of wheel 1 (of the driving wheel), (7):

The momentary efficiency of couple will be calculated directly with

the next relation: The radius of the outside circle of wheel 1 (8):

One determines now the maximum pressure angle of the gear (9):

The momentary losing coefficient [1], will be written:

And now one determines the same parameters for the wheel 2, the

radius of basic circle (10) and the radius of the outside circle (11)

for the wheel 2:

One can easily see that the sum of the momentary efficiency and the

momentary losing coefficient Now one can determine the geometrical

elements of the gear. These elements will be used in determining the

couple efficiency, η.

BROACHING

Production Broaching

50 machines available.

Sharpening, Repair &

Reconditioning

Simple to Complex – We do it all!

ISO 9001-Certified

Design & Manufacture Broaches

Manual and automated tooling packages.

35264 Topps Industrial Pkwy.,

Willoughby, OH 44094, USA

Build & Rebuild Machines Tel: (440) 946-1040 |

Vertical and horizontal machines. Fax: (440) 946-0725 |

12" to 90" stroke / 2 to 50-ton. E-mail: sales@ohiobroach.com

gearsolutionsonline.com • MARCH 2007 • GEAR SOLUTIONS 23

Electronic copy available at: https://ssrn.com/abstract=3076777

Now one can determine the minimum pressure angle of the external gear (12, 13):

The

RIGHT CHOICE

for

Machines,

Services and

Tooling for the

Now one can determine, for the external gear, the minimum (13) and the maximum (9) pres-

Gear Industry sure angle for the right teeth. For the external gear with bended teeth (β≠0) one uses the

relations (14, 15 and 16):

For the internal gear with bended teeth (β≠0) one uses the relations (14 with 17, 18-A or

with 19, 20-B):

A. When the driving wheel 1 has external teeth:

Print and Online B. When the driving wheel 1 has internal teeth:

Services Available

gearsolutionsonline.com

1.800.366.2185

z1 ⋅ cosα t

cosβ

cosα1m =

z1

−2

Published by Media Solutions, Inc. cosβ

P.O. Box 1210

Pelham, AL 35124

24 GEAR SOLUTIONS • MARCH 2007 • gearsolutionsonline.com

Electronic copy available at: https://ssrn.com/abstract=3076777

Determining the Efficiency

The efficiency of the gear will be calculated through the integration of momentary efficiency on all sections of gearing movement, namely

from the minimum pressure angle to the maximum pressure angle, the relation (21), [2, 3]:

αM αM αM

1 1 1 1

η =

Δα

⋅ ∫ η i ⋅ dα =

Δα ∫ cos 2 α ⋅ dα = ⋅ [ ⋅ sin( 2 ⋅ α ) + α ]

2 ⋅ Δα 2 αm

=

am αm (21)

1 sin( 2α M ) − sin( 2α m ) sin( 2 ⋅ α M ) − sin( 2 ⋅ α m )

= [ + Δα ] = + 0. 5

2 ⋅ Δα 2 4 ⋅ (α M − α m )

More precise (5) for determining momentary efficiency is the relation (22):

⎧η i = cos2 α 1 (5)

⎪

⎪ 1

⎨η i = cos α 1 ⋅

2

⎪ π π (22)

1 + cos2 α 1 ⋅ ⋅ ( + tgα 1 )

⎪⎩ z1 2 ⋅ z1

Conclusion

The input parameters are: z 1 = the number of teeth for the driving wheel 1;

z 2 = the number of teeth for the driven wheel 2, or the ratio of transmission, i (i 12=-z 2/z 1);

α 0 = the pressure angle normal on the divided circle;

β = the bend angle.

gearsolutionsonline.com • MARCH 2007 • GEAR SOLUTIONS 25

Electronic copy available at: https://ssrn.com/abstract=3076777

Electronic copy available at: https://ssrn.com/abstract=3076777

Electronic copy available at: https://ssrn.com/abstract=3076777

The efficiency of the gear increases when the number of teeth

for the driving wheel 1, z1, increases too, and when the pressure

angle, α0, diminishes. In addition, z2 or i12 are not much influence

on the efficiency value.

One can easily see that for the value α0=20˚, the efficiency takes

roughly the value η≈0.89 for any values of the others parameters

(this justifies the choice of this value, α0=20˚, for the standard

pressure angle of reference). The better efficiency may be obtained

only for a α0≠20˚, the efficiency takes roughly the value ŋ≈0.89 for

any values of the other parameters (this justifies the choice of this

value,α0 =20°, for the standard pressure angle of reference). The

better efficiency may be obtained only for a α0 ≠20°. But the pres-

sure angle of reference, α0, can be decreased at the same time the

number of teeth for the driving wheel 1, z1, increases, to increase

the gears’ efficiency.

The module of the gear, m, has no influence on the gear’s effi-

ciency value. When α0 is diminished one can take a higher normal

module for increasing the addendum of teeth, but the increase of

the m at the same time with the increase of the z1 can lead to a

greater gauge. The gears’ efficiency, ŋ, is really a function of α0

and z1: ŋ =f(α0,z1); αm and αM are just the intermediate parameters.

For good projection of the gear it’s necessary to have a z1 and z2

greater than 30-60, but this condition may increase the gauge of

mechanism.

In this paper we have discussed how one determines the dynam-

ics efficiency, but at the transmission’s gears the dynamics effi-

ciency is the same as the mechanical efficiency. This is a greater

advantage of the transmission’s gears. This advantage of the

gear’s mechanisms may be found at the cam’s mechanisms with

plate followers, as well.

REFERENCES:

1. Pelecudi, Chr., ş.a., Mecanisme. E.D.P., Bucureşti, 1985.

2. Petrescu, V., Petrescu, I., Randamentul cuplei superioare de la angre-

najele cu roţi dinţate cu axe fixe, In: The Proceedings of 7th National

Symposium PRASIC, Braşov, Romania, vol. I, pp. 333-338, 2002.

3. Petrescu, R., Petrescu, F., The gear synthesis with the best efficiency,

In: The Proceedings of ESFA’03, Bucharest, Romania, vol. 2, pp. 63-70,

2003.

4. Petrescu, R., Petrescu, F., Gear’s design for the mechanism’s highest

efficiency. In: The Proceedings of ICEGD’05, Bucharest, Romania, vol. I,

pp. 257-260, 2005.

5. Petrescu, R.V., Petrescu, F.I., Determining the dynamic efficiency of

gears. In: The Proceedings of SYROM’05, Bucharest, Romania, vol. II,

pp. 381-386, 2005.

ABOUT THE AUTHORS:

Relly Victoria Petrescu is a lecturer and Narcisa Popescu is an

associate professor in the Depar tment of Descriptive Geometr y

and Engineering Graphics at the University Politehnica of

Bucharest. Florian Ion Petrescu is an assistant professor in the

university’s in Depar tment of Mechanisms and Robots.

28 GEAR SOLUTIONS • MARCH 2007 • gearsolutionsonline.com

Electronic copy available at: https://ssrn.com/abstract=3076777

You might also like

- SSP 511 The New EA211 Petrol EngineDocument64 pagesSSP 511 The New EA211 Petrol Engineobpesgal100% (1)

- 2011+ VW Passat - Wiring Diagrams (From August 2014) PDFDocument1,734 pages2011+ VW Passat - Wiring Diagrams (From August 2014) PDFNhật Đặng100% (4)

- Touareg Supplementary HeatingDocument32 pagesTouareg Supplementary HeatingAnonymous t1FCvPRSaNo ratings yet

- D3E80445F60-Electrical System PDFDocument163 pagesD3E80445F60-Electrical System PDFjorge Angel LopeNo ratings yet

- Kadir Izaah Amir Wisdom ® 2023Document1 pageKadir Izaah Amir Wisdom ® 2023KayNo ratings yet

- AGi32 v19 Quick ReferenceDocument8 pagesAGi32 v19 Quick ReferenceNalex GeeNo ratings yet

- Cement Bond Logging Tools-SlbDocument37 pagesCement Bond Logging Tools-SlbIsmail ismailNo ratings yet

- In Process Quality Control Tests (IPQC) For Solid Dosage FromDocument28 pagesIn Process Quality Control Tests (IPQC) For Solid Dosage FromSagar kishor savale75% (8)

- C5-Mechanical Propertise of Hardened Concrete Base On Sample Made in C4Document8 pagesC5-Mechanical Propertise of Hardened Concrete Base On Sample Made in C4Muhammad khairinNo ratings yet

- Qdoc - Tips Manual Kawasaki Bajaj Wind 125Document13 pagesQdoc - Tips Manual Kawasaki Bajaj Wind 125Jose ArancibiaNo ratings yet

- Quality Assurance Synthesis Evaluation ReportDocument94 pagesQuality Assurance Synthesis Evaluation ReportFred Raphael IlomoNo ratings yet

- BL1 Individual Activity 1 AGDocument1 pageBL1 Individual Activity 1 AGSamantha Reynolds-SNo ratings yet

- TmeineDocument1 pageTmeinemclaughaNo ratings yet

- Business Proposal Title: Business ManagerDocument18 pagesBusiness Proposal Title: Business ManagerJansen Carl UsiNo ratings yet

- Graphical RepresentationDocument2 pagesGraphical RepresentationDARWIN JHON ESTENZONo ratings yet

- Name of National Coordinator Course Objectives (What You Will Learn?)Document70 pagesName of National Coordinator Course Objectives (What You Will Learn?)joy 11No ratings yet

- RCoA - NAP7 - BookDocument567 pagesRCoA - NAP7 - Bookeric22hkNo ratings yet

- TimelineDocument1 pageTimelinemclaughaNo ratings yet

- The Bharti Private Limited: ParticularsDocument8 pagesThe Bharti Private Limited: ParticularsGaurav SharmaNo ratings yet

- 2019 Annual Report PDFDocument298 pages2019 Annual Report PDFMohammadOmarFaruq0% (1)

- Archetypes at Work Introduction-WorkbookDocument14 pagesArchetypes at Work Introduction-WorkbookVerónica Ramos MonclaNo ratings yet

- ACE CFRP BladeDocument8 pagesACE CFRP Blader0ll3rNo ratings yet

- Take-Off: Certifica TionDocument18 pagesTake-Off: Certifica TionTj RivasNo ratings yet

- Statistic of Structural Fire According To Ignition Sources For Year 2009Document4 pagesStatistic of Structural Fire According To Ignition Sources For Year 2009wan abdullahNo ratings yet

- Conference Template A4Document4 pagesConference Template A4Frank TangNo ratings yet

- Good Practice Guide 272 - Lighting For PeopleDocument22 pagesGood Practice Guide 272 - Lighting For Peopletreelam100% (1)

- Invitation For Membership: Institute For Lean Construction Excellence (Ilce)Document6 pagesInvitation For Membership: Institute For Lean Construction Excellence (Ilce)JitendraHatwarNo ratings yet

- Accounting and Organizational StructureDocument6 pagesAccounting and Organizational StructureBediru TarekegnNo ratings yet

- Vitality Villas Brochure WebDocument58 pagesVitality Villas Brochure WebRobert ZetkovićNo ratings yet

- Sany Trailer PumpDocument14 pagesSany Trailer PumpSyauqiNo ratings yet

- My First in Past E: CeramicDocument4 pagesMy First in Past E: CeramicceramicameoNo ratings yet

- Pre Ko Borongaj Borongaj Pre KoDocument1 pagePre Ko Borongaj Borongaj Pre Kodominik.dabo7No ratings yet

- Elementary and Middle School Literacy Books To Teach Comprehension StrategiesDocument7 pagesElementary and Middle School Literacy Books To Teach Comprehension StrategiesJoaquinNo ratings yet

- Driver Ed Final Exam UpdatedDocument5 pagesDriver Ed Final Exam UpdatedViera HarriellNo ratings yet

- Meaning Wheel With Citation 6Document1 pageMeaning Wheel With Citation 6Cilka RamírezNo ratings yet

- Vi Vekanandacol L Egeofengi Neer I Ng&Technol OgyDocument2 pagesVi Vekanandacol L Egeofengi Neer I Ng&Technol OgySushanth PoojaryNo ratings yet

- English-K-10-Draft-Syllabus-V2 Pág.Document1 pageEnglish-K-10-Draft-Syllabus-V2 Pág.Carlos Alberto Martinez FloresNo ratings yet

- Advocacy Model: Social Work Models & TheorisDocument7 pagesAdvocacy Model: Social Work Models & TheorisJemie JasmineNo ratings yet

- SebasDocument1 pageSebasjesusNo ratings yet

- Curriculum VitaeDocument1 pageCurriculum VitaeMark GonzalesNo ratings yet

- PhenomenaDocument1 pagePhenomenaClariz Angelika EscocioNo ratings yet

- Vodic Kroz UstavDocument48 pagesVodic Kroz UstavDina VilićNo ratings yet

- 7 Transportation SolutionsDocument1 page7 Transportation Solutionspallawi singhNo ratings yet

- 001bx Sin 261223Document2 pages001bx Sin 261223toavuhNo ratings yet

- MC 21.22 Application Booklet - AIESEC in TurkeyDocument31 pagesMC 21.22 Application Booklet - AIESEC in TurkeyCristian Mejia HernandezNo ratings yet

- Refletindo A Pesquisa ParticipanteDocument186 pagesRefletindo A Pesquisa ParticipanteThiago MatanzaNo ratings yet

- Next Generation CR and Sustainability Jobs - 2017Document10 pagesNext Generation CR and Sustainability Jobs - 2017Ghadeer MohammedNo ratings yet

- One-Mar Ket I NG Cheat SheetDocument1 pageOne-Mar Ket I NG Cheat SheetSonam KumariNo ratings yet

- Probability GCSEDocument49 pagesProbability GCSEDheeraj YadavNo ratings yet

- Silnik MechanikaDocument167 pagesSilnik MechanikamorusNo ratings yet

- Dossier - The Future of Health DataDocument141 pagesDossier - The Future of Health Dataigor100% (1)

- Accruals and Prepayments - TeachingDocument13 pagesAccruals and Prepayments - TeachingFalila Banu ShaikhNo ratings yet

- Meaning Wheel With Citation 6Document1 pageMeaning Wheel With Citation 6Abu HanifahNo ratings yet

- College of Business Education Science & Technology, Inc.: Progress Chart Programming NC IvDocument7 pagesCollege of Business Education Science & Technology, Inc.: Progress Chart Programming NC IvagnesNo ratings yet

- Verbo To Be InfografiaDocument1 pageVerbo To Be InfografiaPedro MelendezNo ratings yet

- National Engineering Handbook - Part 630 - Hydrology - Chapter 21 - Design HydrographsDocument51 pagesNational Engineering Handbook - Part 630 - Hydrology - Chapter 21 - Design HydrographsPatrick Joseph RoblesNo ratings yet

- New Concept of Arch FormDocument16 pagesNew Concept of Arch FormRiddhi Rathi Shet100% (1)

- Centre For Good Governance: Enabling Systems For Improved Service DeliveryDocument12 pagesCentre For Good Governance: Enabling Systems For Improved Service DeliveryAnjana GoulikarNo ratings yet

- DATRON CNC-Machine Catalogue Prosp enDocument44 pagesDATRON CNC-Machine Catalogue Prosp enadNo ratings yet

- Opportunity For ArizonaDocument1 pageOpportunity For ArizonaRepSinemaNo ratings yet

- 30th Sept Protest - PosterDocument1 page30th Sept Protest - PosteredenmorecdpNo ratings yet

- The Crimson Cowboys: The Remarkable Odyssey of the 1931 Claflin-Emerson ExpeditionFrom EverandThe Crimson Cowboys: The Remarkable Odyssey of the 1931 Claflin-Emerson ExpeditionNo ratings yet

- Mussel Farmers of SamarDocument10 pagesMussel Farmers of SamarSimplus CongressusNo ratings yet

- Jonas 0001Document7 pagesJonas 0001marian almiaNo ratings yet

- Growth Performanceof Green Mussel Pernaviridis Transplantedin Buguey Lagoon PhilippinesDocument6 pagesGrowth Performanceof Green Mussel Pernaviridis Transplantedin Buguey Lagoon Philippinesmarian almiaNo ratings yet

- Mussel Farmers of SamarDocument10 pagesMussel Farmers of SamarSimplus CongressusNo ratings yet

- PowerLogic ION8650 - M8650A0C0H5E1B0ADocument4 pagesPowerLogic ION8650 - M8650A0C0H5E1B0AKevin GurungNo ratings yet

- 05 FluorometerDocument26 pages05 FluorometerHassan GillNo ratings yet

- Hempadur 15130Document2 pagesHempadur 15130MuthuKumarNo ratings yet

- Math 2021 Past PaperDocument27 pagesMath 2021 Past PaperayaanrayhaanNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4Pnadia perezNo ratings yet

- Unit 2Document2 pagesUnit 2Rohit GhulanavarNo ratings yet

- Chapter 9 - Linear MotionDocument47 pagesChapter 9 - Linear MotionMohammad VhoraNo ratings yet

- Vegetation Patterns Along A Rainfall Gradient: Ehud Meron, Erez Gilad, Jost Von Hardenberg, Moshe Shachak, Yair ZarmiDocument10 pagesVegetation Patterns Along A Rainfall Gradient: Ehud Meron, Erez Gilad, Jost Von Hardenberg, Moshe Shachak, Yair ZarmiEmmanuel kpegloNo ratings yet

- Scott - 1982 - The Vibrational Structure of Davydov Solitons PDFDocument9 pagesScott - 1982 - The Vibrational Structure of Davydov Solitons PDFЮрий ЮрийNo ratings yet

- Company Profile Indotech 2020Document20 pagesCompany Profile Indotech 2020sabrina saraswatiNo ratings yet

- Worksheet 22Document5 pagesWorksheet 22Begaidarov IsmailNo ratings yet

- Sch4uc PTDocument15 pagesSch4uc PTMarwan MohamudNo ratings yet

- Pre Stressed Concrete Manual Computer Applications On SAP2000, ETABSDocument259 pagesPre Stressed Concrete Manual Computer Applications On SAP2000, ETABSGardener AyuNo ratings yet

- Presentation: Chapter 9 MomentumDocument34 pagesPresentation: Chapter 9 MomentumJohn Anthony YumulNo ratings yet

- Fluorescent Lamp Ballasts: Technology Information SheetDocument4 pagesFluorescent Lamp Ballasts: Technology Information SheetChenaker HamzaNo ratings yet

- Menzel, Kaiser - 2020 - Weimar, Cold War, and Historical ExplanationDocument10 pagesMenzel, Kaiser - 2020 - Weimar, Cold War, and Historical ExplanationDouglas BarrosNo ratings yet

- Covalent and Metallic Bonding Mcqs by FMDocument17 pagesCovalent and Metallic Bonding Mcqs by FMfarymemon15No ratings yet

- Phy Worksheet IG 3 Phase 1Document6 pagesPhy Worksheet IG 3 Phase 1Umair RazaNo ratings yet

- APPENDIX A B C Pump Specifications Vantage 5000 EN v1.7 July 2019Document14 pagesAPPENDIX A B C Pump Specifications Vantage 5000 EN v1.7 July 2019cerro GranadaNo ratings yet

- Huawei DC1 - TP48300A-DX15A1 & Extension User ManualDocument87 pagesHuawei DC1 - TP48300A-DX15A1 & Extension User ManualF. B. I.No ratings yet

- DTR 1500 Eng - 12.2019Document39 pagesDTR 1500 Eng - 12.2019diogo_airjNo ratings yet

- Assignment No. 4 - 2020-21 PDFDocument2 pagesAssignment No. 4 - 2020-21 PDFnikhil khanwaniNo ratings yet

- MN Doped With Ni-MOFDocument8 pagesMN Doped With Ni-MOFBilal KhalidNo ratings yet

- Steps To Improve Roads On Black Cotton SoilsDocument9 pagesSteps To Improve Roads On Black Cotton SoilsAmrutha SivaramanNo ratings yet

- 3G3mx2-v2 Ds e 1 1 csm1126864Document54 pages3G3mx2-v2 Ds e 1 1 csm1126864Pertti HänninenNo ratings yet

- Presentation - Company Products - Eng (June 2012)Document11 pagesPresentation - Company Products - Eng (June 2012)Ricky Ocktavi RizkyNo ratings yet

- Mech 311 Formula Sheet For Final ExamDocument3 pagesMech 311 Formula Sheet For Final ExamJonathon Raymond-SzewczukNo ratings yet